Professional Documents

Culture Documents

PGX2 Ing

Uploaded by

piabOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PGX2 Ing

Uploaded by

piabCopyright:

Available Formats

PG Speed Control

PG-X2 Option Card

Part Number: P/N CDR001015

Applicability. F7 and GPD 515/G5 drives.

Introduction. The PG Speed Control Option Card PG-X2 (Figure 1) is mounted on the drive’s Control Board and performs

speed feedback using the pulse generator (PG) on the motor to correct speed fluctuation caused by motor slip. Motor rotation

direction is detected by phase A and phase B PG pulse inputs. The card can be used for flux vector control or V/Hz with PG

feedback control.

Receiving. All equipment is tested against defect at the factory. Report any damages or shortages evident when the

equipment is received to the commercial carrier who transported the equipment.

Warning: Hazardous voltage can cause severe injury or death. Lock all power sources feeding Drive in “OFF” position.

Caution: This option card uses CMOS IC chips. Use proper electrostatic discharge (ESD) protective procedures when

handling the card to prevent I.C. damage or erratic drive operation.

Important:

a) If other option cards are to be installed at the Option C or Option D positions (See Figure 2), their installation and

wiring should be completed before installation of this option.

b) Before installing this option, a technically qualified individual, who is familiar with this type of equipment and the

hazards involved, should read this entire installation guide.

Mounting Hole

Connector, Rear

Side of Board to

Control Bd., 4CN

Terminal

Block TA2

Terminal Variable Resistor,

Block TA1 Adjusts

+12V PG Power

Variable Resistor,

Adjusts

+5V PG Power

Terminal TA3

Connect Shield

Here

Ground Lead Wire- 2 Mounting Holes

Connects to Grounding

Terminal on Control Board

Figure 1. PG Speed Control Card PG-X2 Figure 2. PG-X2 Option Card installation

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60.PGX2 Page 1 of 5

Date: 4/03/03

PG Speed Control

PG-X2 Option Card

Installation and Wiring.

1. Remove contents from package. Verify that a mounting spacer

(P/N 5RNT41028-9) is included with the card. See Figure 3.

2. Disconnect all electrical power to drive.

3. Remove the drive front cover.

4. Check that the “CHARGE” indicator lamp inside drive is off.

5. Use a voltmeter to verify voltage at incoming power terminals

(L1, L2, L3) has been disconnected.

6. Insert the spacer into the mounting hole in the base of the drive,

just above the top edge of the control board. See Figure 2. Figure 3. Mounting Spacer

Important: G5 models GPD515C-A003 to –A011 and GPD515C-B001 to –B004 models have two closely spaced

mounting holes. Insert the spacer into the hole closest to the control board’s connector 7CN. If inserted in the wrong hole,

the spacer WILL NOT properly align with the option card’s mounting hole.

7. Circuit Board Installation. See Figure 2.

a) Position the bottom edge of the option card into the mounting bracket on the control board’s terminal block. Align

two mounting holes in the card with pins on the bracket.

b) Then angle the top edge of the card into place, carefully aligning connector 4CN on the back of the card with

connector 4CN on the control board. Gently press the card into place until 4CN and the spacer click into place.

c) Connect the green ground wire to the grounding terminal on the main control board.

8. Wiring. Refer to Figure 4 and Tables 1 & 2.

Make wire connections between the PG-X2 card and encoder as well as any external monitoring circuits. Observe the

following:

a) Keep PG-X2 (i.e. control circuit) wiring separate from main circuit input/output wiring. A separate metallic

grounded conduit with ONLY the PG wiring running through it is preferred.

b) To prevent erroneous operation caused by noise interference, use shielded cable for control signal wiring, and

limit the distance to 50m (165 feet) or less.

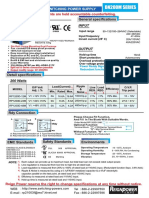

Table 1. Terminal Functions of PG-X2

Terminal Terminal

Functions

Block Symbol Pin Number

+12V Power supply for Pulse Generator (PG).

1

Important: Use either +12V or +5V, but never both at same time.

2 0V +12V, 200mA max.

3 +5V +5V, 200mA Max

4 +

A Pulse

TA1 5 -

6 +

B Pulse PG Signal Inputs

7 -

RS-422 Level Input

8 +

Z Pulse*

9 -

10 0V Common terminal

1 +

A Pulse

2 -

3 +

B Pulse Pulse Monitor Output

TA2 4 - RS-422 Level Output

5 +

Z Pulse*

6 -

7 SG Common terminal

TA3 Shielded Sheath Connection terminal

* Not required for normal operation

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60.PGX2 Page 2 of 5

Date: 4/03/03

PG Speed Control

PG-X2 Option Card

Notes:

(1) Power Supply for PG (from PG-X2)

TA1 1-2: +12V, 200mA max.

Ta1 3-2: +5V, 200mA max

Do Not Use Both Supplies at Same Time.

(2) H20 Dynapar Encoder Connections

Figure 4. Typical PG-X2 Interconnection Diagram

c) Recommended cable is twisted pair, 22AWG, with overall shield, such as Belden 9504.

Refer to “Electrical Installation” in the drive technical manual for further information on use of shielded cable.

The shielded sheath connection points on the PG-X2 card are terminal TA3.

d) Strip back insulation for a distance of 0.22 in. on wire leads connected to the PG-X2 terminals.

Table 2. Terminal and Wire Specification

Terminal Clamping Torque Wire Range

Terminal Symbol 2

Screw Lb-in (N-m) AWG (mm )

26 to 16

TA1, TA2 M2 1.8 to 2.2

(Stranded: 0.14 to 1)

(0.22 to 0.25)

Solid: 0.14 to 1.5)

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60.PGX2 Page 3 of 5

Date: 4/03/03

PG Speed Control

PG-X2 Option Card

9. Adjustment. The+12V and +5V outputs of the PG- Signal type / level requirements. The type of signal that

X2 card are factory adjusted and should not need the PG-X2 card requires from the pulse generator is of the

correction at time of installation. “line driver” and “quadrature” types. As shown in Figure 6,

line driver signals include both a primary signal (Signal A+)

10. Reinstall and secure Drive cover. and it’s compliment (Signal A-). The compliment is a

signal that is the inverse of the primary signal. This

11. Programming. Table 3 lists all drive parameters scheme is used to improve the noise immunity of the

related to PG speed control operation. Ensure that all speed feedback circuit.

of these parameters are programmed to meet the

requirements of the application. NOTE: All signals shown were taken in relation to power

supply common, Pin 2 of the PG-W2 card.

12. Refer to Section 2 in the drive’s technical manual for

testing and start-up information. A qudrature signal is one that lags the primary signal by

90 electrical degrees (1/2 of a pulse). The purpose of this

13. Place this instruction sheet with the drive technical is so that the drive can detect the direction of the motor

manual. shaft. As shown in Figure 6, for “forward” rotation

(C.C.W.), signal A+ will lead signal B+ by 90o. The

14. Application. quadrature signal has it’s own compliment.

If the PG’s power requirement is 200mA or greater,

provide a separate power supply source as shown in If one of the four signals is missing, the drive cannot

Figure 5. If the momentary power loss ride thru function of accurately detect pulse generator speed or direction.

the drive is to be used, include a backup capacitor in the

PG power wiring or take other necessary precautions.

PG Power Supply

AC

0V 12V

PG ENCODER

PG-X2 Card TA1

1

IP12 12V

2 P

IG 0V

3 *

IP5

+

4

A (+)

5 P

A (–)

6 (2)

B (+)

7 P

B (–)

8

Z (+)

9

Z (–)

10

IG

TA3

Figure 6. Pulse Generator Signals – Forward Direction

* Backup capacitor, for momentary

power loss recovery function

Figure 5. Using Separate PG Power Supply

The maximum frequency of PG output pulses that can be

detected by the PG-X2 card is 300 kHz. Find the output

frequency of the pulse generator, fPG (Hz), according to

the following formula:

fPG (Hz) = Motor rotation speed (RPM) at max. frequency output X Encoder PPR (Pulses/Rev) X 1.2

60

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60.PGX2 Page 4 of 5

Date: 4/03/03

PG Speed Control

PG-X2 Option Card

Table 3. F7 and GPD 515/G5 PG Speed Control Parameter List

Control Method

(3)

Digital Change

Para

Operator Digital Operator Setting Factory During

Flux Vector

V/f Control

Open loop

meter Parameter Name Data Selection

V/f w/PG

Function Display Range Setting Operation

Vector

Fdbk

No.

Group (2)

PG Pulse/Rev F1-01 PG Constant 0 to 60000 1024 X X O X O

PG Fdbk Loss Operation at

F1-02 0 to 3 1 X X O X O

Sel PG open Circuit

Operation 0: Ramp to Stop

PG Overspeed

F1-03 selection at 0 to 3 1 X 1: Coast to Stop X O X O

Sel

overspeed 2: Fast-Stop

Operation 3: Alarm Only

PG Deviation Sel F1-04 selection at 0 to 3 3 X X O X O

deviation

0: Fwd=CCW

PG Rotation Sel F1-05 PG rotation 0,1 0 X X O X O

1: Fwd=CW

Integral value

0: Disabled

PG Ramp PI/I Sel F1-07 during accel/decel 0,1 0 X X O X X

1: Enable

enable/disable

PG Overspeed PG overspeed

F1-08 0 to 120% 115% X X O X O

PG Level detection level

Option PG Overspeeed PG overspeed

Setup F1-09 0 to 2.0s 1.0s X X O X O

Time detection delay

Excessive speed

PG Deviation

F1-10 deviation detection 0 to 50% 10% X X O X O

Level

level

Excessive speed

PG Deviation

F1-11 deviation detection 0 to 10s 0.5s X X O X O

Time

delay time

PG# Gear Teeth

F1-12 No. of gear teeth 1 0 to 1000 0 X X O X X

1

PG# Gear Teeth

F1-13 No. of gear teeth 2 0 to 1000 0 X X O X X

2

PGO detection

PGO Detect Time F1-14 0 to 10s 2sec X X O X O

time

Speed Detection

Speed detection 0: No moving AVG

Filter Selection F1-15 0, 1 1 X X O X O

filter selection 1: 2 moving AVG

(F7 only)

ASR proportional

ASR P Gain 1 C5-01 0 to 300.00 0.00 O X O X O

gain 1

ASR integral

ASR I Time 1 C5-02 0 to 10.000s 0.00s O X O X O

time 1

ASR proportional

ASR P Time 2 C5-03 0 to 300.00 0.00 O X O X O

gain 2

ASR ASR integral

ASR I Time 2 C5-04 0 to 10.000s 0.00s O X O X O

Tuning time 2

(1) ASR Limit C5-05 ASR Limit 0.0 to 20% 0.0% X X O X X

ASR primary 0.000 to

ASR Delay Time C5-06 0.000s X X X X O

delay time 0.500s

ASR Gain SW ASR switching 0.0 to

C5-07 0.0Hz X X X X O

Freq freq 400.00Hz

ASR Integral

C5-08 ASR Integral limit 0 to 400% 400% X X X X O

Limit (F7 Only)

(1) ASR – Automatic Speed Regulator Yaskawa Electric America, Inc. – www.drives.com

(2) O = Enable, X = Disable IG.AFD.60.PGX2 Page 5 of 5

(3) O = Setting enable, X = Setting disable Date: 4/03/03

You might also like

- Manual Ingles Dual Encoder PG W2Document6 pagesManual Ingles Dual Encoder PG W2Raul Quis ColNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- INR-SI47-1283b-E - PG Interface CardDocument6 pagesINR-SI47-1283b-E - PG Interface CardSaptyawan KasidjoNo ratings yet

- Manual Tuxon C Uo3rDocument64 pagesManual Tuxon C Uo3relkin carrilloNo ratings yet

- GL840 Um 852 PDFDocument24 pagesGL840 Um 852 PDFAGUS KURNIAWANNo ratings yet

- GS-232B Om Eng Eaa14x105Document24 pagesGS-232B Om Eng Eaa14x105bsaylor123No ratings yet

- Conexiones - BazánDocument3 pagesConexiones - BazánJavier Vidal GonzalesNo ratings yet

- PG Card PG-B3 Invt PDFDocument5 pagesPG Card PG-B3 Invt PDFHiei_zoldyckNo ratings yet

- Manual Inglês AI-14B 3 Entradas 13 Bit+sinal Série-G7Document4 pagesManual Inglês AI-14B 3 Entradas 13 Bit+sinal Série-G7davinmotion051No ratings yet

- Digi-Log Reverb Module (Btdr-3) : A Great Digital Reverb Sound That Easily Replaces A Spring Reverberation UnitDocument3 pagesDigi-Log Reverb Module (Btdr-3) : A Great Digital Reverb Sound That Easily Replaces A Spring Reverberation UnitDmedNo ratings yet

- BTDR 3Document3 pagesBTDR 3FlyinGaitNo ratings yet

- Lcda 608s Digital DC Servo ManualDocument22 pagesLcda 608s Digital DC Servo ManualHoàng NguyễnNo ratings yet

- LTN-REC Converts Resolvers to EncodersDocument1 pageLTN-REC Converts Resolvers to Encodersmohammad shiftehNo ratings yet

- GM300 Acc ConnDocument3 pagesGM300 Acc ConnMichal HorkýNo ratings yet

- Audio Switching Power Supply DatasheetDocument11 pagesAudio Switching Power Supply DatasheetXuân TrườngNo ratings yet

- Manual Inglês AI-040 3 Entradas Isoladas 14-Bit Série-G7Document4 pagesManual Inglês AI-040 3 Entradas Isoladas 14-Bit Série-G7davinmotion051No ratings yet

- Maintenance Manual: Vbm/Vfm/Vfs/Vtm/Vps Series Abm/Afm/Afs/Atm/Aps SeriesDocument72 pagesMaintenance Manual: Vbm/Vfm/Vfs/Vtm/Vps Series Abm/Afm/Afs/Atm/Aps SeriesTian TianNo ratings yet

- HBS86H Hybrid Stepper Servo Drive ManualDocument22 pagesHBS86H Hybrid Stepper Servo Drive ManualPhúc Phan TiếnNo ratings yet

- Aeg-Dvd4535 Service ManualDocument25 pagesAeg-Dvd4535 Service ManualSerp19720% (1)

- GS232ADocument24 pagesGS232AScott GillisNo ratings yet

- Technical Training Z-75, Relay CardDocument26 pagesTechnical Training Z-75, Relay CardRomas Varna100% (1)

- MPC6535 User Manual Improves Major Performance Over MPC6515Document8 pagesMPC6535 User Manual Improves Major Performance Over MPC6515Vijay BhansaliNo ratings yet

- SMPS630-G 17062020Document14 pagesSMPS630-G 17062020MicrosiM diysmpsNo ratings yet

- RT9018ADocument12 pagesRT9018Abusamawan wayanNo ratings yet

- TC78H660FTG Datasheet en 20200714Document26 pagesTC78H660FTG Datasheet en 20200714ehsanNo ratings yet

- PM174 Powermeter Quick Start GuideDocument11 pagesPM174 Powermeter Quick Start Guideusamakhan205No ratings yet

- PV PanelDocument17 pagesPV PanelMuhammad RiazNo ratings yet

- PCB DiagramDocument6 pagesPCB Diagramfreitastsp9166No ratings yet

- Ads-R v7 enDocument2 pagesAds-R v7 enAE Dhanapal AthiyappanNo ratings yet

- TLE6225GPDocument10 pagesTLE6225GPNoelNo ratings yet

- Huawei PI OverviewDocument15 pagesHuawei PI OverviewHdz EdilNo ratings yet

- MCAC706 CatalogDocument23 pagesMCAC706 CatalogAdi FirmansyahNo ratings yet

- Grenergy-GR8313JG C436812Document10 pagesGrenergy-GR8313JG C436812Ahcene MenkouchaNo ratings yet

- PCB DiagramDocument4 pagesPCB Diagramgilberto gutierrezNo ratings yet

- Product Specification: Model: XY - VH2E556 - V2.0Document8 pagesProduct Specification: Model: XY - VH2E556 - V2.0覃小米No ratings yet

- GPIO Option: 92-2427-01 Rev.CDocument14 pagesGPIO Option: 92-2427-01 Rev.CAchraf HouilaNo ratings yet

- Simple Electric Control ManualDocument14 pagesSimple Electric Control ManualHoratiusNo ratings yet

- Smps630-So 2412020Document14 pagesSmps630-So 2412020MicrosiM diysmpsNo ratings yet

- Командный Модуль Vt Swmak 1Document8 pagesКомандный Модуль Vt Swmak 1Александр БулдыгинNo ratings yet

- 1.5Mhz Synchronous Step-Down DC-DC Converter Ap3410Document11 pages1.5Mhz Synchronous Step-Down DC-DC Converter Ap3410Renato HernandezNo ratings yet

- Operation Manual DCS3T-28 - V2Document23 pagesOperation Manual DCS3T-28 - V2miguel cornelioNo ratings yet

- SPC-1000 Manual: Advanced HYBRID ControllerDocument9 pagesSPC-1000 Manual: Advanced HYBRID ControllerEyosyas NathanNo ratings yet

- Tde 1707Document17 pagesTde 1707Fábio MuckenfuhsNo ratings yet

- ID022 ID023 Converter User Manual r1Document3 pagesID022 ID023 Converter User Manual r1Guillermo RiveraNo ratings yet

- Dephy DS ActPack41Document7 pagesDephy DS ActPack41sanchitNo ratings yet

- Puassembly Instructions & General Information: 23006 - 611 User ManualDocument3 pagesPuassembly Instructions & General Information: 23006 - 611 User Manualfreddy brigstoneNo ratings yet

- Sensoriamento Top TopDocument5 pagesSensoriamento Top TopMaykon SantosNo ratings yet

- WB7660QB Battery Monitoring VoltageDocument12 pagesWB7660QB Battery Monitoring VoltageKang UsmanNo ratings yet

- Rak3172-Sip Wisduo Lpwan Sip Datasheet: DescriptionDocument9 pagesRak3172-Sip Wisduo Lpwan Sip Datasheet: DescriptionoliviercorianNo ratings yet

- MUSES8920: High Quality Audio J-FET Input Dual Operational AmplifierDocument9 pagesMUSES8920: High Quality Audio J-FET Input Dual Operational AmplifierНиколайNo ratings yet

- Evaluates: DS28E01/DS28CN01/DS2460 Secure Authentication Starter KitDocument15 pagesEvaluates: DS28E01/DS28CN01/DS2460 Secure Authentication Starter KitWilman LealNo ratings yet

- LUX-H7-User Manual v1Document5 pagesLUX-H7-User Manual v1Shashank SharmaNo ratings yet

- 20BB710-10919-00 r1 BB-USR604 2320qsgDocument2 pages20BB710-10919-00 r1 BB-USR604 2320qsgMalik AbdullahNo ratings yet

- General Purpose Input/Output (GPIO)Document6 pagesGeneral Purpose Input/Output (GPIO)sweetsureshNo ratings yet

- Parameters For IPG-83H40PL-BDocument5 pagesParameters For IPG-83H40PL-BJack DanielsNo ratings yet

- A6/A7/A6C User Manual: GSM/GPRS quad-band+GPS+AGPSDocument21 pagesA6/A7/A6C User Manual: GSM/GPRS quad-band+GPS+AGPSRosmanNo ratings yet

- SU0524 - Datasheet: 4-Channel Low Capacitance Esd Protection Diodes ArrayDocument9 pagesSU0524 - Datasheet: 4-Channel Low Capacitance Esd Protection Diodes Arraytemp001100% (1)

- SU0524 - Datasheet: 4-Channel Low Capacitance Esd Protection Diodes ArrayDocument10 pagesSU0524 - Datasheet: 4-Channel Low Capacitance Esd Protection Diodes ArrayPavel Martínez GonzálezNo ratings yet

- ) 'Ulyh3Dudphwhu$Ffhvv 7Hfkqlfdo0Dqxdo: 0RGHOV&,05) 8 'Rfxphqw1Xpehu70)Document96 pages) 'Ulyh3Dudphwhu$Ffhvv 7Hfkqlfdo0Dqxdo: 0RGHOV&,05) 8 'Rfxphqw1Xpehu70)Andrea VarasNo ratings yet

- GPD 506/P5 Technical Manual: Models: GPD-506V-and CIMR-P5M Document Number: TM4506Document168 pagesGPD 506/P5 Technical Manual: Models: GPD-506V-and CIMR-P5M Document Number: TM4506Juan David MontoyaNo ratings yet

- dn200m (Fuente)Document3 pagesdn200m (Fuente)piabNo ratings yet

- Supplement 4 TS Security Fire Protection ECSPP ECBSDocument30 pagesSupplement 4 TS Security Fire Protection ECSPP ECBSJelena PopovicNo ratings yet

- PSN DC en Ke 07 0260h (Puertas)Document1 pagePSN DC en Ke 07 0260h (Puertas)piabNo ratings yet

- Cleaning Instructions For Filter - TextileDocument2 pagesCleaning Instructions For Filter - TextilepiabNo ratings yet

- TRS 957 (2010) - Annex 3 - WHO GMP For Pharmaceutical Products Containing Hazardous SubstancesDocument17 pagesTRS 957 (2010) - Annex 3 - WHO GMP For Pharmaceutical Products Containing Hazardous SubstancesQuang Hiếu NgôNo ratings yet

- Supplement 11 TS Reefer Qual Final ECSPP ECBSDocument20 pagesSupplement 11 TS Reefer Qual Final ECSPP ECBSMahmoudNo ratings yet

- Rev00 en Brochure Feed PointsDocument12 pagesRev00 en Brochure Feed PointspiabNo ratings yet

- DisclaimerDocument1 pageDisclaimerpiabNo ratings yet

- piPREMIUM Upgrade Kit C21-400Document3 pagespiPREMIUM Upgrade Kit C21-400piabNo ratings yet

- GCDAI Curriculum Sept 2019Document20 pagesGCDAI Curriculum Sept 2019vinodkumarNo ratings yet

- Mayank Gupta: Work ExperienceDocument1 pageMayank Gupta: Work ExperienceSaloni MadhokNo ratings yet

- Level 3 Repair: 8-1. Components LayoutDocument26 pagesLevel 3 Repair: 8-1. Components LayoutKelvin W MezamNo ratings yet

- Virtual Teams: Opportunities and Challenges For E-Leaders: SciencedirectDocument11 pagesVirtual Teams: Opportunities and Challenges For E-Leaders: Sciencedirectمعن الفاعوريNo ratings yet

- IBM MDM Installation GuideDocument214 pagesIBM MDM Installation GuideAdam HowardNo ratings yet

- Pill Camera: A Miniature Camera That Travels Through Your Digestive SystemDocument19 pagesPill Camera: A Miniature Camera That Travels Through Your Digestive SystemBHAGYA LAKSHMINo ratings yet

- Free PDF PrinterDocument18 pagesFree PDF Printermsmith719No ratings yet

- Fluent12 Lecture11 PostDocument49 pagesFluent12 Lecture11 PostAlex__182No ratings yet

- Electronic Remote Control: Operation ManualDocument30 pagesElectronic Remote Control: Operation ManualSurendran PattineyapanNo ratings yet

- Push - Fold - Call - CL TEAMDocument561 pagesPush - Fold - Call - CL TEAMJoão Alisson MendesNo ratings yet

- ANOVA For Linear Model FenolikDocument10 pagesANOVA For Linear Model FenolikAnonymous 4ESTZLGrNo ratings yet

- TDA1519BDocument12 pagesTDA1519BahmedNo ratings yet

- How To Create Id - Me Account (@hackslord)Document6 pagesHow To Create Id - Me Account (@hackslord)Kabano CoNo ratings yet

- 83 FDocument134 pages83 FvinothetisNo ratings yet

- Humacount 5lDocument6 pagesHumacount 5lapi-30960494No ratings yet

- 25-YEAR LINEAR PERFORMANCE GUARANTEE AND 5-YEAR EXTENDED WARRANTYDocument2 pages25-YEAR LINEAR PERFORMANCE GUARANTEE AND 5-YEAR EXTENDED WARRANTYJoe O'ConnorNo ratings yet

- Software Project Management: COCOMO Model Cost EstimationDocument24 pagesSoftware Project Management: COCOMO Model Cost Estimationf180391 Ashar AmjadNo ratings yet

- AT&T Radiated Performance Requirements 20170504054000896Document2 pagesAT&T Radiated Performance Requirements 20170504054000896Vasikaran PrabaharanNo ratings yet

- Consultancy For Design Development and Implementation of SMSUSSD GatewayDocument6 pagesConsultancy For Design Development and Implementation of SMSUSSD GatewaylvlnprajuNo ratings yet

- Manual FusorDocument10 pagesManual FusorrichiuniNo ratings yet

- LEA-5H, LEA-5S, LEA-5A U-Blox 5 GPS and GALILEO Modules: Data SheetDocument15 pagesLEA-5H, LEA-5S, LEA-5A U-Blox 5 GPS and GALILEO Modules: Data Sheet1553No ratings yet

- Microcontroller Based Automatic Power Factor Correction in MinesDocument52 pagesMicrocontroller Based Automatic Power Factor Correction in MinesDdumbaNo ratings yet

- CT2 Coa KCS-302Document3 pagesCT2 Coa KCS-302nandini sharmaNo ratings yet

- P105WDocument7 pagesP105WJake DutkiewiczNo ratings yet

- Coding & Decoding - QuestionsDocument4 pagesCoding & Decoding - QuestionsmoulieswaranNo ratings yet

- Cyber CafeDocument1 pageCyber Cafeindia4gNo ratings yet

- Introduction To CAD CAM MasterCAMDocument28 pagesIntroduction To CAD CAM MasterCAMMuhammad TausiqueNo ratings yet

- AI ConceptDocument351 pagesAI ConceptRadha Rami100% (9)

- Role of Team LeaderDocument48 pagesRole of Team LeaderAkshay Malhotra100% (2)

- Vertex S4HANA Integration Via SAP CPI Configuration GuideDocument14 pagesVertex S4HANA Integration Via SAP CPI Configuration GuidesiddharthadeepakNo ratings yet