Professional Documents

Culture Documents

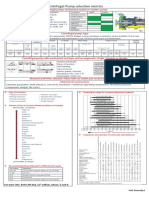

Centrifugal Pump Infographics

Uploaded by

Halimi AyoubCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centrifugal Pump Infographics

Uploaded by

Halimi AyoubCopyright:

Available Formats

Centrifugal Pump Infographics

Mechanical

Key components Impeller Casing Shaft

Seal

Bearings

Key aspects over entire life cycle of Selection Design

Manufacturing installation and Maintenance Operation and

and testing commissioning and overhaul control

pump

Highly reliable, Smooth / Less space /

Simple Wide operating

Advantages over other technology construction

Low

range

Steady non- Smaller

maintenace pulsating flow footprint

Not suitable Constant,

More Priming is

Disadvantages over other technology Less efficient

Expensive

for high accurate flow

necessary

viscocity is not possible

Mechanical

Classification based on hydraulics output Radial flow Mixed flow Axial flow

Seal

Bearings

Pump types as per API 610 Overhung Between bearing Verticle suspended

Engineered Pump

Classifications 6 subtypes 5 Subtypes 7 Subtypes

API 610 ISO 2858, 9905,

ASME B73.1, 73.2, Various ANSI / HI

Applicable international standards API 685

5199, 9908, 13709,

73.3 standard

15783

Special-

Impeller construction types Closed Semi-open Closed

engineered

Volute (Single

Casing design Vortex Diffuser Special

/Double)

Process end shaft Sealing arrangement Gland packing Mechanical Seal Sealless Pump

10.2×𝑃 𝐹𝑙𝑜𝑤 𝑋 ℎ𝑒𝑎𝑑 𝑋 𝑆𝑔

3 ∗ 𝑉𝐼 𝑐𝑜𝑠Ø

Key formulas to assess performance Head=

𝑆𝐺

Phyd=

367

𝑅𝑎𝑡𝑒𝑑 𝐾𝑊 =

1000

Static pressure

Vapor pressure Suction head Friction head

Important components of NPSH available head

at suction

or lift in suction

Velocity Head

source

Low flow High flow Suction starvation Change in fluid

Major operational issues instability instability and Cavitation characteristic

Performance High Abnormal Excessive

Symptoms indicate pump problem issue vibration sound temperature

Leakages

Bent saft /

Dynamic

Major sources of high vibrations unbalance

Mis-alignment excessive run Flow induced Bearing fault

out

Turbulance and Damaged

Major sources of abnormal sound Cavitation

recirculation bearings

Coupling

Rolling element - Radial Hydrodynamic radial and Hydrodynamic - Radial

Bearing types and Thrust rolling element thrust and thrust

Simple Gas seal

Sealing of bearing housing Lip Seal

labyrinth seal

Bearing isolator

(Sealess pump)

Electric Steam

Driver type Gas Turbine Engine

motor turbine

Flexible Rigid Coupling

Power transmission mechanism Direct drive

coupling coupling with Gearbox

Index to evaluate pump design, Suction

Specific speed Shaft stiffness Energy density

performance and reliability specific speed

Suction Lubrication

Healthieness of Strainer

Critical start up check points pressure and Venting

Seal plan cleanliness

quality and

temperature quantity

Suction Total flow Lube

DP. across Discharge Vibration

Pump health check-up parameters pressure

strainer pressure

and input

trends

quality and

and Temp. currant quantity

High

Extremmaly Slurry or highly Light Cryogenic

Challenging applications temperature

High pressure viscous fluid hydrocarbon service

(water or HC)

Seal chamber Impeller back

Wear ring Shaft axial /

Important assembly check points Shaft runout concentricity

clearances

vane / front

radial float

and squareness vane gap

Installation and Energy and Maintenence and

Main components of Life cycle costs Initial cost

commissioning cost operational cost repair cost

Flowserve Sulzer KSB ITT Goulds Sundyne Ruhrpumpen

Key Global player

Grundfos Wilo Weir Ebara Clydeunion SPX

Prepared by: Kirit Domadiya

You might also like

- Centrifugal Pump Infographics: Gland Packing Mechanical Seal Sealless PumpDocument1 pageCentrifugal Pump Infographics: Gland Packing Mechanical Seal Sealless PumpKIESSENo ratings yet

- 587m3h@105m - SCP 200-560Document4 pages587m3h@105m - SCP 200-560Quynh NguyenNo ratings yet

- Power Sonic - PSH-12180FR - DatasheetDocument2 pagesPower Sonic - PSH-12180FR - DatasheetNaitsirch VillegasNo ratings yet

- Wilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetDocument2 pagesWilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetTrung Trần MinhNo ratings yet

- HAITIANMARS2MA GTech20150608Document6 pagesHAITIANMARS2MA GTech20150608Hau TranNo ratings yet

- Bomwebara DieselDocument6 pagesBomwebara DieselTrần Văn ĐạiNo ratings yet

- Santorq ST Series Rev1Document5 pagesSantorq ST Series Rev1rupeshp1989No ratings yet

- RR-Heavy Duty-Main Page 1Document1 pageRR-Heavy Duty-Main Page 1Be HappyNo ratings yet

- Guidelines 0n Pump Vibration First Edition Final July 2013Document5 pagesGuidelines 0n Pump Vibration First Edition Final July 2013Theophilus ThistlerNo ratings yet

- Centrifugal Pumps VibrationDocument5 pagesCentrifugal Pumps VibrationdachrydaxNo ratings yet

- Diaphragm Pump Catalogue Lubrification 2019Document1 pageDiaphragm Pump Catalogue Lubrification 2019Abass BilaNo ratings yet

- Rotary Motions RR-Heavy DutyDocument8 pagesRotary Motions RR-Heavy DutyLucas Vinícius CostaNo ratings yet

- P-807AB - Diesel Fire Water Pump - PISO 100-315H - 125 - 2Document12 pagesP-807AB - Diesel Fire Water Pump - PISO 100-315H - 125 - 2anis.fuad2501No ratings yet

- Catalog DELTA VFD VJDocument28 pagesCatalog DELTA VFD VJmr.zinnguyen36No ratings yet

- Centrifugal Pumps Selection MatrixDocument1 pageCentrifugal Pumps Selection MatrixAli HabibNo ratings yet

- Centrifugal Pump Selection - 230409 - 003734Document2 pagesCentrifugal Pump Selection - 230409 - 003734Yasir NadeemNo ratings yet

- Flex Pump 47Document2 pagesFlex Pump 47Alex Castañeda100% (1)

- KS Vertical Split Coupled CatalogDocument20 pagesKS Vertical Split Coupled CatalogAugusto Alcaraz UgarteNo ratings yet

- Standard Motor CatalogDocument230 pagesStandard Motor CatalogPedro Alva Arce100% (1)

- Roboshot at + Series: High-Performance, High-Reliability and High-Productivity Electric Injection Molding MachineDocument12 pagesRoboshot at + Series: High-Performance, High-Reliability and High-Productivity Electric Injection Molding MachineLeandro SalvadorNo ratings yet

- Fedco HPB 160 LDocument1 pageFedco HPB 160 LIMPARFUME88No ratings yet

- Automax Valve Automation Systems: Pneumatic Actuators and AccessoriesDocument24 pagesAutomax Valve Automation Systems: Pneumatic Actuators and AccessoriesSiddharth VNo ratings yet

- Automax Valve Automation Systems: Pneumatic Actuators and AccessoriesDocument24 pagesAutomax Valve Automation Systems: Pneumatic Actuators and AccessoriesLuis Guillermo BlandónNo ratings yet

- Automax Valve Automation Systems: Pneumatic Actuators and AccessoriesDocument24 pagesAutomax Valve Automation Systems: Pneumatic Actuators and AccessoriesJUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Hydraulic Tube Bender: Series HTB & HTB-A Operation and Maintenance ManualDocument4 pagesHydraulic Tube Bender: Series HTB & HTB-A Operation and Maintenance ManualLord KrsnikNo ratings yet

- 220 PasDocument2 pages220 PasGerardo ChairezNo ratings yet

- Valvula Belimo F780hdu - GMX24-MFT-X1Document5 pagesValvula Belimo F780hdu - GMX24-MFT-X1Lionel ZacharonokNo ratings yet

- Hydron Servo Catalogue 100 To 450 TDocument7 pagesHydron Servo Catalogue 100 To 450 TabhishekNo ratings yet

- Hypac C 766 C 778Document4 pagesHypac C 766 C 778Dave100% (1)

- Tatsuno Sunny GL - 2018Document7 pagesTatsuno Sunny GL - 2018warung1bensinNo ratings yet

- Series: Servo Energy Saving Injection Molding MachineDocument8 pagesSeries: Servo Energy Saving Injection Molding MachineJosé TorricoNo ratings yet

- ISIC Heavy Duty Pneumatic ActuatorDocument14 pagesISIC Heavy Duty Pneumatic Actuatoraizat91.acisNo ratings yet

- Weatherford Artificial Lifts Progressing Cavity Pumping Systems PDFDocument12 pagesWeatherford Artificial Lifts Progressing Cavity Pumping Systems PDFFan JackNo ratings yet

- Robbins 34RH: Low Profile Raiseboring Machine For Holes Ranging From 0.6 To 1.5 M in DiameterDocument5 pagesRobbins 34RH: Low Profile Raiseboring Machine For Holes Ranging From 0.6 To 1.5 M in DiameterIng del PeleNo ratings yet

- API Verses Non APIDocument19 pagesAPI Verses Non APIsandeshNo ratings yet

- SIMOVERT MASTERDRIVES Low Voltage Converters enDocument2 pagesSIMOVERT MASTERDRIVES Low Voltage Converters enEduardo Jose UribeNo ratings yet

- Ar enDocument8 pagesAr enthanhNo ratings yet

- P1PD Medium Pressure Axial Piston Pumps-HY28-2665-01 - P1 - ENDocument72 pagesP1PD Medium Pressure Axial Piston Pumps-HY28-2665-01 - P1 - ENJuan Carlos CastroNo ratings yet

- Fixed Displacement Radial Piston Pump: Replaces: 03.95Document16 pagesFixed Displacement Radial Piston Pump: Replaces: 03.95kamalNo ratings yet

- 2019-2020 Resource Guide and Parts CatalogDocument140 pages2019-2020 Resource Guide and Parts CatalogRafael RafaelNo ratings yet

- 2A.I - Panel 1 - Hariram Subramanian - HuaweiDocument2 pages2A.I - Panel 1 - Hariram Subramanian - HuaweiMNo ratings yet

- ds2001 PDFDocument3 pagesds2001 PDFGiancarloNo ratings yet

- Oleo Buffer Stop Hydraulic FrictionDocument2 pagesOleo Buffer Stop Hydraulic FrictionShahryarNo ratings yet

- Doosan BR15-18J-5 BrochureDocument4 pagesDoosan BR15-18J-5 BrochureMuhammad SohailNo ratings yet

- P1PD Medium Pressure Axial Piston Pumps-HY28-2665-01 - P1 - ENDocument68 pagesP1PD Medium Pressure Axial Piston Pumps-HY28-2665-01 - P1 - ENGilson RodriguesNo ratings yet

- PDS en-MY 20220422Document2 pagesPDS en-MY 20220422Arif ZakuanNo ratings yet

- Oleo Buffer Stop Fixed HydraulicDocument2 pagesOleo Buffer Stop Fixed HydraulicShahryarNo ratings yet

- Motor Grader PDFDocument10 pagesMotor Grader PDFLianNo ratings yet

- SBI Ball GuideDocument38 pagesSBI Ball Guidenamrata kNo ratings yet

- Unistar: High Capacity Soil SeparatorDocument6 pagesUnistar: High Capacity Soil SeparatorFabianoNo ratings yet

- 00 Introduction - Spare Systems - Repair Services For Hydraulic & Pneumatic ComponentsDocument1 page00 Introduction - Spare Systems - Repair Services For Hydraulic & Pneumatic ComponentsKaran AgrawalNo ratings yet

- TECS-WL-M Modular Water-Cooled Oil-Free Centrifugal Chiller B212 CCU 01-03-2019 EN-SHDocument7 pagesTECS-WL-M Modular Water-Cooled Oil-Free Centrifugal Chiller B212 CCU 01-03-2019 EN-SHxuyen tranNo ratings yet

- Gerotor Research Maha PDFDocument25 pagesGerotor Research Maha PDFVladimir KarichkovskyyNo ratings yet

- Ultra Lightweight: Drilling PumpDocument2 pagesUltra Lightweight: Drilling PumpJimy BarronNo ratings yet

- 70ziv 2Document12 pages70ziv 2DaniNo ratings yet

- Flyer AL-267 A4 en WebDocument2 pagesFlyer AL-267 A4 en WebPhyoe Wai AungNo ratings yet

- Ps 10 6 Ea4 PDFDocument4 pagesPs 10 6 Ea4 PDFYeisson Beltran AquinoNo ratings yet

- Super II Max Rate Sell Sheet (LITSUPIIMX17)Document2 pagesSuper II Max Rate Sell Sheet (LITSUPIIMX17)Faisal Ba-AgeelNo ratings yet

- Field Production EngineeringDocument71 pagesField Production EngineeringMoujahed FaresNo ratings yet

- Contact Type in Oil and Gas - 1Document5 pagesContact Type in Oil and Gas - 1Halimi AyoubNo ratings yet

- Awp CertificateDocument1 pageAwp CertificateHalimi AyoubNo ratings yet

- Process CapabilityDocument13 pagesProcess CapabilityHalimi AyoubNo ratings yet

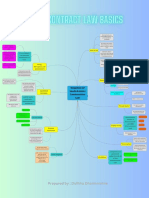

- KSA Construction Law BasicsDocument1 pageKSA Construction Law BasicsHalimi AyoubNo ratings yet

- HARTDocument10 pagesHARTHalimi AyoubNo ratings yet

- Motor Starting PDF-1Document35 pagesMotor Starting PDF-1Halimi AyoubNo ratings yet

- Technical Note Plugged Impulse Line Detection Rosemount 3051s Advanced Diagnostics en Us 4232882Document10 pagesTechnical Note Plugged Impulse Line Detection Rosemount 3051s Advanced Diagnostics en Us 4232882Halimi AyoubNo ratings yet

- General Specifications: Integrated Production Control System CENTUM VP SystemDocument37 pagesGeneral Specifications: Integrated Production Control System CENTUM VP SystemHalimi AyoubNo ratings yet

- Spartan Controls Challenges of Burner Management System ApplicationsDocument12 pagesSpartan Controls Challenges of Burner Management System ApplicationsHalimi AyoubNo ratings yet

- Xxiv Paper 24Document10 pagesXxiv Paper 24Halimi AyoubNo ratings yet

- CAMS Outline Rev 1.2Document2 pagesCAMS Outline Rev 1.2Halimi AyoubNo ratings yet

- Synthesis of Isoamyl Acetate PDFDocument4 pagesSynthesis of Isoamyl Acetate PDFJenny MorenoNo ratings yet

- Technical Specification: Product Name: Eltesol SC 40/sodium Cumene SulphonateDocument1 pageTechnical Specification: Product Name: Eltesol SC 40/sodium Cumene SulphonateMOGES ABERANo ratings yet

- Engineering Physics Questions and AnswersDocument95 pagesEngineering Physics Questions and AnswersSheambom Nelson100% (1)

- Colegio de San Sebastian Sablayan, Occidental Mindoro: Fluid MechanicsDocument16 pagesColegio de San Sebastian Sablayan, Occidental Mindoro: Fluid MechanicsSanta mariaNo ratings yet

- MATS Mod 3 Lec 4Document27 pagesMATS Mod 3 Lec 4Tim WuNo ratings yet

- Hazardous Waste ManagementDocument20 pagesHazardous Waste ManagementYuki SalemNo ratings yet

- 4CzIPN T Bu-Catalyzed Proton-Coupled Electron Transfer For Photosynthesis of Phosphorylated N HeteroaromaticsDocument9 pages4CzIPN T Bu-Catalyzed Proton-Coupled Electron Transfer For Photosynthesis of Phosphorylated N HeteroaromaticsLalchan MiahNo ratings yet

- Ix-Practice Paper-Science-Set-1Document5 pagesIx-Practice Paper-Science-Set-1Ch Saswat SamalNo ratings yet

- Exercise6 Stripper SolutionDocument8 pagesExercise6 Stripper SolutionHoney AlarconNo ratings yet

- Approach TemperaturesDocument4 pagesApproach TemperaturesrutabawellarsNo ratings yet

- Buoyancy and StabilityDocument56 pagesBuoyancy and StabilityJuan Sebastian Varela SanabriaNo ratings yet

- Karakteristik Bioplastik Alginat Dari Rumput Laut Ulva Lactuca (Tinjauan Suhu Dan Lama Gelatinisasi)Document8 pagesKarakteristik Bioplastik Alginat Dari Rumput Laut Ulva Lactuca (Tinjauan Suhu Dan Lama Gelatinisasi)Yugi mutouNo ratings yet

- 8 - Bhattiacademy - Com - Physics - 7. Kips Acadmy (Objective) PDFDocument17 pages8 - Bhattiacademy - Com - Physics - 7. Kips Acadmy (Objective) PDFmalik bilal ahmad0% (1)

- Material Engineeringg CeramicsDocument36 pagesMaterial Engineeringg CeramicsAndy WidyasayogoNo ratings yet

- Chapter 2 Structure of AtomDocument48 pagesChapter 2 Structure of AtomRehan AhmadNo ratings yet

- High-Temperature Tensile and Creep Data For Inconel 600Document13 pagesHigh-Temperature Tensile and Creep Data For Inconel 600Gustavo Alonso Luévanos Arizmendi100% (1)

- Primer Mixes Composition and Behaviour.: Marco MorinDocument15 pagesPrimer Mixes Composition and Behaviour.: Marco Morin9976382No ratings yet

- Yang Et Al. (2011) PDFDocument7 pagesYang Et Al. (2011) PDFLucas SantosNo ratings yet

- DNV Software: Chapter 2: Performing A Worst-Case AnalysisDocument36 pagesDNV Software: Chapter 2: Performing A Worst-Case AnalysisprashantNo ratings yet

- Engineering Thermodynamics - A Computer Approach (SI Units Version) - R. K. Rajput PDFDocument431 pagesEngineering Thermodynamics - A Computer Approach (SI Units Version) - R. K. Rajput PDFShahzad Ali RanaNo ratings yet

- Air Conditioner: Service ManualDocument81 pagesAir Conditioner: Service ManualLenka CapovaNo ratings yet

- Cambridge IGCSE™: Biology 0610/61 May/June 2022Document9 pagesCambridge IGCSE™: Biology 0610/61 May/June 2022Bashir SsekalegaNo ratings yet

- NPSHDocument17 pagesNPSHcrazynup100% (2)

- Choice and Analysis of The Launcher Interface Optimal Solution For AnDocument5 pagesChoice and Analysis of The Launcher Interface Optimal Solution For AnAntonio Pérez AlonsoNo ratings yet

- Safety Data Sheet: Dimethylaminopropylamine (DMAPA)Document7 pagesSafety Data Sheet: Dimethylaminopropylamine (DMAPA)harris fikrenNo ratings yet

- Aiman Shukri Exp 3Document10 pagesAiman Shukri Exp 3zaizilan69No ratings yet

- Astm D129Document1 pageAstm D129Sylab InstrumentsNo ratings yet

- 1bcd PDFDocument12 pages1bcd PDFAlonso Aguilar SalasNo ratings yet

- ,. Treatment: NALCO 4f554Document2 pages,. Treatment: NALCO 4f554ChanBoonChewNo ratings yet

- 1 Introduction To Heat TransferDocument12 pages1 Introduction To Heat TransferAli RazaNo ratings yet