Professional Documents

Culture Documents

Te 1405 Ea

Uploaded by

statisticssales0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

te1405ea

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageTe 1405 Ea

Uploaded by

statisticssalesCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Antispread E2/50 FE 60

Article No. TE1405

Epilamisation Agent for Metals and Plastics

Product Specifications

Product

Technical Information: cohesive force adhesive force balance of

Function the agent polymerizes on the solid causes total causes total cohesion and

surface on evaporation of its solvent unwetting wetting adhesion

Film Thickness approx. 0.04 µm (E2/50)

Active Ingredient fluorinated polymer (solid) with a

repelling effect on allknown lubricants Antispread reduces the surface tension of the solid as far as

(reduced efficiency with fluorinated silicon oil can´t spread any more. Bearing material

lubes)

apparent slope caused by

Solvent Partially fluorinated ether (FE 60); different surface

(contains no chlorine, does not contain tensions

perfluorinated carbons PFCs) Lubricant creeps to the Anti-

untreated area. spread

Thermal Stability -75 °C to +200 °C layer

(film) [-103 °F to +392 °F] sliding

Density 1.5 g/cm³ at 20 °C [+68 °F] element Application

Epilam layer is removed by Anti-

spread

temperature

Color colorless friction. layer

Boiling Range 30 °C to 60 °C [86 °F to 140 °F] lubricant remains

Anti- within the sliding zone

Ecology GWP = 350 (low global warming potential) spread

ODP = 0 (no ozone depleting potential) layer

ALT = 5 years (atmospheric life time) If possible sliding elements should be allowed to work

Inflammability not inflammable without lubrication for a short time, thus the antispread

layer being removed and the lubricant applicated remaining Bearing load

Toxicology physiologically harmless, if used properly; precisely at the point or area of friction.

details see safety data sheet

Coverage approx. 85 g/m², depending on

method of application and type of parts Directions:

Cleaning surface contaminants, such as corrosion

Compatibility with Plastics (static tests) inhibiting oils, detaching fluids and water

compatible PE, PP, POM, PBT, PA66, PC*, PPOX*, must be removed before using Antispread.

PMMA, ASA*, ABS*, elastomers (butyl-

rubber, natural rubber, EPDM, EPR) Immersing 5-10 seconds at room temperature Sliding speed

*additionally tension crack tests Spraying caution, use only in well ventilated

limited compatible PTFE, silicone rubber (swelling during areas.

longer exposure)

Brushing should be done rapidly. Antispread is

Efficacy on all materials, except PTFE highly volatile!

Stamping a circular stamp can be used to build a

barrier.

Antispread Drying approx. 10 seconds at room temperature. Durability

layer Warm air speeds the process.

zone of low fluorinated

lubricant

(drop)

Application:

surface tension molecules The use of Antispread is recommended for precision and

Antispread for lifetime lubrication in precision machinery. The use

layer of Antispread ist essential for the silencing effect of high

viscous lubricants in quartz clocks with step motors. The use Viscosity

base of Antispread is imperative for the lubrication of plastics.

material For dented wheels, bottom plates, electric contacts, printed

circuit boards, ball bearings, sensitive machine tools,

The Antispread coating acts as a network whose fluorine counters, printers, open bearings. Using the system

„bristles“ repel the lubricant. bearing/shaft both parts, bearing as well as shaft must be

treated with Antispread.

Test of Efficacy: Wetting

Apply drop of test fluid of 1 mm diameter ro treated parts.

Over 4-hour period, area covered by drop may not become

bigger. Contact angle must be between 5° and 45° at room

temperature.

P246a

Dr. Tillwich GmbH Werner Stehr Phone: +49 (0) 7451 5386-0 All information reflects our best knowledge. No responsibility is Certified

Murber Steige 26 Telefax: +49 (0) 7451 5386-70 taken for printed data. Technical and chemical changes may occur acc. to

D-72160 Horb (Ahldorf) info@tillwich-stehr.com without notice. We cannot be held liable for any use or application. ISO 9001

You might also like

- A Level Organic Chemistry NotesDocument68 pagesA Level Organic Chemistry NotesTeejay Makazhu100% (11)

- Flooring Construction CoatingsDocument5 pagesFlooring Construction CoatingsWall E NguyễnNo ratings yet

- Jotun Jota Ep Mastic 66Document4 pagesJotun Jota Ep Mastic 66Abi PutraNo ratings yet

- Pilot QD Primer: Technical Data SheetDocument4 pagesPilot QD Primer: Technical Data SheetShreenivas ThakurNo ratings yet

- Sizing at A GlanceDocument6 pagesSizing at A Glancesoyeb60No ratings yet

- Te 1305 EaDocument1 pageTe 1305 EastatisticssalesNo ratings yet

- KCC DataSheet EP1760ENGDocument2 pagesKCC DataSheet EP1760ENGNguyen1987 TrungNo ratings yet

- Penguard Topcoat: Technical Data SheetDocument4 pagesPenguard Topcoat: Technical Data SheetSafinahNo ratings yet

- 509 - F 250 BODYFIBER - TdsDocument1 page509 - F 250 BODYFIBER - TdsИван ПетровNo ratings yet

- رنج جوتن ابوكسيDocument4 pagesرنج جوتن ابوكسيSami KahtaniNo ratings yet

- Conseal Touch-Up: Technical Data SheetDocument4 pagesConseal Touch-Up: Technical Data SheetSyilla ShopeNo ratings yet

- Scotch-Weld Neoprene High Performance Rubber and Gasket Adhesive 1300L TFDocument5 pagesScotch-Weld Neoprene High Performance Rubber and Gasket Adhesive 1300L TFQUALITYNo ratings yet

- TDS Zinc Rich Primer STDocument4 pagesTDS Zinc Rich Primer STBadar MinhasNo ratings yet

- Jotun Hardtop XPL TDSDocument4 pagesJotun Hardtop XPL TDSRajan SteeveNo ratings yet

- High Heat Primer: Technical Data ATO-56Document2 pagesHigh Heat Primer: Technical Data ATO-56anil_24_007No ratings yet

- Marathon XHB - TDSDocument5 pagesMarathon XHB - TDSDamar WardhanaNo ratings yet

- Jotamastic Plus - TDS.engDocument5 pagesJotamastic Plus - TDS.engJayasurya PaluriNo ratings yet

- SRT-13 Stops Rust Cold Galvanizing Spray TDSDocument2 pagesSRT-13 Stops Rust Cold Galvanizing Spray TDSIngeniero CivilNo ratings yet

- KCC DataSheet EH2350 (P) (ENG) PDFDocument3 pagesKCC DataSheet EH2350 (P) (ENG) PDFLim DongseopNo ratings yet

- Hardtop XP AluDocument5 pagesHardtop XP AluAsebaho BadrNo ratings yet

- Hardtop XP Alu PDFDocument5 pagesHardtop XP Alu PDFBiju_PottayilNo ratings yet

- ATO-83 Automotive Professional Grade Truck Bed Coating TDSDocument2 pagesATO-83 Automotive Professional Grade Truck Bed Coating TDSJackie JohnsonNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- TDS Futura AS Euk GB PDFDocument4 pagesTDS Futura AS Euk GB PDFFu AdNo ratings yet

- 3rd-Temadur 20Document2 pages3rd-Temadur 20Erikas KulpinasNo ratings yet

- Jotun Malathon TDSDocument5 pagesJotun Malathon TDSBiju_PottayilNo ratings yet

- Solvalitt ALU - TDS.eng PDFDocument5 pagesSolvalitt ALU - TDS.eng PDFsaiful anwarNo ratings yet

- TDS 429 Conseal Touch-Up Euk GBDocument4 pagesTDS 429 Conseal Touch-Up Euk GBGalih WicaksonoNo ratings yet

- Silent Running SR-1000-Data-PageDocument2 pagesSilent Running SR-1000-Data-PageEduardo JimenezNo ratings yet

- Phenoline 300: Selection & Specification DataDocument4 pagesPhenoline 300: Selection & Specification DataNicolas Montore RosNo ratings yet

- Aluminium Paint H.R.: Technical Data SheetDocument4 pagesAluminium Paint H.R.: Technical Data SheetBiju_PottayilNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSNguyễn Duy BiênNo ratings yet

- Thermaline 450 EP: Selection & Specification DataDocument3 pagesThermaline 450 EP: Selection & Specification DataGMSNo ratings yet

- Penguard Clear SealerDocument4 pagesPenguard Clear SealerInaam Ullah MughalNo ratings yet

- Jotamastic Plus: Technical Data SheetDocument5 pagesJotamastic Plus: Technical Data SheetBiju_PottayilNo ratings yet

- Synthetic Enamel - Matt FinishDocument3 pagesSynthetic Enamel - Matt FinishSameer HyderNo ratings yet

- JOTUN TDS - Penguard E50Document5 pagesJOTUN TDS - Penguard E50Sachin SinghalNo ratings yet

- TDS Penguard Tie Coat 100 Euk GBDocument6 pagesTDS Penguard Tie Coat 100 Euk GBIliyan PetrovNo ratings yet

- SUPER COVER ACRYLIC Technical Data SheetDocument3 pagesSUPER COVER ACRYLIC Technical Data SheetPaul HillierNo ratings yet

- PDS7010EDocument2 pagesPDS7010EElie KhawandNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSdgambhavaNo ratings yet

- Hi Pon 20 07 Epoxy Zinc Phosphate 70 Ver 13.0 PDFDocument4 pagesHi Pon 20 07 Epoxy Zinc Phosphate 70 Ver 13.0 PDFPushpendraNo ratings yet

- Intergard 345: Product Description Intended UsesDocument4 pagesIntergard 345: Product Description Intended UsesRafael AlvaresNo ratings yet

- Technical Data Sheet: Kan-SUPRA Polyurethane FinishDocument3 pagesTechnical Data Sheet: Kan-SUPRA Polyurethane FinisholiviaNo ratings yet

- Interline 985+ds+eng PDFDocument4 pagesInterline 985+ds+eng PDFMohamed NouzerNo ratings yet

- Intertherm 79: Temporary Protective PrimerDocument4 pagesIntertherm 79: Temporary Protective PrimerNassim Ben AbdeddayemNo ratings yet

- Devcon Flexane-High-Performance-Putty - 15330Document2 pagesDevcon Flexane-High-Performance-Putty - 15330Yajaira ValdezNo ratings yet

- TDS 41048 Hardtop WF Euk GBDocument6 pagesTDS 41048 Hardtop WF Euk GBKingsman 86No ratings yet

- TDS Kan HB Epoxy ZP Primer 290119Document3 pagesTDS Kan HB Epoxy ZP Primer 290119oliviaNo ratings yet

- Barrier 80Document5 pagesBarrier 80Biju_PottayilNo ratings yet

- Durebild Ste Aug 2018Document4 pagesDurebild Ste Aug 2018Biju_PottayilNo ratings yet

- Barrier 77: Technical Data SheetDocument4 pagesBarrier 77: Technical Data SheetNurmalinda SihombingNo ratings yet

- Jotamastic Plus: Technical Data SheetDocument5 pagesJotamastic Plus: Technical Data SheetRamlialianNo ratings yet

- NSF 61 PaintDocument2 pagesNSF 61 Paintraviraj londheNo ratings yet

- Hardtop XP: Technical Data SheetDocument5 pagesHardtop XP: Technical Data SheetQuoc VinhNo ratings yet

- Bar-Rust 231 Surface Tolerant EpoxyDocument4 pagesBar-Rust 231 Surface Tolerant EpoxyAhmed IbrahimNo ratings yet

- Marathon XHBDocument5 pagesMarathon XHBakbarNo ratings yet

- Jotafloor EP SLDocument4 pagesJotafloor EP SLEduardo Vera portocarreroNo ratings yet

- Jen. 2 Pack Pu Enamel Jen. 2 Pack Pu Enamel: Berger Industrial Manual Berger Industrial ManualDocument1 pageJen. 2 Pack Pu Enamel Jen. 2 Pack Pu Enamel: Berger Industrial Manual Berger Industrial Manualআফজাল -উল ইসলাম নূরNo ratings yet

- Safeguard Universal ES: Technical Data SheetDocument5 pagesSafeguard Universal ES: Technical Data SheetIsaacNarendraAkbarNo ratings yet

- Epimastic 7200 SRDocument2 pagesEpimastic 7200 SRqc_531040655No ratings yet

- S-Coat E41: Modified Epoxy CoatingsDocument1 pageS-Coat E41: Modified Epoxy CoatingsmohdnazlanNo ratings yet

- Precision Grease R 27Document1 pagePrecision Grease R 27statisticssalesNo ratings yet

- Silber BDocument1 pageSilber BstatisticssalesNo ratings yet

- Precision Grease B 52Document1 pagePrecision Grease B 52statisticssalesNo ratings yet

- PTFE-Grease K 7132Document1 pagePTFE-Grease K 7132statisticssalesNo ratings yet

- Pi - WF Pro - enDocument1 pagePi - WF Pro - enstatisticssalesNo ratings yet

- Brochure WatchesJewellery ENDocument20 pagesBrochure WatchesJewellery ENstatisticssalesNo ratings yet

- Pi - Suprol Pro - enDocument1 pagePi - Suprol Pro - enstatisticssalesNo ratings yet

- Pi Unimix enDocument1 pagePi Unimix enstatisticssalesNo ratings yet

- Brochure Elmasolvex ENDocument8 pagesBrochure Elmasolvex ENstatisticssalesNo ratings yet

- SDB - Suprol Pro - GBDocument16 pagesSDB - Suprol Pro - GBstatisticssalesNo ratings yet

- PI - ELMA RED 1zu9 - ENDocument1 pagePI - ELMA RED 1zu9 - ENstatisticssalesNo ratings yet

- 103 F9220.product - InfoDocument1 page103 F9220.product - InfostatisticssalesNo ratings yet

- 6292 - P - Suprol Pro - GB2Document1 page6292 - P - Suprol Pro - GB2statisticssalesNo ratings yet

- SDB - ELMA RED 1zu9 - GBDocument17 pagesSDB - ELMA RED 1zu9 - GBstatisticssalesNo ratings yet

- 6379 BA Elmasolvex RM ENDocument42 pages6379 BA Elmasolvex RM ENstatisticssalesNo ratings yet

- 6291 - S - Suprol Pro - GBDocument9 pages6291 - S - Suprol Pro - GBstatisticssalesNo ratings yet

- 3245 Safetydatasheet.F9220groupDocument6 pages3245 Safetydatasheet.F9220groupstatisticssalesNo ratings yet

- Manual: (JserDocument12 pagesManual: (JserstatisticssalesNo ratings yet

- Omala s4 GXV 220Document2 pagesOmala s4 GXV 220Igreja CCMVNo ratings yet

- 4470 Lecture 3 2013Document24 pages4470 Lecture 3 2013ZakyKikyNo ratings yet

- Materials 16 04052Document16 pagesMaterials 16 04052NIBIN BINU B.Tech ME B 2020-2024No ratings yet

- Masterflow 648CPDocument4 pagesMasterflow 648CPMoustafa HelmyNo ratings yet

- EXPERIMENT 2 Reduction of CamphorDocument2 pagesEXPERIMENT 2 Reduction of CamphorDania FaridNo ratings yet

- Structure of DNA & RNADocument3 pagesStructure of DNA & RNAtrekzbetsNo ratings yet

- Assembly Fluid 1 TDSDocument1 pageAssembly Fluid 1 TDSpokleNo ratings yet

- Yardim2016 Shear Strengthening of Unreinforced Masonry Wall With Different Fiber Reinforced Mortar JacketsDocument6 pagesYardim2016 Shear Strengthening of Unreinforced Masonry Wall With Different Fiber Reinforced Mortar JacketsAbdulkhaliq AbdulyimahNo ratings yet

- Basu Particle Size TRFCTNDocument9 pagesBasu Particle Size TRFCTNhafisNo ratings yet

- MoA-Classification v10.5 28mar23Document40 pagesMoA-Classification v10.5 28mar23zahra07No ratings yet

- Advances in Mechanics 1Document14 pagesAdvances in Mechanics 1yuvaraj gopalNo ratings yet

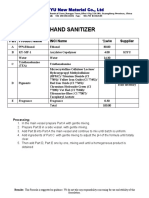

- Hand Sanitizer FormulaDocument1 pageHand Sanitizer FormulaUsman KhalidNo ratings yet

- 101 Reasons To Use Flamebar BW11Document2 pages101 Reasons To Use Flamebar BW11Ngô Xuân HàNo ratings yet

- Suppository, Insert & StickDocument3 pagesSuppository, Insert & StickCorina Faye RosarioNo ratings yet

- IChO 49# (KIMOR)Document14 pagesIChO 49# (KIMOR)Michael MichaelNo ratings yet

- Mastics, Glues For Marble, Granite, StoneDocument6 pagesMastics, Glues For Marble, Granite, StoneNaveen GuptaNo ratings yet

- A Guide To Common Plastics PDFDocument1 pageA Guide To Common Plastics PDFmuammal abbasNo ratings yet

- Chemistry 1405 Practice Exam # 4 (CH 8-10)Document8 pagesChemistry 1405 Practice Exam # 4 (CH 8-10)Nesrine LaradjiNo ratings yet

- Title of The Project ThesisDocument87 pagesTitle of The Project ThesisIrfan IqbalNo ratings yet

- GSA Preservation Brief On Composition OrnamentDocument11 pagesGSA Preservation Brief On Composition OrnamentmordeauxNo ratings yet

- General Absence DeclarationDocument5 pagesGeneral Absence DeclarationAparesh GantaitNo ratings yet

- Special Project DLSHSI - SALADsDocument9 pagesSpecial Project DLSHSI - SALADsKristine RamosNo ratings yet

- Jute Short + PLADocument7 pagesJute Short + PLARamkumar RamaiahNo ratings yet

- FDM ATR Drugs Chemical Name IndexDocument8 pagesFDM ATR Drugs Chemical Name Indexamin138irNo ratings yet

- Carbenoids 2Document15 pagesCarbenoids 2costea0028No ratings yet

- PP-0299 H 125 - HOMO PP - RIS - BRAZIL (v2.4)Document18 pagesPP-0299 H 125 - HOMO PP - RIS - BRAZIL (v2.4)jhonyNo ratings yet

- 07 Ceiling & LiningDocument30 pages07 Ceiling & LiningAjithkumarNo ratings yet