Professional Documents

Culture Documents

Dismantling-Joints Dn40-Dn300 VJ Ds Eng 0721

Dismantling-Joints Dn40-Dn300 VJ Ds Eng 0721

Uploaded by

junaidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dismantling-Joints Dn40-Dn300 VJ Ds Eng 0721

Dismantling-Joints Dn40-Dn300 VJ Ds Eng 0721

Uploaded by

junaidCopyright:

Available Formats

Dismantling Joints Cast DN40 to DN300 (PN10,16,25,40)

Datasheet 1/4

Dismantling Joint (Cast)

MAXIMUM LENGTH (D)

(E) (E)

(A)

Ø FLANGE DIA.

MINIMUM LENGTH (C)

MATING MATING

FLANGE NOMINAL LENGTH (B) FLANGE

Note: Maximum Longitudinal Adjustment = Maximum Length – Minimum Length

Dismantling Joints (Standard Product)

Table provides details of standard product – for products offering longer flange dimensions and / or increased longitudinal

adjustment contact Viking Johnson.

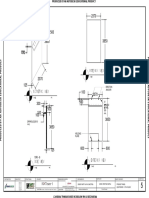

Flange Details Flange to Flange Details Tie Rod Details

Flange Thickness Flange OD Nominal Length Minimum Length Maximum Length Steel Tie Rod Stainless Steel Tie Rod

Nom Drilling Flange Total Total

Spigot A B C D Dia x Length Dia x Length

Adaptor No. Weight No. Weight

E (mm) (mm) (mm) (mm) (mm) (mm) (mm)

E (mm) of DJ (kg) of DJ (kg)

50 PN10,16,25,40 17 17 165 194 174 214 M16 x 300 4 6.9 M16 x 300 4 6.9

65 PN10,16 17 17 185 194 174 214 M16 x 300 4 7.7 M16 x 300 4 7.7

80 PN10,16,25,40 17 17 200 194 174 214 M16 x 300 4 9.4 M16 x 300 4 9.4

100 PN10,16 17 17 220 194 174 214 M16 x 300 4 10.4 M16 x 300 4 10.4

125 PN10,16 17 17 250 194 174 214 M16 x 300 4 11.9 M16 x 300 4 11.9

150 PN10,16 17 17 285 194 174 214 M20 x 310 4 15.8 M20 x 310 4 15.8

200 PN10 20 20 340 194 174 214 M20 x 310 4 21.6 M20 x 310 4 21.6

200 PN16 20 20 340 194 174 214 M20 x 310 4 21.6 M20 x 310 4 21.6

250 PN10 19 20 395 194 174 214 M20 x 310 4 28.9 M20 x 310 4 28.9

250 PN16 19 20 405 194 174 214 M24 x 330 4 31.6 M24 x 330 4 31.6

300 PN10 19 19 445 194 174 214 M20 x 310 4 32.8 M20 x 310 4 32.8

300 PN16 19 20 460 194 174 214 M24 x 330 4 35.4 M24 x 330 4 35.4

DR10450_21_07_2021_ISSUE 7

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Crane Ltd assumes no responsibility or liability for typographical errors

or omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

104 Viking Johnson Dismantling Joint Telephone: +44 (0)1462 443322

Dismantling Joints Cast DN40 to DN300 (PN10,16,25,40)

Datasheet 2/4

Technical Information Materials & Relevant Standards

Working Pressure Rating Flange Drilling Tie Rods, Studs, Nuts and Washers

Water - In accordance with the flange rating BS EN1092-1 The following two options are as

(formerly BS4504), ISO7005 standard variants:-

Gas 6 bar

Cast Flange Adaptor Body Option 1: Zinc Plated Steel

Vacuum Pressure

& End Rings

Capable of accommodating a vacuum pressure of -0.7 bar

Ductile Iron to BS EN1563: Tie Rods

Couplings & Flange Adaptors

Symbol EN-GJS-450-10

Site Test Pressure ASTM A193 (Grade B7/MB7)

equivalent to BS EN10269:+A1:

1.5 times working pressure for short duration (2 hours) Cast Flange Spigot: Name 42CrMo4 (Yield 725N/mm²)

Ductile Iron to BS EN1563:

Angularity Symbol EN-GJS-450-10 Tie Rod Nuts

Dismantling joints are in essence double flanged pipe ASTM A194 Grade 2H/M2H

where the flange to flange dimension can be adjusted, Steel Spigot Options: equivalent to BS EN20898-2:

and therefore are not able to accommodate any angularity. ➤ Steel tube to BS EN10255 Property Class 8.00

➤ Steeltube to BS EN10216-1:

Bolt Torque/Spanner Flange Adaptor Studs

Grade P265TR1

M12; Torque 55-65Nm on every bolt Steel to BS EN ISO898-1:

➤ Rolledsteel to BS EN10025-2:

Grade S275 Property Class 4.8

Tie rods

Torque is a function of the flange connecting gasket, not Gaskets Flange Adaptor Nuts

supplied by Viking Johnson; consult flange gasket supplier. Steel to BS4190: Grade 4

Standard:

Temperature Rating of Product ➤ EPDM to BS EN681-1: Type WA Flange Adaptor Washers

EPDM -20°C to +90°C Other gasket grades are available

Stainless Steel to BS1449:Part 2:

contact Viking Johnson.

Nitrile -20°C to +90°C Grade 304S15

For use on applications with fluctuating and / or elevated Coatings

Option 2: Stainless Steel

Dedicated

temperatures (> 60°C) may require regular maintenance Flange Adaptor, Spigot

to re-tighten the bolts and must be included in any & End Ring:

maintenance schedule. Tie Rods

➤ RilsanNylon 11 to

WIS 4-52-01 Part 1 Stainless Steel to BS EN3506-1:

Approvals Grade A4 Property Class 70

Option 1 Flange Adaptor (Yield 450N/mm²)

The following water contact materials used in Dismantling bolts & Nuts:

Joints are approved for use with potable water:-

➤ Sheraplex to WIS 4-52-03 Tie Rod Nuts

Rilsan Nylon 11:

Steel Tie Rods/Nuts: Stainless Steel to BS EN3506-2:

➤ WRAS, AS/NZS 4020, DVGW, W270, ACS & KIWA

➤ Zn3 Zinc coated Grade A4 Property Class 80

EPDM Gaskets:

➤ WRAS, AS/NZS 4020 Flange Adaptor Studs

Stainless Steel to

BS EN ISO 3506-1: grade A4

property class 50

Flange Adaptor Nuts

Stainless Steel to

BS EN ISO 3506-2: grade A4

property class 80

Flange Adaptor Washers

Stainless Steel to BS1449:

Part 2: Grade 304S15

DR10450_21_07_2021_ISSUE 7

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Crane Ltd assumes no responsibility or liability for typographical errors

or omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

www.vikingjohnson.com Viking Johnson Dismantling Joint 105

Dismantling Joints Fabricated DN40 to DN300 (PN10,16,25,40)

Datasheet 3/4

Dismantling Joint (Fabricated)

MAXIMUM LENGTH (D)

(E) (E)

(A)

Ø FLANGE DIA.

MINIMUM LENGTH (C)

MATING MATING

FLANGE NOMINAL LENGTH (B) FLANGE

Note: Maximum Longitudinal Adjustment = Maximum Length – Minimum Length

Dismantling Joints (Standard Product)

Table provides details of standard product – for products offering longer flange dimensions and / or increased longitudinal

adjustment contact Viking Johnson.

Flange Details Flange to Flange Details Tie Rod Details

Flange Thickness Flange OD Nominal Length Minimum Length Maximum Length Steel Tie Rod Stainless Steel Tie Rod

Nom Drilling Flange Total Total

Spigot A B C D Dia x Length Dia x Length

Adaptor No. Weight No. Weight

E (mm) (mm) (mm) (mm) (mm) (mm) (mm)

E (mm) of DJ (kg) of DJ (kg)

40 PN10,16,25,40 18 18 150 187 167 207 M16 x 300 4 7.8 M16 x 300 4 7.8

100 PN25,40 25 25 235 194 174 214 M20 x 320 4 19.2 M20 x 320 4 19.2

125 PN25,40 25 25 270 194 174 214 M24 x 330 4 26.2 M24 x 330 4 26.2

150 PN25 25 25 300 194 174 214 M24 x 330 4 28.9 M24 x 330 4 28.9

150 PN40 25 25 300 194 174 214 M24 x 330 4 28.8 M24 x 330 4 28.8

200 PN25 25 25 360 194 174 214 M24 x 340 4 37.5 M24 x 340 4 37.5

200 PN40 25 25 375 194 174 214 M27 x 350 4 42.6 M27 x 350 4 42.6

250 PN25 25 25 425 194 174 214 M27 x 350 4 49.1 M27 x 350 4 49.1

250 PN40 25 25 450 194 174 214 M30 x 370 4 57.9 M30 x 370 4 57.9

300 PN25 25 25 485 194 174 214 M27 x 350 4 57.1 M27 x 350 4 57.1

300 PN40 25 25 515 194 174 214 M30 x 380 4 69.8 M30 x 380 4 69.8

DR10450_21_07_2021_ISSUE 7

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Crane Ltd assumes no responsibility or liability for typographical errors

or omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

106 Viking Johnson Dismantling Joint Telephone: +44 (0)1462 443322

Dismantling Joints Fabricated DN40 to DN300 (PN10,16,25,40)

Datasheet 4/4

Technical Information Materials & Relevant Standards

Working Pressure Rating Flange Drilling Tie Rods, Studs, Nuts and Washers

Water - In accordance with the flange rating BS EN1092-1 The following two options are as

(formerly BS4504), ISO7005 standard variants:-

Gas 6 bar

Fabricated Flange Adaptor Body Option 1: Zinc Plated Steel

Vacuum Pressure

Rolled Steel to BS EN 10025-2:

Capable of accommodating a vacuum pressure of -0.7 bar Grade S275 Tie Rods

Couplings & Flange Adaptors

Site Test Pressure ASTM A193 (Grade B7/MB7)

End Rings

equivalent to BS EN10269:+A1:

1.5 times working pressure for short duration (2 hours) Rolled Steel to BS EN 10025-2: Name 42CrMo4 (Yield 725N/mm²)

Grade S275

Angularity Tie Rod Nuts

Ductile Iron to BS EN1563:

Dismantling joints are in essence double flanged pipe Symbol EN-GJS-450-10 ASTM A194 Grade 2H/M2H

where the flange to flange dimension can be adjusted, equivalent to BS EN20898-2:

and therefore are not able to accommodate any angularity. Sleeve Options Property Class 8.00

➤ Steel Tube to BS EN10255

Bolt Torque/Spanner Flange Adaptor Studs

➤ SteelTube to BS EN10216-1:

M12; Torque 55-65Nm on every bolt Steel to BS EN ISO898-1:

Grade P265TR1

M16; Torque 95-110Nm on every bolt Property Class 4.8

➤ RolledSteel to BS EN 10025-2:

Grade S275

Tie rods Flange Adaptor Nuts

Torque is a function of the flange connecting gasket, not Fabricated Flange Spigot: Steel to BS4190: Grade 4

supplied by Viking Johnson; consult flange gasket supplier.

Rolled steel to BS EN10025-2:

Flange Adaptor Washers

Grade S275

Temperature Rating of Product

Stainless Steel to BS1449:Part 2:

EPDM -20°C to +90°C Steel Spigot Options: Grade 304S15

Nitrile -20°C to +90°C ➤ Steel tube to BS EN10255

Option 2: Stainless Steel

Dedicated

For use on applications with fluctuating and / or elevated ➤ Steeltube to BS EN10216-1:

temperatures (> 60°C) may require regular maintenance Grade P265TR1

Tie Rods

to re-tighten the bolts and must be included in any ➤ Rolledsteel to BS EN10025-2:

maintenance schedule. Grade S275 Stainless Steel to BS EN3506-1:

Grade A4 Property Class 70

Approvals Gaskets (Yield 450N/mm²)

The following water contact materials used in Dismantling Standard: Tie Rod Nuts

Joints are approved for use with potable water:- ➤ EPDM to BS EN681-1: Type WA Stainless Steel to BS EN3506-2:

Rilsan Nylon 11: Grade A4 Property Class 80

Other gasket grades are available

➤ WRAS, AS/NZS 4020, DVGW, W270, ACS & KIWA contact Viking Johnson.

EPDM Gaskets: Flange Adaptor Studs

Coatings

➤ WRAS, AS/NZS 4020 Stainless Steel to

Flange Adaptor, Spigot BS EN ISO 3506-1: grade A4

& End Ring: property class 50

➤ RilsanNylon 11 to

WIS 4-52-01 Part 1 Flange Adaptor Nuts

Option 1 Flange Adaptor Stainless Steel to

bolts & Nuts: BS EN ISO 3506-2: grade A4

property class 80

➤ Sheraplex to WIS 4-52-03

Steel Tie Rods/Nuts: Flange Adaptor Washers

➤ Zn3 Zinc coated Stainless Steel to BS1449:

Part 2: Grade 304S15

DR10450_21_07_2021_ISSUE 7

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Crane Ltd assumes no responsibility or liability for typographical errors

or omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

www.vikingjohnson.com Viking Johnson Dismantling Joint 107

You might also like

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- A7 - Octavia - OwnersManual ARABICDocument234 pagesA7 - Octavia - OwnersManual ARABICAhmedRamadanNo ratings yet

- The Elements of Boat Strength: For Builders, Designers, and OwnersFrom EverandThe Elements of Boat Strength: For Builders, Designers, and OwnersRating: 5 out of 5 stars5/5 (8)

- Manual de Partes GA250 - SERIE S99150101-02 PDFDocument119 pagesManual de Partes GA250 - SERIE S99150101-02 PDFJerson PortocarreroNo ratings yet

- Duco Paint Rate AnalysisDocument6 pagesDuco Paint Rate AnalysisKuldeep Kumar Pandita0% (2)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Vi: the Ironhead Sportster: 1957 to 1985From EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Vi: the Ironhead Sportster: 1957 to 1985No ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- HF 74 R6 P20 Treated Effluent Pump 105 KWDocument8 pagesHF 74 R6 P20 Treated Effluent Pump 105 KWAhmedRamadanNo ratings yet

- Fees and Charges Credit Cards ARDocument1 pageFees and Charges Credit Cards ARAhmedRamadanNo ratings yet

- Goulds-Pumps Fundamentals PDFDocument140 pagesGoulds-Pumps Fundamentals PDFAgustinus Made Theo Dwijaya100% (2)

- Sereco Grit RemovalDocument6 pagesSereco Grit RemovalAhmedRamadanNo ratings yet

- HF 74 R5 P20Document1 pageHF 74 R5 P20AhmedRamadanNo ratings yet

- Project Timeline1Document2 pagesProject Timeline1AhmedRamadanNo ratings yet

- Technical Specification: ConfigurationDocument7 pagesTechnical Specification: ConfigurationAhmedRamadanNo ratings yet

- Technical Specification: ConfigurationDocument5 pagesTechnical Specification: ConfigurationAhmedRamadanNo ratings yet

- Dismantling-Joints VJ Bro 0821 Eng+v1Document25 pagesDismantling-Joints VJ Bro 0821 Eng+v1AhmedRamadanNo ratings yet

- Technical Specification: ConfigurationDocument7 pagesTechnical Specification: ConfigurationAhmedRamadanNo ratings yet

- FileDocument1 pageFileAhmedRamadanNo ratings yet

- Stop Logs SpecsDocument2 pagesStop Logs SpecsAhmedRamadanNo ratings yet

- Waste Water Treatment PlantsDocument748 pagesWaste Water Treatment PlantsAhmedRamadan100% (1)

- Hot Dip Galvanizing To EN ISO 1461 and CDocument12 pagesHot Dip Galvanizing To EN ISO 1461 and CAhmedRamadanNo ratings yet

- DISMANTLING JOINTS - 4 40in AWWA VJ - BRO - 0821Document2 pagesDISMANTLING JOINTS - 4 40in AWWA VJ - BRO - 0821AhmedRamadanNo ratings yet

- VAG Pressure Management: Solutions For Water Loss ReductionDocument4 pagesVAG Pressure Management: Solutions For Water Loss ReductionAhmedRamadanNo ratings yet

- En1092-Flange PN10 16Document4 pagesEn1092-Flange PN10 16AhmedRamadanNo ratings yet

- Wall Mounted PenstockDocument1 pageWall Mounted PenstockAhmedRamadanNo ratings yet

- 1316 EKN Hotwater Edition3Document11 pages1316 EKN Hotwater Edition3AhmedRamadanNo ratings yet

- Wastewater2 Spec Book 2015 - 201504201118263001Document20 pagesWastewater2 Spec Book 2015 - 201504201118263001AhmedRamadanNo ratings yet

- Thomas and Betts (Cabletrays)Document256 pagesThomas and Betts (Cabletrays)wtforkNo ratings yet

- Curvy Wire Mesh Fence CatalogDocument3 pagesCurvy Wire Mesh Fence CatalogtempfencingNo ratings yet

- AGRU Tech Info eDocument105 pagesAGRU Tech Info ejavierNo ratings yet

- 2 CA2 Series CylindersDocument16 pages2 CA2 Series CylindersSinggih KurniawanNo ratings yet

- Etapas Del Proceso Productivo SiderÚrgicoDocument9 pagesEtapas Del Proceso Productivo SiderÚrgicodesttis@hotmail.com100% (4)

- Ejercicios 4 y 5Document10 pagesEjercicios 4 y 5jhonNo ratings yet

- GalvInfoNote 1 2Document4 pagesGalvInfoNote 1 2JdjoNo ratings yet

- Kronospan Wall ChartDocument14 pagesKronospan Wall ChartbugnickNo ratings yet

- Curries Tech Manual (Door Section)Document178 pagesCurries Tech Manual (Door Section)johnNo ratings yet

- Bordereau Des Prix UnitairesDocument46 pagesBordereau Des Prix UnitairesmarthialprofNo ratings yet

- Ijseas CRDocument3 pagesIjseas CRravibelavadiNo ratings yet

- Normas Del CementoDocument18 pagesNormas Del CementoAndretti Carcagno Quiliano100% (1)

- SS5100 Rev 34 (Hole Sizes)Document30 pagesSS5100 Rev 34 (Hole Sizes)mtcengineering100% (2)

- BOMBA BARISCORicambi - Spare Parts - JP 4-250 F (SM) - 2013.12 Rev.01 - IT-ENDocument4 pagesBOMBA BARISCORicambi - Spare Parts - JP 4-250 F (SM) - 2013.12 Rev.01 - IT-ENEdwin BonillaNo ratings yet

- Chassis: LNVU1CA39BVL02648 - VP: 98CS9AF1000027 - Model: A50.13 P.D.MY2008 - Class: 54 - Group: 32 - Subgroup: 60 - Plate: 94782Document2 pagesChassis: LNVU1CA39BVL02648 - VP: 98CS9AF1000027 - Model: A50.13 P.D.MY2008 - Class: 54 - Group: 32 - Subgroup: 60 - Plate: 94782Khin ChoayeNo ratings yet

- MasterFlow810 TDSDocument2 pagesMasterFlow810 TDSPT PP BIH SanurNo ratings yet

- Grinding Wheels Specification PDFDocument4 pagesGrinding Wheels Specification PDFPENONVVNo ratings yet

- Erection Anchor: Engr. Rostum Capili Engr. Raffy Jay A. Bacting Precast Panel at Exterior - 10Th FloorDocument1 pageErection Anchor: Engr. Rostum Capili Engr. Raffy Jay A. Bacting Precast Panel at Exterior - 10Th FloorSimeon James Defeo VillacrusisNo ratings yet

- Product Manual enDocument122 pagesProduct Manual enadacostNo ratings yet

- Gost 8278 83Document8 pagesGost 8278 83PetarNo ratings yet

- FT8 Cinta ButilDocument2 pagesFT8 Cinta ButilMerlinOaNo ratings yet

- Especificaciones Tecnicas Arquitectura Vivero CCDocument46 pagesEspecificaciones Tecnicas Arquitectura Vivero CCEnrique Pacheco RamosNo ratings yet

- DH77KDocument29 pagesDH77KJames Allen Roberts Sr.100% (1)

- Cswip 3.1 Part 2Document20 pagesCswip 3.1 Part 2Alam MD SazidNo ratings yet

- Un Terraplen Es Una Plataforma Compactada Por CapasDocument4 pagesUn Terraplen Es Una Plataforma Compactada Por CapasDAYLER MORENONo ratings yet

- Behaviour of Crimped Steel Fiber in ConcreteDocument11 pagesBehaviour of Crimped Steel Fiber in ConcreteRainakNo ratings yet

- Fibras Textiles, PetroquimicaDocument31 pagesFibras Textiles, PetroquimicaDaniela LeonorNo ratings yet

- Corte e SoldaDocument9 pagesCorte e SoldasantosNo ratings yet