Professional Documents

Culture Documents

Up 3672 BF

Uploaded by

Mena TharwatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Up 3672 BF

Uploaded by

Mena TharwatCopyright:

Available Formats

Updated on Jan.

2022 Page 1 of 1

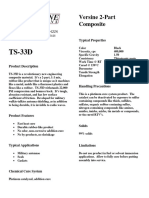

TECHNICAL DATA SHEET

RARESTER UP 3672 BF

Pre-accelerated unsaturated polyester resin for the manufacture of Body putty (filler) compounds

FEATURES APPLICATIONS

• Good sandability • Standard body putty (filler) Compounds

• Good flexibility • Light weight body putty (filler) Compounds

• Very Good curing properties • Designed for the production of knifing putty to be applied

• Amine accelerated unsaturated polyester on metal, wood, marble and concrete substrates

• Sanding machine is recommended

CHARACTERISTICS

• Solid Content 67± 2%

• Viscosity by Gardner @25⁰C N-Q

• Viscosity by cp @25⁰C 350- 440 Cp

• Type of solvent Styrene

• Acid Value mg KOH/gm as such 15±5

• Color Gardner 6 max

• Gel time 8-12 min

• Cure time 13-16 min

• Peak exotherm temp. 130±10⁰C

CURE CHARACTERISTICS

Are those obtained using 2% Benzoyl Peroxide 50% in 100 gram of resin at 25⁰C

When the putty has hardened (this will take 20-25 minutes), sand first with 120-grit dry sandpaper. To avoid scratching the

bodywork, follow this up with a finer paper such as a 180-grit paper. Then finish off with 320-grit sandpaper.

Sanding machine is recommended

SOLUBILITY DATA Soluble Limited Insoluble

Stryene + - -

Ketones + - -

Esters + - -

Aromatic solvents - + -

Aliphatic solvents - - +

DELIVERY FORM DETAILS

It's available at 67% in styrene

Storage Conditions

This product should be stored in its sealed containers out of direct sunlight at a temperature not exceeding 25 °C

SHELF Life

Under the above mentioned storage conditions the satability of this product will be 6 months from the production date

DISCLAIMER

This information contained in the data sheet is to the best of our knowledge correct and up to date. Under well-defined conditions. Its accuracy or suitability under the actual conditions of

any independent use is not guaranteed and must be determined by the user. All advice given about this product is given in good faith. Since as we have no control over conditions of

substrate, manufacturer and seller cannot accept any liability in connection with the use of the product relative to coverage, performance, injury, or damage, unless we specify in writing to

do so. The information in this data sheet is subject to change without prior notice and it is the user responsibility to ensure it is current. For further information and advice please contact RAR

RESIN Technical Service Department.

11th Floor, 1 Lake Plaza, Jumeirah Lake Towers, P.O. Box: 47381, Dubai UAE | Tel: +971 4 4356517, +971 4 4356516 | Fax: +971 4 4356518, Email: info@rarresin.com

www.rarresin.com

You might also like

- 5 - Body Filler - Polyester Putty - 2019 EditionDocument2 pages5 - Body Filler - Polyester Putty - 2019 Editiondamax rec100% (1)

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Albafluid CD Lubricant: Technical Data SheetDocument5 pagesAlbafluid CD Lubricant: Technical Data SheetsaskoNo ratings yet

- Product Data Sheet of Resin DM 470-300 PDFDocument4 pagesProduct Data Sheet of Resin DM 470-300 PDFPrashant ShindeNo ratings yet

- Up 3644 BFDocument1 pageUp 3644 BFMena TharwatNo ratings yet

- Up 1705 WFDocument1 pageUp 1705 WFMena TharwatNo ratings yet

- Up 1755 WFDocument1 pageUp 1755 WFMena TharwatNo ratings yet

- Ap 26033 XLDocument2 pagesAp 26033 XLMena TharwatNo ratings yet

- Ap 47048 XlbaDocument2 pagesAp 47048 XlbaMena TharwatNo ratings yet

- Semkim SMK 4444 TDSDocument1 pageSemkim SMK 4444 TDSDuman AbbasovNo ratings yet

- Ap 46525 XlbaDocument2 pagesAp 46525 XlbaMena TharwatNo ratings yet

- Solvoya® CP6202-XSM: Technical DatasheetDocument1 pageSolvoya® CP6202-XSM: Technical DatasheetI Love MusicNo ratings yet

- Technical Data Sheet: SNDA-EAGLE (COCX32-97/60) 60%Document1 pageTechnical Data Sheet: SNDA-EAGLE (COCX32-97/60) 60%Fadi MagdyNo ratings yet

- Technical Data Sheet: SNDA-EAGLE (COCX35-97/60) 60%Document1 pageTechnical Data Sheet: SNDA-EAGLE (COCX35-97/60) 60%Fadi MagdyNo ratings yet

- Solvoya® CP7046-XSM: Technical DatasheetDocument1 pageSolvoya® CP7046-XSM: Technical DatasheetI Love MusicNo ratings yet

- CASSIDA GREASE EPS Food Grade Synthetic GreaseDocument2 pagesCASSIDA GREASE EPS Food Grade Synthetic GreaseChiranjeevi VijayaraghavanNo ratings yet

- Up 5604 GPDocument1 pageUp 5604 GPMena TharwatNo ratings yet

- Solvoya® CP7109-XAC: Technical DatasheetDocument1 pageSolvoya® CP7109-XAC: Technical DatasheetI Love MusicNo ratings yet

- RPCDocument6 pagesRPCamnulNo ratings yet

- Technical Data Sheet: LA-EAGLE (SW61-9/55) 70%Document1 pageTechnical Data Sheet: LA-EAGLE (SW61-9/55) 70%Fadi MagdyNo ratings yet

- Sripath PGXpand Brochure A4Document2 pagesSripath PGXpand Brochure A4Muhammad Farhan Bin SukorNo ratings yet

- Spray Nine Grez-Off Heavy-Duty Degreaser TDS 1 GallonDocument1 pageSpray Nine Grez-Off Heavy-Duty Degreaser TDS 1 GallonAsadNo ratings yet

- Solvoya l3865-Wk TdsDocument1 pageSolvoya l3865-Wk TdsOsama GabrNo ratings yet

- Foodlube Multipaste - GBDocument2 pagesFoodlube Multipaste - GBtKc1234No ratings yet

- Sun Kissed Coral Formula CardDocument1 pageSun Kissed Coral Formula CardEricaDalcinNo ratings yet

- Solvoya® D6518-X: Technical DatasheetDocument1 pageSolvoya® D6518-X: Technical DatasheetOsama GabrNo ratings yet

- Permatex Industrial Strength Cleaner & Degreaser TDS 1 GallonDocument1 pagePermatex Industrial Strength Cleaner & Degreaser TDS 1 GallonAsadNo ratings yet

- Technical Data Sheet: SDA-EAGLE (SX35-18/50) 60%Document1 pageTechnical Data Sheet: SDA-EAGLE (SX35-18/50) 60%Fadi Magdy0% (1)

- Weber .Ad 225 MB: SBR Latex-Based Bonding AgentDocument2 pagesWeber .Ad 225 MB: SBR Latex-Based Bonding AgentWaleed MedhatNo ratings yet

- Solvoya® CP6909-WVT: Technical DatasheetDocument1 pageSolvoya® CP6909-WVT: Technical DatasheetI Love MusicNo ratings yet

- En Anderol 5460 Xep 20120328Document1 pageEn Anderol 5460 Xep 20120328Shaara NeyNo ratings yet

- Technical Data Sheet: LA-EAGLE (SW60-36/55) 70%Document1 pageTechnical Data Sheet: LA-EAGLE (SW60-36/55) 70%Fadi MagdyNo ratings yet

- Synolac 162 W 70: Product Application DetailsDocument2 pagesSynolac 162 W 70: Product Application DetailsmonrmNo ratings yet

- TDS Weberad 220 SBRDocument2 pagesTDS Weberad 220 SBRMahmoudFarhatNo ratings yet

- Resins: Singh Plasticisers & Resins (I) Pvt. LTDDocument26 pagesResins: Singh Plasticisers & Resins (I) Pvt. LTDmadumaxNo ratings yet

- Bentone 128 OilDocument3 pagesBentone 128 OilJorge Vásquez CarreñoNo ratings yet

- TDS Hyd 9810-35 PDFDocument1 pageTDS Hyd 9810-35 PDFForeverNo ratings yet

- Ra22 ArmourZinc 120 PrimerDocument2 pagesRa22 ArmourZinc 120 PrimerDenis MNo ratings yet

- Araldit-STANDARD Datasheet PDFDocument3 pagesAraldit-STANDARD Datasheet PDFsiva shanmugamNo ratings yet

- Joncryl 2560Document4 pagesJoncryl 2560ichsan hakimNo ratings yet

- Araldite Standard PDFDocument3 pagesAraldite Standard PDFGRAVYMATRIX VENTURESNo ratings yet

- Alfakyd O27 x60Document1 pageAlfakyd O27 x60Екатерина НечетNo ratings yet

- TDS 1365882 1405419 1461229 US Loctite Super Glue Professional Carded Bottle 20 G 2018 04 06pdfDocument3 pagesTDS 1365882 1405419 1461229 US Loctite Super Glue Professional Carded Bottle 20 G 2018 04 06pdfwand.surveyNo ratings yet

- Wilsonart® 3132 Hot or Cold Press PVA Adhesive Technical DataDocument1 pageWilsonart® 3132 Hot or Cold Press PVA Adhesive Technical Datacoli_23No ratings yet

- Synolac 60 WD 70Document2 pagesSynolac 60 WD 70monrmNo ratings yet

- Abecote 400 HBDocument3 pagesAbecote 400 HBengramir07No ratings yet

- PT NASCO Sustainable Pine ResinDocument1 pagePT NASCO Sustainable Pine ResinAayush TekriwalNo ratings yet

- Bentone 2018Document2 pagesBentone 2018Victor ZhicayNo ratings yet

- TS 33DTDSDocument2 pagesTS 33DTDSAdiel KazadiNo ratings yet

- Solvoya CP5607-WR TDSDocument1 pageSolvoya CP5607-WR TDSI Love MusicNo ratings yet

- Carbothane 134 HS PDSDocument4 pagesCarbothane 134 HS PDSDuongthithuydungNo ratings yet

- Fire Retardant Latex: Product Description Product CharacteristicsDocument3 pagesFire Retardant Latex: Product Description Product CharacteristicsHabiba JamilNo ratings yet

- Benefits:: Characteristics Test Method Unit SpecificationsDocument1 pageBenefits:: Characteristics Test Method Unit SpecificationsNguyen Van TuanNo ratings yet

- Accelerator 960-1 052018Document4 pagesAccelerator 960-1 052018hemapaluri50No ratings yet

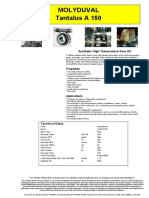

- Tantalus A 150Document1 pageTantalus A 150Selçuk MerterNo ratings yet

- Wearing CompoundDocument2 pagesWearing CompoundJuan GuillermoNo ratings yet

- Admix 225 MB: SBR Latex-Based Bonding AgentDocument2 pagesAdmix 225 MB: SBR Latex-Based Bonding Agentmaga2292No ratings yet

- Hycar 26084: Product DescriptionDocument2 pagesHycar 26084: Product DescriptionChuy DiazNo ratings yet

- The Nail technician’s Career Guide - The blueprint to a successful nail salon businessFrom EverandThe Nail technician’s Career Guide - The blueprint to a successful nail salon businessNo ratings yet