Professional Documents

Culture Documents

Rolled Ball Screws Rolled Ball Screws

Uploaded by

trungOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rolled Ball Screws Rolled Ball Screws

Uploaded by

trungCopyright:

Available Formats

Rolled Ball Screws Rolled Ball Screws

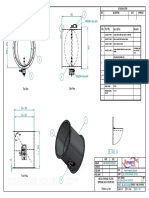

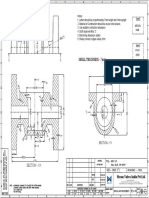

−Thread Diameter 12, 14, Lead 4, 5, 10, Thread Diameter 14, Lead 5 − Precision Grade C7, C10 −Thread Diameter 15, Lead 5, 10 and 20 − Precision Grade C7, C10

Type Precision Thread Thread Shaft Nut Type Precision Thread Thread Shaft Nut

Lead Lead

Standard F, P Configurable Grade Diameter m n l m n l Standard F, P Configurable Grade Diameter m n l m n l

BSST − C7 12 4 − ePhosphate Coating BSST − C7 − ePhosphate Coating

BSSR BSSRK 1055 Induction Phosphate Coating Carburized Low Temperature BSSR BSSRK 1055 Induction Phosphate Coating Carburized Low Temperature

Hardened JIS-SCM420 15 5 · 10 · 20 Hardened JIS-SCM420

BSRR BSRRK C10 12 · 14 4 · 5 · 10 Carbon Steel 58~62HRC Low Temp. Black Chrome Plating 58~62HRC Black Chrome BSRR BSRRK C10 Carbon Steel 58~62HRC Low Temp. Black Chrome Plating 58~62HRC Black Chrome

Plating Plating

BSSZ BSSZK − BSSZ BSSZK −

eNut flanged mounting surface of BSST is not surface-treated. M6x1.0 Depth 6 (Oiling Inlet) †Included Collar A eNut flanged mounting surface of BSST is not surface-treated. †Included Collar

A *Applicable to 1210 Only m 1045 Carbon Steel B 10 30° 30° m 1045 Carbon Steel

Ø 9.6 −0.09

−0.003

Ø 12 −0.018

B T l Black Oxide l Black Oxide

−0.1

D −0.5

*Applicable to 1405 Only (Relief Machining Required)

Ø 7.6 −0.06

30° 30°

0

7 *BSRR_ is low C *BSRR_ is low temperature

0

P −0.009

−0.1

Ø 30 −0.5

temperature black black chrome plated

ØThread Diameter

R0.3 or less R0.3 or less

0

chrome plated

Ø 15

X C †Included Collar

−0.002

Ø10 −0.015

1210 is adhesive type

P −0.009

−0.002

Ø 10 −0.015

R0.2 or less

Ø15 ±0.1

+0.1

0

R0.2 or less †Included Collar

Ø12 0

H

+0.1

−0.002

Ø 8 −0.015

†Ø12±0.1

Ø10 0

†Collar

H

7

C0.5 C0.5 C0.5 C0.5 10

+0.14

† Collar 1.15 0 2−Seal X

C0.5 10 †1405 is Ø14 +0.1

C0.5 C0.5 C0.5 9.15 10 4−d Drill Through

+0.1

0 5

0.9 0

2−Seal

X 12 Y (Hardened Area) 10 30 F M12x1.0 34 M6x1.0 Depth 6 (Oiling Inlet)

+0.1 (1204 is no adhesive)

7.9 0 10 L View X - X

10 Y (Hardened Area) 10 30 F M10x1.0 V 4−d Drill Through

View X - X

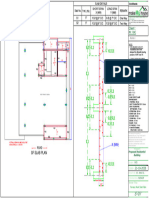

L Precision Part Number 1mm Increment Twisting No. of Ball Axial Basic Load Rating

Grade † † † Y A B D H C d Direction Turns Dia. Play C (Dynamic) kN Co (Static) kN

Type Thread Dia. Lead L F P

Precision Part Number 1mm Increment Twisting No. of Ball Axial Basic Load Rating C7 BSST 0.03 or Less

Grade Type Thread Dia. Lead L †

F †

P

Y A B T H C V d Direction Turns Dia. Play C (Dynamic) kN Co (Static) kN

C7 BSST 150~795 0.03 or Less BSSR BSRR 15 10 L−67

BSSR BSRR 15 8 L−65 BSSZ 05 150~1200 40 30 34 54 44 4.5 0.10 or 5.1 10.5

2.5 turns, C10

BSSZ 12 04 150~800 35 27 8 50 40 30 4.5 2.3812 0.05 or 2.6 5.8 BSSRK BSRRK Less

BSSRK BSRRK 1 line BSSZK 15~30 6~10 L−(52+F)

15~24 5~8 L−(50+F) Less 2.5 turn,

BSSZK

BSSR BSRR

C7 BSST 1 line 0.03 or Less

15 8 L−65 1.5 turns, 0.10 or BSSR BSRR 15 10 L−67

32 5.5 Right

BSSZ

C10 BSSRK BSRRK 12 10 150~800 44 32 12 54 41 3.175 2.85 4.95 BSSZ 0.10 or

1 line Less 15 10 200~1200 52 42 34 57 45 5.5 Right 3.175 5.1 10.5

BSSZK

15~24 5~8 L−(50+F) C10

BSSRK BSRRK Less

BSSR BSRR 15~30 6~10 L−(52+F)

15 8 L−65 2.5 turns, 0.10 or BSSZK

BSSZ

BSSRK BSRRK

14 05 150~800 40 30 10 50 40 34 4.5 3.175 4.4 7.3 C7 BSST 0.03 or Less

15~24 5~8 L−(50+F) 1 line Less

BSSZK BSSR BSRR 15 10 L−67 1.5 turn,

†F and P are configurable for BSSRK, BSRRK and BSSZK only. eF≤Px3 eFor features of low temperature black chrome plating, refer to hP.534. kgf=Nx0.101972 BSSZ 20 200~1200 59 49 34 57 45 5.5 0.10 or 5.8 13.3

C10 2 lines

BSSRK BSRRK Less

Part Number − L − F − P 15~30 6~10 L−(52+F)

6 Express A $8.00/piece h P.92 BSSZK

BSSR1204 − 270

BSSZK1204 − 270 − F15 − P6 eNon-Returnable P.92 eA flat charge of $21.60 for 3 or more identical pieces. †L of BSRR · BSRRK is up to 1000. F and P are configurable for BSSRK, BSRRK and BSSZK only. eF≤Px3 eFor features of low temperature black chrome plating, refer to hP.534. kgf=Nx0.101972

BSSR1204L − 300 (L Type Greased) Available Grease Type alternatives. •BSRR · BSRRK •BSRR, BSRRK

BSSR1204G − 300 (G Type Greased) For production time, prices and specs, refer to 11 eNon-Returnable P.92 Part Number − L − F − P 6 Express A $8.00/piece h P.92 11

BSSR1204H − 300 (H Type Greased) h P.560 BSSR1505 − 350

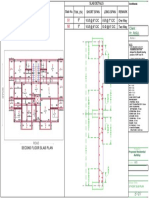

Unit Price Qty. 1~4 Unit Price Qty. 1~4 BSSZK1505 − 400 − F20 − P8 eNon-Returnable P.92 eA flat charge of $21.60 for 3 or more identical pieces. eNon-Returnable P.92

L L

BSST 1204 BSSR 1204 BSSRK1204 BSRR1204 BSRRK1204 BSSZ1204 BSSZK1204 BSSR1405 BSSRK1405 BSRR1405 BSRRK1405 BSSZ1405 BSSZK1405 BSSR1520L − 1000 (L Type Greased) Available Grease Type alternatives. For production time, prices and specs, refer to h P.560

150~400 359.00 182.10 201.60 255.40 274.90 145.40 164.90 150~400 202.80 231.80 282.20 311.20 162.20 191.20

Unit Price Qty. 1~4

401~600 379.50 199.70 219.20 279.10 298.60 159.10 178.60 401~600 216.10 245.10 302.90 331.90 172.90 201.90 L

601~800 399.90 231.30 250.80 308.80 328.30 185.00 204.50 601~800 261.00 290.00 331.00 360.00 208.80 237.80 BSST1505 BSSR1505 BSRR1505 BSSZ1505 BSST1510 BSSR1510 BSRR1510 BSSZ1510 BSST1520 BSSR1520 BSRR1520 BSSZ1520 eFor larger quantity orders "Days to Ship" may differ from published catalog term. hP.91

150~ 200 307.00 202.70 282.20 162.20 307.00 202.70 292.20 162.20 354.00 234.10 326.70 186.70 ePrice of Fixed Side Dimension Specified Type BS__K is price of Fixed Type plus $29.00.

Unit Price Qty. 1~4 eFor larger quantity orders "Days to Ship" may differ from published catalog term. hP.91 201~ 400 317.00 209.60 287.50 167.50 307.00 202.70 292.20 162.20 354.00 234.10 326.70 186.70

L ex. ) BSSZK1505−400−F20−P8

BSSR1210 BSSRK1210 BSRR1210 BSRRK1210 BSSZ1210 BSSZK1210 401~ 600 328.00 216.50 302.90 172.90 314.00 207.30 305.20 165.20 381.00 252.50 342.00 202.00

150~400 198.90 218.40 269.10 288.60 159.10 178.60

eCaution on Attachment: Do not remove nut from ball screws. 601~ 800 352.00 233.30 326.70 186.70 345.00 228.00 322.10 182.10 404.00 267.80 354.20 214.20 …167.50+29.00=$196.50

401~600 220.30 239.80 296.00 315.50 176.00 195.50 (The balls fall off.) 801~ 900 370.00 244.80 335.80 195.80 361.00 239.40 341.30 191.30 421.00 278.50 372.60 222.60

601~800 256.30 275.80 325.00 344.50 205.00 224.50 eFor precision of rolled ball screws, refer to P.535 and P.536. 901~1200 398.00 263.20 350.40 210.40 375.00 247.90 358.10 198.10 434.00 287.60 389.50 229.50

Part Number − L − F − P − (FC, KC…etc.) eFor support units, refer to P.563~P.570. Part Number − L − F − P − (FC · KC…etc.) eCaution on Attachment: Do not remove nut from ball screws. (The balls fall off.)

eFor nut brackets, refer to P.571 and P.572. eFor precision of rolled ball screws, refer to P.535 and P.536.

BSSR1204 − 270 − SC7 BSSR1505 − 350 − KC10

eFor support units, refer to P.563~P.570.

BSRR · BSRRK 11 eNon-Returnable P.92 BSRR · BSRRK 11 eNon-Returnable P.92 eFor nut brackets, refer to P.571 and P.572.

Alterations Code Details Price Adder Alterations Code Details Price Adder Alterations Code Details Price Adder Alterations Code Details Price Adder

No Machining on Support Side Thread End Fixed Side Wrench Flats Machining Machines wrench flats on the shaft end of fixed side. No Machining on Support Side Thread End Machines no thread end on the support Fixed Side Wrench Flats Machining

Machines wrench flats on the shaft end of fixed side.

Machines no thread end on the support Ordering Code SZC Shaft Diameter a b (c) NC side. −25.00

12 8 5 20

Ordering Code NC Ordering Code SZC

NC side. −25.00 b 5 SZC 14 10 7 22 7.00 L

0 7 5 SZC eThe balls fall off if the nuts reaches the

7.00

Ordering Code NC

0

a -0.2 (c) eThe balls fall off if the nuts reaches Nut Direction 10 -0.2 (22)

L

(Support Side) (Fixed Side)

flat part.

Incomplete Hardened Area the flat part. Incomplete Hardened Area

Standard Changes the nut direction. Free of

Nut Direction Key Groove on Fixed Side Thread End Adds a key groove on the fixed part thread end. RLC Ordering Code RLC charge Key Groove on Fixed Side Thread End Adds a key groove on the fixed part

(Support Side) (Fixed Side) For detailed key groove dim., refer to hP.536. j P=5 is not applicable. For detailed key groove dim., refer to hP.536. thread end.

Standard

Changes the nut direction. Free of Change

RLC Ordering Code RLC charge KC KC=1mm Increment 14.00 KC KC=1mm Increment 14.00

Ordering Code KC10 No Retaining Ring Groove on Support Side Thread End Machines no retaining ring groove on Ordering Code KC10

Change KC Free of KC

e3≤KC≤Px3 KC≤F−1 RNC the support side end. charge e3≤KC≤Px3 KC≤F−1

No Retaining Ring Groove on Key Groove on Fixed Side Thread End Adds a key groove on the specified area on Ordering Code RNCeCombination with or FC is not available. Adds a key groove on the specified area on

Machines no retaining ring groove on Key Groove on Fixed Side Thread End

Support Side Thread End the fixed side thread end. (Key groove Dim. Support Side Thread End Length Changes the length of support side thread end. the fixed side thread end.(Key groove dim.

the support side end. Free of is the same as KC.)

RNC Ordering Code RNC charge KLC K,S=1mm Increment

14.00 FC=1mm Increment

KLC

is the same as KC.)

14.00

FC Ordering Code FC20 7.00 K,S=1mm Increment

eCombination with FC is not available. K S Ordering Code KLC−K5−S2 9.15 K S Ordering Code KLC−K5−S3

e4≤K+S≤Px3 K+S≤F−1 e13≤FC≤30

Changes the machining on support side. FC eY dimension is shortened. e4≤K+S≤Px3 K+S≤F−1

Machining on Fixed Part Thread End Machines a flat on the fixed side thread

Support Side Thread For thread shaft 12, select from Q = 6, 8; Flat Machining Fixed Part Thread End Machines a flat on the fixed side

end. Machining on Changes the machining on support side.

for thread shaft 14, select from Q = 6, 8 and 10 Flat Machining thread end.

GC 10.00 SC SC=1mm Increment 7.00 Support Side Thread Select from Q=8, 10 and 12.

Qh7

G=1mm Increment SC SC=1mm Increment 7.00

Ordering Code SC7 GC G=1mm Increment 10.00

Qh7

G Ordering Code GC−Q8−G20 SC 0.5 Ordering Code SC10

e5≤G≤Qx3 e5≤SC≤Px3 SC≤F−1 Ordering Code GC−Q8−G20 SC 0.5

G e5≤SC≤Px3 SC≤F−1

Support Side Thread End Length Changes the length of support side thread end. Fixed Part Thread End Flat Machining (2 set) Machines two flats on the fixed side e5≤G≤Qx3

thread end. Machines tapping on support side thread Fixed Part Thread End Flat Machining (2 set) Machines two flats on the fixed side

FC=1mm Increment SWC SGC Tapping on Support Side Thread End

SWC SWC: 90° Position SGC: 120° Position end. thread end.

0.5

0.5

FC Ordering Code FC20 7.00 7.00 each MC=1mm Increment SWC SGC

SGC 1mm Increment SWC SWC:90°Position SGC:120°Position

M

7.9

0.5

0.5

e11≤FC≤20 MC Ordering Code MC20 14.00 7.00 each

Ordering Code SWC7 ℓ 9.15 SGC 1mm Increment

FC eY dimension is shortened. SWC·SGC 0.5 0.5 M ℓ eY dimension is

539 e5≤SWC · SGC≤Px3 SWC · SGC≤F−1

MC M5x0.8

e18≤MC≤30

12 shortened. SWC·SGC 0.5 0.5 Ordering Code SWC10 540

e5≤SWC · SGC≤Px3 SWC · SGC≤F−1

You might also like

- Code Specl IonDocument12 pagesCode Specl IonbalajiNo ratings yet

- CE Equations For Weldability of SteelsDocument1 pageCE Equations For Weldability of SteelsVivek Panse100% (1)

- Part 4 Tubing Sizing and Well Performance New PDFDocument93 pagesPart 4 Tubing Sizing and Well Performance New PDFRanim HishamNo ratings yet

- Wood ScrewsDocument178 pagesWood ScrewsOmar AL-jazairiNo ratings yet

- Supplement To Materials and Processes For NDT TechnologyDocument76 pagesSupplement To Materials and Processes For NDT TechnologyTC Capulcu Mustafa M100% (4)

- Rycroft Calorifier CatalogueDocument20 pagesRycroft Calorifier CataloguemasoodaeNo ratings yet

- Sae J1392 2001 PDFDocument10 pagesSae J1392 2001 PDFcharssx0% (1)

- API Valve Trim ChartDocument2 pagesAPI Valve Trim ChartkhaireddinNo ratings yet

- WISS CSWIP General Multiple Choice Exam 3 Version A 18 August 2014Document5 pagesWISS CSWIP General Multiple Choice Exam 3 Version A 18 August 2014rinhycra100% (1)

- Based On Grades Based On Applications (Coated Carbide) : HarderDocument1 pageBased On Grades Based On Applications (Coated Carbide) : HardermihaidelianNo ratings yet

- BS 1243-1978 Metal Ties For Cavity WallDocument8 pagesBS 1243-1978 Metal Ties For Cavity Wallnickdash09No ratings yet

- Poster - Welding Positions - en PDFDocument1 pagePoster - Welding Positions - en PDFmjaric8150% (2)

- Astm 672Document7 pagesAstm 672Ecruz Cruz LNo ratings yet

- 3D PV 2017 BrochureDocument6 pages3D PV 2017 BrochurehabilNo ratings yet

- Poster Weldingpositions enDocument1 pagePoster Weldingpositions endpit1No ratings yet

- S.No. Part No. Description Remarks: 11.5 MM Dia #12 Equal Distance Both Side 550 6 M5X40#4 Allen BoltDocument1 pageS.No. Part No. Description Remarks: 11.5 MM Dia #12 Equal Distance Both Side 550 6 M5X40#4 Allen Boltsabir hussainNo ratings yet

- C1-F1 Plan: Foundation Plan Typical Column Detail Typical Wf-1 DetailDocument1 pageC1-F1 Plan: Foundation Plan Typical Column Detail Typical Wf-1 DetaildellcyberNo ratings yet

- Annex B Learners Achievement Monitoring ReportDocument2 pagesAnnex B Learners Achievement Monitoring ReportAJ Acuña0% (2)

- Course Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)Document8 pagesCourse Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)SanthaKumar Muthu ThankaveluNo ratings yet

- Standard Sprockets Standard Sprockets: 40B Series 50B SeriesDocument1 pageStandard Sprockets Standard Sprockets: 40B Series 50B SeriesTomi KazuoNo ratings yet

- GRW Bearings CatalogDocument105 pagesGRW Bearings CatalogShubh BhawsarNo ratings yet

- p1 725Document1 pagep1 725RIZKI WARDANANo ratings yet

- Hardened Spur Gears: Thermal Refined RacksDocument1 pageHardened Spur Gears: Thermal Refined Racksqwerty 12345No ratings yet

- Standard Sprockets Standard Sprockets / Double Sprockets: 60B Series 80B Series 40SD, 50SD SeriesDocument1 pageStandard Sprockets Standard Sprockets / Double Sprockets: 60B Series 80B Series 40SD, 50SD SeriesTomi KazuoNo ratings yet

- 00 Ball Float Full WebDocument9 pages00 Ball Float Full WebWagner LimaNo ratings yet

- 400&600 Ball Valve KitzDocument1 page400&600 Ball Valve KitzSofyan CV. BLINo ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-5.GF ROOF SLAB PLANDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-5.GF ROOF SLAB PLANMr. SinghNo ratings yet

- SSR Steel Ring Gears (Spur Gears)Document1 pageSSR Steel Ring Gears (Spur Gears)dindo_waeNo ratings yet

- Mack Ball Float ValvesDocument12 pagesMack Ball Float ValvesJOHNNo ratings yet

- Ductile Iron Fully-Lugged PN16: Features & BenefitsDocument1 pageDuctile Iron Fully-Lugged PN16: Features & BenefitsRonaldNo ratings yet

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocument1 pagePesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNo ratings yet

- LEAD SCREW - p1 - 785Document1 pageLEAD SCREW - p1 - 785wawandev7No ratings yet

- SF SlabDocument1 pageSF SlabVijaya RajuNo ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-7.SF ROOF SLAB PLAN PDFDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-7.SF ROOF SLAB PLAN PDFMr. SinghNo ratings yet

- Ip67 Diecast Aluminium Box: SeriesDocument7 pagesIp67 Diecast Aluminium Box: SeriesDAVID SALVADORNo ratings yet

- Hydroseal Valve Cat D98!9!12Document4 pagesHydroseal Valve Cat D98!9!12Aibek AkbalikovNo ratings yet

- Fig FM276 Strainers CraneFS DS 1702 P208Document1 pageFig FM276 Strainers CraneFS DS 1702 P208ธนาธิป 002No ratings yet

- ThreadsDocument122 pagesThreadsferNo ratings yet

- Macks TrainersDocument9 pagesMacks TrainersJOHNNo ratings yet

- Trim Number Chart API Valve PDFDocument2 pagesTrim Number Chart API Valve PDFtungxuanbrNo ratings yet

- YA-SY18: Tin/Ticn-Coated HSS-PM (Powder Metallurgy) TAPSDocument12 pagesYA-SY18: Tin/Ticn-Coated HSS-PM (Powder Metallurgy) TAPSpo truongNo ratings yet

- Rondelle Inox Acton Ron Lfam1Document20 pagesRondelle Inox Acton Ron Lfam1Elie KhawandNo ratings yet

- Tank Drawing MarkupDocument2 pagesTank Drawing MarkupbharanidharanNo ratings yet

- Fig-970-970G-NEW DESIGNDocument1 pageFig-970-970G-NEW DESIGNAsmaaNo ratings yet

- P-04 Protection WorkDocument1 pageP-04 Protection Workshafiq_05No ratings yet

- House Service Connection NEW BSR 2020-1Document1 pageHouse Service Connection NEW BSR 2020-1Deshraj BairwaNo ratings yet

- Especificaciones Tecnicos de Los EngranajesDocument1 pageEspecificaciones Tecnicos de Los EngranajesGary Hans Aüe AnteloNo ratings yet

- Sintered Metal Element: EB /ESDocument15 pagesSintered Metal Element: EB /ESpitrer123No ratings yet

- Butterfly Valve Wafer TypeDocument2 pagesButterfly Valve Wafer TypeHardik ShahNo ratings yet

- Poster Weldingpositions en SWDocument1 pagePoster Weldingpositions en SWAbin sha john The gipsyNo ratings yet

- Shafts - Precision Standards: Circularity / Straightness / L Dimension Accuracy Straightness Measuring MethodDocument1 pageShafts - Precision Standards: Circularity / Straightness / L Dimension Accuracy Straightness Measuring MethodArdiansyah Oktavianus Wahyudi100% (1)

- Part 4-1 Tubing Sizing and Well Performance NewDocument24 pagesPart 4-1 Tubing Sizing and Well Performance Newmohsen ThabetNo ratings yet

- Api600 Valve Trim ChartDocument2 pagesApi600 Valve Trim ChartBoankNo ratings yet

- Stainless Steel Worms: Spur Gears Spur GearsDocument3 pagesStainless Steel Worms: Spur Gears Spur GearsOriental BearingNo ratings yet

- V1141 - EN-Gate ValveDocument1 pageV1141 - EN-Gate ValveHai PhanNo ratings yet

- V20D Ga 2.5 R3Document1 pageV20D Ga 2.5 R3sanjeevNo ratings yet

- Steel Racks Steel Racks With Machined Ends: Recommended Mating PinionsDocument1 pageSteel Racks Steel Racks With Machined Ends: Recommended Mating Pinionsindro wibowoNo ratings yet

- Ball Valve Full PortDocument2 pagesBall Valve Full PortHardik ShahNo ratings yet

- 82-200/240 Series: Submittal Sheet Bronze, 3-Piece, Full Port Medical Gas Valve - No Gauge PortsDocument1 page82-200/240 Series: Submittal Sheet Bronze, 3-Piece, Full Port Medical Gas Valve - No Gauge PortsAniket AngreNo ratings yet

- Precisions StandarDocument1 pagePrecisions StandarJoseph Rubyanto SudrajadNo ratings yet

- 25NB BALL VALVE BODY CS-ModelDocument1 page25NB BALL VALVE BODY CS-ModelMahendra PatilNo ratings yet

- A2-Floor Plan, ElevationsDocument1 pageA2-Floor Plan, ElevationsRonnel John CruzNo ratings yet

- 300 WW 14T2 1 009 Bk1.shaDocument1 page300 WW 14T2 1 009 Bk1.shaABDERRAZZAKNo ratings yet

- 2020 KYOCERA Round Tools Digest Catalog Modified v.1Document209 pages2020 KYOCERA Round Tools Digest Catalog Modified v.1nguyễn khắc namNo ratings yet

- Foundation Plan For StorageDocument4 pagesFoundation Plan For StoragePia LagmanNo ratings yet

- Forming Taps SD Non FerrousDocument7 pagesForming Taps SD Non FerrousnagarajuNo ratings yet

- Stripping CableDocument1 pageStripping CablelyxuandatbkNo ratings yet

- PDF Izometrie Rampa Incarcare - DescarcareDocument16 pagesPDF Izometrie Rampa Incarcare - Descarcarealexandru-adrianNo ratings yet

- 77F-100 Series: Submittal Sheet Full Port Threaded End Brass Ball ValveDocument1 page77F-100 Series: Submittal Sheet Full Port Threaded End Brass Ball ValveAna Karen LandaNo ratings yet

- Chapter 1: Introduction: 1.1 Stainless Steels Introduction and HistoryDocument10 pagesChapter 1: Introduction: 1.1 Stainless Steels Introduction and Historyفهد عبداللهNo ratings yet

- Cast Iron Heat TreatmentDocument29 pagesCast Iron Heat TreatmentHoang LamNo ratings yet

- Sample - Global Niobium Market (2016-2026) - Mordor Intelligence1621280011177Document38 pagesSample - Global Niobium Market (2016-2026) - Mordor Intelligence1621280011177Mahmoud BakryNo ratings yet

- I.S - 2062-2021Document13 pagesI.S - 2062-2021Gajendrasingh RajputNo ratings yet

- Amacan K 700-371 - 226UEG1Document6 pagesAmacan K 700-371 - 226UEG1Santiago RodaNo ratings yet

- República Democrática de Timor-Leste Ministerio Das Obras PúblicasDocument11 pagesRepública Democrática de Timor-Leste Ministerio Das Obras PúblicasManuel Francisco BarbosaNo ratings yet

- MASTER - Publications 51Document1 pageMASTER - Publications 51gioNo ratings yet

- WPS Format For Asme Ix - Wps - SmawDocument1 pageWPS Format For Asme Ix - Wps - SmawThe Welding Inspections CommunityNo ratings yet

- Paper 2 Question BankDocument258 pagesPaper 2 Question BankPramod P Nair67% (3)

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- Military-Grade Steel: What It Is & How It's Used - Federal Steel SupplyDocument1 pageMilitary-Grade Steel: What It Is & How It's Used - Federal Steel SupplyYanyan2009No ratings yet

- Ar Ms2200 Hook LockDocument2 pagesAr Ms2200 Hook LockUI564INo ratings yet

- PWPS Eksperimen Super DuplexDocument33 pagesPWPS Eksperimen Super Duplexryan.sNo ratings yet

- ASTMF436Document6 pagesASTMF436Zara DholkawalaNo ratings yet

- Outokumpu Corrosion Management News Acom 3 2014Document11 pagesOutokumpu Corrosion Management News Acom 3 2014Joshua WalkerNo ratings yet

- Kitchen Equipment Supplier in UaeDocument3 pagesKitchen Equipment Supplier in UaeMUTQAN STEELNo ratings yet

- Weldhelp MatrixDocument1 pageWeldhelp MatrixJoel BrasilBorgesNo ratings yet

- 2011 Vol 30-31-32 Reprint-Welding Processes, Faults, Defects, Etc ReprintDocument28 pages2011 Vol 30-31-32 Reprint-Welding Processes, Faults, Defects, Etc ReprintMuhammad UmairNo ratings yet

- Handbook - Joint Design & PrepDocument1 pageHandbook - Joint Design & PrepkassembaalbakiNo ratings yet