Professional Documents

Culture Documents

603.93.476 - Inglese Iveco Manual

Uploaded by

Quido KoutOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

603.93.476 - Inglese Iveco Manual

Uploaded by

Quido KoutCopyright:

Available Formats

ARWAY ELECTRIC/ELECTRONIC SYSTEM 1

SECTION 14

Electric/electronic system

Page

GENERAL REMARKS . . . . . . . . . . . . . . . . . . . . . 3

ELECTRONIC SYSTEMS . . . . . . . . . . . . . . . . . . 47

CIRCUIT CARDS . . . . . . . . . . . . . . . . . . . . . . . . 73

Print 603.93.476 Base — September 2005

2 ELECTRIC/ELECTRONIC SYSTEM ARWAY

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 3

General remarks

Page

GENERAL CONDITIONS FOR WIRING

DIAGRAM LAYING . . . . . . . . . . . . . . . . . . . . 5

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

- General warnings . . . . . . . . . . . . . . . . . . . . . . 6

- General warnings on the electric system . . . . 7

ELECTROMAGNETIC COMPATIBILITY AND

GROUND CONCEPTS . . . . . . . . . . . . . . . . . 8

- Grounds and screening . . . . . . . . . . . . . . . . . . 9

ELECTROMECHANIC OPTIONAL ITEM

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 10

EXTERNAL ACCESS POINTS . . . . . . . . . . . . . . 12

MAIN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . 13

....................................... 15

- Left side dashboard . . . . . . . . . . . . . . . . . . . . . 15

- Central dashboard . . . . . . . . . . . . . . . . . . . . . . 17

- Cluster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

- .................................... 19

- .................................... 22

- Movable panel (inner side of compartment

under the driver) . . . . . . . . . . . . . . . . . . . . . . . 25

- Movable panel (outer side of compartment

under the driver) (with C.M. ZF) . . . . . . . . . . 26

- Rear panel (left side) . . . . . . . . . . . . . . . . . . . . 27

- .................................... 28

- .................................... 30

- .................................... 32

- Initials and description of cable harnesses . . . . 33

ENGINE COMPONENT IDENTIFICATION . . . 35

- Engine rear view . . . . . . . . . . . . . . . . . . . . . . . 35

- Engine left side view . . . . . . . . . . . . . . . . . . . . 36

- Engine right side view . . . . . . . . . . . . . . . . . . . 37

- Engine front view . . . . . . . . . . . . . . . . . . . . . . 38

Print 603.93.476 Base — September 2005

4 GENERAL REMARKS ARWAY

Page

POSITION OF ELECTRIC COMPONENTS IN THE

ENGINE COMPARTMENT . . . . . . . . . . . . . . . 39

- Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

- Starting motor . . . . . . . . . . . . . . . . . . . . . . . 41

- Pump injector . . . . . . . . . . . . . . . . . . . . . . . . 42

BODE OUTSWINGING DOORS . . . . . . . . . . . . 43

- Description . . . . . . . . . . . . . . . . . . . . . . . . . . 43

- Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

- Pneumatic actuator . . . . . . . . . . . . . . . . . . . . 44

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 5

GENERAL CONDITIONS FOR WIRING DIAGRAM LAYING

- MASTER CURRENT REMOTE-CONTROL SWITCH OFF

- KEY SWITCH OFF

- INTERNAL-COMBUSTION ENGINE OFF

- PARKING BRAKE ON

- PNEUMATIC SYSTEM AIR Lacking

- FLUIDS LEVEL Normal

- GEAR SHIFT POSITION Neutral

- CENTRAL EMERGENCY CONTROL OFF

Warnings

The symbols illustrated below will appear on the following pages.

The instructions and warnings contained in this manual shall be followed strictly and carefully, in order to ensure both operator and

vehicle safety.

Failure to comply with the instructions may cause personal injury.

Failure to comply with the instructions may cause damage to the electric system, equipment and/or instruments.

General warning.

!

Print 603.93.476 Base — September 2005

6 GENERAL REMARKS ARWAY

GENERAL WARNINGS

NEVER DISCONNECT THE SYSTEM BATTERIES OR OPEN THE MASTER CURRENT REMOTE-CONTROL

! SWITCH WHEN THE INTERNAL-COMBUSTION ENGINE IS RUNNING.

THE ENGINE SHALL BE STARTED ONLY AFTER THE BATTERIES HAVE BEEN CONNECTED IN A PERMANENT

WAY.

- Secure the vehicle by means of suitable wedges or chocks, prior to carrying out work on the same.

- Do not use quick-charge devices to start the engine. Starting shall only be carried out with separate batteries or a suitable trolley.

- Check correct polarity of the battery terminals when starting the engine by means of an auxiliary trolley.

- Wrong polarization of the electronic control unit supply voltage (e.g. wrong battery polarization) may cause the control units

to be broken irreparably.

- Should the batteries need be disconnected from the system always first disconnected the chassis ground cable from the negative

terminal of the batteries themselves.

- Prior to connecting the batteries to the system, make sure that the latter is properly insulated.

- When troubleshooting (with the master current switch set to the running position), place a movable fuse between the negative

terminal of the battery and the chassis ground cable.

- Prior to removing the electric and/or electronic components, disconnect the ground cable from the negative terminal of the

battery.

- Disconnect the batteries from the system when the former are being charged by means of an external device.

- Disconnect the external charging device from the mains prior to removing the charging device pliers from the battery terminals.

- Do not insert or remove the management electronic control unit connector when the power supply is ON.

- The management electronic control units shall be removed when the temperature is higher than 80°C (drying furnaces).

- Disconnect the management electronic control unit connectors when electric welding work is carried out.

- During the connection phase, screw down the flap nuts of the connectors (temperature sensors, pressure sensors, etc.) only

to the specified tightening torque.

- Insulate the system prior to disconnecting the junction connector from an electronic control unit.

- Do not generate sparks to check for voltage in a circuit.

- Do not use a test lamp to check circuit continuity; instead, use only suitable inspection equipment.

- Do not directly power the components interlocked by electronic control units with the vehicle’s rated voltage.

- Do not put the measuring instrument prods into the electronic control unit connector plugs. Measurements, if any, shall be

made by means of a UNITESTER device.

- Make sure that the electronic device wiring (i.e. length, type of conductor, arrangement, straps, screening braided wire

connection, grounding, etc.) conforms to the IVECO system, and that the wiring is resumed correctly after any repair or

maintenance operation has been carried out. To avoid possible malfunction of the electronic systems fitted to the vehicle, the

auxiliary device wiring shall follow a different path from the one of the above-mentioned systems.

- The components shall be replaced only with genuine IVECO parts.

- Do not install auxiliary electric and/or electronic devices not provided for by IVECO or the local law regulations in force.

- Do not connect the auxiliary system negatives to the electronic system negatives.

- Remove the control units and electronic components in case of furnace paint baking.

The measurements in the management electronic control units, plug connections and electric connections to the

! components, can only be made on suitable test lines by means of adequate plugs and plug bushings. Never use improper

means such as metal wires, screwdrivers, retainers and the like. Otherwise, short-circuits may occur, and the plug

connections may be damaged, which will subsequently cause contact problems.

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 7

General warnings on the electric system

In the event that work has to be carried out on the electric/electronic system, disconnect the batteries from the system,

! taking care to always disconnect first the chassis ground cable from the negative terminal of the batteries themselves.

Prior to connecting the batteries to the system, verify that the latter is properly insulated.

Disconnect the external recharging unit from the mains prior to removing the pliers of the same from the battery

terminals.

Do not generate sparks when checking for voltage within a circuit.

Do not use a test lamp in order to check circuit continuity; instead, use only suitable inspection equipment.

Make sure that the electronic device wiring (i.e. length, type of conductor, arrangement, straps, screening braided wire

connection, grounding, etc.) conforms to the IVECO system, and that the wiring is resumed correctly after any repair

or maintenance operation has been carried out.

The measurements in the management electronic control units, plug connections and electric connections to the

components can only be made on suitable test lines by means of adequate plugs and plug bushings. Never use improper

means such as metal wires, screwdrivers, retainers and the like. Otherwise, short-circuits may occur, and the plug

connections may be damaged, which will subsequently cause contact problems.

Do not use quick-charge devices to start the engine. The engine shall only be started by means of separate batteries

or a suitable trolley.

Wrong polarization of the management electronic control unit supply voltage (e.g. wrong battery polarization) may

cause the control units to be broken irreparably.

Disconnect the batteries from the system when the former are being charged by means of an external device.

During the connection phase, screw down the flap nuts of the connectors (temperature sensors, pressure sensors, etc.)

only to the specified tightening torque.

Insulate the system prior to disconnecting the junction connector from an electronic control unit.

Do not directly power the components interlocked by electronic control units with the vehicle’s rated voltage.

The cable must be arranged in such a way that they are parallel to the reference plane, i.e. as near the chassis/body

structure as possible.

After the work on the electric system has been completed, restore the connectors and wiring in accordance with the

original layout.

The key memorization procedures are affected by electromagnetic noise (mobile phones, etc.). For this reason, the

following precautions shall be taken during the key memorization phase:

1. make sure that no noise source is found inside the cabin or next to the key;

2. any key not inserted into the board shall be at least 1 m far.

NOTE The available connectors are viewed from the cable side. The connector views illustrated in the manual are

representative of the cable side.

Print 603.93.476 Base — September 2005

8 GENERAL REMARKS ARWAY

ELECTROMAGNETIC COMPATIBILITY AND GROUND CONCEPTS

An electric system is customarily a single-pole system. The bodywork, chassis and electromechanic component metal shells act

as equipotential conductors for return to the generator, since any point of their metal structure or any non-insulated negative

terminals of theirs is at the same reference potential, or GROUND. This is why the ground has been chosen as the reference for

the entire system, and the 0 V voltage value has been ascribed to it by convention.

Due to various construction reasons, several ground points reach the system’s negative network, which are located on the vehicle

depending on the component position on the chassis, engine and bodywork.

Ideally, all the devices should instead be connected to one single ground point in order to ensure a clearly defined ground reference

to them (in particular, the electronic devices).

For the above reasons, a distinction should be made between the power supply ground (or system ground), characterized by

heavy direct current intensity (> 1 A for the electromechanic components), and the analog ground, characterized by waveforms

at certain frequencies and very small current intensity (mA, µA) for the electronic systems.

The definition of the signal ground or analog ground depends on the electronic systems sensitivity to the EMC (electromagnetic

compatibility), since parasitic signals (emitted by systems fitted to the vehicle or outside the same) lead to malfunction and/or

degradation of the systems themselves.

In order to minimize noise or interferences (both continuous and transient) generated by stray irradiation, you must always bear

in mind that proper efficiency of the reference plane or system ground depends, at each of its connecting points, on the superior

conductivity features (contact resistance tending to zero).

To sum it, it can be stated that the ground, meant as an equipotential electric conductor, i.e. as a potential reference for all of the

vehicle’s electric/electronic components, is divided into system ground and analog ground.

Figure 1

6616

EQUIVALENT CIRCUIT OF THE VEHICLE’S ELECTRIC NETWORK

Ba. Battery — R. Loads — Rz. Chassis impedance — M. Ground

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 9

Grounds and screening

The negative conductors connected to a system ground point shall be as short as possible and “wye” connected with one another,

and shall also be tightened in a proper, orderly manner (Figure 2, ref. M).

Moreover, the following instructions concerning the electronic components shall be strictly followed.

— The electronic control units shall be connected to the system ground if they are equipped with metal shell.

— The negative cables of the electronic control units shall be connected both to a system ground point, e.g. dashboard

compartment ground (avoiding “serial” or “chain” connections) and to the negative terminal of the battery.

— The analog grounds (sensors) shall, though they are not connected to the system ground/battery negative terminal, be properly

insulated. As a result, great care shall be taken with the cable terminal stray resistance: oxidation, seaming defects, etc.

— The screened circuit metal braided wire shall only come into contact on the end facing the control unit where the signal enters

(Figure 3).

— In the presence of junction connectors, the unscreened length “d” next to the latter shall be as short as possible (Figure 3).

— Cables shall be arranged in such a way that they are parallel to the reference plane, i.e. as near the chassis/bodywork structure

as possible.

— The auxiliary electromechanic systems shall be connected with great care to the system ground, and shall not be laid by the

side of the electronic component cables.

Figure 2

Negative cable “WYE” connection to the system ground “M”

Figure 3

88039

Metal braided wire cable screening to an electronic component — C. Connector —

d. Distance → 0

Print 603.93.476 Base — September 2005

10 GENERAL REMARKS ARWAY

ELECTROMECHANIC OPTIONAL ITEM INSTALLATION

Any accessory installation, addition and modification to the vehicle shall be made in accordance with the IRISBUS IVECO assembling

instructions (the specific publication entitled “Body building and modification directives” is available at any Dealership workshop).

Please note that, especially as far as the electric system is concerned, several electric outlets are available as standard (or optional)

items in order to make it easier and orderly for the body builders to carry out the electric work.

Any deviation from the assembling directives shall be subject to authorization from IRISBUS IVECO.

Failing to observe the above mentioned specifications and requirements involves forfeiture of the warranty cover.

It is strictly forbidden to make modifications or connections to the electric control unit wiring; in particular, the

line for data interconnection between the control units (CAN line) shall not be tampered with for any reasons

whatsoever.

Any diagnosis or maintenance operation shall be carried out by authorized personnel only by making use of

IVECO-approved equipment.

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 11

The system ground points shall be the ones provided by the manufacturer, and shall obviously be free from paint, oxidation, grease,

dust, etc.

Figure 4

106294

Figure 5

4972 86686 4974

1 — Ground connections: A. Efficient ground point — B. Inefficient ground point — 2. Fastening order:

A. Screw — B. Cable terminal — C. Washer — D. Nut — 3. Cable connected to the ground

If the ground cables need be disconnected from the chassis, the original conduction paint shall be fully removed when the connection

is resumed, and an even coat of BH44D paint (complying with the 18-1705 IVECO Standard requirements) shall be applied by

proceeding as described below.

- Remove the paint, either mechanically or by using a suitable chemical, both on the chassis and terminals sides.

- Apply the paint with a brush or an aerosol bomb.

- Connect the ground cables within 5 minutes at the most after the paint has been applied.

- In the event that a new ground contact is applied, file the area around the terminal fastening hole until the anaphoretic chassis

paint is fully removed, to create a supporting plane free from dents or steps.

Print 603.93.476 Base — September 2005

12 GENERAL REMARKS ARWAY

EXTERNAL ACCESS POINTS

1. Air filter — air-conditioning system compressor 12. Driver’s lower compartment upper panel

2. Air-conditioning system evaporator 13. Driver’s lower compartment lower panel — moving panel

3. Central door 14. Left-hand rear panel

4. Luggage compartment 15. Air-conditioning system condenser

5. Fuel pipe union — button for front door opening/closing 16. Windscreen wiper

from the outside

17. Spare wheel — access to lights and lamps

6. Button for rear door opening/closing from the outside

18. Engine water self-contained engine heating system boiler

7. Front door unit (Webasto)

8. Radiator cooling fan 19. Luggage compartment

9. Alternator belts 20. Battery

10. Air-conditioning system compressor 21. Silencer (SCR + CRT)

11. Engine

Figure 6

107303

107304

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 13

MAIN FEATURES

Bus (length: 12-12.8 m) equipped with two ejecting outswinging service doors.

The front chassis consists of channel side members made of stamped steel sheet, which are connected by welded crosspieces. The

central portion of the chassis, next to the luggage compartment, is of the trellis type, made from rectangular-section steel tubes.

The bodywork consists of a framing of tubes and metal box sectional irons electrically welded to one another, so as to create a

full, enclosed structure integrating the chassis.

The structure thus obtained conforms to the requirements of the EC 66 anti-tilting regulations.

Engine

The engine is of the vertical type and is fitted centrally on the rear pivot.

Type: IVECO F2B.

Six in-line cylinders.

Pump injector type injection.

Emission levels conforming to the EURO 4 regulatory standard.

Fan cooling system with viscostatic drive.

Automatic transmission

VOITH Diwa 864.5D gearbox with 4 speeds + reverse gear and built-in retarder.

Rear axle

Meritor U167.

Front axle

RI 75 R independent-wheel type.

Drive

ZF 8098 power steering drive.

Print 603.93.476 Base — September 2005

14 GENERAL REMARKS ARWAY

Electric system

The electric system is of the multiplex type.

Simplified cable codes (shown on the cables), with numeric codes that identify the cable function and intended use.

Voltage: 24 V.

Two batteries (12 V, 220 Ah) fitted side by side on the sliding tray under the driver’s seat; two alternators (90 A).

Starting motor (4.5 kW).

Master current remote-control switch actuated from the driver’s seat by means of a push-button switch.

Engine start cut-off from the driver’s seat with engine hatch open.

Circuit protection by means of manually-reactivated automatic magnetothermal switches.

Central emergency control.

Antistart device with engine running.

Current tap for external power supply.

Doors

Driver’s doors

Without the driver’s door.

Service doors

Two electropneumatically operated outswinging doors (dual central door).

One electropneumatically operated outswinging door (front door).

Door opening from the outside, with push-button on the front door (it also performs the door emergency unlocking function).

Central/front door unlocking emergency devices.

External lighting

The external lighting conforms to the right-hand drive EC regulations.

On the front head:

Light cluster:

- Low-beam and high-beam headlamps

- Dimmers

- Indicator lights

- White upper clearance lights

- Fog lamps.

On rear head:

Lamp cluster:

- Dimmers

- Brake lights

- Indicator lights

- Rear fog lights

- Reversing lights

- Upper clearance lights

- License plate lights.

On the sides:

Indicator lights

“Side marker” lights

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 15

Left side dashboard

Figure 7

106874

Print 603.93.476 Base — September 2005

16 GENERAL REMARKS ARWAY

LIST OF COMPONENTS

Ref. Description

1 Emergency stop switch

2 Emergency light switch

3 Left window shade switch

4 Right window shade switch

5 Retarder cut—off switch

6 Rear—view mirror defrosting switch

7 Driver’s window defrosting switch

8 Front door defrosting switch

10 Disabled access ramp switch 1

11 Disabled access ramp switch 2

12 Air suction turbine speed switch

13 Driver ventilation switch

14 Fridge switch

15 Reversing signalling device deactivation switch

16 Third axle discharge switch

20 Idling increase switch

21 Driver’s seat heater switch

22 Bitonal warning horn switch

23 External lighting switch

24 Driver’s light switch

25 Individual passenger light switch

26 Luggage compartment light switch

27 Information panel lighting switch

28 Spare

34 Suspension height decrease safety control switch

35 Suspension height decrease switch

36 Suspension height increase switch

37 Door open warning signal enable switch

38 Cooker switch

39 Fault signalling reset switch

40 Spare

41 Central emergency switch (with safety seal)

42 Fog light switch

43 Rear fog light switch

44 Light illumination switch

46 Passenger heating control

47 Air flow control

48 Heating thermoregulator

A Cigar lighter

B Rear—view mirror control

C 12 V current tap

D Parking brake control

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 17

Central dashboard

Figure 8

106875

LIST OF COMPONENTS

Ref. Description

29 Front door opening button

30 Rear door opening button

31 Luggage compartment lock/unlock switch

32 Driver’s seat lighting switch

33 Coffee maker switch

45 Indicator light warning function

E 12 V current tap

F Webasto heater programming

G Tachograph

H Air—conditioning system control panel

I CD/DVD player

J Radio

K Driver’s seat air—conditioning system control panel

Print 603.93.476 Base — September 2005

18 GENERAL REMARKS ARWAY

Cluster

Figure 9

106876

Ref. Description

1 Left indicator light

2 Engine hood open

3 Obstacle indicator

4 Geared—down speeds engaged

5 Parking lights

6 Spare

7 Fog lights

8 Rear fog lights

9 Retarder ON

10 ABS failure

11 Electronic engine control unit

12 Right indicator light

13 High—beam headlights

14 Emergency lights

15 Dashboard failure

16 Engine preheating

17 Exhaust brake

18 Speed limiter

19 Braking system failure

20 Power take—off

21 Door locked

22 Safety protection on doors

23 Heated rear—view mirrors

24 Parking brake

25 Chassis lowering

26 Hydraulic retarder function

27 ECAS failure

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 19

Figure 10

106877

Print 603.93.476 Base — September 2005

20 GENERAL REMARKS ARWAY

LIST OF COMPONENTS

Component

Ref. Description

code

1 TB21 Connector TB21

2 S4 Connecting bridge S4

3 SM2 Connector SM2

4 K48 Door closing

5 K46 Door

6 CB1 Connector CB1

7 CB2 Connector CB2

8 TB18 Connector TB18

9 SM6 Connector SM6

10 TC21 Connector TC21

11 K52 Driver’s light

12 — Thermal switches

13 S15 Connecting bridge S15

14 S13 Connecting bridge S13

15 S17 Connecting bridge S17

16 SC6 Connector SC6

17 K28 Brake lights

18 S19 Connecting bridge S19

19 HS18 Connector HS18

20 K29 Brake lights

21 SM18 Connector SM18

22 K90 Not used

23 AR18 Connector AR18

24 TB12 Connector TB12

25 TB21A Connector TB21A

26 — Thermal switches

27 AR21 Connector AR21

28 SC21 Connector SC21

29 K18 Emergency stop

30 K17 Emergency stop

31 K59 Parking brake minimum pressure

32 S5 Connecting bridge S5

33 AR18A Connector AR18A

34 K65 Central locking

35 AR21A Connector AR21A

36 K64 Central locking

37 K94 Not connected

38 K69 Central locking

39 OR6 Connector OR6

40 MR6 Connector MR6

41 K93 Not connected

42 K13 Signalling lights

43 K19 Telma decelerator

44 K26 Dimmers

45 K27 Dimmers

46 S12 Connecting bridge S12

47 — Thermal switches

48 S11 Connecting bridge S11

49 S20 Connecting bridge S20

50 S18 Connecting bridge S18

51 S14 Connecting bridge S14

52 S16 Connecting bridge S16

53 MASSE Ground connector

54 BAT1 Connector BAT1

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 21

LIST OF COMPONENTS

Component

Ref. Description

code

55 BAT2 Connector BAT2

56 K43 Door pressure buzzer

57 K15 Battery disconnecting switch

58 K21 Low—beam headlights

59 — Thermal switches

60 K20 High—beam headlights

61 K91 Not connected

62 FA18 Connector FA18

63 K22 Connector SM6

64 K92 Not connected

65 JR6 Connector JR6

66 LR6 Connector LR6

67 K44 Door delay

68 TG6 Connector TG6

69 K45 Door closing

70 K32 FIPO

71 PV12 Connector PV12

72 K47 Door delay

73 PT12 Connector PT12

74 K56 Stop request

75 K58 Door open signalling

76 PV21 Connector PV21

77 K57 Stop request

Print 603.93.476 Base — September 2005

22 GENERAL REMARKS ARWAY

Figure 11

106878

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 23

LIST OF COMPONENTS

Component

Ref. Description

code

1 KX1 Auxiliary turbine

2 K8 Low—speed turbines

3 KX4 Air pulse ventilation

4 KX3 Air pulse ventilation

5 KX6 Air pulse ventilation

6 — Thermal switches

7 KX9 Bulbs

8 KX10 Arway HD — Bulbs

9 K35 Low—speed heater

10 K53 Arway HD — Internal lighting

11 K51 Air pulse vent

12 K3 Aerotherm heater

13 K50 Arway 15M — Aerotherm heater

14 S1 Connecting bridge S1

15 K23 FIPO

16 K1 Vent

17 S7 Connecting bridge S7

18 K25 VCM

19 K68 Webasto unit

20 K4 Heater

21 K9 Arway HD — Water control

22 K49 Arway 15M — Aerotherm heater

23 S8 Connecting bridge S8

24 K2 Heater

25 K5 Aerotherm heater

26 — Connector

27 — Connector

28 — Connector

29 SC18 Connector SC18

30 S2 Connecting bridge S2

31 SC21 Connector SC21

32 S3 Junction bridge S3

33 HS12 Connector HS12

34 BAT Connector BAT

35 AS12 Connector AS12

36 SC6 Connector SC6

37 AR21 Connector AR21

38 — Thermal switches

39 SP21 Connector SP21

40 MASSE Ground connector

41 AR18 Connector AR18

42 K66 Increase

43 K67 Increase

44 TG12 Connector TG12

45 K62 Arway 15M — Third axle

46 K14 Third axle signalling

47 K61 T90S — A.15M — Third axle

48 K63 V30KM/H — Increase

49 AR21A Connector AR21A

50 K37 Reduction ON

51 K41 Reduction signalling

52 K39 Reduction solenoid valve

53 K38 Reduction OFF

54 K11 Internal lighting

Print 603.93.476 Base — September 2005

24 GENERAL REMARKS ARWAY

LIST OF COMPONENTS

Component

Ref. Description

code

55 TC18 Connector TC18

56 K40 Reduction

57 K16 Air conditioning

58 SP12 Connector SP12

59 K6 Low—speed window fan

60 FA12 Connector FA12

61 K7 High—speed window fan

62 K12 Glove compartment lighting

63 TC18A Connector TC18A

64 PV12 Connector PV12

65 TC21 Connector TC21

66 K10 Window defrosting

67 K55 Defrosting

68 K54 Defrosting

69 KX5 Air pulse ventilation

70 KX7 Air pulse ventilation

71 PV12A Connector PV12A

72 KX8 Air pulse ventilation

73 PT6 Connector PT6

74 S6 Connector S6

75 CH18 Connector CH18

76 PA21 Connector PA21

77 CH12 Connector CH12

78 PV18 Connector PV18

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 25

Movable panel (inner side of compartment under the driver)

Figure 12

106879

LIST OF COMPONENTS

Component

Ref. Description

code

1 86121 VBC control unit (CAMU)

2 68118 IOU (Input—Output Unit) control unit

3 86029 Central locking

4 88000 ABS control unit

5 — VCM (Vehicle Control Module) control unit

Print 603.93.476 Base — September 2005

26 GENERAL REMARKS ARWAY

Movable panel (outer side of compartment under the driver) (with C.M. ZF)

Figure 13

106880

LIST OF COMPONENTS

Component

Ref. Description

code

1 85033 Converter 24V / 12 V —10 A

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 27

Rear panel (left side)

Figure 14

106882

LIST OF COMPONENTS

Ref. Description

1 Lighting remote—control switch

2 Preheating remote—control switch

3 Engine stop remote—control switch

4 Engine starting remote—control switch

5 DCU emergency remote—control switch

6 ECM emergency remote—control switch

7 Cable junction connector

8 Cable junction connector

9 Cable junction connector

10 Cable junction connector

11 Cable junction connector

12 Cable junction connector

13 Cable junction connector

14 Terminal board

15 Thermal switches

16 Positive terminal board for power supply

17 Auxiliary heating remote—control switch

18 3—way cable junction connector (version with Voith gearbox only)

19 3—way cable junction connector (version with Voith gearbox only)

20 2—way cable junction connector

21 2—way cable junction connector

Print 603.93.476 Base — September 2005

28 GENERAL REMARKS ARWAY

Figure 15

106883

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 29

Function of thermal switches

Rating

Ref. Pos. Description

(A)

1 F26 5 Tachograph

2 F24 5 Stop request

3 F35 16 Professional radio

4 F36 8 Classic line radio

5 F25 10 Spr1

6 F38 8 Light control

7 F74 16 Central locking

8 F16 10 SWI F42 — VBC

9 F71 16 Toilet

10 F39 8 Door

11 F15 5 Dimmers

12 F22 5 Brake lights

13 F14 5 Dimmers

14 F23 5 Brake lights

15 F42 20 Not used

16 F91 25 Not used

17 F77 16 Emergency stop

18 F73 16 Central locking

19 F48 5 Not used

20 F72 5 Fridge

21 F50 10 VBC

22 F57 25 Emergency stop

23 F12 20 IOU

24 F56 8 Emergency stop

25 F11 16 Emergency lights

26 F10 25 Emergency stop remote—control switch

27 F95 — Not used

28 F94 — Not used

29 F92 — Not used

30 F93 — Not used

31 F21 5 Low—beam headlamps

32 F20 5 Low—beam headlamps

33 F19 5 High—beam headlamps

34 F18 5 High—beam headlamps

35 F17 8 Fog headlamps

Print 603.93.476 Base — September 2005

30 GENERAL REMARKS ARWAY

Figure 16

106884

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 31

Function of thermal switches

Rating

Ref. Pos. Description

(A)

1 F68 20 Air pulse valve

2 F7 25 Auxiliary turbines

3 F6 8 Fan, heater control

4 F66 25 Air pulse ventilation

5 F62 25 Air pulse ventilation

6 F61 25 Air pulse ventilation

7 F65 25 Air pulse ventilation

8 F64 25 Air pulse ventilation

9 F63 25 Air pulse ventilation

10 F69 25 Bulbs

11 F9 16 Defrosting

12 F70 16 Door defrosting

13 F34 16 Defrosting

14 F5 16 Window fan

15 F40 10 Glove compartment lighting

16 F67 16 Internal lighting

17 F59 20 Aerotherm heater

18 F8 10 Air conditioning

19 F37 16 Internal lighting

20 F49 5 Vehicle lifting

21 F3 25 Aerotherm heater

22 F60 5 Radián heater

23 F13 20 IOU

24 F75 8 Webasto preheater

25 F31 5 Drier

26 F58 20 Aerotherm heater

27 F4 25 Aerotherm heater

28 F43 5 ABS

29 F33 8 Cigar lighter

30 F44 25 ABS

31 F47 5 VCM

32 F41 5 Light above door

33 F2 16 Webasto

34 F1 16 Webasto

Print 603.93.476 Base — September 2005

32 GENERAL REMARKS ARWAY

Figure 17

106886

Function of thermal switches

Rating

Ref. Pos. Description

(A)

1 F06 25 ECM

2 F07 5 NOX

3 F05 16 DCU

4 F09 3 EV Turbo

5 F04 5 DCU

6 F03 5 ECM

7 F02 16 Preheating

8 F01 16 Engine starting

9 F08 8 (version with Voith gearbox only)

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 33

Initials and description of cable harnesses

ARA2 — TELMA power supply

ARA4 — Air conditioner power supply cable harness

ARA5 — Front board connection

ARA7 — TELMA console

ARA9 — TELMA

ARA9A — Intarder cable harness

ARA9B — VOITH control cable harness

ARA9C — Astronic — 15M

ARA61 — CIP power supply

ARA62 — CICH power supply

FAA1 — Vehicle rear cable harness

GMA1 — Engine compartment cable harness

GMA2 — F2B engine, BVM, TELMA

GMA3 — Starting motor power supply

GMA4 — TELMA power supply

GMA9 — Bodywork ground

GMA10 — Air preheating ground

GMA11 — WEBASTO

GMA11A — Eberspächer

GMA11E — Without WEBASTO

GMA51 — Rear left light cable harness

GMA52 — Rear right light cable harness

GMA61 — Alternators (2 x 90)

GMA62 — Alternators (140 + 80)

GMA81 — Alternator ground (2 x 90)

GMA82 — Alternator ground (140 + 80)

PVA1 — Front board connection (upper)

PVA2 — Narrow door

PVA2A — Two-shutter door

PVA3 — Air pulse cable harness

PVA5 — Two buttons

PVA6 — Rear upper lights

PVA7 — Left-hand air pulse + bulbs

PVA7A — Left-hand bulbs

PVA9 — Fluorescent bulbs, 2 fans

PVA9D — Bulbs, 2 fans + air conditioning

PVA9F — Fluorescent bulbs, 2 fans + air conditioning

PVA9G — Bulbs, 2 fans + air conditioning

PVA10 — WILKE G reversing FSC

PVA11 — WILKE D reversing FSC

PVA12 — Driver fan

PVA13 — Front door defrosting

PVA14 — Punching machine provision

PVA17 — TK air conditioning power supply

PVA18 — TK air conditioning ground

PVA19 — TK compressor power supply

PVA20 — TK air conditioning control

PVA51 — TCP/ right side 4AD buttons

Print 603.93.476 Base — September 2005

34 GENERAL REMARKS ARWAY

PVA52 — TCP/left side 4AD buttons

PVA71 — Right-hand air pulse + bulbs

PVA71A — Right-hand bulbs

SOA1 — Batteries and electronic isolating switch

SOA2 — Battery ground

SOA3 — Rear board power supply

SOA4 — Air sensor cable harness (doors)

SOA5 — FENWICK connector

SOA5A — M LUNEL connector

SOA5B — KAROSA connector

SOA6 — Chassis cable harness

SOA7 — ABS cable harness

SOA8 — Diode connection

SOA9 — Tachograph cable harness

SOA11 — Connection between the mechanic and electronic isolating switches

SOA13 — Front board (isolating switch)

SOA14 — CAN — Astronic/Intarder/VOITH

SOA61 — 4 air heaters

SOA61A — 3 air heaters

SOA61B — Convection

SOA62 — DCU harness

TBA1 — Dashboard

TBA2 — Air heater heating control

TBA3 — Contact cable harness (central)

TBA4 — “Classic line” cable harness

TBA4B — “Profi line” cable harness

TBA5 — Driver microphone cable harness

TBA7 — Contact cable harness (front)

TBA8 — Contact cable harness (rear)

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 35

ENGINE COMPONENT IDENTIFICATION

Engine rear view

Figure 18

107783

1. Injector unit connector — 2. Alternator 1 — 3. Alternator 2 — 4. Pulley on drive shaft — 5. Oil filter — 6. Automatic belt

stretcher — 7. Water pump — 8. Poly V-belt — 9. Turbine actuator — 10. Engine coolant temperature sensor

Print 603.93.476 Base — September 2005

36 GENERAL REMARKS ARWAY

Engine left side view

Figure 19

107782

1. Camshaft sensor — 2. Air compressor — 3. Power fan pump — 4. Starting motor — 5. Oil sump —

6. Power steering pump — 7. Servo-assisted steering pump — 8. Fuel pump — 9. EDC 7 control unit — 10. Alternators —

11. Air pressure/temperature sensor

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 37

Engine right side view

Figure 20

107781

1. Exhaust manifold — 2. Turboblower speed sensor — 3. Turboblower — 4. Oil pressure/temperature sensor —

5. Low engine oil pressure signalling pressure switch — 6. Engine oil pressure meter transmitter — 7. Oil filter —

8. Engine oil filter clogging sensor — 9. VGT solenoid valve air filter — 10. Turbine precombustion chamber pressure sensor —

11. VGT control solenoid valve — 12. Oil pressure relief valve (5 bar) — 13. Sensor on flywheel

Print 603.93.476 Base — September 2005

38 GENERAL REMARKS ARWAY

Engine front view

Figure 21

107780

1. Turboblower — 2. Engine flywheel — 3. Inspection hole for flywheel positioning during adjustments —

4. Flywheel rotation tool application window — 5. Power fan pump — 6. Valve gear cover with blow-by filter —

7. Blow-by valve

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 39

POSITION OF ELECTRIC COMPONENTS IN THE ENGINE COMPARTMENT

Figure 22

107779

Component

Ref. Description Circuit card

code

1 53590 Engine rear hatch circuit interlocking limit switch 11

2 — Engine cooling water tank level meter —

3 39004 Engine compartment lighting lamp 2

4 53006 Switch for engine start from the engine compartment 12

5 53007 Switch for engine stop from the engine compartment 12

6 — Fire sensor —

7 78006 Engine water cooling solenoid valve 4

8 86013 Sensor for signalling the presence of water in the fuel filter —

9 47042 Fuel temperature sensor 13

10 42552 Fuel filter clogging signalling switch 13

Print 603.93.476 Base — September 2005

40 GENERAL REMARKS ARWAY

Figure 23 Alternator

Features

Supplier MITSUBISHI 28V 90 A

Rated voltage 28.3 ± 0.5 V (20°C)

Rated current delivery 90 A

Normal operating speed 5,000 r.p.m.

Belt tension 730 N

Direction of rotation clockwise (viewed from the pulley)

Weight 6.9 kg

Tightening torque at terminal B+ 12.5 ± 2 Nm

106281

ALTERNATOR WIRING DIAGRAM

L To the recharge warning light

IG Alternator switch-on

S Battery voltage sensor

Figure 24 Figure 25 0300

106282

106300

ALTERNATOR CURRENT DELIVERY CURVE

PERSPECTIVE VIEW

Figure 26

106283

TECHNICAL VIEW

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 41

Starting motor

Features

Voltage 24 V

Rated output 4.5 kW

Direction of rotation (drive side) clockwise

Electromagnet absorption 12 A

Number of pinion teeth 10

Supplier DENSO

Weight ∼ 8.4 kg

Tightening torque at terminal 30 17.6 ÷ 24.5 Nm

Tightening torque at terminal 50 2.6 ÷ 4.6 Nm

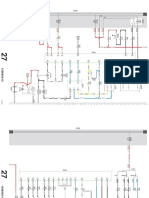

Figure 27

VOLTAGE

TORQUE

OUTPUT

SPEED

TORQUE

VOLTAGE

OUTPUT

SPEED

CURRENT (A) 107241

STARTING MOTOR PERFORMANCE Wiring diagram

1. Control electromagnet — 2. Electric motor — 3. Batteries

Figure 28 1000

107242

TECHNICAL VIEW

Print 603.93.476 Base — September 2005

42 GENERAL REMARKS ARWAY

Pump injector

It essentially consists of the following:

- plunger;

- nozzle;

- solenoid valve.

All of the above components CANNOT be replaced as separate items and CANNOT be overhauled.

The plunger is mechanically operated by a rocker arm upon every single cycle and compresses the fuel contained in the delivery

chamber.

The nozzle (the design and operation of which are similar to those of traditional injectors) is open by fuel under pressure and

injects the finely atomized fuel into the combustion chamber.

A solenoid valve directly actuated by the electronic control unit determines the delivery mode depending on the control signal.

An injector case houses the lower part of the pump injector in the cylinder head.

The EURO 4 F2B engine makes use of the PDE 30 pump injector with a different nozzle from the preceding one.

In case of replacement, every single pump injector shall have to be recognized by the EDC 7 UC31 control unit.

Figure 29

44908

PUMP INJECTOR

1. Diesel fuel/oil seal ring — 2. Diesel fuel/diesel fuel seal ring — 3. Diesel fuel/exhaust gas seal ring

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 43

BODE OUTSWINGING DOORS Figure 31

Description

The vehicle is equipped with outswinging, outward opening

doors designed in such a way that they match with the rest

of the vehicle’s side surface when they are closed, thus

ensuring better aerodynamic efficiency and less noise.

The system is of the electro-pneumatic type. Figure 30

illustrates the position of the components that make up the

above system.

Operation

Doors are opened/closed from the inside by pressing the

buttons placed on the left side board (figure 31, ref. 1-2).

107507

1. Front door control button — 2. Central door control

button

Figure 30

107508

1. Door controls on driver’s board — 2. Switch for front door opening from the outside —

3. Door opening cylinders — 4. JOUCOMATIC control blocks

Print 603.93.476 Base — September 2005

44 GENERAL REMARKS ARWAY

Figure 32 The pneumatic actuators that operate the doors (figure 32)

are controlled by the solenoid valves below:

78100 (see circuit card 28) for the front door;

78101 (see circuit card 29) for the central door.

Figure 33 illustrates the position of the switch for front door

control from the outside (53019, circuit card 28).

9029

PNEUMATIC ACTUATOR

Figure 33

Pneumatic actuator

Figure 35

107509

SWITCH FOR FRONT DOOR OPENING FROM THE

OUTSIDE

Figure 34

107511

1. Switch for step illumination and door open/closed

signalling on the dashboard — 2. Door safety device

107510 (INVERSION) deactivation switch — 3. Door safety device

TWO-SHUTTER DOOR — POSITION OF PNEUMATIC (INVERSION) actuation switch

SHUTTER ACTUATOR

Base — September 2005 Print 603.93.476

ARWAY GENERAL REMARKS 45

This component is equipped with adjustable cams (figure 36, Figure 37

ref. 1).

After loosening the screw placed on the actuator cam, the

contact closing and opening movement can be adjusted.

The door shutter positions itself 30 mm far from the

bodywork.

At this time, both contacts should open.

Both the step illumination ceiling light and the door open

signalling warning light on the dashboard will now go out.

Moreover, door opening/closing inversion deactivation will

be disabled: this means that the door safety device is OFF.

If the door is not adjusted this way, the screws on the cams

shall be loosened and adjusted to a distance of 30 mm.

In the event that a person is crushed by the moving door, the

door movement will stop itself, and the door will be raised

by approximately 14 mm.

107513

Door raising will cause the contact to close and the door

shutters to open again. JOUCOMATIC CONTROL BLOCK

If the door safety device actuation switch is not accompanied

by the inversion switch, the door will be fully opened again

after it is fully closed. Figure 38

This is due to the very design of the door opening cylinder,

which will raise and lower the door control rod by

approximately 14 mm upon every closing/opening

movement. This will ensure mechanic closing of shutters

when the bus is running and passengers are pushing against

the door from inside. For this reason, the door safety switch

is available, which will, after properly adjusting, turn the

inversion function OFF when the shutters are 30 mm far from

the bodywork.

The BODE outswinging door pneumatic actuator switches

are represented by components 53570 and 53571 of circuit

cards 28 and 29, respectively.

107514

Figure 36

1. Door opening/closing electromagnets — 2. Sensor

Figure 37 illustrates the position of the JOUCOMATIC

control block above the door.

The JOUCOMATIC control block is made up of the

following components:

- two door opening and closing electromagnets (figure 38,

ref. 1);

- one door emergency status signalling sensor (vent air)

(figure 38, ref. 2).

107512

Print 603.93.476 Base — September 2005

46 GENERAL REMARKS ARWAY

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 47

Electronic systems

Page

CURSOR ENGINE MANAGEMENT . . . . . . . . . 49

EDC SYSTEM (ECM) . . . . . . . . . . . . . . . . . . . . . 49

- Electric injector connector “2” . . . . . . . . . . . . 51

- Sensor connector “1” . . . . . . . . . . . . . . . . . . . 52

- Chassis connector “3” . . . . . . . . . . . . . . . . . . . 53

MULTIBUS SYSTEM . . . . . . . . . . . . . . . . . . . . . . 54

“CAMU” UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . 54

IOU UNIT (INPUT/OUTPUT UNIT) . . . . . . . . . 54

- Synoptic diagram of the MULTIBUS system, CAN

VDB line and CAN EDB line on vehicles equipped

with mechanic transmission and TELMA retarder 55

ELECTRONIC CONTROL UNIT ANALYSIS . . 56

VCM (Vehicle Central Module) ELECTRONIC

CONTROL UNIT . . . . . . . . . . . . . . . . . . . . . 64

NITRIC OXIDE (NOX) REDUCTION SYSTEM MANA-

GEMENT ELECTRONIC CONTROL UNIT — DCU

(DOSING CONTROL UNIT) . . . . . . . . . . . . 66

TACHOGRAPH . . . . . . . . . . . . . . . . . . . . . . . . . 67

- Digital tachograph (DTCO) . . . . . . . . . . . . . . 67

- Tachograph pin-out . . . . . . . . . . . . . . . . . . . . . 68

KNORR ABS/ASR ELECTRONIC SYSTEM

(ABS 6 4S/4M) . . . . . . . . . . . . . . . . . . . . . . . . 69

- Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

- Operation logic . . . . . . . . . . . . . . . . . . . . . . . . 69

- Electronic control module . . . . . . . . . . . . . . . . 69

- Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

- ABS modulating solenoid valves . . . . . . . . . . . 70

- ASR solenoid valve . . . . . . . . . . . . . . . . . . . . . 70

- ABS warning light . . . . . . . . . . . . . . . . . . . . . . 70

- ASR warning light . . . . . . . . . . . . . . . . . . . . . . 70

Print 603.93.476 Base — September 2005

48 ELECTRONIC SYSTEMS ARWAY

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 49

CURSOR ENGINE MANAGEMENT

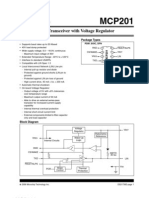

EDC SYSTEM (ECM)

EDC 7 UC 31 electronic control unit

Figure 1

106923

1. Sensor connectors — 2. Injector connectors — 3. Chassis connector — 4. Atmospheric pressure sensor

Print 603.93.476 Base — September 2005

50 ELECTRONIC SYSTEMS ARWAY

Figure 2

107368

EDC 7 UC 31 CONTROL UNIT

1. Sensor connector — 2. Injector connector — 3. Chassis connector

The EDC 7 UC 31 control unit is fitted directly onto the engine by means of a heat exchanger used for control unit cooling,

by making use of elastic dowels that reduce the vibrations transmitted by the engine.

The control unit is powered through a fuse (25 A).

The main relay normally used to power the system is placed inside the control unit itself.

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 51

Electric injector connector “2”

Figure 3

106922

VIEW (ON CABLE SIDE)

Pin Function

1 Positive for cylinder 5 electronic injection solenoid valve

2 Positive for cylinder 6 electronic injection solenoid valve

3 Positive for cylinder 4 electronic injection solenoid valve

4 Positive for cylinder 1 electronic injection solenoid valve

5 Positive for cylinder 3 electronic injection solenoid valve

6 Negative for cylinder 2 electronic injection solenoid valve

7 Current-controlled engine decompression solenoid valve (not connected)

8 Engine decompression solenoid valve (not connected)

9 Not connected

10 Not connected

11 Positive for cylinder 2 electronic injection solenoid valve

12 Negative for cylinder 3 electronic injection solenoid valve

13 Negative for cylinder 1 electronic injection solenoid valve

14 Negative for cylinder 4 electronic injection solenoid valve

15 Negative for cylinder 6 electronic injection solenoid valve

16 Negative for cylinder 5 electronic injection solenoid valve

Print 603.93.476 Base — September 2005

52 ELECTRONIC SYSTEMS ARWAY

Sensor connector “1”

Figure 4

107769

VIEW (ON CABLE SIDE)

Pin Function

1 Variable-geometry turbine control solenoid valve

2 Not connected

3 Variable-geometry turbine control solenoid valve

4 Not connected

5 Not connected

6 Not connected

7 Not connected

8 Not connected

9 Signal from engine revs number sensor on valve gear

10 Ground for engine revs number sensor on valve gear

11 Not connected

12 Not connected

13 Not connected

14 Not connected

15 Signal from coolant temperature sensor

16 Not connected

17 Low fuel pressure/temperature sensor negative

18 Not connected

19 Signal from engine revs detecting sensor on flywheel

20 Signal from turboblower speed sensor

21 Not connected

22 Not connected

23 Signal from engine revs detecting sensor on flywheel

24 Oil pressure and temperature sensor negative

25 Air pressure and temperature sensor negative

26 Fuel temperature sensor and coolant temperature sensor negative

27 Pressure signal from oil temperature and pressure sensor

28 Temperature signal from oil temperature and pressure sensor

29 Not connected

30 Signal from turboblower speed sensor

31 Not connected

32 Oil pressure and temperature sensor positive

33 Air pressure and temperature sensor positive

34 Pressure signal from air pressure and temperature sensor

35 Signal from fuel temperature sensor

36 Temperature signal from air pressure and temperature sensor

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 53

Chassis connector “3”

Figure 5

71 89 72 54 6 11

1

7

12

106920

53 35 18 36 17

VIEW (ON CABLE SIDE)

Pin Function

1 Not connected

2 +30 battery positive (3)

3 +30 battery positive (4)

4 Not connected

5 Battery negative (3)

6 Battery negative (4)

7 Not connected

8 +30 battery positive (1)

9 +30 battery positive (2)

10 Battery negative (1)

11 Battery negative (2)

12 Preheating actuation enable remote-control switch

13 — 23 Not connected

24 Negative for particulate filter exhausted gas temperature sensor

25 Particulate filter exhausted gas temperature sensor signal

26 Moisture sensor analog input

27 Signal from ambient temperature sensor

28 Negative for ambient temperature sensor

29 Ground

30 — 31 Not connected

32 Signal from switch for engine start from the engine compartment

33 Not connected

34 CAN — L line

35 CAN — H line

36 — 39 Not connected

40 +15 battery positive

41 — 46 Not connected

47 Signal from switch for engine stop from the engine compartment

48 — 56 Not connected

57 Engine fan 1 positive

58 — 74 Not connected

75 Positive for preheating actuation enable remote-control switch

76 — 80 Not connected

81 Signal from particulate filter differential pressure sensor

82 Positive for particulate filter differential pressure sensor

83 Negative for particulate filter differential pressure sensor

84 — 88 Not connected

89 EDC control unit diagnosis “K” line

Print 603.93.476 Base — September 2005

54 ELECTRONIC SYSTEMS ARWAY

MULTIBUS SYSTEM Moreover, the storing of all the data detected by the

The Multibus system is a modular system made up of the peripheral units makes it possible to perform centralized

following electronic control units: diagnosis of the entire electric/electronic system by

— 1 CAMU (VBC); interfacing the CAMU with the specific diagnosis instruments,

— 1 IOU (INPUT/OUTPUT UNIT). without having to test every single actuator.

The above-mentioned electronic units are connected to

each other through a serial line, in accordance with the CAN IOU UNIT (INPUT/OUTPUT UNIT)

protocol. It is an electronic unit used to monitor and drive most electric

sensors and electric devices.

“CAMU” UNIT The IOU is directly connected to such loads as electric

The CAMU unit is the central unit: therefore, it will manage motors, lamps and solenoid valves without having to actuate

all the peripheral units available in the system (IOU unit). the thermal protections.

The peripheral units will be managed through the phases Moreover, the IOU is capable of driving local functions

below: without the intervention of the CAMU and also

pre-processing the data to be transmitted to the CAMU so

— acquiring of the data (INPUT) detected by every single as not to saturate the central unit.

peripheral unit;

Circuit card 7 illustrates all the ARWAY IOU connections.

— processing through the program of the logic functions

stored into the FLASH EPROM memory available in the

CAMU unit; MULTIBUS CAN line:

— sending the results (OUTPUT) to the concerned CAN H Cable colour code: 7834

peripheral units. CAN L Cable colour code: 7835

The logic function program can be modified according to the

specific customer requirements by making use of a diagnosis VDB CAN line:

instrument. CAN H Cable colour code: 6110

The CAMU unit is equipped with an EPROM memory used CAN L Cable colour code: 6111

to store the parameters representative of the customer

specifications.

EDB CAN line:

CAN H Cable colour code: 6113

CAN L Cable colour code: 6114

Figure 6

107773

CAMU

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 55

Synoptic diagram of the MULTIBUS system, CAN VDB line and CAN EDB line on vehicles equipped

with mechanic transmission and TELMA retarder

Figure 7

CAN VDB line CAN EDB line

107601

CAMU (VBC vehicle management electronic control unit) — IOU (Input/Output unit) —

SPRI (Electronic dashboard with microprocessor for instrument and warning light display, or Screen Control Unit) —

VCM (Vehicle Control Module) — ECM (Engine Control Module) —

DCU (Nitric oxide reduction system management electronic control unit) —

TELMA MCR (Electric decelerator drive control unit) —

TACHOGRAPH (Electronic tachograph) — ABS/ASR (ABS system electronic control unit) —

SWI (Steering Wheel Interface: multiplex control unit for interfacing with the steering driving shaft) —

DIAG (30-pole diagnosis connector) — ODB (On-Board Diagnostic) —

NOX SENSOR (Control unit for conversion from analog signal on the NOX sensor to digital signal on the EDB CAN line).

Print 603.93.476 Base — September 2005

56 ELECTRONIC SYSTEMS ARWAY

ELECTRONIC CONTROL UNIT ANALYSIS

CAMU connector pin-out

Figure 8

107771

Figure 9

107772

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 57

Connector CN1 pin-out

Signal

Pin Customer name Cable code Function

name

1 + APC — 7826 Battery+ power supply

2 — BAT — 0000 Ground

Connector CN2 pin-out

Signal

Pin Customer name Cable code Function

name

1 ADCAN_0 CAN ADDRESSAGE 7833 IOU

2 CAN_2_L CAN L VBD 6111 INTA

3 CAN_2_H CAN H VBD 6110 INT/VCM

4 CAN2—120 — — —

5 BLIND_1 CAN 0 0807 IOU

6 CAN_1_L CAN L 7835 IOU

7 CAN_1_H CAN H 7834 IOU

Connector CN3 pin-out

Signal

Pin Customer name Cable code Function

name

1 ADCAN_1 — — —

2 CAN_3_L — — —

3 CAN_3_H — — —

4 CAN3_120 — — —

5 BLIND_1 CAN 0 VDB 0805 VCM/INT

6 CAN_1_L — — —

7 CAN_1_H — — —

Print 603.93.476 Base — September 2005

58 ELECTRONIC SYSTEMS ARWAY

Connector CN4 pin-out

Signal

Pin Customer name Cable code Function

name

1 KLINE LIGNE K 2303 Diagnosis

2 ELOG1 — —

3 ELOG0 EPORTE 6906 Door open information

4 ELOG14 EFREIN3 7874 Power supply

5 EFREQ1 — — —

6 EFREQ0 — — —

7 EREV1 EDETR 2507 Emergency lights

8 EREV0 EAURGENCE 8321 Emergency light actuation

9 EANA0 EPRAIR 5801 Rear wheel pad position

10 EANA1 — 5849 Front wheel pad position

11 EANA2 EABAR 2279 Rear fog light

12 EANA3 EAVSON 7774 SWI

13 EANA4 EPOS 3380 Dimmer

14 LLINE LIGNE L 1190 Diagnosis

15 ELOG4 ERAL 6942 TELMA

16 MASSE MASSE 0651 GROUND

17 ELOG6 EMINFR — Low front brake air pressure signalling

18 ELOG7 EMINPS 6815 Low parking brake air pressure signalling

19 ELOG8 — — —

20 ELOG9 EFREIN2 7875 Power supply

21 J1708+ — — —

22 J1708— — — —

23 ELOG12 EABAISS 8549 Kneeling

24 ELOG13 EABAV 2289 Fog light actuation

25 EANA5 ECROI 2237 VBC low-beam headlamp

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 59

Connector CN5 pin-out

Signal

Pin Customer name Cable code Function

name

1 +BAT — — —

2 OUT13 SBEP4 9942 TELMA

External light actuation remote-control

3 OUT14 SPOSIG 1606

switch (K27)

High-beam headlamp actuation

4 OUT17 SROUTE 2200

remote-control switch (K20)

Fog light actuation remote-control switch

5 OUT18 SABAV 2228

(K22)

6 OUT19 SPCHAU 7026 VCM alarm clock

7 OUT12 SBEP3 9946 TELMA

8 OUT11 SBEP2 9940 TELMA

9 OUT10 SBEP1 9943 TELMA

10 OUT9 SDEM 7614 VCM alarm clock

11 OUT8 — — —

12 OUT7 EPLAQAR 6030 Rear wheel shoe wear signalling

13 OUT6 SDESHUIL 9047 Settling apparatus heating resistor

14 OUT20 SVIT 5807 Doors

Low-beam headlamp actuation

15 OUT16 SCROI 2201

remote-control switch (K21)

External light actuation remote-control

16 OUT15 SPOSID 1607

switch (K26)

17 OUT21 SRECUL 2227 Reverse gear alarm switch

18 OUT23 SMTOUR 8909 Discharge

19 OUT22 SAVSON 1116 Warning horn

20 OUT0 SCLAVD 1123 Power supply

21 OUT1 SCLAVD 2506 Power supply

22 OUT2 SCLAVG 1129 Power supply

23 OUT3 SCLAVG 2505 Power supply

Shutting solenoid valve for engine cooling

24 OUT4 SREMOT 9166

control

25 OUT5 — — —

Print 603.93.476 Base — September 2005

60 ELECTRONIC SYSTEMS ARWAY

IOU connector pin-out

Figure 10

107766

Figure 11

107770

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 61

Connector CN1 pin-out

Signal

Pin Customer name Cable code Function

name

1 + APC + APC 7828 Battery+ power supply

2 — BAT — BAT — Ground

Connector CN2 pin-out

Signal

Pin Customer name Cable code Function

name

1 ADCAN_0 CAN ADDRESSAGE_0 7833 VBC

2 K_LINE — — —

3 RS 485 + — — —

4 SHIELD CAN 0 (BLIND) 0807 VBC

TERM/RS 485

5 — — —

—

6 CAN_L CAN_L 7835 VBC

7 CAN_H CAN_H 7834 VBC

Connector CN3 pin-out

Signal

Pin Customer name Cable code Function

name

1 ADCAN_1 CAN ADDRESSAGE_1 — —

2 K_LINE BLIND — —

3 RS 485 + — — —

4 SHIELD — — —

5 TERM/RS 485— R120 Ohm 7838 Connected to PIN 6

6 CAN_L CAN_L 7838 Connected to PIN 5

7 CAN_H CAN_H — —

Print 603.93.476 Base — September 2005

62 ELECTRONIC SYSTEMS ARWAY

Connector CN4 pin-out

Signal

Pin Customer name Cable code Function

name

GROUND

1 — — —

ANA

2 EANA0 — — —

3 EANA1 — — —

4 EANA2 — — —

GROUND

5 — — —

ANA

6 EANA3 EPLAQAV 6025 Front wheel shoe wear signalling

7 EANA4 EFREINI 6830 VBC

8 EANA5 EDEGRE 8830 INFO DEFR. MIRRORS

GROUND

9 — — —

ANA

SENSOR

10 — — —

SUPPLY

11 EFREQ0 — — —

12 EFREQ1 EAPC 7813 EAPC

13 EFREQ2 — — —

GROUND

14 — — —

LOG

GROUND LO-

15 — — —

G

16 EREV0 — — —

17 EREV1 — — —

18 NC — — —

19 ELOG0 EAFIX 8873 LIMIT CONTACT

20 ELOG1 ENEUTRE 5815 VCM

21 ELOG2 EANFIPO

22 ELOG3 EISORAL 7872 Foot-operated TELMA disconnection

23 ELOG4 ECOLHUI 9827 Oil filter clogging

24 ELOG5 ECOLGAZ 9828 Fuel filter clogging

25 ELOG6 ERECUL 2226 Reversing light actuation switch

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 63

Connector CN5 pin-out

Signal

Pin Customer name Cable code Function

name

1 +BAT — — Power supply

2 +BAT — 7829 Power supply

3 OUT9 — — —

4 OUT10 SABAR 2282 Rear fog light

5 OUT14A — — —

6 OUT12D — — —

7 OUT1 SSTOP 1176 Brake light actuation

8 OUT2 SPOLV 8886 Windscreen washing pump

9 OUT2 SSTOP 1173 Brake light actuation

10 OUT4 SDETR 0023 Rear light actuation

11 OUT6 SCLREG 1185 Trailer intermittent lights

12 OUT7 SCLARDH 1612 Rear right indicator light

13 OUT8 SCLARGH 1611 Rear left indicator light

14 OUT11 SCLARD 1610 Rear right indicator light

15 OUT11 SCLARD — Rear right indicator light

16 OUT12 SEVPV 8882 Low speed

17 OUT12 SEVPV — Low speed

18 OUT13 SCLARG 1613 Rear left indicator light

19 OUT13 SCLARG — Rear left indicator light

20 OUT14 SCLREG 1180 Trailer intermittent lights

21 OUT14 — —

22 OUT5 SBALIS 4801 Rear lights

23 OUT5 SBALIS — Rear lights

24 OUT0 SEVGV 8881 High speed

25 OUT0 SEVGV — High speed

Print 603.93.476 Base — September 2005

64 ELECTRONIC SYSTEMS ARWAY

VCM (Vehicle Central Module) ELECTRONIC CONTROL UNIT

Figure 12

107764

The VCM control unit is located on the inner side of the moving panel placed in the compartment under the driver (see figure

13).

Connector X2 is not connected.

Figure 13

107515

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 65

VCM control unit connector pin-out

Connector:

Pin Cable code Function

4 7727 +30

5 7614 +15

6 0000 GND

15 0808 LSD01 (start-up remote-control switch ground)

16 8888 HSD07 (start-up remote-control switch power supply)

Connector:

Pin Cable code Function

1 6110 CAN H VDB

2 6111 CAN L VDB

8 7612 DI16

10 8159 Exhaust brake disconnection

12 8892 Start-up

14 6828 Brake pedal, 2nd contact

15 6826 Brake pedal, 1st contact

17 0831 +5 V ref.

19 6113 CAN H Engine EDB

20 6114 CAN L Engine EDB

28 6814 Hand brake ON switch

29 0092 Engine hood contact

34 0158 Idling position

35 5157 Accelerator pedal position

46 — PTO2

47 — PTO1

51 0160 Engine position detecting sensor

52 5161 Idling position

53 5158 Accelerator pedal ground

54 2503 Diagnosis

Figure 14

107765

Print 603.93.476 Base — September 2005

66 ELECTRONIC SYSTEMS ARWAY

NITRIC OXIDE (NOX) REDUCTION SYSTEM MANAGEMENT ELECTRONIC CONTROL UNIT

— DCU (DOSING CONTROL UNIT)

Figure 15

6 8 16 9 15 22

4

5

1 3 23 30 36 29

102379

CONNECTOR VIEW (ON CABLE SIDE)

Pin Function Cable code

1 Power supply 7508

2 Power supply 7808

3 Ground 0000

4 Ground 0000

5 Urea pressure compensation tube heating resistor power supply 9813

6 Negative for Ad Blue tank heating water solenoid valve

7 CAN — L line (EDB) 6114

8 CAN — H line (EDB) 6113

9 Power supply 7606

10 ÷ 13 Spare —

14 DCU control unit diagnosis line “K” 2501

15 ÷ 17 Spare —

18 Signal from urea tank temperature sensor 6542

19 Urea tank level and temperature sensor ground 0543

20 Signal from urea tank level sensor (Ad Blue level) 6543

21 Spare —

22 SCR catalyst inlet gas temperature sensor ground 0851

23 SCR catalyst outlet gas temperature signal 9819

24 SCR catalyst inlet gas temperature sensor ground 0850

25 SCR catalyst inlet gas temperature signal 9818

26 Positive for Ad Blue injection solenoid valve 9821

27 Negative for Ad Blue injection solenoid valve 0852

28 Power supply for resistor heating the pipe for urea inlet to the pump 9815

29 Urea recovery pipe heating resistor power supply 9814

30 Spare —

31 Positive for Ad Blue tank heating water solenoid valve 9816

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 67

TACHOGRAPH

Digital tachograph (DTCO) Figure 16

The digital tachograph (DTCO) (see figure 15) is supplied as

a standard item on newly produced vehicles, and supersedes

the analog tachograph in case of failure.

The DTCO electric connections are the same as the ones

found on the MTCO. As regards the DTCO tachograph, the

sensor on the gearbox shall be replaced, which is the same,

from an electric viewpoint, as the previous one. In fact, the

sensor used with the MTCO tachograph (KITAS 2170)

cannot be used with the new DTCO tachograph, to which

the KITAS 2171 sensor is fitted.

This sensor (i.e. KITAS 2171) is compatible also with the

MTCO; yet, it can only be used with this tachograph family

after it has been configured.

On circuit card 15, the KITAS 2171 sensor is represented by

component 40031.

106342

DTCO DIGITAL TACHOGRAPH

Figure 17

106343

TACHOGRAPH SENSOR (KITAS 2171)

Print 603.93.476 Base — September 2005

68 ELECTRONIC SYSTEMS ARWAY

Tachograph pin-out

Figure 18

106344

Pin Function Cable colour code

1 +30 positive direct to the battery 7806

2 Ideograph illumination 4801

3 +30 positive direct to the battery 7768

A 4 CAN “H” line (VDB) 6110

((white)) 5 Ground 0000

6 Ground 0000

7 CAN “O” line (VDB) 0805

8 CAN “L” line (VDB) 6111

1 Pin 1 sensor power supply 5514

2 Pin 2 sensor ground 0058

3 Pin 3 sensor speed signal 5517

B 4 Pin 4 sensor inverted signal 6820

5 — —

(yellow)

6 — —

Speed signal for pin 28 diagnosis connector (30-pole) and SPEEDOMATIC

7 5540

control unit (TELMA decelerator)

8 — —

1 — —

2 — —

3 — —

C 4 — —

(red) 5 — —

6 — —

7 — —

8 — —

1 — —

2 — —

3 — —

D 4 — —

(brown) 5 — —

6 — —

7 Line “K”: cluster pin B 1 / Diagnosis (30-pole) pin 14 2299

8 — —

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 69

KNORR ABS/ASR ELECTRONIC SYSTEM (ABS 6 4S/4M)

Description

The ABS/ASR braking system is implemented by means of traditional pneumatic elements assisted by a driving electronic control

unit (see figure 19), by sensors with their respective phonic wheels and by two solenoid valves used to modulate the pressure

for the ABS/ASR functions.

Operation logic

The purpose of the electronic control unit is to decelerate the vehicle as quick as possible while ensuring vehicle stability and

avoiding the wheels’ tendency to get stuck.

To achieve both of the above goals, the electronic control unit will, during the braking action, be informed of:

- the braking intensity requested by the driver, through the rear axle pressure sensor;

- the deceleration response due to the pressure made available through the speed sensor signals.

Continuous monitoring and processing of this information, relative to the set goal, will determine proper actuation of the rear

axle modulating valves and the resulting optimization of the braking action.

Braking pressure

Braking REAR AXLE

action Request for braking intensity

Braking pressure Wheel speed

AXLE

CENTER

OBJECTIVE

Skidding = 0

Electronic control module

Figure 19

X1

X2

107767

Version 6S/6M

Print 603.93.476 Base — September 2005

70 ELECTRONIC SYSTEMS ARWAY

The electronic control module consists of two microprocessors that continuously exchange information with each other. When

either of them undergoes a change, an initial crosscheck reaction takes place; afterwards, failure to reactivate will lock the system

by reducing or preventing its operation.

The function of the module is to control the braking system, determining the deceleration values depending on the parameters

measured by the various system components.

It communicates with the vehicle’s electronic systems through the CAN line, and is connected to the vehicle wiring by means

of two polarized connectors.

When the key is turned to the “RUNNING” position, a microprocessor self-test is carried out; moreover, all the system

components are checked, in order to detect possible interruptions or short-circuits, and a solenoid valve actuation test is also

carried out.

Sensors

The function of sensors, assisted by the phonic wheels, is to provide the electronic control module with the information on the

speed of every single wheel.

ABS modulating solenoid valves

The ABS pressure modulating solenoid valves, which are capable of performing eight full air inlet/exhaust cycles per second, make

it possible to avoid wheel locking, with the additional advantages of increasing road grip, improving the braking action, avoid vehicle

skid on road surfaces with poor grip or when cornering, and also reducing the braking distance.

When the ABS system comes into action, the RETARDER operation is temporarily interrupted.

ASR solenoid valve

The ASR solenoid valve, assisted by the ABS modulating solenoid valves depending on the vehicle speed/wheel turn ratio, is used

to reduce the rotation speed of the driving wheel slipping during the acceleration phase. Moreover, it prevents, by balancing the

deflecting torque for the wheel losing its grip with the road surface, the vehicle from slipping and skidding off when cornering

on roads with poor grip conditions. It is also equipped with a warning light that informs the driver that the ASR system has come

into operation.

ABS warning light

The ABS warning light informs the driver that a fault is found in the ABS system. It comes on when the key is turned to

“RUNNING” and goes out when the vehicle speed exceeds 7 k.p.. to signal correct operation of the system. This warning light

remains ON if a fault is found in the system.

ASR warning light

The ASR warning light only comes on when the respective function is actuated.

Base — September 2005 Print 603.93.476

ARWAY ELECTRONIC SYSTEMS 71

Connector X1 pin-out

Figure 20

107951

Pin Cable colour code Function

1 9921 To the front left solenoid valve pin 3

2 9803 To the front left solenoid valve pin 1

3 0122 To the front left solenoid valve pin 2

4 9930 To the front left solenoid valve pin 3

5 5570 Front right sensor

6 0835 To the front right solenoid valve pin 2

7 9928 To the front right solenoid valve pin 1

8 5823 Front right sensor

9 0118 To the rear right solenoid valve pin 2

10 9931 To the rear right solenoid valve pin 3

11 5820 Front left sensor

12 0834 To the rear left solenoid valve pin 2

13 9929 To the rear left solenoid valve pin 1

14 5821 Front left sensor

15 5572 Rear left sensor

16 9920 To the rear left solenoid valve pin 3

17 9918 To the rear left solenoid valve pin 1

18 5822 Rear left sensor

Print 603.93.476 Base — September 2005

72 ELECTRONIC SYSTEMS ARWAY

Connector X2 pin-out

Figure 21

107951

Pin Cable colour code Function

1 0000 Ground

2 — Spare

3 8847 Power supply positive direct to the battery

4 9961 ASR solenoid valve (78053)

5 9962 ASR solenoid valve (78053)

6 — Spare

7 CAN L VDB

8 CAN H VDB

9 — Spare

10 5573 Rear right sensor

11 5819 Rear right sensor

12 — Negative direct to the battery

13 2299 Line “K” (diagnosis)

14 1199 Line “L” (diagnosis)

15 — Spare

16 7619 Power supply positive direct to the battery

Base — September 2005 Print 603.93.476

ARWAY CIRCUIT CARDS 73

Circuit cards

Page

Print 603.93.476 Base — September 2005

74 CIRCUIT CARDS ARWAY

Base — September 2005 Print 603.93.476

ARWAY CIRCUIT CARDS 75

108112

Print 603.93.476 Base — September 2005

76 CIRCUIT CARDS ARWAY

Figure 22

107341

Base — September 2005 Print 603.93.476

ARWAY CIRCUIT CARDS 77

Legend

F10 Fuse (25 A)

F11 Fuse (16 A)

F57 Fuse (25 A)

F56 Fuse (5 A)

F77 Fuse (16 A)

FUS 100A Fuse (100 A)

20000 Starting battery

25804 Remote-control switch for internal light switch-on with safety control ON (K17)

25899 Remote-control switch for load deactivation with battery disconnecting switch open (K18)

25900 Main current remote-control switch

52029 Central emergency control switch

52600 Main current switch

72022 2-pole coupling for engine starting from the outside

X1 Supply connector

1. Rear lights

2. Emergency lights

3. VBC

4. Injection control unit

5. Webasto unit

6. ECM

7. Door lights

8. Diagnosis

9. Radio

10. Clock

11. Front doors

12. Central doors

13. Electronic dashboard with microprocessor for instrument and warning light display

14. Fridge

15. Closing

16. Prearrangement

17. Control 2000

18. Alternator 1

19. ABS

20. Alternator 2

21. IOU