Professional Documents

Culture Documents

Hot Work Sample 5

Hot Work Sample 5

Uploaded by

zaimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Work Sample 5

Hot Work Sample 5

Uploaded by

zaimCopyright:

Available Formats

HOT WORK PERMIT

VALID FROM ____________AM/PM____________DATE TO_____________AM/PM_________________________Report No.__________________

PERMISSION IS GRANTED TO SECTION/CONTRACTOR________________________________________________________________________

NATURE OF WORK_____________________________________________________________________________________________________

LOCATION OF WORK__________________________________NEAREST FIRE ALARM NO.____________________________________________

THE FOLLOWING ITEMS SHALL BE CHECKED BEFORE ISSUING THE PERMIT

(PLEASE MARK APPLICABLE BOXES)

NOT NOT

ITEMS DONE ITEMS DONE

DONE DONE

1 Equipment/work area inspected. 14 Portable equipments/nozzles properly grounded

2 Surrounding area checked/cleaned up, oil/rags 15 Standby personnel provided from vessel entry

Considered hazard from other routine/non-routine Standby personnel provided for fire watch from

3 16

operations and concerned person alerted process/maint/Contractor /Fire Dept.

Equipment electrically isolated and tagged (vide

4 17 Iron sulphide removed/kept wet

Permit no._____________________)

5 Fire water hose /portable fire extinguisher provided 18 Area cordoned off

Fire water system checked for readiness

6 Equipment blinded/disconnected/closed 19 Clearance obtained from technical/concerned Dept.

/isolated/wedged open

7 Equipment properly drained/depressurised 20 Checked spark arrester on mobile equipments

Checked for oil/gas trapped behind lining in

8 Equipment properly steamed/purged 21

equipments

9 Equipment water dashed 22 Precautions against public traffic taken

1

Shield against spark provided 23 Precautions taken for working at height

0

1

Proper ventilation and lighting provided 24 Welding machine checked for safe locations

1

1 Checking for earthing/return connection to the

Proper means of exit provided 25

2 equipment being welded

1 Oxygen and Acetylene (D.A.)cylinders kept outside

Precautionary tags/boards provided 26

3 the vessel/tank

SPECIAL INSTRUCTION

Following personal protective equipment are required(check all items required):

1 Safety helmet/Gloves/Goggles/Safety shoes/Boiler suit/welding suit/Dust Respirator/Face shield/Fresh air Mask/Apron/life line/ safety harness

In case of fire siren all work must be stopped. All personnel must leave work site and proceed to designated areas. In case of disaster siren assemble

2

at nearby Assembly point.

3 In case of liquid/gas release stop work and immediately advise concerned Supervisor/Engineer/Site In-charge

4 Only certified vehicle/engines and permitted type of electrical equipment and tools are allowed in operating area.

5 Insure proper grounding/earthing/installation of cables.

6 For hot tapping ensure continuous /sufficient flow in the line .

7 This permit is must be available at work site at all times.

8 No hot work shall be permitted unless the Explosimeter reading is zero.

Vessel entry, where no hot work is to be carried out .may be permitted if combustible gases are up-to 5% of lower explosive limit (LEL).Entry with an

9 air supplied mask may be permitted with LEL of up to 20% The oxygen level should be at least 19.5% vol. and the concentration of toxic gases below

the threshold limits.

1

Additional remarks if any:______________________________________________________________________________________________

0

Contractor

Signature Signature Signature

Name Name Name

Mechanical Incharge Safety Officer Site In-charge/RCM

ON HEARING FIRE SIREN STOP THE HOT JOB

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Kitchen Hood Cleaning Checklist-1-2Document2 pagesKitchen Hood Cleaning Checklist-1-2zaimNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

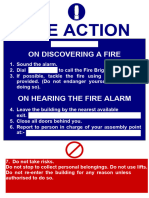

- Fire Action NoticeDocument1 pageFire Action NoticezaimNo ratings yet

- SGTM 5 B Attitudes & Behaviour " Cultural Awareness"Document29 pagesSGTM 5 B Attitudes & Behaviour " Cultural Awareness"Maggi BoldNo ratings yet

- COSHH Clenzol (APC)Document3 pagesCOSHH Clenzol (APC)zaimNo ratings yet

- Grievance PolicyDocument3 pagesGrievance PolicyzaimNo ratings yet

- Tunnel PTW R2.4-Water Tank PPMDocument2 pagesTunnel PTW R2.4-Water Tank PPMzaimNo ratings yet

- Tank Cleaning Equipment ListDocument1 pageTank Cleaning Equipment ListzaimNo ratings yet

- Signs & TagsDocument16 pagesSigns & TagszaimNo ratings yet

- EEBA Inspection LogDocument1 pageEEBA Inspection LogzaimNo ratings yet

- 02 PTW Risk AssessmentDocument22 pages02 PTW Risk Assessmentzaim100% (2)

- COSHH DrakerDocument2 pagesCOSHH DrakerzaimNo ratings yet

- Electrical 1Document4 pagesElectrical 1zaimNo ratings yet

- Health & Safety ALERTDocument4 pagesHealth & Safety ALERTzaimNo ratings yet

- SignsDocument14 pagesSignszaimNo ratings yet

- COSHH Assessment (Aqua Kleene)Document3 pagesCOSHH Assessment (Aqua Kleene)zaimNo ratings yet

- Slips Trips Falls Working SurfacesDocument27 pagesSlips Trips Falls Working SurfaceszaimNo ratings yet

- CorrosivesDocument21 pagesCorrosiveszaimNo ratings yet

- Doc14251520191031091437 013Document1 pageDoc14251520191031091437 013zaimNo ratings yet

- PMEC-OSH-F23-REV.O (Site Inspection Report)Document2 pagesPMEC-OSH-F23-REV.O (Site Inspection Report)zaimNo ratings yet

- TBT Accident Prevention 1Document2 pagesTBT Accident Prevention 1zaimNo ratings yet

- Eih Machinery ListDocument6 pagesEih Machinery ListzaimNo ratings yet

- Risk Assessment ScanDocument8 pagesRisk Assessment ScanzaimNo ratings yet

- Working On or Near Water (River) Safety PlanDocument16 pagesWorking On or Near Water (River) Safety PlanzaimNo ratings yet

- Doc14251520191031091437 010Document1 pageDoc14251520191031091437 010zaimNo ratings yet

- Doc14251520191031091437 011Document1 pageDoc14251520191031091437 011zaimNo ratings yet

- Doc14251520191031091437 003Document1 pageDoc14251520191031091437 003zaimNo ratings yet

- FE - JuneDocument1 pageFE - JunezaimNo ratings yet

- Doc17525720201228113910 001Document1 pageDoc17525720201228113910 001zaimNo ratings yet

- Hse PlanDocument44 pagesHse Planzaim100% (1)

- HSE PLAN (Split AC Unit Installation)Document28 pagesHSE PLAN (Split AC Unit Installation)zaim100% (1)