Professional Documents

Culture Documents

Centrifugal Pump Selection - 230409 - 003734

Uploaded by

Yasir NadeemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centrifugal Pump Selection - 230409 - 003734

Uploaded by

Yasir NadeemCopyright:

Available Formats

Centrifugal Pump selection metrics

Centrifugal pump: mechanical sealed or sealless pump

Selection parameter Parameter Sealed Sealess

Nature of product, Hazardous service

Solid handling Solid handling

Vapor pressure, Initial cost

Specific gravity and viscosity, maintenance cost

Operating and min / max T, P Efficiency

Lifecycle Cost

Initial budget, O&M cost Safety

Reliability

Centrifugal pump Type

Selection parameter: Hydraulics (Flow X head) requirement, NPSHa, Budget, Suction discharge orientation, Space available, Driver and

coupling arrangement, applicable standard, installation and maintenance cost. API 610 pump types are listed below.

Flexibly Coupled Rigidly Close Coupled 1-2 Stage Multi Stage Single Casing Double

Coupled Casing

Horizontal Vertical Radially Split Separate

In Line High Discharge

with Speed

Bearing Vertical In Vertical Integrally Axially Radially Axially Discharge Through

Bracket Line In Line Geared Split Split Split Column Diffuser Volute

Foot Centreline Single Double Axial Line

Mounted support Casing Casing Diffuser Volute Flow Shaft Cantilever

OH1 OH2 OH3 OH4 OH5 OH6 BB1 BB2 BB3 BB4 BB5 VS1 VS2 VS3 VS4 VS5 VS6 VS7

Centrifugal pump with mechanical seal type and arrangement: Single, Tandem or double

Selection parameter

Parameter Single Tandem Double

Nature of product, Clean non s

Solid handling HC / Emission control

Vapor pressure, Abrasive / corrosive

Specific gravity, viscosity, Back up / containment

Operating & min / max T, Pr Monitoring system

Initial budget, O&M cost

Mechanical API Plan selection: Please refer my earlier post exclusively on this topic

Material of construction

Selection parameter: Fluid (Abrasive, corrosive), Maximum / minimum operating temperature, Maximum pressure,

component, budget, life cycle (

Type of Corrosion Temperature range for common elastomeric material

• Galvanic corrosion • Uniform corrosion

• Pitting corrosion • Intergranular corrosion

• Erosion corrosion • Stress corrosion

• Crevice corrosion • Graphitization

Galvanic Series of Common Metals and Alloys in Seawater

Most Noble, or Cathodic

Platinum

Gold

Graphite

Titanium

Silver

Hastelloy C

Stainless steel (passive)

Nickel (passive)

Monel

Bronze

Copper

Brass

Hastelloy B

Comparison of properties of commonly used elastomer

Nickel (active)

Tin

Lead

Stainless steel (active)

Ni-Resist

Cast iron

Steel

Aluminium

Cadmium

Zinc

Magnesium

Least Noble, or Anodic

Recommended Pump Materials for Different pH Liquids

PH Value Material

10–14 Corrosion-resistant alloys or non-metals

8-10 All Iron

6-8 Bronze fitted r Standard fitted

4-6 All Bronze

0-4 Corrosion-resistant alloys or non-metals

For more info. Refer API 610, 12th edition, Annex. G and H

Kirit Domadiya

You might also like

- Volvo Ingersoll Rand DD14S DD16Document4 pagesVolvo Ingersoll Rand DD14S DD16Jozef50% (2)

- Impact Crusher SheetDocument2 pagesImpact Crusher SheetStephanie SanchezNo ratings yet

- Test Plan TemplateDocument3 pagesTest Plan TemplateMurtazaNo ratings yet

- Dawn of The DhammaDocument65 pagesDawn of The Dhammaarkaprava paulNo ratings yet

- Data Sheet For T-8101.RevCDocument5 pagesData Sheet For T-8101.RevCSuresh SjNo ratings yet

- List of Marketing Metrics and KpisDocument5 pagesList of Marketing Metrics and KpisThe KPI Examples ReviewNo ratings yet

- Common Rail Injector Tester CR-C +S60H Multifunction Test MachineDocument3 pagesCommon Rail Injector Tester CR-C +S60H Multifunction Test MachineAlen HuangNo ratings yet

- Volvo Single Drum Compactors 11.1 T 74 KW: Volvo Construction Equipment. Building TomorrowDocument2 pagesVolvo Single Drum Compactors 11.1 T 74 KW: Volvo Construction Equipment. Building TomorrowMannanNo ratings yet

- Weatherford Artificial Lifts Progressing Cavity Pumping Systems PDFDocument12 pagesWeatherford Artificial Lifts Progressing Cavity Pumping Systems PDFFan JackNo ratings yet

- ECS 3390 - Business and Technical CommuncationsDocument293 pagesECS 3390 - Business and Technical CommuncationsEliseo Robles0% (3)

- The Engineer Needs To ConfirmDocument4 pagesThe Engineer Needs To ConfirmQuang VoNo ratings yet

- Centrifugal Pumps Selection MatrixDocument1 pageCentrifugal Pumps Selection MatrixAli HabibNo ratings yet

- Centrifugal Pump Infographics: Gland Packing Mechanical Seal Sealless PumpDocument1 pageCentrifugal Pump Infographics: Gland Packing Mechanical Seal Sealless PumpKIESSENo ratings yet

- 22-DS-R-006 Rev 0 P-4110 A-B Firewater PumpDocument3 pages22-DS-R-006 Rev 0 P-4110 A-B Firewater PumpChike NwachukwuNo ratings yet

- Product Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Document1 pageProduct Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Joe CruzNo ratings yet

- EagleBurgmann - Cartex Single Seals - ENDocument5 pagesEagleBurgmann - Cartex Single Seals - ENsaroat moongwattanaNo ratings yet

- Centrifugal Pump InfographicsDocument1 pageCentrifugal Pump InfographicsHalimi AyoubNo ratings yet

- SEM 915 - NewDocument2 pagesSEM 915 - NewDedy setiawanNo ratings yet

- Lonking 833Document1 pageLonking 833Hoàng Anh PhạmNo ratings yet

- 22-DS-R-010 Rev 0 P-2440 Fire Water Feed PumpDocument3 pages22-DS-R-010 Rev 0 P-2440 Fire Water Feed PumpChike NwachukwuNo ratings yet

- Buy Australian Made Cranes: Technical Specification and Price of 5t Overhead CraneDocument3 pagesBuy Australian Made Cranes: Technical Specification and Price of 5t Overhead CraneQuang VoNo ratings yet

- U-Packing: Valqua No. 4060-UHS (FKM) Product Name Custom-Made Synthetic Rubber Molded Product U-PackingDocument2 pagesU-Packing: Valqua No. 4060-UHS (FKM) Product Name Custom-Made Synthetic Rubber Molded Product U-PackingmahmudNo ratings yet

- Alfa Laval Sru Rotary Lobe Pump Product LeafletDocument7 pagesAlfa Laval Sru Rotary Lobe Pump Product LeafletErickson HamonanganNo ratings yet

- Datasheet Flygt 2201 012 HT-MT 60hz En-UsDocument2 pagesDatasheet Flygt 2201 012 HT-MT 60hz En-UsCristhian Vilca SilvestreNo ratings yet

- LD36D Tier 2Document2 pagesLD36D Tier 2majuindonesia972No ratings yet

- 22-DS-R-008 Rev 0 P 2460 A-B Utility Water PumpDocument3 pages22-DS-R-008 Rev 0 P 2460 A-B Utility Water PumpChike NwachukwuNo ratings yet

- Medium Pressure Filters Models 15CN, 40CN, 80CN: P A G EDocument7 pagesMedium Pressure Filters Models 15CN, 40CN, 80CN: P A G EHidralteka SandelisNo ratings yet

- Pump MDSDocument2 pagesPump MDSVipul GandhiNo ratings yet

- Angular Gripper-Cam Driven Series-HeadingDocument2 pagesAngular Gripper-Cam Driven Series-HeadingBe HappyNo ratings yet

- Product Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Document1 pageProduct Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Joe CruzNo ratings yet

- Engineering: GREAT SolutionsDocument4 pagesEngineering: GREAT SolutionsPeter RhoadsNo ratings yet

- 182590-615ASTRO-N7 CHSM72NDGF-BH 2382x1134x30 EN 20230802Document2 pages182590-615ASTRO-N7 CHSM72NDGF-BH 2382x1134x30 EN 20230802Gilberto SousaNo ratings yet

- Wilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetDocument2 pagesWilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetTrung Trần MinhNo ratings yet

- 6'' VMG-55DVHX2Document1 page6'' VMG-55DVHX2REGHIS HaouesNo ratings yet

- Eng DetailsDocument2 pagesEng DetailsSchields PedroNo ratings yet

- 587m3h@105m - SCP 200-560Document4 pages587m3h@105m - SCP 200-560Quynh NguyenNo ratings yet

- CDM 856 WheelloaderweichaiengineDocument1 pageCDM 856 WheelloaderweichaiengineRusmiyanto YantoNo ratings yet

- Dynapac CC122Document2 pagesDynapac CC122Corona CoronaNo ratings yet

- Lonking CDM856 ZFDocument2 pagesLonking CDM856 ZFBagus RusliNo ratings yet

- Shut Off Valve He-D-Midi: Data SheetDocument1 pageShut Off Valve He-D-Midi: Data SheetRichard Rodriguez GarciaNo ratings yet

- Alfa Laval Sru Rotary Lobe Pump Product LeafletDocument5 pagesAlfa Laval Sru Rotary Lobe Pump Product Leafletمصطفى محمدNo ratings yet

- Piston Pumps Hyxooy1-Motor DrivenDocument4 pagesPiston Pumps Hyxooy1-Motor DrivenmapalptsNo ratings yet

- EagleBurgmann HJ92N enDocument4 pagesEagleBurgmann HJ92N enJohnNo ratings yet

- ArgueCard IVR-L 40&65Document2 pagesArgueCard IVR-L 40&65Pulse XNo ratings yet

- CT-1205H-SMT Datasheet - MAGNETIC BUZZER TRANSDUCER - CUI IncDocument3 pagesCT-1205H-SMT Datasheet - MAGNETIC BUZZER TRANSDUCER - CUI IncrstramirezNo ratings yet

- SEIP For 014-AC-101D: Damage History No Service Induced Indication Noticed On Air Cooler None Inspection Area NIL OthersDocument12 pagesSEIP For 014-AC-101D: Damage History No Service Induced Indication Noticed On Air Cooler None Inspection Area NIL OthersThinh NguyenNo ratings yet

- Copeland Scroll (36 PT.) Vilter Single Screw Compressors: Outdoor Condensing Unit (23 PT.) For Industrial RefrigerationDocument4 pagesCopeland Scroll (36 PT.) Vilter Single Screw Compressors: Outdoor Condensing Unit (23 PT.) For Industrial RefrigerationPatiana TereiraNo ratings yet

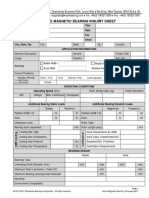

- F048-1 - Active Magnetic Bearing InquiryDocument2 pagesF048-1 - Active Magnetic Bearing Inquiryfrana hadiNo ratings yet

- Brochure Lonking LG 833 NM PDFDocument2 pagesBrochure Lonking LG 833 NM PDFlampardNo ratings yet

- Brochure Lonking LG 833 NM PDFDocument2 pagesBrochure Lonking LG 833 NM PDFlampardNo ratings yet

- 101.1 IntroductiontoALDocument29 pages101.1 IntroductiontoALBassemNo ratings yet

- Series: Pneumatic PumpDocument2 pagesSeries: Pneumatic Pumpadrian hernandezNo ratings yet

- XMP Data Sheet PackerDocument2 pagesXMP Data Sheet PackerAli AliNo ratings yet

- Rod Lift - Sys & EquipDocument12 pagesRod Lift - Sys & EquipHimanshu KesarwaniNo ratings yet

- 22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecDocument48 pages22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecChike NwachukwuNo ratings yet

- Handpump-HHP-700 BarDocument2 pagesHandpump-HHP-700 BartruongNo ratings yet

- Tapered Roller Bearings, Single Row, Metric BearingsDocument1 pageTapered Roller Bearings, Single Row, Metric BearingsMapleNo ratings yet

- Dynapac CA4000 DCO Dynapac CA4000 DCO: Single Drum Vibratory Rollers Single Drum Vibratory RollersDocument2 pagesDynapac CA4000 DCO Dynapac CA4000 DCO: Single Drum Vibratory Rollers Single Drum Vibratory Rollersabdelrhmangbr86No ratings yet

- 014-AC-101A (Rev 01)Document22 pages014-AC-101A (Rev 01)Thinh NguyenNo ratings yet

- Practical Well Log Standards For Acquisition Curves: Paul Maton, POSC Jim Theriot, POSC Alan Doniger, POSC April 2005Document16 pagesPractical Well Log Standards For Acquisition Curves: Paul Maton, POSC Jim Theriot, POSC Alan Doniger, POSC April 2005ariosabzNo ratings yet

- High-Pressure Pump: Under The Scenes of Our LivesDocument5 pagesHigh-Pressure Pump: Under The Scenes of Our Lives김기준No ratings yet

- MTX CM300.1 PC EN V3 0916 - ReadersDocument16 pagesMTX CM300.1 PC EN V3 0916 - Readersjuan perez mendezNo ratings yet

- Articulating Wheel Loader Price ScheduleDocument8 pagesArticulating Wheel Loader Price ScheduleBidawi ZubirNo ratings yet

- DG2/40 HS: Flat Transmission Belts Technical Data SheetDocument2 pagesDG2/40 HS: Flat Transmission Belts Technical Data Sheetdirkz26No ratings yet

- PQS Catalogue 4 2Document143 pagesPQS Catalogue 4 2sagarNo ratings yet

- 6 1 Maxima and MinimaDocument10 pages6 1 Maxima and MinimaSebastian GarciaNo ratings yet

- Myplan Assessment Skills Profiler Report Summary AnalysisDocument5 pagesMyplan Assessment Skills Profiler Report Summary Analysisapi-338283524No ratings yet

- Useful C Library FunctionDocument31 pagesUseful C Library FunctionraviNo ratings yet

- Siemens 6SL31622AA000AA0 CatalogDocument20 pagesSiemens 6SL31622AA000AA0 CatalogIrfan NurdiansyahNo ratings yet

- Infoblatt Skischulen Trends Port eDocument18 pagesInfoblatt Skischulen Trends Port eAustrian National Tourism BoardNo ratings yet

- Science9 Q3 SLM1Document15 pagesScience9 Q3 SLM1Zandra Musni Delos ReyesNo ratings yet

- Theories of GrowthDocument33 pagesTheories of Growthdr parveen bathlaNo ratings yet

- Compuware DCRUM Intro 2012 Version 12.00Document142 pagesCompuware DCRUM Intro 2012 Version 12.00JanNo ratings yet

- Internet in My LifeDocument4 pagesInternet in My LifeАндріана ПрусNo ratings yet

- Practical Econometrics Data Collection Analysis and Application 1st Edition Hilmer Test BankDocument27 pagesPractical Econometrics Data Collection Analysis and Application 1st Edition Hilmer Test Bankdavidhallwopkseimgc100% (28)

- PriceDoxy 09 September 2011Document56 pagesPriceDoxy 09 September 2011Elena OltuNo ratings yet

- Hurricanes Reading Comprehension FreebieDocument20 pagesHurricanes Reading Comprehension FreebieAlex WaddellNo ratings yet

- Robe Draft Geotechnical Report - Edited by k2nDocument43 pagesRobe Draft Geotechnical Report - Edited by k2nASAMNEW GULILATNo ratings yet

- Installing Go Language in UbuntuDocument3 pagesInstalling Go Language in UbuntupanahbiruNo ratings yet

- AMST 398 SyllabusDocument7 pagesAMST 398 SyllabusNatNo ratings yet

- Module 1 Learning PrinciplesDocument2 pagesModule 1 Learning PrinciplesAngela Agonos100% (1)

- Adobe Scan 23-Feb-2024Document4 pagesAdobe Scan 23-Feb-2024muzwalimub4104No ratings yet

- Stacy Frysinger - Him ExperienceDocument2 pagesStacy Frysinger - Him Experienceapi-250552115No ratings yet

- 1st Quarter 2016 Lesson 5 Powerpoint With Tagalog NotesDocument25 pages1st Quarter 2016 Lesson 5 Powerpoint With Tagalog NotesRitchie FamarinNo ratings yet

- Ssi-199-22 D Vikran Dolphin Rev.1Document2 pagesSsi-199-22 D Vikran Dolphin Rev.1ANGEL ANTONIO GUTIERREZ CONTRERASNo ratings yet

- Philippines and Singapore Trade Relations and Agreements: 1. What Leads To Said Agreement?Document11 pagesPhilippines and Singapore Trade Relations and Agreements: 1. What Leads To Said Agreement?Ayrah Erica JaimeNo ratings yet

- MP CRPDocument2 pagesMP CRPankutupanaNo ratings yet