Professional Documents

Culture Documents

Technical Documentation Material PMMA July 2021

Uploaded by

Naruto UzumakiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Documentation Material PMMA July 2021

Uploaded by

Naruto UzumakiCopyright:

Available Formats

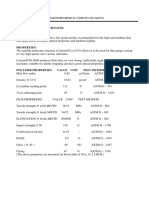

POLY-METHYL METHACRYLATE (PMMA)

Materials recommended by our engineering department and regularly used in production.

Physical and mechanical properties: PMMA is especially known for its exceptional optical properties. This

uncrystallized polymer shows remarkable transparency (92% light transmission) in the visible range from 380 to 780

nm. The angle of total reflection on an inner surface is 41 to 42° (which allows it to be used for making light

"conductors", fiber optic filament ...). Its index of refraction (for λ= 587.6 nm helium) is 1.491, which makes it a material

suitable for manufacturing optical products.

PMMA is an uncrystallized polymer whose vitreous transition temperature ranges from 110 up to 135°C, i.e. at ambient

temperature it is hard, rigid, and brittle with little elongation. PMMA is hygroscopic and, under extreme conditions,

the water absorbed will act as a plasticizer and will modify the properties of the material. Its creep is fairly limited.

When critical stress is exceeded, PMMA is subject to crazing. This phenomenon is even accentuated in the presence

of corrosive agents (alcohol, gasoline ...). Resistance to shock is relatively low and the polymer is brittle. This resistance

can be improved by adding an anti-shock agent. PMMA resists scratching to a good degree under normal conditions

of use. However, when cleaned frequently or used in a dusty environment, it could be scratched. PMMAs are easily

polished.

Chemical properties: PMMA is tasteless and odorless and can, in certain cases, be recognized as being suitable for

use with food. Up to 60°C, PMMA resists fairly well organic acids and diluted minerals as well as diluted alkaline

solutions, but it is attacked by the common products on the list in the table. Its resistance to diminishing light

transmission due to aging is very good.

Acetone Chloroform Naphtha

Alcohol Cyclohexane Nitrobenzene

Thyl alcohol Hydrogen peroxide Petroleum

Ammonia (liquid) Turpentine Phenol

Benzene Hydrocarbon Trichloroethylene

Aircraft fuel Carbon tetrachloride

Liquid chlorine Methanol (30%)

Electrical properties: The electrical properties can be sharply affected by the absorption of humidity. Its resistance to

arcing is excellent. PMMA is electrostatic which can spoil its appearance (attraction of dust). This drawback can be

corrected by using ant-static products.

Thermal properties: PMMA is combustible and burns without producing an excessive amount of smoke (UL 94 HB). Its

retraction when molded is small (0.4 to 0.7%) as for uncrystallized polymers. As its coefficient of linear expansion is very

different from that of metals and its elasticity low, it is not advisable to use metal inserts in a part made of injected

PMMA. The maximum operating temperature is low (< 85° C). Printing and marking properties: PMMA is suitable for

both vacuum-applied metallization and silk-screening.

Implementation properties:

Injection: The high viscosity of PMMA in the melted state requires high injection pressures (up to 1500 bars).

Machining: The machining of PMMA is easy provided that shock and overheating is avoided.

Gluing: As solvent glues release stresses, parts must be annealed (2 to 3 hrs at 80°C). PMMA is easily glued

either with pure solvents (chloroform) or with PMMA dissolved in a solvent.

Welding: PMMA can be readily welded but appearance and solidity are not as good as with gluing. Welding

is limited to high-frequency, hot-gas and ultrasonic welding. PMMA shows good dimensional stability and

limited retraction due to its uncrystallized structure.

Summary by GAGGIONE SAS

Information taken from MATIERE PLASTIQUE NATHAN – SEPTEMBER 2007.

P1

You might also like

- Polyacrylic or Acrylic Resin (Pmma)Document1 pagePolyacrylic or Acrylic Resin (Pmma)Dl Al-azizNo ratings yet

- Properties & Manufacturing & Applications & Limitations of PolymethylmethacrylateDocument4 pagesProperties & Manufacturing & Applications & Limitations of PolymethylmethacrylateRohith RaviNo ratings yet

- TDS Durazane® 1800Document3 pagesTDS Durazane® 1800siaoling.bioNo ratings yet

- Overviews On PMMADocument44 pagesOverviews On PMMANathawat PleumsamranNo ratings yet

- May 2018 Technical Data Sheet: Octyl/Decyl Trimellitate TMC - CDocument1 pageMay 2018 Technical Data Sheet: Octyl/Decyl Trimellitate TMC - CLim Chee SiangNo ratings yet

- ACRALOCK PP 1-02 Karta Techniczna ENGDocument3 pagesACRALOCK PP 1-02 Karta Techniczna ENGJoanna SąsaraNo ratings yet

- Petronas Methanol LabuanDocument18 pagesPetronas Methanol LabuanSheena DovenantNo ratings yet

- LX+MMA+Brochure Polymer ENG 2021 2Document20 pagesLX+MMA+Brochure Polymer ENG 2021 2Andrian EvanNo ratings yet

- Lotrene ® FE8000: Low Density Polyethylene DescriptionDocument2 pagesLotrene ® FE8000: Low Density Polyethylene DescriptionEngr Ali ShaikhNo ratings yet

- Poly Phenylene Oxide (PPO) : Corporate Training and PlanningDocument27 pagesPoly Phenylene Oxide (PPO) : Corporate Training and PlanningAkash YadavNo ratings yet

- N-Methyl-2-Pyrrolidone: CharacteristicsDocument3 pagesN-Methyl-2-Pyrrolidone: CharacteristicsAarfebreNo ratings yet

- Tds Plexus Ma420 EngDocument2 pagesTds Plexus Ma420 EngCarlos SantosNo ratings yet

- Petroleum ResinDocument4 pagesPetroleum Resinkelk200No ratings yet

- FLAMEGARD Line PDFDocument16 pagesFLAMEGARD Line PDFxy2zjgNo ratings yet

- Inver Powderpaint SpecirficationsDocument2 pagesInver Powderpaint SpecirficationsArun PadmanabhanNo ratings yet

- PDS - Ehg250 68 37Document4 pagesPDS - Ehg250 68 37MichaelNo ratings yet

- Astman NPG Glycol: Powder Coating Resin PC-17-4N Based OnDocument4 pagesAstman NPG Glycol: Powder Coating Resin PC-17-4N Based OnRAZA MEHDINo ratings yet

- Thanetop P772: (抗磨、抗塵、抗滑溜) 1.0 DescriptionDocument1 pageThanetop P772: (抗磨、抗塵、抗滑溜) 1.0 DescriptionHelen ChoiNo ratings yet

- 2 - Denture Materials PMMADocument22 pages2 - Denture Materials PMMAMohamedAliNo ratings yet

- Atlac 430 AOC-konverteret - 1Document3 pagesAtlac 430 AOC-konverteret - 1Gilberto YoshidaNo ratings yet

- PPO SlideDocument29 pagesPPO SlideRadhashyam GiriNo ratings yet

- Presentation Hans Ridderikhoff - BPM Symposium 15-06-2011 SecuredDocument0 pagesPresentation Hans Ridderikhoff - BPM Symposium 15-06-2011 SecuredHugo WizenbergNo ratings yet

- Poly (Methyl Methacrylate) (PMMA) : PropertiesDocument5 pagesPoly (Methyl Methacrylate) (PMMA) : PropertiesizzacahyaNo ratings yet

- Pom, Pet, PC, TpuDocument81 pagesPom, Pet, PC, TpuPreksha AgrawalNo ratings yet

- PMMADocument17 pagesPMMAAnurag KhandelwalNo ratings yet

- Tea PDFDocument2 pagesTea PDFLalit KalraNo ratings yet

- AZ4562 Photresist - TDS PDFDocument3 pagesAZ4562 Photresist - TDS PDFahmed pashaNo ratings yet

- Polymer Preparation:: 1.basic SynthesisDocument20 pagesPolymer Preparation:: 1.basic Synthesiswaqar_baloch_07No ratings yet

- Products For Radiation CuringDocument12 pagesProducts For Radiation CuringJuan Angel DechimaNo ratings yet

- Chlorokote FinishDocument2 pagesChlorokote FinishKhirod KroutNo ratings yet

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typess.mladinNo ratings yet

- PeekDocument23 pagesPeekwamikshahidrizviNo ratings yet

- Iriotec - 8850 - EMD - TDS (For US and Canada) PDFDocument2 pagesIriotec - 8850 - EMD - TDS (For US and Canada) PDFxy2zjgNo ratings yet

- Plastisan BDocument2 pagesPlastisan BJorgeMelguizoNo ratings yet

- Palatal A408-972 (E) For PultrusionDocument1 pagePalatal A408-972 (E) For Pultrusionbourne029No ratings yet

- B-120 LN-enUS-ASTMDocument1 pageB-120 LN-enUS-ASTMEyad AlsheiikhNo ratings yet

- High Durability Print: On Labels That LastDocument2 pagesHigh Durability Print: On Labels That LastHardware 02No ratings yet

- (PR-999) TDS Thermal Etch ResistDocument2 pages(PR-999) TDS Thermal Etch Resistnithu17_4uNo ratings yet

- Unit 10 Methanol To OlefinDocument19 pagesUnit 10 Methanol To Olefinsafavi91No ratings yet

- Road Marking Paints PDFDocument9 pagesRoad Marking Paints PDFThomas Gunawan100% (1)

- Colpoly 736 WAT TDSDocument2 pagesColpoly 736 WAT TDSKristjan PosavecNo ratings yet

- TDS - Premix Marine ThixotropeDocument3 pagesTDS - Premix Marine ThixotropegmNo ratings yet

- Tensan SMT Red Glue TS4109A TDSDocument1 pageTensan SMT Red Glue TS4109A TDSthe hoangNo ratings yet

- Mechster 5310FR: Commitment To Quality and ConsistencyDocument1 pageMechster 5310FR: Commitment To Quality and ConsistencyreinpolyNo ratings yet

- Clearstrength E 920: Product DescriptionDocument8 pagesClearstrength E 920: Product DescriptionHan PhamNo ratings yet

- Mechster 5310 (N) - 300: Commitment To Quality and ConsistencyDocument1 pageMechster 5310 (N) - 300: Commitment To Quality and ConsistencyreinpolyNo ratings yet

- PMMA ReportDocument7 pagesPMMA ReportShubham100% (1)

- Mdpe 3802Document1 pageMdpe 3802Indrajeet DodlaNo ratings yet

- PBT Polybutylene Terephthalate: WWW - Cjpsales.co - UkDocument3 pagesPBT Polybutylene Terephthalate: WWW - Cjpsales.co - UkAndy GilhamNo ratings yet

- Cmt608 PolymerDocument14 pagesCmt608 PolymerNur Yumni ZalikhaNo ratings yet

- 9HS PDS AiDocument4 pages9HS PDS AiHrvoje RuzicNo ratings yet

- Spek-Produk MasterTop TC 941 Pigmented BASFDocument5 pagesSpek-Produk MasterTop TC 941 Pigmented BASFbilly ramadhanNo ratings yet

- Product Selector Z-Fold 210x444 HRDocument2 pagesProduct Selector Z-Fold 210x444 HRm daneshpour0% (1)

- 10EPDM16Aug2012 PDFDocument4 pages10EPDM16Aug2012 PDFTaranom SpNo ratings yet

- Exact Brochure For Your Precise NeedsDocument4 pagesExact Brochure For Your Precise NeedsmaheshgupteNo ratings yet

- Terokal 5089-EN PDFDocument2 pagesTerokal 5089-EN PDFLuis Velasquez SilvaNo ratings yet

- Hunstman Jeffcat CatalystsDocument5 pagesHunstman Jeffcat Catalystssnaps4allNo ratings yet

- Sikafloor - 81 Epocem: 3-Part Cement and Epoxy Combination Mortar For Self-Smoothening Floor Screeds of 1.5 To 3MmDocument10 pagesSikafloor - 81 Epocem: 3-Part Cement and Epoxy Combination Mortar For Self-Smoothening Floor Screeds of 1.5 To 3Mmmuhamadrafie1975No ratings yet

- Defects of Bricks: 2. Defects Due To FungiDocument1 pageDefects of Bricks: 2. Defects Due To FungiRayNo ratings yet

- Development of A Model Code For Direct Displacement Based Seismic Design Calvi 2009Document31 pagesDevelopment of A Model Code For Direct Displacement Based Seismic Design Calvi 2009pouyamhNo ratings yet

- Kevlar Fiber: Devansh GuptaDocument23 pagesKevlar Fiber: Devansh Guptagopal rao sirNo ratings yet

- Processing and Recycling in Mining andDocument2 pagesProcessing and Recycling in Mining andHenockNo ratings yet

- Unit 6 - Week 03: Mass Transfer Coefficient and Interface Mass TransferDocument3 pagesUnit 6 - Week 03: Mass Transfer Coefficient and Interface Mass TransferSandra GilbertNo ratings yet

- Technical Data: Protective Grease For Overhead Line ConductorsDocument3 pagesTechnical Data: Protective Grease For Overhead Line ConductorssreedharNo ratings yet

- Komet Dihart Reamax TS: Modular Reaming SystemDocument8 pagesKomet Dihart Reamax TS: Modular Reaming SystemLuis LopezNo ratings yet

- Internship On Vermicomposting Edit NewDocument12 pagesInternship On Vermicomposting Edit NewApoorva JainNo ratings yet

- 10749-Article Text PDF-30111-3-10-20180322 PDFDocument13 pages10749-Article Text PDF-30111-3-10-20180322 PDFTogi HutaNo ratings yet

- Dot 36734 DS2 PDFDocument122 pagesDot 36734 DS2 PDFArab WeldersNo ratings yet

- Industrial Strainers Filters Y StrainerDocument1 pageIndustrial Strainers Filters Y StrainerEi Ei PhyoNo ratings yet

- Extra Item Rates AnalysisDocument18 pagesExtra Item Rates AnalysisAnish DhillonNo ratings yet

- Test For CARBOHYDRATESDocument7 pagesTest For CARBOHYDRATESSoham N100% (2)

- Composite Stress MethodsDocument47 pagesComposite Stress Methodsluuvandong48xf396No ratings yet

- PlasticsDocument21 pagesPlasticsJaypee MontealegreNo ratings yet

- Class-XII Chemistry: S No Unit Portion To Be ReducedDocument3 pagesClass-XII Chemistry: S No Unit Portion To Be ReducedShivanshu JainNo ratings yet

- Multi Axial Loading - ResourceDocument29 pagesMulti Axial Loading - ResourceEirickTrejozuñigaNo ratings yet

- Zinc Sulfate 35 Maxi Granular Spec Sheet CCIDocument1 pageZinc Sulfate 35 Maxi Granular Spec Sheet CCIricko4001No ratings yet

- Glossary of Terms Used in Galvanizing of SteelDocument11 pagesGlossary of Terms Used in Galvanizing of SteelMaria Ines CastelluccioNo ratings yet

- 2002-4.5 Effect of Shrinkage PDFDocument29 pages2002-4.5 Effect of Shrinkage PDFMy Dad My WorldNo ratings yet

- Potassium ProcessDocument4 pagesPotassium ProcessIda AsyaniNajmaNo ratings yet

- EagleBurgmann - DMS - MSE - E7 - PDF - Cnetic CouplingsDocument10 pagesEagleBurgmann - DMS - MSE - E7 - PDF - Cnetic Couplingsdavid leeNo ratings yet

- UC XLPE CatalogueDocument80 pagesUC XLPE CatalogueNICHOLASNo ratings yet

- What Is Sintering?Document15 pagesWhat Is Sintering?Vu VoNo ratings yet

- Mark Scheme (Final) January 2009: GCE Chemistry (6244/01)Document20 pagesMark Scheme (Final) January 2009: GCE Chemistry (6244/01)Aaisha AfaNo ratings yet

- Single Core Cables To IEC 60502Document12 pagesSingle Core Cables To IEC 60502rose chen100% (1)

- FT Bitumseal enDocument1 pageFT Bitumseal enGerman GonzalezNo ratings yet

- MEM460 Report FoundryDocument7 pagesMEM460 Report FoundrySiti Maizatul AkmaNo ratings yet

- Ed0754a 50a10 Ab4dDocument3 pagesEd0754a 50a10 Ab4dRocco SozeNo ratings yet