Professional Documents

Culture Documents

Study Notes Video 3 580 Terms Rev 1

Uploaded by

majid0 ratings0% found this document useful (0 votes)

1 views6 pagesOriginal Title

Study notes video 3 580 Terms rev 1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views6 pagesStudy Notes Video 3 580 Terms Rev 1

Uploaded by

majidCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

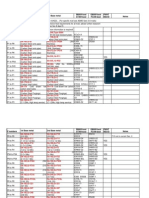

Study notes video 3 580 Terms

Terms, Definitions, Acronyms, and Abbreviations

absolute risk

An ideal and accurate description and quantification of risk.

acceptable risk

A level of risk that is acceptable to the owner-user.

as low as reasonably practical ALARP

A concept of minimization that postulates that attributes (such as risk) can only be reduced to a

certain minimum under current technology and with reasonable cost.

components

Parts that make up a piece of equipment or equipment item. For example a pressure boundary may

consist of components (pipe, elbows, nipples, heads, shells, nozzles, stiffening rings, skirts, supports,

etc.) that are bolted or welded into assembles to make up equipment items.

consequence

An outcome from an event. There may be one or more consequences from an event. Consequences

may range from positive to negative. However, consequences are always negative for safety aspects.

Consequences may be expressed qualitatively or quantitatively.

corrosion specialist

A qualified person in the specific process chemistries, corrosion degradation mechanisms, materials

selection, corrosion mitigation methods, corrosion monitoring techniques, and their impact on

pressure equipment.

cost-effective

An activity that is both effective in resolving an issue (e.g. some form of mitigation) and is a financially

sound use of resources.

damage (or deterioration) mechanism

A process that induces micro and/or macro material changes over time that are harmful to the

material condition or mechanical properties. Damage mechanisms are usually incremental,

cumulative, and, in some instances, unrecoverable. Common damage mechanisms include corrosion,

stress corrosion cracking, creep, erosion, fatigue, fracture, and thermal aging.

damage (or deterioration) mode

The physical manifestation of damage (e.g. wall thinning, pitting, cracking, rupture).

damage tolerance

The amount of deterioration that a component can withstand without failing.

design premise

Assumptions made during the design (e.g. design life and corrosion allowance needed).

deterioration

The reduction in the ability of a component to provide its intended purpose of containment of fluids.

This can be caused by various damage mechanisms (e.g. thinning, cracking, mechanical). Damage or

degradation may be used in place of deterioration.

equipment

An individual item that is part of a system. Examples include pressure vessels, relief devices, piping,

boilers, and heaters.

event

Occurrence of a particular set of circumstances. The event may be certain or uncertain. The event

can be singular or multiple. The probability of an event occurring within a given period of time can be

estimated.

event tree

An analytical tool that organizes and characterizes potential occurrences in a logical and graphical

manner and shows the events relationship to each other. The event tree begins with the identification

of potential initiating events. Subsequent possible events (including activation of safety functions)

resulting from the initiating events are then displayed as the second level of the event tree. This

process is continued to develop pathways or scenarios from the initiating events to potential

outcomes.

external event

Events resulting from forces of nature, acts of God, sabotage, or events such as neighbouring fires or

explosions, terrorism, neighbouring hazardous material releases, electrical power failures, forces of

nature, and intrusions of external transportation vehicles, such as aircraft, ships, trains, trucks, or

automobiles. External events are usually beyond the direct or indirect control of persons employed at

or by the facility.

facility

Any location containing equipment and/or components to be addressed under this RP.

failure

Termination of the ability of a system, structure, equipment, or component to perform its required

function of containment of fluid (i.e. loss of containment). Failures may be unannounced and

undetected at the instant of occurrence (unannounced failure). For example, a slow leak under

insulation may not be detected until a pool of fluid forms on the ground or someone notices a drip or

wisp of vapor. A small leak may not be noticed until the next inspection (unannounced failure), e.g.

slow leakage from buried piping or small leak in a heat exchanger tube, or they may be announced

and detected by any number of methods at the instance of occurrence (announced failure), e.g.

rupture of a pipe in a process plant or sudden decrease in pressure in the system.

failure mode

The manner of failure. For RBI, the failure of concern is loss of containment of pressurized equipment

items. Examples of failure modes are small hole, crack, and rupture.

Fitness-For-Service Assessment

A methodology whereby damage or flaws/imperfections contained within a component or equipment

item are assessed in order to determine acceptability for continued service.

hazard

A physical condition or a release of a hazardous material that could result from component failure and

result in human injury or death, loss or damage, or environmental degradation. Hazard is the source

of harm. Components that are used to transport, store, or process a hazardous material can be a

source of hazard. Human error and external events may also create a hazard.

hazard and operability study HAZOP

A HAZOP study is a form of failure modes and effects analysis (FMEA). HAZOP studies, which were

originally developed for the process industry, use systematic techniques to identify hazards and

operability issues throughout an entire facility. It is particularly useful in identifying unforeseen hazards

designed into facilities due to lack of information or introduced into existing facilities due to changes in

process conditions or operating procedures. The basic objectives of the techniques are:

a) to produce a full description of the facility or process, including the intended design conditions;

b) to systematically review every part of the facility or process to discover how deviations from the

intention of the design can occur;

c) to decide whether these deviations can lead to hazards or operability issues;

d) to assess effectiveness of safeguards.

inspection

Activities performed to verify that materials, fabrication, erection, examinations, testing, repairs, and

any other data relevant to the equipment conform to applicable codes, engineering, and the owner-

user’s written procedure

requirements. Inspection includes the planning, implementation, and evaluation of the results of

inspection activities. The external, internal, or on-stream assessment (or any combination of the

three) of the condition of pressure equipment.

inspection plan

A documented set of actions and/or strategies detailing the scope, extent, methods, and timing of

specific inspection activities in order to determine the condition of a specific piece of equipment. For

the purposes of this document, the inspection plan is the product of an RBI analysis.

integrity operating windows IOWs

Established limits for process variables that can affect the integrity of the equipment if the process

operation deviates from the established limits for a predetermined amount of time.

ISO-risk

A line of constant risk and method of graphically showing probability of failure (POF) and

consequence of failure (COF) values in a two-dimensional plot where risk increases toward the upper

right-hand corner. Components near an ISO-risk line (or ISO-line for risk) represent an equivalent

level of risk, while the contribution of POF and COF may vary significantly.

Likelihood See probability.

logic model

A tool used to depict the effectiveness in depicting a combination of events that could result in a loss

of containment event.

management of change MOC

A documented management system for review and approval of changes in process, equipment, or

piping systems prior to implementation of the change.

management system

A management system is the framework of work processes and procedures used to provide

assurance that an organization can fulfill all tasks required to achieve its objectives.

mitigation

Limitation of any negative consequence or reduction in probability of a particular event.

physical model

A tool used to depict the progression of events and the release of a hazardous material to the

environment.

probabilistic

Systematic and comprehensive methodology to evaluate risks associated with a complex engineered

entity, which is based on or adapted to a theory of probability; subject to or involving chance variation.

probability

Extent to which an event is likely to occur within the timeframe under consideration. The mathematical

definition of probability is “a real number in the scale 0 to 1 attached to a random event.” Probability

can be related to a long-run relative frequency of occurrence or to a degree of belief that an event will

occur. For a high degree of belief, the probability is near one (1). Frequency rather than probability

may be used in describing risk. Degrees of belief about probability can be chosen as classes or ranks

like “rare unlikely moderate likely almost certain” or incredible improbable remote/occasional probable

frequent.”

process unit

A group of systems arranged in a specific fashion to produce a product or service. Examples of

processes include power generation, acid production, fuel oil production, and ethylene production.

qualified person

A competent person who has met the knowledge and skill requirements and expectations of the

owner-user.

qualitative risk analysis

A risk analysis using primarily subject matter expertise and experience to assign broad

categorizations for POF and COF.

quantitative risk analysis

A risk analysis that uses primarily model-based approaches where numerical values are calculated

and more discreet input data used.

reassessment

The process of integrating inspection data or other changes into the risk analysis.

relative risk

The comparative risk of a facility, process unit, system, equipment item, or component to other

facilities, process units, systems, equipment items, or components, respectively.

residual risk

The risk remaining after risk mitigation.

risk

Combination of the probability of an event and its consequence. In some situations, risk is a deviation

from the expected. When probability and consequence are expressed numerically, risk is the product.

risk acceptance

A decision to accept a risk. Risk acceptance depends on risk criteria.

risk analysis

Systematic use of information to identify sources and to estimate the risk. Risk analysis provides a

basis for risk evaluation, risk mitigation, and risk acceptance. Information can include historical data,

theoretical analysis, informed opinions, and concerns of stakeholders.

risk assessment

Overall process of risk analysis and risk evaluation.

risk avoidance

Decision not to become involved in, or action to withdraw from, a risk situation. The decision may be

taken based on the result of risk evaluation.

Risk-Based Inspection RBI

A risk assessment and management process that is focused on loss of containment of pressurized

equipment in processing facilities, due to material deterioration. These risks are managed primarily

through equipment inspection.

risk communication

Exchange or sharing of information about risk between the decision maker and other stakeholders.

The information may relate to the existence, nature, form, probability, severity, acceptability,

mitigation, or other aspects of risk.

risk criteria

Terms of reference by which the significance of risk is assessed. Risk criteria may include associated

cost and benefits, legal and statutory requirements, socio-economic and environmental aspects,

concerns of stakeholders, priorities, and other inputs to the assessment.

risk driver

An item affecting either the probability, consequence, or both such that it constitutes a significant

portion of the risk.

risk estimation

Process used to assign values to the probability and consequence of a risk. Risk estimation may

consider cost, benefits, stakeholder concerns, and other variables, as appropriate for risk evaluation.

risk evaluation

Process used to compare the estimated risk against given risk criteria to determine the significance of

the risk. Risk evaluation may be used to assist in the acceptance or mitigation decision.

risk identification

Process to find, list, and characterize elements of risk. Elements may include source, event,

consequence, and probability. Risk identification may also identify stakeholder concerns.

risk management

Coordinated activities to direct and control an organization with regard to risk. Risk management

typically includes risk assessment, risk mitigation, risk acceptance, and risk communication.

risk mitigation

Process of selection and implementation of measures to modify risk. The term risk mitigation is

sometimes used for measures themselves.

risk reduction

Actions taken to lessen the probability, negative consequences, or both associated with a particular

risk. A semiquantitative analysis includes aspects of both qualitative and quantitative analyses.

service life

The expected lifetime or the acceptable period during which a pressure-containing asset and/or

component can safely and reliably perform within its intended operating envelope.

source

Thing or activity with a potential for consequence. Source in a safety context is a hazard.

stakeholder

Any individual, group or organization that may affect, be affected by, or perceive itself to be affected

by the risk.

system

A collection of equipment assembled for a specific function within a process unit. Examples of

systems include service water system, distillation systems, and separation systems.

toxic chemical

Any chemical that presents a physical or health hazard or an environmental hazard according to the

appropriate material safety datasheet. These chemicals (when ingested, inhaled, or absorbed through

the skin) can cause damage to living tissue, impairment of the central nervous system, severe illness,

or in extreme cases, death. These chemicals may also result in adverse effects to the environment

(measured as ecotoxicity and related to persistence and bioaccumulation potential).

turnaround

A period of downtime to perform inspection, maintenance, or modifications and prepare process

equipment for the next operating cycle.

unmitigated risk

The risk prior to mitigation activities.

Acronyms and Abbreviations

ACC American Chemistry Council

ALARP as low as reasonably practical

BLEVE boiling liquid expanding vapor explosion

CCPS Center for Chemical Process Safety

COF consequence of failure

FMEA failure modes and effects analysis

HAZOP hazard and operability assessment

IOWs integrity operating windows

LOPA layers of protection analysis

MOC management of change

MSD material selection diagrams

NDE non destructive examination

PASCC polythionic acid stress corrosion cracking

PHA process hazards analysis

PMI positive material identification

POF probability of failure

PSM process safety management

PVRC Pressure Vessel Research Council

QA/QC quality assurance/quality control

QRA quantitative risk assessment

RBI Risk-Based Inspection

RCM reliability centered maintenance

RMP risk management plan

SIL safety integrity level

UT ultrasonic testing

You might also like

- API 580 - RBI 580 Definitions - 54 TermsDocument6 pagesAPI 580 - RBI 580 Definitions - 54 TermsSERFORTEC CIA. LTDA.No ratings yet

- RBI of ASTDocument10 pagesRBI of ASTangelo.petteNo ratings yet

- Formal Safety Assessment: Basic Glossary of TermsDocument7 pagesFormal Safety Assessment: Basic Glossary of Termshafidhrahadiyan2No ratings yet

- Five Fatal Flaws in API 581Document12 pagesFive Fatal Flaws in API 581Geert Henk WijnantsNo ratings yet

- Fault Tree AnalysisDocument7 pagesFault Tree AnalysisthawdarNo ratings yet

- Unit 2 - Hazard Identification & Risk Assesament Techq.Document144 pagesUnit 2 - Hazard Identification & Risk Assesament Techq.Madhan M100% (3)

- Ed Loss of ContainmentDocument47 pagesEd Loss of Containmentliamo88880No ratings yet

- Process Hazard Analysis-Hazard Id Techniques - ModifiedDocument85 pagesProcess Hazard Analysis-Hazard Id Techniques - ModifiedDaniel Omashola Osifo OtahNo ratings yet

- Chemical Engineering Plant Design: Protection AnalysisDocument26 pagesChemical Engineering Plant Design: Protection AnalysisMuhammad BilalNo ratings yet

- API 580 - RBI Question BankDocument30 pagesAPI 580 - RBI Question BankSabarni Mahapatra100% (3)

- Process Safety Notes 1Document18 pagesProcess Safety Notes 1Zia AhmadNo ratings yet

- Hazard Assessment and Risk Management Techniques for IndustriesDocument51 pagesHazard Assessment and Risk Management Techniques for IndustriespotatoteddyNo ratings yet

- User Guide for Petrom EP Standard on Technical Integrity ManagementDocument13 pagesUser Guide for Petrom EP Standard on Technical Integrity ManagementagaricusNo ratings yet

- Hazard Identification & Risk Assessment (Hira)Document23 pagesHazard Identification & Risk Assessment (Hira)Ked KubenNo ratings yet

- SHM - Practical 12 - Risk Assessment MethodsDocument8 pagesSHM - Practical 12 - Risk Assessment MethodsBhaliya AadityaNo ratings yet

- Safety EngineeringDocument6 pagesSafety EngineeringValentin RadulescuNo ratings yet

- CCPS Guidelines For LOPC CasesDocument24 pagesCCPS Guidelines For LOPC CasesMuhammad Wahaj ButtNo ratings yet

- Safety Engineer Safety Engineering Is An Engineering Discipline Which Assures That Engineered SystemsDocument5 pagesSafety Engineer Safety Engineering Is An Engineering Discipline Which Assures That Engineered SystemsJohn Nate RiveraNo ratings yet

- Guidelines For Hazard Evaluation Procedures 2nd Edition With Worked ExamplesDocument12 pagesGuidelines For Hazard Evaluation Procedures 2nd Edition With Worked Exampleskkkelvin21% (14)

- Process Safety Management CH-523 Prof.: Zahoor@neduet - Edu.pkDocument70 pagesProcess Safety Management CH-523 Prof.: Zahoor@neduet - Edu.pkNaik LarkaNo ratings yet

- Wellcontrol dwc01Document13 pagesWellcontrol dwc01daburto2No ratings yet

- RBIDocument19 pagesRBIseth_007No ratings yet

- Lopa SilDocument10 pagesLopa Silkhali54No ratings yet

- Safety SystemDocument81 pagesSafety SystemNguyễnQuíTrọngNo ratings yet

- Safety System - Emergency Shutdown System P1Document41 pagesSafety System - Emergency Shutdown System P1عزت عبد المنعم100% (2)

- Loss Prevention: An Insurance Term Where The Loss Represents TheDocument13 pagesLoss Prevention: An Insurance Term Where The Loss Represents TheKhadeejaNo ratings yet

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Designing Instrumentation and Control For Process SafetyDocument7 pagesDesigning Instrumentation and Control For Process SafetyAdebamboAinaNo ratings yet

- How To Perform Bow Tie AnalysisDocument21 pagesHow To Perform Bow Tie AnalysisKareem RasmyNo ratings yet

- Topic Five: Risk Assessment & ManagementDocument35 pagesTopic Five: Risk Assessment & ManagementvikramNo ratings yet

- Five Fatal Flaws in API RP 581: The Hague, Netherlands Helle@corrosioncontrol - NuDocument12 pagesFive Fatal Flaws in API RP 581: The Hague, Netherlands Helle@corrosioncontrol - NuCALLESJNo ratings yet

- L09 - Reliability EngrgDocument32 pagesL09 - Reliability EngrgU Kyaw Kyaw Naing100% (2)

- Probability Bow-Ties: A Transparent Risk Management ToolDocument10 pagesProbability Bow-Ties: A Transparent Risk Management ToolRmz ExeNo ratings yet

- Formal Safety Assessment: Basic Glossary of TermsDocument7 pagesFormal Safety Assessment: Basic Glossary of TermsReuben LanfrancoNo ratings yet

- Risk-based inspection optimizationDocument5 pagesRisk-based inspection optimizationjrbeheraNo ratings yet

- Safety Engineering: Felipe A. Arnejo Ii Sheila Marie C. Cagadas Jamelee S. Marzonia John Henry V. MoratallaDocument11 pagesSafety Engineering: Felipe A. Arnejo Ii Sheila Marie C. Cagadas Jamelee S. Marzonia John Henry V. MoratallaSheila Marie CagadasNo ratings yet

- Advanced Regulatory Control (ARC) or Advanced Process Control (APC) ?Document17 pagesAdvanced Regulatory Control (ARC) or Advanced Process Control (APC) ?AndresVillaNo ratings yet

- DNV RP 116 SchemeDocument13 pagesDNV RP 116 SchemePasquale CutriNo ratings yet

- Aircraft System Safety: Assessments for Initial Airworthiness CertificationFrom EverandAircraft System Safety: Assessments for Initial Airworthiness CertificationNo ratings yet

- Reliability EngineeringDocument31 pagesReliability Engineeringshreeram79No ratings yet

- 1.0 Introduction On Reliability: Figure 1.0 Bathtub Curve, Failure Rate vs. TimeDocument9 pages1.0 Introduction On Reliability: Figure 1.0 Bathtub Curve, Failure Rate vs. TimeShukri ShabriNo ratings yet

- Iec 61508Document14 pagesIec 61508Pandhu DewantoNo ratings yet

- Tank Inspection Base On RiskDocument16 pagesTank Inspection Base On Riskthawatchai11222512100% (1)

- Hazard Identification Techniques in IndustryDocument4 pagesHazard Identification Techniques in IndustrylennyNo ratings yet

- Best Practices For Temporary Interlock BypassDocument5 pagesBest Practices For Temporary Interlock BypassjrfmlNo ratings yet

- 02 - HAZID Techniques - Applications and LimitationsDocument12 pages02 - HAZID Techniques - Applications and Limitationsarman_morala100% (1)

- Critical Asset Identification and Maintenance Risk ReductionDocument4 pagesCritical Asset Identification and Maintenance Risk ReductionAramis Alfonso LlanesNo ratings yet

- G 63 Quality Risk Management (QRM) Application For Critical Instrument CalibrationDocument7 pagesG 63 Quality Risk Management (QRM) Application For Critical Instrument CalibrationDoan Chi Thien100% (1)

- Track 1 - Cesar Malpica - PaperDocument10 pagesTrack 1 - Cesar Malpica - PaperfredyNo ratings yet

- Qualitative Fault Tree Analysis of Blowout Preventer Control System For Real Time Availability MonitoringDocument11 pagesQualitative Fault Tree Analysis of Blowout Preventer Control System For Real Time Availability MonitoringKirillNo ratings yet

- RP Tutorial 1Document7 pagesRP Tutorial 1LinuschooNo ratings yet

- DuPont Methodology For Risk Assessment and Process Hazard AnalysisDocument65 pagesDuPont Methodology For Risk Assessment and Process Hazard Analysisfahadullah100% (1)

- Sauf SIL Paper 4-99 (Public)Document13 pagesSauf SIL Paper 4-99 (Public)Ahmad AzabNo ratings yet

- La Técnica Del HazOpDocument13 pagesLa Técnica Del HazOpEugenio DuranNo ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Fault Diagnosis and Sustainable Control of Wind Turbines: Robust Data-Driven and Model-Based StrategiesFrom EverandFault Diagnosis and Sustainable Control of Wind Turbines: Robust Data-Driven and Model-Based StrategiesRating: 4 out of 5 stars4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Semi-Markov Models: Control of Restorable Systems with Latent FailuresFrom EverandSemi-Markov Models: Control of Restorable Systems with Latent FailuresNo ratings yet

- API 580 - RBI Table and Info For COF - 27 TermsDocument5 pagesAPI 580 - RBI Table and Info For COF - 27 TermsmajidNo ratings yet

- Study Notes Video 2 580 Scope Rev 1Document3 pagesStudy Notes Video 2 580 Scope Rev 1majidNo ratings yet

- 1 API 653 Memories March 2014 ExamDocument16 pages1 API 653 Memories March 2014 ExammajidNo ratings yet

- Study Notes Video 0 Introduction Rev 1Document1 pageStudy Notes Video 0 Introduction Rev 1majidNo ratings yet

- 1 API 653 Memories Sept 2012Document20 pages1 API 653 Memories Sept 2012majid100% (1)

- API 580 - RBI 580 Tables and Info For POF - 25 TermsDocument4 pagesAPI 580 - RBI 580 Tables and Info For POF - 25 TermsmajidNo ratings yet

- 1 API 653 Exam Mar 2015 MemoryDocument12 pages1 API 653 Exam Mar 2015 MemorymajidNo ratings yet

- 1 API 653 Memories Sept 2013Document7 pages1 API 653 Memories Sept 2013majidNo ratings yet

- 5 - 653 Exam 150 Q ADocument36 pages5 - 653 Exam 150 Q Amajid100% (2)

- Corrosion Rev02aDocument500 pagesCorrosion Rev02aDany Gonzalez HerreraNo ratings yet

- API 580 - RBI Section 11.3 To 11.6 COF - 19 TermsDocument5 pagesAPI 580 - RBI Section 11.3 To 11.6 COF - 19 TermsmajidNo ratings yet

- API 580 - Section 5 - 5 TermsDocument1 pageAPI 580 - Section 5 - 5 TermsThomas TuckerNo ratings yet

- RT TheoryDocument58 pagesRT TheoryArunNo ratings yet

- Determination of Defect Depth in Industrial Radiograp 2020 NuclearDocument5 pagesDetermination of Defect Depth in Industrial Radiograp 2020 NuclearAhmed LepdaNo ratings yet

- TWI Radiographic Interpretation. (Weld Defects & Repair)Document61 pagesTWI Radiographic Interpretation. (Weld Defects & Repair)jar_2100% (3)

- TWI Radiographic Interpretation. (Weld Defects & Repair)Document61 pagesTWI Radiographic Interpretation. (Weld Defects & Repair)jar_2100% (3)

- Read MeDocument1 pageRead MeUtsaav Sharma PoudyalNo ratings yet

- 2 Intro - To - Ultrasonics 03092013 OKDocument43 pages2 Intro - To - Ultrasonics 03092013 OKferyNo ratings yet

- Welding Procedures and Welders WG01 7th November 2012Document18 pagesWelding Procedures and Welders WG01 7th November 2012RamanujadaasanNo ratings yet

- Gulfpub - HP - Ebooks-Industrial WaterDocument85 pagesGulfpub - HP - Ebooks-Industrial WatermajidNo ratings yet

- Olympus EPOCH 600 ManualDocument316 pagesOlympus EPOCH 600 ManualMohd Shabir83% (6)

- Asme Sec Ix GR IntroductionDocument71 pagesAsme Sec Ix GR IntroductionmajidNo ratings yet

- 2 Intro - To - Ultrasonics 03092013 OKDocument43 pages2 Intro - To - Ultrasonics 03092013 OKferyNo ratings yet

- Painting Defects - Cswip BgasDocument63 pagesPainting Defects - Cswip BgasLuan Nguyen86% (7)

- ASNT Level I II III Q&A Ultrasonic Testing PDFDocument63 pagesASNT Level I II III Q&A Ultrasonic Testing PDFShyam Sundar Gayen83% (35)

- Welding RodDocument368 pagesWelding Rodjrod91586% (29)

- Ultrasonic Testing - ETS Course Notes - Issue 17 - PPDocument116 pagesUltrasonic Testing - ETS Course Notes - Issue 17 - PPmajidNo ratings yet

- RT TheoryDocument58 pagesRT TheoryArunNo ratings yet

- Asme Sec Ix GR IntroductionDocument71 pagesAsme Sec Ix GR IntroductionmajidNo ratings yet

- Astm-E-2373e2373m-14 TofdDocument13 pagesAstm-E-2373e2373m-14 TofdmajidNo ratings yet

- Embedded Sat Ate Machines ImplementationDocument11 pagesEmbedded Sat Ate Machines ImplementationObamaDoutrinadorNo ratings yet

- SmartStudio User ManualDocument73 pagesSmartStudio User ManualAhmad GustoniNo ratings yet

- This Document Is A Collection of The Interview Experiences of Current and It'S Advice From Your Potential Seniors! JokajokaDocument62 pagesThis Document Is A Collection of The Interview Experiences of Current and It'S Advice From Your Potential Seniors! JokajokaDebayan GangulyNo ratings yet

- CM1 Din 2012Document248 pagesCM1 Din 2012Aurel ZimbruNo ratings yet

- NARAYANA IIT ACADEMY JR.IIT CO SUPER CHAINA & SUPER CHAINA N120/MAINS QP KEY & SOLUTIONDocument12 pagesNARAYANA IIT ACADEMY JR.IIT CO SUPER CHAINA & SUPER CHAINA N120/MAINS QP KEY & SOLUTIONYugandher BadanaNo ratings yet

- Some Glances at Topos Theory: Francis BorceuxDocument63 pagesSome Glances at Topos Theory: Francis BorceuxmattNo ratings yet

- Statistics Term Paper ExampleDocument7 pagesStatistics Term Paper Exampleafmzrxbdfadmdq100% (1)

- Circolumn As Per Is 456Document20 pagesCircolumn As Per Is 456Bilal Ahmed Barbhuiya100% (1)

- IT-UG Curriculum and SyllabusDocument257 pagesIT-UG Curriculum and SyllabusKak SakaNo ratings yet

- Windows - How To Rotate Shapes in C# - Stack Overflow PDFDocument1 pageWindows - How To Rotate Shapes in C# - Stack Overflow PDFVerruumm AmineNo ratings yet

- Donald E. Knuth - Surreal NumbersDocument65 pagesDonald E. Knuth - Surreal NumbersMaurizioLeonardi100% (1)

- Phys 126 Ch 18 Review Electric ChargeDocument2 pagesPhys 126 Ch 18 Review Electric ChargeJustin BNo ratings yet

- 1 Preliminaries: K J 1 2 K JDocument8 pages1 Preliminaries: K J 1 2 K JSiraj Ud-DoullaNo ratings yet

- College Essay - Anzo TehDocument2 pagesCollege Essay - Anzo TehElevenPlus ParentsNo ratings yet

- Stats Chap10Document63 pagesStats Chap10Sameh SalahNo ratings yet

- Backlog +do+this+to+save+your+11th+classDocument33 pagesBacklog +do+this+to+save+your+11th+classAryan KulhariNo ratings yet

- Local Center Manifold TheoryDocument4 pagesLocal Center Manifold TheoryAlfredo MartínezNo ratings yet

- 2021MATHADVHO9.2 Learning ModuleDocument120 pages2021MATHADVHO9.2 Learning ModuleChang CarelNo ratings yet

- Fiitjee Straight LineDocument3 pagesFiitjee Straight LineMayank VatsaNo ratings yet

- DB2 Program PreperationDocument6 pagesDB2 Program PreperationSudheer.rbNo ratings yet

- Dashiell E.A. FryerDocument2 pagesDashiell E.A. FryerKevin WangNo ratings yet

- IGO2022Document40 pagesIGO2022RuanMoura100% (1)

- Formula 2 PFDocument32 pagesFormula 2 PFAnwar HossainNo ratings yet

- MCQ of Mth634Document6 pagesMCQ of Mth634Aiman khanNo ratings yet

- Cambridge IGCSE™: Mathematics 0580/23 May/June 2022Document8 pagesCambridge IGCSE™: Mathematics 0580/23 May/June 2022hildebrandokNo ratings yet

- TransformationDocument12 pagesTransformationDevil InsideNo ratings yet

- 1 - Number SystemsDocument15 pages1 - Number Systemskaziba stephenNo ratings yet

- Inclined PlanesDocument4 pagesInclined PlanesnotgettingitNo ratings yet

- EEC110A Win 2010 Final Exam: Name: ID #Document35 pagesEEC110A Win 2010 Final Exam: Name: ID #Zoro ZhaoNo ratings yet