Professional Documents

Culture Documents

Jsa No. 039 - Loading Unloading and Mobilization Material and Equipment With TMC at CPS

Jsa No. 039 - Loading Unloading and Mobilization Material and Equipment With TMC at CPS

Uploaded by

Asrarudin0 ratings0% found this document useful (0 votes)

13 views7 pagesJSA Loading Unloading

Original Title

JSA NO. 039_LOADING UNLOADING AND MOBILIZATION MATERIAL AND EQUIPMENT WITH TMC AT CPS

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJSA Loading Unloading

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views7 pagesJsa No. 039 - Loading Unloading and Mobilization Material and Equipment With TMC at CPS

Jsa No. 039 - Loading Unloading and Mobilization Material and Equipment With TMC at CPS

Uploaded by

AsrarudinJSA Loading Unloading

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

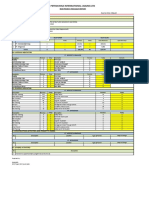

PCJL/BSP/HSE/JSA/07-2019/39

PetroChina International

Jabung Ltd.

o &

SkKMIGAS teommetane

Dat

20 JULI 2019

Job Safety Analysis

Set

JOB: LOADING UNLOADING AND MOBIFIZATION MATERIAL AND EQUPMENT WITH | Title of person “analyzed by

TMC / LIGHT VEHICLE AT CPS who does the job: Work Craw Work Crew Leader

BONGKAR MUAT DAN MOBILISASI MATERIAL DAN PERALATAN MENGGUNAKAN

TMC / KENDERAAN RINGAN DI CPS | { x

See Reviewed by Approved br

PT. Bina Sarana Putra Work Crew Supy/Delegate: Work Grew supp/Delegate:

‘Area Supy/!

4 $ Ef

Personal protective equipment (PPE): Put 1 On PPE required fora saejob,

1 Safety hat / helmet 6. Face shield 11, SCBA

16. Safety shoes / boots | ¥)

2. Safety glasses 7. Far plugs /mufis 12. Gloves ~ Ordinary

3. Goggles ~ ordinary 13, Gloves “Chemicals

‘SB-WB PERMANENT FACILITIES CPS MODIFIFATION / BCD -518-CA

4. Goggles = tinted 14. Gloves = The

5. Goggles = Chemicals 15. Rubber gloves

Sequence of Basic Job Steps Potential Hazards Protective Equipment | Safe Procedures

7. Team Work & Communication > Miscommunication Pre-job safety meeting,

> Misunderstanding Discuss JSA to workers before

> Failure job.

> Discuss emergency response

prepared

emergency situa

» Good co

| __ personnel

| > Everyone has permission to

| stop the job

1. Kerjasama &komunikasi > Miskomunikasi > Melakukan pembicaraan

> Kesalahpahaman keselamatar sebelum bekerja

> Terjadt kegagalan | % Membicaraian SA kepada

pekerja sebelum bekerja

> Membicaralan tanggap darurat

ke pokerja jika terjadi_situasi

1

darurat.—

Komunikasi yang baik antar

ersonil

Setiap orang mendapatkan hak

untuk menghentikan pekerjaan

Gika dapat membahayakan

pekerja dan plant).

2. Prepare Document, Tools, and

Equipment

Pinch point

‘Miscommunication

inderstanding

vvvy|

Use hand gloves

Be careful when pick up tools.

Watch body position,

Everyone must pay attention at

alltimes.

Stay focused,

Ensure tools ready to use.

Ensure all document already

accepted and reviewed.

2 Mempersiapkan dokumen dan alat-

alat

Terjepit

Miskomunikasi

Kesalahpahaman

Terjadi kegagalan

vvvy

“Menggunakan sarung tangan

Berhatihati

peralatan.

‘Memperhatican posisi tubuh.

Setiap orang harus

‘memperhatkan pekerjaannya

dan lingkungannya setiap waktu.

Tetap focus.

‘Memastikan semua peralatan

slap untuk éigunakan,

‘Memastikan semua dokumen

telah disetujus dan ditinjau

kembali.

ka mengambil

3. Secure area > Unauthorized personnel

> Other activity in the same area

Barricade tape / Safety line

‘Warning sign

Supervisor must know area for

work,

To ensure wea safe for work.

Barricade area with tag line and

give waming sign for

‘unauthorized personnel.

3. Mengamankan area kerja > Personilyang tidak berkepentingan

Kegiatan lain di area yang soma

v

‘SB-WB PERMANENT FACILITIES CPS MODIFIFATION / BCD -518-CA.

Garis barikade

Tanda bahaya

‘Supervisor harus mengetahui

‘area kerja yang akan dikerjakan.

untuk bekera,

Barikade area dengan garis

barikade don warning sign yang

tidak berkepentingan dilarang

masuk.

“Mobilization and demobilization

with TMC / light vehicle to work area

Hitby pipe existing / broken bridge

Tip / vanish

Burn

Crush

Slipping into trench

vvvvy|

v|

Survey

Medical check

Warning sign

Barricade

Spark arrester

Gas test

Fire Extinghuiser

Inspection

vyvvy

vy

v

e

vy

Do a survey of the road that wil

be passed

Make sure the driver is in goo

health

Measure the height of pipe rack

Checking of the bridge that wi

be passed.

Coordination with PCL.

Make sure the road enough t

maneuver the TMC/light vehicle.

Given barricade/warning sign 0

dangerous area,

Make sure the TMC is equipped

spark arrester in plant

Perform testing of gas to the road

tobe traversed

Porvide a fire extinguisher.

Adhere to existing signs

Make sure there is alway

Flagman ata crossroad.

Make sure there are escort

safetyman,

Make sure the speed does not

exceed 10 km/h atthe plant.

Ensure all vehicle in goo

condition and have been

inspected property

Make sure the trench clos

enough sandbags (ifnecessary).

Use a plateto cover the trench (i

necessary).

% Mobilisasi dan demobilisasi

‘menggunakan TMC /kenderaan

> Terkena pipa existing /Jembatan rusak

> Terguling/Amblas

> Survey

> Pemeriksaan kesehatan

¥|

Takukan sirvey terhadap jalan

Se EET enP np rer nrpreneeee nee RERUN

‘SB-WB PERMANENT FACILITIES CPS MODIFIFATION / BCD -518-CA

‘ringan ke area kerja > Kebakaran > Tanda bahaya > Pastikan sopir dalam keadaan

> Tabrakan > Bares sehat

> Teryelincr kedolam part > Sparcarester > kur inggidor pine rack

> castes > Pengecekan terhadap Jembatad

> aan yang akan tat

> inspelt > “Koordnas dengan PCL

> Pastkan elon culup unt

rmanuver TWC/kenderaanringan,

> Pasang barketanda bahay

pada area yang bahay,

> Peston THC diengkop! spar

arrester dilam plan

> Latukn pengetesan gs terhad

Jalan yong eka dau

> Sediakan’ elt. pemadam op

ringa

> Patan! ramberambu yong oda

> Pasttan gman sella ada

simpang jain

> Pastkan eda sofeyman yon

mengawel

> Pastkan kecepaton tidak melebi

10m/jam i dalem plant

> Pastton enue kendaraan dolar}

ond bath don layak dgunak

serta telah dinspekst

> Pastkan hantorg postr cue

menutup parit (jika perlu).

> Pergunator plat untuk menue

parit (jika perlu).

5 Loading unloading materialand > Wand pinched / jared > Tiber Make sure band postion do not

equipment with TMC /lightvehicle | > Hitby material and equlpment > Usehand gloves under the material and

> Swing TMC hit by pie rack > Tagline equipment

> Broken of material and equipment > Waring sign > Usewood t backs.

> Tumbled of TMC > arcade > Usehand goves,

> Workers dehydration > sw > Usete rope to gude equipment

> Stink bett and mater

> Water drink > Make sure the condl

‘SB-WB PERMANENT FACILITIES CPS MODIFIFATION / BCD -518-CA

operator isgood.

¥

a

e

Ensure the operator

instructed by rigger have

certification

Ensure workers position not

under the material and

equipment.

Ensure the workers are in safe

warning signif

TMC/light ehicle on operation.

Workers unauthorized are not

wed inthe work area

Make sure the slinkbelts. in

accordance with SWL and do

inspection before use.

Make sure the TMC is at a safe

distance with the pipe rack.

Make sure the material and

‘equipment to ted in correctly.

Used the sink belt for tied the

material and equipment.

Make sure the slink long

enough,

Ensure the position of TMC is

not tlt ané stable, install base

plate necessary.

‘Make sure the TMC position on

ahard land,

Make sure the load is lifted does

not exceed the SWL and the

radius corresponding to the

load chart,

Make sure there is enough

water in the work area.

5. Memuat dan membongkar peralatan

dan material menggunakan TMC /

kenderaan ringan.

>

>

Tangan terjepit/terluka

Tertimpa/ terbentur peralatan dan

material

Swing TMC menabrak pipe rack

Peralatan dan material jatuh

vyvvy

Timber

Gunakan sarung tangan

lipandu

Tanda bahaya

Bariket

¥

>

Pastikan posisitangan tidak di

bawah perdatan an material.

Gunakan balok kayu sebagal

ganjal.

Gunakan sarung tangan.

ST

‘SB-WB PERMANENT FACILITIES CPS MODIFIFATION / BCD -518-CA

5

> TMC terbalik

> Pekerja dehidrasi

> SWE

> Stink bele

> Airminum

+

v

“Gunakan tal untuk mengarahkan

peralatan dan material

Pastikan operator dalam keadaan|

sehat.

Pastikan operator diarahkan oleh

rigger yang bersercfikat.

Pastikan pekerja tidak berada

dibawah peralatan dan material

Pekerja berada dalam jarak yang

aman,

Pasang tanda bahaya bila TMC/

kenderaan ringan sedang

beroperasi

Pekerja yang tidak

berkepentingan tidak

diperbolehlan berada di area

kerja.

Pastikan sing belt sesuat dengan

‘SWLnya dan lakukan inspekst

Pastikan TMC di pandu oleh juru

‘kat yang bersertfikat.

astikan TMC berada pada jarak

‘aman dengan pipe rack

Pastikan peralatan dan material

ditkat dengon benar.

Gunakan slink belt untuk

‘mengikat peralatan dan material.

astikan parjang sling cukup.

TMC tidak miring

dan stabi, tila dipertukan pasang

base plate.

Pasttkan poss! TMC dl tanah yang|

eras.

Pastikan besan yang diangkat

tidak melebihi SWL dan dalam

radius yangsesuai dengan load

chart

Pastikan tersedia air minum

yang cukupdi area kerja.

_—_——_

‘SB-WB PERMANENT FACILITIES CPS MODIFIFATION / BCD -518-CA

6

6. Housekeeping

> Pinch Points

Use hand gloves

> Usehand gloves

> Ensure no waste at work area

> Ensure area clean before finish

the workers safety performance

work — loca and.

immediately corrected them if

any found substandard

action/condition.

6 Membersihkan area kerja

> Terjepie

> Gunakan sorung tangan

> Menggunalan sarung tangan.

> Memastikan tidak ada sompah di

‘area kerja.

> Memastikan area kerja. bersih

ssebelum mengakkhiri pekerjaan.

> Supervisor harus — memantau

ksealamatan pekerja di daerah

pekerjaan mereka dan langsung

‘membetulkan kesalahan pekerja

jk terdapat perilaku tidak

‘aman ataypun kondisi yang

tidak aman.

Remarks:

‘SB-WB PERMANENT FACILITIES CPS MODIFIFATION / BCD -518-CA

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Jsa No. 037 - Lifting Glycol Reboiler, Charcoal Filter and Particulate Filter at NGFDocument7 pagesJsa No. 037 - Lifting Glycol Reboiler, Charcoal Filter and Particulate Filter at NGFAsrarudinNo ratings yet

- Jsa No. 036 - Lifting New Cooler at NGFDocument7 pagesJsa No. 036 - Lifting New Cooler at NGFAsrarudinNo ratings yet

- WI Function Test Fire Hidrant - PrintDocument8 pagesWI Function Test Fire Hidrant - PrintAsrarudinNo ratings yet

- JSA Site SurveyDocument2 pagesJSA Site SurveyAsrarudin100% (1)

- HSE Daily Report May 03,2020Document1 pageHSE Daily Report May 03,2020AsrarudinNo ratings yet