Professional Documents

Culture Documents

Special Steels RE60S: For Structural Products

Uploaded by

Rollpass DesignOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Special Steels RE60S: For Structural Products

Uploaded by

Rollpass DesignCopyright:

Available Formats

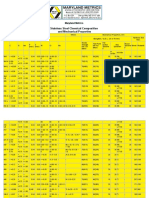

(E335+S) - Nr.(1.

0060) SPECIAL

(E335GC) - Nr. (1.0543) STEELS

STANDARD REFERENCE:

EN 10025-2: 2004 (Hot-rolled products) | EN 10277-2: 2008 (Bright products)

RODACCIAI REFERENCES AND COMPARABLE STANDARDS

EUROPE ITALY GERMANY FRANCE UK USA

EN 10025-2: 2004

(UNI 7070 - 72) (DIN 17100-80) (NF A 35-501-83) (BS 4360 - 90) ASTM A 29

EN 10277-2: 2008

Grade N° Werkstoff N°

(E335+S) (1.0060)

(Fe 590+S) (St 60-2+S) (1.0060) (A 60 - 2 +S) - -

(E335GC) (1.0543)

COMPOSIZIONE CHIMICA (ANALISI DI COLATA) (%)

C Si / max Mn / max P / max S N/ max

0,37÷0,45 0,50 1,40 0,045 0,080÷0,120 0,011

CARATTERISTICHE MECCANICHE LAMINATI

Size mm Rp 0,2 (MPa) min Rm (MPa) A5 (%) min

≤16 335 570÷710 16

>16 ≤40 325 570÷710 16

>40 ≤63 315 570÷710 15

>63 ≤80 305 570÷710 14

>80 ≤100 295 570÷710 14

>100 ≤150 275 550÷710 12

>150 ≤200 265 540÷710 11

>200 ≤230 255 540÷710 11

CARATTERISTICHE MECCANICHE FINITI A FREDDO

Size as Rolled + Turned (+SH) Cold Drawn (+C)

mm Hardness HB Rm (MPa) Rp 0,2 (MPa) min Rm (MPa) A5 (%) min

≥5 ≤10 - - 540 700÷1050 5

>10 ≤16 - - 480 680÷970 6

>16 ≤40 169÷211 570÷710 390 640÷930 7

>40 ≤63 169÷211 570÷710 340 620÷870 8

>63 ≤100 169÷211 570÷710 295 570÷810 8

TEMPERATURE DI LAVORAZIONE CONSIGLIATE

Operation Hot forgings deformation Soft annealing

°C 900÷1150 650÷700

rev. 10/2018

Mark Rodacciai Download APP

SPECIAL STEELS

RE60S

FOR STRUCTURAL PRODUCTS

You might also like

- BS 4360 specification for structural steel plates and productsDocument1 pageBS 4360 specification for structural steel plates and productsHong Rui Chong100% (1)

- BS 3059-2Document11 pagesBS 3059-2abhiNo ratings yet

- Hatz Dieselmotoren ES71 E785 Service Manual in German (Auf Deutsch)Document63 pagesHatz Dieselmotoren ES71 E785 Service Manual in German (Auf Deutsch)czwnkNo ratings yet

- Summary Note For CSWIP 3.1Document9 pagesSummary Note For CSWIP 3.1Muhamad ShakyreenNo ratings yet

- Direct-Hardening: Free-Cutting Steels 35S20Document1 pageDirect-Hardening: Free-Cutting Steels 35S20Biaizidi Abbou SamirNo ratings yet

- FREE-CUTTING 36SMnPb14 - Nr.1.0765 STEELS MECHANICAL AND CHEMICAL PROPERTIESDocument1 pageFREE-CUTTING 36SMnPb14 - Nr.1.0765 STEELS MECHANICAL AND CHEMICAL PROPERTIESDragos AndreiNo ratings yet

- 36smnpb14 1.0765 pr80 11l37 EngDocument1 page36smnpb14 1.0765 pr80 11l37 EngJason-chungNo ratings yet

- 46S20PB - 46SPb20-Nr 1 0757-ENGDocument1 page46S20PB - 46SPb20-Nr 1 0757-ENGVipul SharmaNo ratings yet

- Technical Card: Information OnlyDocument1 pageTechnical Card: Information OnlyBhuvnesh VermaNo ratings yet

- 50CRMO4_50CrMo4-Nr.1.7228-ENGDocument2 pages50CRMO4_50CrMo4-Nr.1.7228-ENGLuiz Antonio dos AnjosNo ratings yet

- Special Steels CB10FF: For Cold Deformation and BearingsDocument1 pageSpecial Steels CB10FF: For Cold Deformation and BearingsRollpass DesignNo ratings yet

- 34CRNIMO6 - 34CrNiMo6-Nr 1 6582-ENGDocument2 pages34CRNIMO6 - 34CrNiMo6-Nr 1 6582-ENGNarimane BentyNo ratings yet

- KV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGDocument2 pagesKV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGBiaizidi Abbou SamirNo ratings yet

- Stainless Steels 430F: MartensiticDocument2 pagesStainless Steels 430F: MartensiticRavindra ErabattiNo ratings yet

- P355GH boiler plate steel specsDocument1 pageP355GH boiler plate steel specsCommercial MarocNo ratings yet

- 304 - X5CrNi18 10 Nr.1.4301 ENG PDFDocument2 pages304 - X5CrNi18 10 Nr.1.4301 ENG PDFGaurav AggarwalNo ratings yet

- Stainless Steels 410: MartensiticDocument2 pagesStainless Steels 410: MartensiticKiranNo ratings yet

- 34CrNiMo6 1.6582 ENGDocument2 pages34CrNiMo6 1.6582 ENGAmarendra PendseNo ratings yet

- DC01 Steel Data Sheet: Mechanical Properties, Chemical Composition, ApplicationsDocument9 pagesDC01 Steel Data Sheet: Mechanical Properties, Chemical Composition, ApplicationsHung NguyenNo ratings yet

- Astm Standartlar 6060 6063 6082Document2 pagesAstm Standartlar 6060 6063 6082kartepe.tercumanNo ratings yet

- Special Steels SB4: For Cold Deformation and BearingsDocument1 pageSpecial Steels SB4: For Cold Deformation and BearingsRollpass DesignNo ratings yet

- Insert Type, Relief, Direct Acting Poppet Type: Special Cavity, 730-ADocument2 pagesInsert Type, Relief, Direct Acting Poppet Type: Special Cavity, 730-ATaller PahrNo ratings yet

- Principal Application Fields General Application SteelDocument1 pagePrincipal Application Fields General Application SteelBhuvnesh VermaNo ratings yet

- KV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGDocument2 pagesKV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGNarimane BentyNo ratings yet

- Not Alloyed: Case-Hardening Steels C16EDocument1 pageNot Alloyed: Case-Hardening Steels C16Esafat parNo ratings yet

- Stainless Wire e 04-06Document2 pagesStainless Wire e 04-06ravindra erabattiNo ratings yet

- En S275JR PDFDocument2 pagesEn S275JR PDFThanh NguyenNo ratings yet

- Lasdraad HTS 70 PRIORDocument1 pageLasdraad HTS 70 PRIORCem DufourNo ratings yet

- STAINLESS STEEL - Chemical & Mechanical PropertiesDocument3 pagesSTAINLESS STEEL - Chemical & Mechanical PropertiesGregorio KilatonNo ratings yet

- FICHA TECNICA CAMPANA DE 250Wn 1 1Document8 pagesFICHA TECNICA CAMPANA DE 250Wn 1 1Jacquelin ManriqueNo ratings yet

- 420C - X39Cr13-Nr 1 4031-ENGDocument2 pages420C - X39Cr13-Nr 1 4031-ENGJózsef SchwarczNo ratings yet

- RK1 RK1PB - 42CrMo4 Nr.1.7225 42CrMoS4 Nr.1.7227 ENG PDFDocument2 pagesRK1 RK1PB - 42CrMo4 Nr.1.7225 42CrMoS4 Nr.1.7227 ENG PDFAnonymous yshOO0tEjKNo ratings yet

- Dokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfDocument2 pagesDokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfraduonoNo ratings yet

- Steel BS4360 43A PDFDocument1 pageSteel BS4360 43A PDFscmNo ratings yet

- Steel BS4360 43A PDFDocument1 pageSteel BS4360 43A PDFsyakiroh100% (1)

- BS 4360 specification for structural steel plates and productsDocument1 pageBS 4360 specification for structural steel plates and productsscmNo ratings yet

- X2CrNiN23 4 1.4362 2304 ENGDocument1 pageX2CrNiN23 4 1.4362 2304 ENGShariq KhanNo ratings yet

- Steel Grade Diameter Tensile Strength (RM) YIE Point (RP0.2) Elongation (A5) Hardness Impact Test (J at - 20°C)Document1 pageSteel Grade Diameter Tensile Strength (RM) YIE Point (RP0.2) Elongation (A5) Hardness Impact Test (J at - 20°C)Kuya Fabio VidalNo ratings yet

- Material delivery specificationsDocument2 pagesMaterial delivery specificationsviyfNo ratings yet

- C% Si% MN% P% S% CR% Ni% Mo% Cr+Mo+Ni % From TODocument2 pagesC% Si% MN% P% S% CR% Ni% Mo% Cr+Mo+Ni % From TOHarekrushna PradhanNo ratings yet

- c40 Carbon Steel Round Bar PDFDocument2 pagesc40 Carbon Steel Round Bar PDFRamNo ratings yet

- C4C - Special Steel for Cold Deformation and BearingsDocument1 pageC4C - Special Steel for Cold Deformation and BearingsObaciuIonel100% (1)

- Chemical Composition % of Steel S355J2 (+N) (1.0570 (Dubl) ) : EN 10250-2-2000Document1 pageChemical Composition % of Steel S355J2 (+N) (1.0570 (Dubl) ) : EN 10250-2-2000dneprmt1No ratings yet

- Tehnicki - Podaci HATZ MotoriDocument4 pagesTehnicki - Podaci HATZ MotoriVikko TriNo ratings yet

- Ta450dc A33534-58Document2 pagesTa450dc A33534-58marcosNo ratings yet

- SGS Speeds Feeds 135 3D MetricDocument2 pagesSGS Speeds Feeds 135 3D MetricPuneeth KumarNo ratings yet

- Photo Conductive Cell: FeaturesDocument1 pagePhoto Conductive Cell: FeaturesIbrahim HasanNo ratings yet

- Ventilador Interno PowerFlex 753 Frame 4 e 5 Nidec Ta225DC M34313-16Document3 pagesVentilador Interno PowerFlex 753 Frame 4 e 5 Nidec Ta225DC M34313-16Rogerio Pereira de PaulaNo ratings yet

- RK0S RK0SPB - 25CrMo4 Nr.1.7218 25CrMoS4 Nr.1.7213 ENG PDFDocument2 pagesRK0S RK0SPB - 25CrMo4 Nr.1.7218 25CrMoS4 Nr.1.7213 ENG PDFtosse atanasovNo ratings yet

- ACI 318-05 column design analysisDocument4 pagesACI 318-05 column design analysisJaime Diaz UcedaNo ratings yet

- 56 Si 7Document2 pages56 Si 7Bhuvanesh ShanmugamNo ratings yet

- EN 10213 Material SpecificationsDocument1 pageEN 10213 Material Specifications김창배No ratings yet

- Deviation and Grade TableDocument9 pagesDeviation and Grade TableNiresh MuneesNo ratings yet

- JIS Steel Norms For General Structural SteelDocument3 pagesJIS Steel Norms For General Structural SteelValentin StănescuNo ratings yet

- Better corrosion resistance with Thalachrome SE 120Document1 pageBetter corrosion resistance with Thalachrome SE 120thyskieNo ratings yet

- Product Description: 1. Grade and Chemical Composition (%)Document2 pagesProduct Description: 1. Grade and Chemical Composition (%)hansNo ratings yet

- EN Thalachrome S PDFDocument1 pageEN Thalachrome S PDFthyskieNo ratings yet

- Ejercicios Programacion LienalDocument99 pagesEjercicios Programacion LienalJUAN JOSE GONZALEZ MIRANDANo ratings yet

- SA/AS1548 - 7 - 460R: XlerplateDocument3 pagesSA/AS1548 - 7 - 460R: XlerplatenavNo ratings yet

- API 571 Study Guide Questions for CUI Corrosion InspectionDocument5 pagesAPI 571 Study Guide Questions for CUI Corrosion InspectionNIMANo ratings yet

- Minerals Grade 11 Cookery-B Earth & LifeDocument7 pagesMinerals Grade 11 Cookery-B Earth & LifeMaximo CajerasNo ratings yet

- 渦電流 微結構Document90 pages渦電流 微結構Chin-Min YangNo ratings yet

- METAL CASTING TECHNOLOGY: CONTINUOUS, SLUSH & ELECTRO-SLAGDocument13 pagesMETAL CASTING TECHNOLOGY: CONTINUOUS, SLUSH & ELECTRO-SLAGGoutham ReddyNo ratings yet

- General Principles and Processes of Isolation Elements: Chapter - 6Document28 pagesGeneral Principles and Processes of Isolation Elements: Chapter - 6Mukul MathurNo ratings yet

- European Steel and Alloy GradesDocument3 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Evaluation of A Diagnostic Leaching Technique For Gold inDocument12 pagesEvaluation of A Diagnostic Leaching Technique For Gold inEdgar PérezNo ratings yet

- Alloys: Prepared By: Ahmad Najibullah Bin Che MohdDocument22 pagesAlloys: Prepared By: Ahmad Najibullah Bin Che Mohdganu89No ratings yet

- Tensile shear strength and dynamic properties of dissimilar metal spot weldingDocument9 pagesTensile shear strength and dynamic properties of dissimilar metal spot weldingAbraham Adera BezabihNo ratings yet

- Astm A800 - A800m - 20Document7 pagesAstm A800 - A800m - 20reza acbariNo ratings yet

- Design Guide For Surface Coating 05 v18 72dpiDocument54 pagesDesign Guide For Surface Coating 05 v18 72dpifunluaslan100% (2)

- Development of Stretch Flangeable Ferrite-Bainite Grades Through Thin Slab Casting and RollingDocument9 pagesDevelopment of Stretch Flangeable Ferrite-Bainite Grades Through Thin Slab Casting and RollingBalakrishnan RagothamanNo ratings yet

- Trim Numbers Nordic Pipe AbDocument1 pageTrim Numbers Nordic Pipe Abfer_2586No ratings yet

- Perth Mining Geology Conference 2019 Special Report: A Selection of Resource and Exploration Analytical DataDocument20 pagesPerth Mining Geology Conference 2019 Special Report: A Selection of Resource and Exploration Analytical DatageyunboNo ratings yet

- Materials Selection Materials Selection Ffo Orr S Sul Ulffur Uriic Ca Ac Ciid DDocument290 pagesMaterials Selection Materials Selection Ffo Orr S Sul Ulffur Uriic Ca Ac Ciid DSumit KumarNo ratings yet

- Astm A494 - A494m - 13Document7 pagesAstm A494 - A494m - 13raul100% (1)

- Forging Process: Types, Advantages & ApplicationsDocument10 pagesForging Process: Types, Advantages & ApplicationsVipin TitariyaNo ratings yet

- Practical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsDocument8 pagesPractical Guidelines For The Inspection and Repair of Hot Dip Galvanized CoatingsIan FletcherNo ratings yet

- Full ThesisDocument102 pagesFull ThesisUma KoduriNo ratings yet

- Metallic Glasses: July 2012Document49 pagesMetallic Glasses: July 2012carlos jose peckermanNo ratings yet

- API 526 6th Edition Errata 2 2009Document1 pageAPI 526 6th Edition Errata 2 2009Noralia Amanina Osman0% (1)

- Introduction To Powder MetallurgyDocument3 pagesIntroduction To Powder MetallurgyAnonymous VRspXsmNo ratings yet

- EC 1350-O Product Specification Rev.0Document3 pagesEC 1350-O Product Specification Rev.0serkan temelNo ratings yet

- Chemistry Project On Metal Coupling in Rusting of IronDocument2 pagesChemistry Project On Metal Coupling in Rusting of IronAshwin Naresh MNo ratings yet

- l6 Minerals - Earth ScienceDocument29 pagesl6 Minerals - Earth ScienceManuel ParillaNo ratings yet

- Unit-Ii QBDocument16 pagesUnit-Ii QBAnonymous ZB6qyhD6No ratings yet

- People Also Ask: Web ResultsDocument4 pagesPeople Also Ask: Web ResultsAmit ChapagainNo ratings yet

- Production Technology Ch31Document9 pagesProduction Technology Ch31Nimmagadda BharathNo ratings yet

- S1 2015 302503 BibliographyDocument2 pagesS1 2015 302503 BibliographydikNo ratings yet