Professional Documents

Culture Documents

Steps Item Calculation or Reference Value: PT Cipta Beton Sinar Perkasa

Steps Item Calculation or Reference Value: PT Cipta Beton Sinar Perkasa

Uploaded by

Bengkulu BetonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steps Item Calculation or Reference Value: PT Cipta Beton Sinar Perkasa

Steps Item Calculation or Reference Value: PT Cipta Beton Sinar Perkasa

Uploaded by

Bengkulu BetonCopyright:

Available Formats

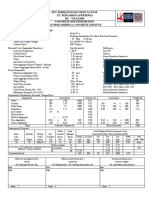

PT CIPTA BETON SINAR PERKASA Standard Practice for Selecting Proportions for

Pabrik Campuran Beton Jadi & Kontraktor LABORATORY

Jl. Garuda No. 45 A , Telp. / Fax : 0431 - 8802225 Normal, Heavyweight, & Mass Concrete (ACI 211.1-91) DEVISION BATCHING

Kec. Wenang, Manado 95112 - Sulawesi Utara PLANT

Plant : Jl. Ring Road Method by Volume

STEPS ITEM CALCULATION OR REFERENCE VALUE

1 1.1 Mix Identification PT. Putra Morowali Sejahtra 001

1.2 Cubical Strength fc' (MPa) 300

ACI 318-95, Table 5.3.2.2 - Required average compressive strength

1.3 Margin 45 74

when data are hot availeble to establish a standard deviation

1.4 Target Mean Strength (Cylinderical) fcr' (MPa) = fc'+sd*1.645 374

1.5 Cement Tonasa Original Portland Cement (OPC) Type I

1.6 Aggregate Characteristics Kema size 30.5mm Kinilow size 19,0mm Sand Dust

Specific Gravity 2.84 2.84 2.55 2.55

SPGR 2.84 2.55

% Water Absorption 0.98% 0.98% 3.77% 3.77%

Fineness Modulus 7.10 6.87 2.88 2.80

Dry Rodded Unit Weight 1547 1547 2.88

Average 1,547 Kg/m3 1545 Kg/m3

2 Mess Concrete Temperature ACI 305 R - Hot Weather Concreting 35 ⁰C

3 Target Slump 100 ± 20 mm

Table 6.3.3 - Approximate mixing water and air content requirements

Nominal Size of Aggregate for different slumps and nominal maximum sizes of aggregates 19.0 mm

Entrapped Air in non-air entrained concrete Measured in accordance with ASTM C 231, C 173, or C 138. 2.0%

†Air-content tolerance is ±1-1/2%.

Required Mixing Water 190 kg/m3

Because it uses an admixture that reduces water Water Reducing 0.0 %

consumption (Water) 0.00 kg

Admixture Consol SG Type D 0.00% Dosage 0.15% - 0.5% by Weight of Cement ASTM C 494 0.00 kg/m3

Admixture Consol P200 Type F 0.00% Dosage 0.8% - 2% by Weight of Cement ASTM C 494 - kg/m3

Mixing Water Corrected 188 kg/m3

Table 6.3.4(a) - Relationship between water - cement or water

4 Water/Cement Ratio 0.47 %

cementitious materials ratio and compressive strength of concrete

5 Cement Content 188.0 /0,52 400 kg/m3

Silica Fume - dosage 3% s/d 15% 0% ACI 234 R-96 Sheet 23 - 5.3.7 Sulfate Resistance 0 kg/m3

Cementitious 400 kg/m3

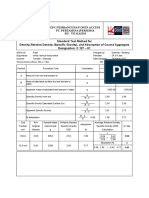

6 Quantity of Coarse Agg. Per unit vol. of concrete Table 6.3.6 - Vol.of coarse agg. per unit of vol.of concrete 0.66

* The required Dry Mass is , therefore 0.66 x 1547 1021.0 kg/m3

Volume Correction faktor Dry Rooded CA 1021.02 x 1 1021.0 kg/m3

7 Required Fine Aggregate * With the quantity of Water, Cement & Coarse Agg established

7.1. The Sand Content can be Calculated by Absolute Volume Basis

Volume of ingredients of the concrete per cubic meter Volume of water 188.00 x 1000 0.188 m3

is calculated as follows Solid volume of cement 400.00 / 3,14 x 1000 0.127 m3

Solid volume of Fume 0.00 / 2,2 x 1000 - m3

Solid volume of Admixture Type D 0.00 / 1,16 x 1000 0.000 m3

Solid volume of Admixture Type F 0.00 / 1,17 x 1000 - m3

Solid volume of Coarse aggregate 1021.02 / 2,54 x 1000 0.360 m3

Volume of entrapped air 0.02 x 1 0.020 m3

Total solid vol. of ingredients except fine agg. Sum = 0.695 m3

7.2. Solid volume of fine aggregate is therefore 1 - 0.695 0.305 m3

7.3. Required weight of fine aggregate 0.305 x 2,55 x 1000 778.00 Kg

8 Batch masses per cubic meter of concrete K,300 Water (net mixing) 188 Kg

Amount of Cement 400 Kg

Silica Fume - Kg

Admixture Consol SG Type D - L

Admixture Consol P200 Type F - L

Combined - Particle Size - 30.5mm 0% Weight coarse aggregate(G1) - Kg

- Particle Size - 19.0mm 100% Weight coarse aggregate(G2) 1021 Kg

Over Size % Comulative passing sieve 9.5mm 100% Weight fine aggregate Sand 778 Kg

% Comulative passing sieve 9.5mm 100% Weight fine aggregate Dust 0 Kg

Table 6.3.7.1 - First estimate of weight of fresh concrete 2387 Kg/m3

Prepared and Tested by Witnessed and Checked by Witnessed and Approved by

Date Sign Date Sign Date Sign

Name Name Name

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Concrete LabDocument43 pagesConcrete LabBengkulu BetonNo ratings yet

- Agg CTBCDocument2 pagesAgg CTBCBengkulu BetonNo ratings yet

- GRadasi FRaksiDocument6 pagesGRadasi FRaksiBengkulu BetonNo ratings yet

- Mix ACI by Volume Buat ArdiDocument1 pageMix ACI by Volume Buat ArdiBengkulu BetonNo ratings yet

- Cv. Zhafirah Mulia MandiriDocument15 pagesCv. Zhafirah Mulia MandiriBengkulu BetonNo ratings yet

- Epc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteDocument4 pagesEpc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteBengkulu BetonNo ratings yet

- 3.4 Concrete Mix Design Using ACI FormatDocument6 pages3.4 Concrete Mix Design Using ACI FormatBengkulu BetonNo ratings yet

- Consol SG: Water Reducing and Set Retarding Concrete AdmixtureDocument1 pageConsol SG: Water Reducing and Set Retarding Concrete AdmixtureBengkulu BetonNo ratings yet

- Monitoring Pengecoran 2022-2023Document8 pagesMonitoring Pengecoran 2022-2023Bengkulu BetonNo ratings yet

- ASTM C 28 Berat Jenis PasirDocument3 pagesASTM C 28 Berat Jenis PasirBengkulu BetonNo ratings yet

- ASTM C 27 Berat Jenis KerikilDocument1 pageASTM C 27 Berat Jenis KerikilBengkulu BetonNo ratings yet

- ASTM C 566 Kadar AirDocument2 pagesASTM C 566 Kadar AirBengkulu BetonNo ratings yet

- Mix Design (Aci - Method)Document14 pagesMix Design (Aci - Method)Bengkulu BetonNo ratings yet

- Epc Pembangunan Open Access Di Pt. Pertamina (Persero) Ru-Vii KasimDocument3 pagesEpc Pembangunan Open Access Di Pt. Pertamina (Persero) Ru-Vii KasimBengkulu BetonNo ratings yet

- Studi Pengaruh Penambahan Roadcel-50 Terhadap Karakteristik Campuran Lapis Tipis Beton Aspal (HRS-WC)Document15 pagesStudi Pengaruh Penambahan Roadcel-50 Terhadap Karakteristik Campuran Lapis Tipis Beton Aspal (HRS-WC)Bengkulu BetonNo ratings yet

- Mortar BusaDocument164 pagesMortar BusaBengkulu BetonNo ratings yet