Professional Documents

Culture Documents

Applications of Industrial Engineering

Applications of Industrial Engineering

Uploaded by

SuhailShaikhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Applications of Industrial Engineering

Applications of Industrial Engineering

Uploaded by

SuhailShaikhCopyright:

Available Formats

Title: Applications of Industrial Engineering

Introduction

Industrial Engineering (IE) is a branch of engineering that focuses on optimizing complex systems and processes within various

industries. It combines principles from mathematics, science, and engineering to improve efficiency, productivity, and quality in

manufacturing, service, and other sectors. Industrial engineers are the problem solvers of the business world, utilizing their skills to

design, analyze, and implement systems that make organizations run more smoothly and profitably. This essay explores the diverse

applications of industrial engineering across different industries.

Manufacturing Industry

1. Process Optimization: Industrial engineers play a crucial role in manufacturing by optimizing production processes. They use

techniques like Six Sigma and Lean manufacturing to identify bottlenecks, reduce waste, and enhance overall efficiency. This leads to

increased productivity and cost savings.

2. Quality Control: Ensuring product quality is a primary concern in manufacturing. Industrial engineers develop quality control

methods and systems to monitor and maintain product standards, reducing defects and improving customer satisfaction.

3. Inventory Management: Managing inventory is critical for maintaining a balance between supply and demand. Industrial engineers

employ various tools and methodologies to optimize inventory levels, reducing carrying costs while ensuring products are available

when needed.

Service Industry

1. Supply Chain Management: Industrial engineers help service-oriented businesses manage their supply chains efficiently. They

design logistics systems that minimize transportation costs, reduce lead times, and improve the flow of goods and services.

2. Healthcare: In healthcare, IE principles are applied to streamline processes, reduce patient waiting times, and enhance resource

utilization. For instance, optimizing hospital layouts and staff scheduling can significantly improve patient care.

3. Retail: Industrial engineers help retailers optimize store layouts, inventory management, and checkout processes. This leads to

better customer experiences and increased profitability.

Information Technology

1. Software Development: Industrial engineers apply project management techniques to software development projects, ensuring

that they are completed on time and within budget. They also work on improving software development processes to enhance

efficiency.

2. Data Analysis: In data-driven industries, industrial engineers use their analytical skills to make sense of large datasets. They help

organizations extract valuable insights and develop data-driven strategies.

3. Cybersecurity: IE principles can be applied to enhance cybersecurity by designing secure systems and processes, managing risk, and

ensuring data privacy.

Energy and Environmental Management

1. Energy Efficiency: Industrial engineers work on energy management systems to reduce energy consumption in industries. They

design and implement strategies to improve energy efficiency and reduce carbon footprints.

2. Environmental Compliance: Industrial engineers help organizations adhere to environmental regulations by designing processes

that minimize waste, emissions, and resource consumption.

Conclusion

Industrial engineering has a wide range of applications across various industries, and its principles are essential for improving

efficiency, reducing waste, and enhancing quality. Industrial engineers are key contributors to organizational success, whether they

are optimizing manufacturing processes, streamlining service operations, managing information systems, or promoting

sustainability. As technology advances and industries continue to evolve, the role of industrial engineers will remain crucial in

addressing the complex challenges of today's global business environment.

You might also like

- Favoritism in The Workplace and Its Effect On The OrganizationDocument11 pagesFavoritism in The Workplace and Its Effect On The OrganizationSuhailShaikhNo ratings yet

- Operations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationFrom EverandOperations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationNo ratings yet

- Maintenance and Operational Reliability: 24 Essential Building BlocksFrom EverandMaintenance and Operational Reliability: 24 Essential Building BlocksNo ratings yet

- An Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleFrom EverandAn Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleNo ratings yet

- Taguchi on Robust Technology Development: Bringing Quality Engineering UpstreamFrom EverandTaguchi on Robust Technology Development: Bringing Quality Engineering UpstreamRating: 1 out of 5 stars1/5 (1)

- AI in Manufacturing Driving Innovation and Efficiency: A Comprehensive Toolkit for Startups and Maintenance Ladyluck M: 1, #1From EverandAI in Manufacturing Driving Innovation and Efficiency: A Comprehensive Toolkit for Startups and Maintenance Ladyluck M: 1, #1No ratings yet

- Smart Research Questions and Analytical Hints: Manufacturing IndustryFrom EverandSmart Research Questions and Analytical Hints: Manufacturing IndustryNo ratings yet

- Artificial Intelligence & The Transformation of The Global ManufacturerFrom EverandArtificial Intelligence & The Transformation of The Global ManufacturerNo ratings yet

- Maintenance Excellence: Principles, Practices, and Future TrendsFrom EverandMaintenance Excellence: Principles, Practices, and Future TrendsNo ratings yet

- AI for Solutions Architects: Driving Intelligent Solution Design and Implementation: 1, #1From EverandAI for Solutions Architects: Driving Intelligent Solution Design and Implementation: 1, #1No ratings yet

- The Role of Data Management in Building Sustainable AI SystemsFrom EverandThe Role of Data Management in Building Sustainable AI SystemsNo ratings yet

- Optimal Control and Optimization of Stochastic Supply Chain SystemsFrom EverandOptimal Control and Optimization of Stochastic Supply Chain SystemsNo ratings yet

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- Industrial Agents: Emerging Applications of Software Agents in IndustryFrom EverandIndustrial Agents: Emerging Applications of Software Agents in IndustryPaulo LeitãoNo ratings yet

- Facilities Management - The Ultimate Guide: Business Advice & Training, #3From EverandFacilities Management - The Ultimate Guide: Business Advice & Training, #3No ratings yet

- The Management of Additive Manufacturing: Enhancing Business ValueFrom EverandThe Management of Additive Manufacturing: Enhancing Business ValueNo ratings yet

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- Industrial Project Management Decoded: Things I Wish My Boss Would Have Told MeFrom EverandIndustrial Project Management Decoded: Things I Wish My Boss Would Have Told MeNo ratings yet

- Statistical Monitoring of Complex Multivatiate Processes: With Applications in Industrial Process ControlFrom EverandStatistical Monitoring of Complex Multivatiate Processes: With Applications in Industrial Process ControlNo ratings yet

- Industrial Applications of Formal Methods to Model, Design and Analyze Computer SystemsFrom EverandIndustrial Applications of Formal Methods to Model, Design and Analyze Computer SystemsNo ratings yet

- Book Series: Increasing Productivity of Software Development, Part 1: Productivity and Performance Measurement - Measurability and MethodsFrom EverandBook Series: Increasing Productivity of Software Development, Part 1: Productivity and Performance Measurement - Measurability and MethodsNo ratings yet

- Do It Smart: Seven Rules for Superior Information Technology PerformanceFrom EverandDo It Smart: Seven Rules for Superior Information Technology PerformanceRating: 3 out of 5 stars3/5 (1)

- A Study of the Supply Chain and Financial Parameters of a Small BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNo ratings yet

- IoT Standards with Blockchain: Enterprise Methodology for Internet of ThingsFrom EverandIoT Standards with Blockchain: Enterprise Methodology for Internet of ThingsNo ratings yet

- Intelligent Document Processing (IDP): A Comprehensive Guide to Streamlining Document ManagementFrom EverandIntelligent Document Processing (IDP): A Comprehensive Guide to Streamlining Document ManagementNo ratings yet

- Cost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsFrom EverandCost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsNo ratings yet

- Artificial intelligence: AI in the technologies synthesis of creative solutionsFrom EverandArtificial intelligence: AI in the technologies synthesis of creative solutionsNo ratings yet

- History and Development of Industrial EngineeringDocument2 pagesHistory and Development of Industrial EngineeringSuhailShaikhNo ratings yet

- Management Science Its Historical DevelopmentDocument3 pagesManagement Science Its Historical DevelopmentSuhailShaikhNo ratings yet

- The Concept of Industrial Engineering Enhancing Efficiency and ProductivityDocument2 pagesThe Concept of Industrial Engineering Enhancing Efficiency and ProductivitySuhailShaikhNo ratings yet

- The Tools of Management ScienceDocument3 pagesThe Tools of Management ScienceSuhailShaikhNo ratings yet

- Personnel Management Nurturing Human Capital For Organizational SuccessDocument2 pagesPersonnel Management Nurturing Human Capital For Organizational SuccessSuhailShaikhNo ratings yet

- The Role of An Industrial EngineerDocument2 pagesThe Role of An Industrial EngineerSuhailShaikhNo ratings yet

- Network Analysis Unveiling The Hidden Structures of Our Connected WorldDocument2 pagesNetwork Analysis Unveiling The Hidden Structures of Our Connected WorldSuhailShaikhNo ratings yet

- Production Management The Key To Efficient ManufacturingDocument2 pagesProduction Management The Key To Efficient ManufacturingSuhailShaikhNo ratings yet

- The Art and Science of Decision-MakingDocument2 pagesThe Art and Science of Decision-MakingSuhailShaikhNo ratings yet

- Welcome: A Guide To Accessibility ofDocument18 pagesWelcome: A Guide To Accessibility ofSuhailShaikhNo ratings yet

- Production and Productivity Driving Forces of Economic GrowthDocument2 pagesProduction and Productivity Driving Forces of Economic GrowthSuhailShaikhNo ratings yet

- Online Restaurant Delivery Guide To Getting Started: Will You Deliver Yourself?Document1 pageOnline Restaurant Delivery Guide To Getting Started: Will You Deliver Yourself?SuhailShaikhNo ratings yet

- Welcome: A Guide To Accessibility ofDocument18 pagesWelcome: A Guide To Accessibility ofSuhailShaikhNo ratings yet

- 7 Steps To Start Goat Farming Business For ProfitDocument8 pages7 Steps To Start Goat Farming Business For ProfitSuhailShaikhNo ratings yet

- Neha Chauhan (04) Bhawna Pandwar (30) : Presented byDocument47 pagesNeha Chauhan (04) Bhawna Pandwar (30) : Presented bySuhailShaikhNo ratings yet

- Aina - e - Qismat October 2019Document60 pagesAina - e - Qismat October 2019SuhailShaikhNo ratings yet

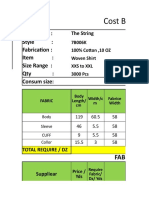

- Costing Sheet For Woven ShirtDocument9 pagesCosting Sheet For Woven ShirtSuhailShaikhNo ratings yet

- Performance Polos Classic PolosDocument37 pagesPerformance Polos Classic PolosSuhailShaikhNo ratings yet

- Biogas Plant Sizes and DimensionsDocument7 pagesBiogas Plant Sizes and DimensionsSuhailShaikhNo ratings yet

- Profile To PrintDocument10 pagesProfile To PrintSuhailShaikhNo ratings yet

- Frequently Asked Questions: RewardDocument6 pagesFrequently Asked Questions: RewardSuhailShaikhNo ratings yet