Professional Documents

Culture Documents

Sign Board Calculation Sheets

Sign Board Calculation Sheets

Uploaded by

أبو نادر0 ratings0% found this document useful (0 votes)

48 views22 pagesOriginal Title

Sign Board Calculation Sheets-

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

48 views22 pagesSign Board Calculation Sheets

Sign Board Calculation Sheets

Uploaded by

أبو نادرCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 22

4. INTRODUCTION

Structural calculations of the

gn board structure have been performed according To the design loads and criteria

indicated in the specifications issued to our side. For support design issues we use manual calculation analysis. Al

(LRED) steel design provisions used with ASCE-7 load combinations

GENERAL DESCRIPTION

Sign board consist of five panels with height 600mm and pane! with 1600mm fixed on two IPE200 columns that

supported by IPE200 trusses

3. LOAD COMBINATIONS (ASCE.

-MBOLS AND NOTATIONS

weight of space frame

D:

LL: live load.

W: wind load

E: earthquake load

T: slf-straining force;

UH: load due to lateral earth pressure, ground water pressure, or pressure of bulk materials

f1 = 1.0 for areas occupied as places of public assembly, fr live loads in excess of 5,0 kNim2, and for

Parking garage live load.

#1.=0.5 for other live lords

STRENGTH DESIGN

140-8) SBC (Eq, 232-1)

12 (D+F +7) +1.6(L+H) +05 (LrorR) SBC (Eq, 232-2)

12+ 1,6(LrorR) + (f1L oF 08 W) SBC (Eq, 23.2:3)

12D + L.SW + IL +05 (Lr or R) SBC (Eq. 23.2-4)

12D+LOE+ AL SBC (Eq. 232-5)

09D + LeW + L6tt SBC (Eq. 232-6)

09D + 10E-+ 1.6H SBC (Eq, 232-1)

4, WIND LOADS CALCULATION:

Velocity Pressure:

The velocity pressures are computed using SBC 301 code and Velocity pressure, qz evaluated at height z shall be

caleulated by the following equation:

ge 0.0473 x 10-3 Kx*Kat*KdeVL (KNim2; SBC (Bq. 72-12)

Where

V =152 kaw is basic 3-second gust wind speed from Figure 6.4-1(Jeddah area)

K¢=0.85 is the wind directionality factor defined in Section 6.4.1, (Open Signs and Lattice Framework)

K2(7.5m)-0.72 is the velocity pressure exposure coeflicient defined in Section 7.2.6 (exposure category B)

Kzt"1 isthe topographie Factor defined in Section 6.4.3

«i the velocity pressure calculated using Eg, 72-12 at mean roof height h.

F-1.1Simportance factor with category (III) and Regions with V= 136-160 kmh

2 = 0.0473 x 10-3 *0,724140,85%1522*1,15-0.77 kNim2

‘opus eg ae

— ce

stasis oe

co Sin slammed ons

cs un

[Figure 716 Fores Gocthicients Cr | Solid Freestanding Walls and Solid Sigus

pO

y G MN G

sa ce <6 1

5 13 a 13

20 15 0 17s

Design Force for sign board Structure

The design wind fre fr open buildings and other structures shal be determine by the flloing formula

FeqeG'erar (Eq 12-22)

Whore

"0.77 velocity pressure evaluated at eight z ofthe centroid of area Af using exposure defined in Section 6.42.5;

G=L.15 gust effect factor tobe calelated by (Ba, 7.2-5) because f< | Hz, Section 7.27.25

‘Af=5.1°2-713.77n?(contervative) projected are normal othe wind except where ris specified for the actual surface

area, m2

C= net force coeficients fom Figures 7.2-16

Ratio of height to widih 18/2722 8863 so Cf 1.2 (Figure 7.216)

P= qe"G*CAF=0.7781.1581. 24137

14.63 kn or (14.6314

L062kw/ms? we used 1.3 kn? as more onservative)

[0 View Uniform Loads Gioba-xX OW”) |

£

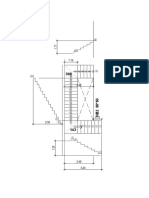

5. FIGURES:

6. CODE & MATERIALS PROPERTIES:

Design Codes:

SAUDIBUILDING CODE3O1 2007.

ASC 13th Steel Construction Manu

AISC 360-05

ACISISM-14

ASCE 7.05

INTERNATIONAL BUILDING CODE (BC 2012)

Materials propertie

Materials Grade 5 Ky Fe

Steel grade of column A36 2482 | 400

Steel grade of Base plate A36. 2482 | 400

Steel grade of bolts A307 Gra 450.

Grade of weld material E7OXX 483,

Concrete Grade of support 30. : : 30

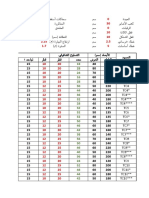

7. STEEL FRAME DESIGN

x9) nf adh

zoo [vasa [evo eso] T zo] ‘seman | poet —T 2 I TRB

3000 SBeSsoW ON [ExO=x0936N 2 sho

‘swan | 2000 sooo BESTOW ON fexO9x003NL 2 ‘ans

‘esnson | roo! “FEvrOon" SEESOION 2 hos

essen | 100 BESO ON > sais

BeSFOHION. 2 ‘ahs

a TaRGn_| Seo | Sa | t 1 SEESSSHION | L 2 BOIS

SBESOWON 2 SROs

2 wawen | —_se00 | essa BESOIN 2 ahDIs

I I I I SEO ONT I 2 anos

a Tae] Se, BESTOW ON 2 a0

SHESFOHTON 3 Boos

a FaRG_| OT SRESOHION 2 ans

100. nson—| 1900. TRCN, 2 oanis

Toxo | —wssan_—| ceo | vsasan SBeSTSWON| —oozsat—| wD BROS

o asusen | 100 eSksa0 Peswoo7s | 1200 ‘aBessow on [exOsx0930TU| —_UUMIOD iy

erreDooo o 3200 ‘SBeSFOWON fexoaxo9sanA| VINOD OTROS

[=a FARE | STOOD | PEST wrooeo | —seoo | geRLOGTT | —z00, SBESTSWON jexosxossenA| —_UUMOS orm

syteooo0 | #200 0 #200 ‘SessoW ON Jexosxo930nA| UND Uy

eaRGN | SrOROGOT | FaNSaR | eeeo0oo | seo | eeErOGTT | —se00, SRESTOWON exoaxossanul wD ores

yswscn | ero | esusan | erseoo00 | eveo [tooo | reo. aessewon| oozsal_[ wane orks

wsnson | e700 —|_estisan| eraeoo00_[ evo | tooo | veo. Besse ON | — 00234 my OTROS

wsnscn|Zeo0 | esnsan|- coo | esro| 2000) 130 ‘SBeTeWON| —oozsar—|—wUMD Tras

ysnscn_| ceo | _ysusan_| coo | esro_[ coro | varo. aBessoWON| —ooesat—[_wuneD uy

‘gsnson | 2000 | eshsan. o sto | raze00oo | A100 ‘SessoW ON fexOaKODIaT| UNION ‘zkiois

[issrooro | 2100 9 at00 SBESTOWON JexosxOssanU UES zines

Tawen_| 1000 Test0000-|—c100, 0 ‘SBessow ON Jexosxo930na| UMD uy

Toato000 | —r00 0 ‘SBeSFOWON fexoaxo9sanA VINOD zhong

[=o aE Two [estore [2100 oT SEESEVION [EXOSHOSIANUL zs

2 200 0 sro Too. SessIWON| 002i

° ZED. o srro | 1000 HESFOHTON

Too. 200 Too | ea —eo0 SEEEHION

roo —[~tsnson | £200 zoo | csv [coo SeFOION

0, Ze Zer0000, SRESaTON

osrson_| eo raw a a ESs9W ON [€x0930930

Szt000o z000—|ZF000o ‘SBESTOW ON fexO9KO0INL FINOIS

zoo | c2v0000 SIESaHTON Psy

200. 000. SESW ON IK

200. ooo HESTON 0

o o SEEEHION STR

° a ameSFOHTON 109) STAOIS

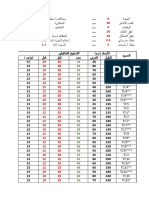

voter | oneva | oneuwind [oaweswind) snes ‘dh, uaisaq [awenanbun| roger ‘os

Too Lt TSE ooo a TOO | SIRS [PSN ON | ErOSKORIAL | UT TERE

S000 00. Ts ooo | eewIOGOT. SBESSeN ON | EROBKOBITT 7a_ [eros

2000 Too Tsasan 000 aReSso ON] EROOKOOTEAL Za_[ethONS

100 Too Tsas0n 700 aiesrent ON | EXOKOOIENL 7a_[erhons

a SBeSF=WN ON | EXORXOBTIN: Za_[pWONS

wo Too Tas 00 aBeSsON ON] EROKOOTEAL Z_[pThOIS

f 7800 SEENON, 39 cots

a rae 70 5600 SETI 39 [ eho

nro SISSON. [choos

a Essa a0 ST Tro SEENON 33 [cots

a0 SESS ON. 33 [ekg

a Ea 0 Son 500 SEWN 3 [ekos

S00 aBeSsoN ON. 9 | etous

a Ea Tao aS 500 SISSON. [ets

I 1 [190 aiesrayt ON | EYODXOOSENL I 1a woos |

a snr ooo wasn 0 190 SBESFOWN ON] EX09KOO EAL #2 [phos

wae 700. E10 —|_Wesisan-[ stesso on exoaxooaen | oUnIOy [whos

[= asa ooo SOT e000 [two | r009 [ero | alvsnsan | aBesren oN] erosxO—SER | —UUIHIES | [poss |

2000 Too [eee007 | —Et9.O—|Wrsisan_|a¥essow ON | ExOaKONAENL | wu 13 [phos

3 Fa ooo aS e000 100. 7oo0_[9t9o | TaWsWsan | SBessSIW aN | ExOBKOBIENE | —UURIED Tapes

OT HOT | sea] soo | sian [aReSSNON| oes | —vURTED 39 [wots

3 Eas Too asa 2000 sro | stoo | eeo0 | airsnsan_[atessonven| —oozaar—| wunje> 3 [phos

zoo vivo | —t199 [seo | frsason_[atessarvon| 0023 33 [ots

p Ss 100 son 2000 3100 |_st00 aBesse WON] OOZ3AL z $9 [phos

Troe Soro [sea aBesso ON] —Oaeael_—] —ouIOD 1 [35 shows

[Feo Ear wo EO e100 Toro | e007 sierra ow] —0z3d1 Te SoS

1100. 5000 | seoa aBesreW ON] —_OOzIaL a sais

200 Ea Ea} Ea e100 Zov0 | eo aiesra ON] 003A z EWaIS

f S070 | 30070 stesso ON | CWOSKOOIEAL So

3 in Toao SOT Soro | —s000 Besse ON EROOKOOTEAL 03 cog

e000 | 1090 aiesrayi ON | EXORXODSENL om uO

a El Oo aso 600 1000. aBes591N ON] EXORROBTEN: 0 ah0%5

e000 | 1090 aBeSFo ON] EROOKOOTEAL 97 ahOTS

[= raat ooo Sm [000 aiesrayt ON | EXOOKODSENL [3 1

500 SESW ON| —_ OdEIEL ze

a Ea ry Ea S500 SRW ON. ze

I 1 [7500 —T SEEN [= 1

a Isa rao wasn se00 SBeSso WON. 5

500 SERN. ee

To ETT wo Ta 3300 SBE ON ec

S300 SBS ON] — OOH oF

eRENZOUATA | oaDD SUIT | REHLOTRW A ORES OTEWA [OREHAOUNTA | PREUZOTENTH | Ones seis [uoRea5 ul oak usea | sueNSTONT

Fay m0 aT Ta 0 SaaATON| —OaERA

7100, 5109,

Tao eo | ear 719) 3200)

50

0

| aa | eo 7100, 709)

Fa 7190) 70

700, 500)

Fay Zao | eT 7100 20

00 HT

aa aan || 700. 3500

a0 710) san

zooo | esasan zoo | esmsan [oo Tero [stro JesRSGN ‘D0z3at

7509) #100 | ORSTSON wae

Z aa so | SOT Ta 2300) 2100 coed

t | [_sineo003 | a0 [00 00233

z RGR so | sa 100 2003) 2100) oaeial

vev0000 [soo S000 SHESSaATON| 0073

z a ao | aT 3 S009, o—| “2000 sresenon| —orsa

wa To99 [was | e800 Sassoon | EROBWOOTRT

Tag aa | ao | 3500) von —[szevon79| —2200 SsESSOATON | HORNOOANL

$070 099 saesronoh|

z aa wo | asa e000 Za99—| 1099 [ 2100

5200 Zoo —|“1003—| 3900

a awe | aS 5200 “091099 | 5900

e200 Zo0 [1099 | 3900

aa aso | oo | oT 200 Tigo —|~100 3-390 002391

2100 vo9—| 1099 | 8100 exOHNO90NT

0. Zoo | aa z50—|“Tsv0000-| “200 | “1200 SROSHOOEAL

7600 t990_—| 1000 | 600. 05109301

Ta zoo | aa ray yon 2000 | 8600 ExOHHOOIEL

t | [so] [68

a TO $50 360

3800 tag9 1099 | #800 ExORHOOIENL

coro wooo [esnsan [sao 000 zoo | 2600 Ex03x093aL

iso S009 [1099 | 9600 SxOBHOOTL

coy Toxo | aa oo tooo |“ 1099 | e800 EXOSHOOIEAL

00 tooo —| ssa 30r zoo | eTsTao7o| Boro BOSNOOTTTL

Tor zoo —[ veto00 0 | —eoro—[ Tnsisa [exonxo5ran

Ta RAT RATA | HATTA] NATTA TAL] TALATEN] oheua [ORRNAE] ORwOD ANA] MNS [woes wimg] sa VSO

o wo [we aT eA ces [_Se ZO RR

vETGOO | FeO | eo] OT esWon] woes | Sea | oe | a |S

z ToT wo | aT TOT To | 0 | B00 iagesA on] caesar —| sea | — 06 — eo eas

eae woo | soa] teoo jsesew on] cozaar | em [Rea BOR

ESC SS wo] ear essWon] —caeaal —| Sem 7 [Rea ema

aod | wero | wo] wre aeAeN] —oaela | Bea | se ea

7 TSR eee] aT Too sro | wo] Te SSessWon] —coeaal | Sea] 96 [ea

TOOT wo | soo 10 esaWon| cas | SER pr

7 Tas] eo] aT W000 sro] 0] sero isaeswon] cozaar | pe

MD [sensAon] — caesar | eA] ear [ora

o Tas 50] OT] Ta a0 | a0] we [sesswon] cars| Sea] oor [ora

REIT | avo | wee] eT aR] oacaaT Cai

z Tasso | eT Too woo | aoe] wea essen] woes | Sea | ee

TOT a0] 0] Oo [sesaw on] cosa | Se wea

sano | wo | aa aaa | aa] a8 aiersAn| —cocsa—| S| a ee

307 ao | soo] oT [sesenoa] corsa | =e [so

were | sn | soa] essa] F008 a [snes en] ooze | Se [50

oo oo] wo] eT SesSWon| —oBE a = [oa

[aaersouinr A oque5 ouMT A oTeH Ten Al ORE IEW A| SHER TOUA WI oTRN STRAT) oTeH a |SnFRINAA| srieig _[ooqbes irea) sah isa swensnbwn|eaer] ois

7. BASE PLATE THICKNESS CHECK (10MM):

Code used AISC Manual (American Institute for Steel Construction) withthe LRFD requirements

(Part 14; Design of Beam Bearing Plates, Cokuran Base Plates, Anchor Rods, and Column Splices)

Case 1: Design of Base Plate fora IShaped Column Subject to Axial Compression Load Only:

Axial Compression Load Pa=35.86kn

Select base plate width, B, and a baseplate length, N such that

'B=3S0mm > bt + 100mm =100+100=200, and

N=350mm > d + 100mm ~200+100-300,

Determine the plate cantilever lngths,m and n

r= (N-0.954) 2= (350-0.95*300) 210mm

1 (B-O8*b1/2 ~ 350-0.8"200)/2-95mm (largest value governs)

‘The required minimum base plate thickness given

pont 2ePulg*BENTFS))

~95+9(2°35.86"1000/(0.9*350*350"250)) 4. 84mm

$0 we will use base plate 380x380x10mm

(Case 2: Design of Base Plate fora I-Shaped Column Subject to Axial tension Load Only:

Axial tension Load Pu = 26.28ka (6.37kn per bolt)

The applied moment per unit width inthe base plate duc tothe uplift force is

Mu=(Tuin)* y/ 2*y) =Tw (2m) (anchor bots inside of cokuran footprint)

1y=Distance from the centroid ofthe anchor rod tothe web of the wide flange column,

Tu =Total net uplift force on the colum

‘n= Total number of anchor rods in tension

The bending strength ofthe base plate bending about its weak axis is

Mn =9*Zy*Fy =9r(b484)*Fy

[Note that §Mn=Mu,m yields the required minimum baseplate thickness as

VAT W(p%n*Fy)) —V(2"26 28° 1000(0.9°4"250))=7.65mm,

‘SO we will use base plat

0x350s10mm

8. ANCHORAGE CALCULATIONS:

Code used ACI3I8-14 (Building Code Requirements for Structural Concrete and Commentary)

(Chapter 17: anchoring to concrete)

The effective stud embedment depth is hef=250mm

To calculate connection strength, check ifthe studs act asa group or act individually

Critical stud spacing = Shef =3250=750mm >230mm therefor studs resisted tension as group

‘Assume that

* The stud reactions are proportional tothe distance from the stee] Bear's compression flange toe.

+ The compression force is resisted by a concrete reaction centered dircetly beneath the steel beams compression

ange

+ Concrete is cracked.

Determine just four stads’ forces only setting on concrete beams, but this method is conservative

Force in each anchor is calculated from the Following equation, summing moments around the bolts line

2 Tapa *0.230-2*6,57¥0,230°3,02kn.m TaQoi=26,28/4-6.57kn Tension

The anchor design strengths must satisty the following inequalities:

¢Nsa (Steel strength in tension)

Ncbg (Conerete breakout)

#Npn (Anchor pullout)

(i Pais (W Conte beck

© Steet tension:

‘Nominal stel strength is the stel tensile Strength (fata) times the stud area (Ase.N),

Nsa=Asesn¥ fula ACI31S-14 (17.4.1.2)

Check that futa = 450 mpa is smaller than 1.9fya=1,9*352=668.8mpa and 860mpa

For stud diameter is da16mm and area Asen=201mn?

Nsa-201"450-90450 2 -90.45kn

Used @ factor for ductile anchor =0.75 therefor

Check that design strength is greater than required strength:

Nsa~0,75*90.45-67.83kw/per stud > 6.57kn so ok

+ Concrete breakout

‘Nominal conerete breakout strength of group of anchors in tension (Eg. ACI318-14(17.42.1b):

Nebg=Ane/Ancot¥ec*Wed*We;ntepintNb ACIBI8-14 (17.42.16)

‘Anco 9*hefF=9"250S62500mn? — ACISIB-14 (17.4.2.1c)

‘Anc= (1.5#250+230+1.5%250)* (1.5*250+230+1.5*250) =960400mm? <$*562500=2812500mm?

‘ee: modification factor for anchor groups loaded eccentrically in tension

For the anchor group the load is

ACBI8-14 (17.42.4)

Ye

‘¥ed=I modification factor for cast-in anchor edge effec; four anchors in

Tension are located close tothe edge; ACIBI8-14 (17.42.56)

ce

>I Shof=1.5*250=375mm,

‘We,n: modification factor for concrete condition at service load levels;

Assume member is cracked, ACIBI8-14 (17.4.2.6) Wen

‘Yep.n: modification factor for post installed anchors in un cracked concrete

Without supplementary reinforcement to coatrol splitting. ACISI8-14 (17.4.2.7) ep.

Nb: basie concrete breakout strength, either ealeulate from Eq, ACISI8-14 (17.4.2.2a)

Nb=Kety# Fe’ *hef?'1.5=10#1*¥30*250"1.5=216.506kn

‘Nebg-960400/562500°1* 1*1*1#216.506~369.65kn

Used 6 factor for a castin headed studs with supplementary reinforcement, Condition A applies

Therefor § Nebg=0.75*369.65 =277.24> 26.28kn $0 0k

+ Pullout

‘Nominal pullout strength is calculated from Eq, ACI318-14 (17.4.3.1)

Non='¥e,p*Np

“Yesp=factor to modify pullout strength of anchor in cracked conerete. Ve,p=1

Np-=the basic pullout strength is either to calculate from Eq, ACIS18-14 (17.4.3.4)

en-70mm hook length (hooked ancht

Np= 0.9%en*Fe"*ds=0,9°70*30"1

Npn=1*30.24-30.24ka

Used @ factor for castin headed studs with supplementary reinforcement,

Condition A applies ~0.7 therefore

@Npn=0,730.24-21.16kn> 26,284-6.57kn $0 0K

+ Side-face blowout

Side-face blowout needs to be considered for multiple headed anchors with

(het =250mme2.Seal=2.5*S10-1275mm) and

With anchor spacing not less than 6ca1=6*510=3060mm > 230mm,

Therefore side face blowout is nat consider $0 0k

+ Splitting falure

This type of failure can occur in thin members because studs torque is applied

[And anchor has an edge distance of not less

Than 6da=6°16=96mm @Vuag=14.3kn

© Steet shear

Nominal steel strength isthe steel shear Strength (fut) times the stud area (Ase,v).

Vsa=0.6%Ase,v* fata ACIBI8-14 (17.512)

Check that futa ~ 450 mps is smaller than I.9fya~1.9*352°668.8mpa and 860xapa

For stud diameter is da=16mm and arca Ase,v=201mm

‘Because grout located between steel base plate and top of concrete pedestal, 0.8 reduction factor is applied

Vsa=0.6¥0,8*201"450=43.416kn

Used ¢ factor for ductile anchor =0.65 therefor

Check that design strength is greater than required strength

Vsu-0.65%43.416-28.22kn per stud> 14.3/2°7.15kn 00k

Assume only two anchors closest tothe edge in the direction of shear foree ate resisting the shear force

+ Concrete breakout

The anchors closed to edge are subjected to $0% of anchor force

Nominal concrete breakout shear strength of single anchor is

‘Vebg-AveiAveotVec,v"Vedv"Vev"thv*Vb ACI318-14 (17.5.2.1b)

Avoo= 4.5teal=4.5510°=1170450mm? — ACISI8-14 (17.52.le)

‘Aye= (ca24stea2)*h = (510+230-510)*700 -875000mmn"

‘Yee,v: modification factor for anchor groups loaded eccentrically in shear=1 ACIS18-14 (1.5.2.8)

Yoav: moslfication factor for cast-in anchor edge effect; four anchors in

Shear are located close to the edge; ACI318-14 (17.5.2.6)

(€22=5100mm = [.S*eal=765mm,

YWod,y=0.740,34ea0i(1.5*eal)W0.740,3*S10/(1,5*S10)=0.9

\We,v: modification factor for concrete condition at service load levels;

Because the pedestal has No.4 tes that act as supplementary reinforcement:

ACIB18-14 (17.5.2.7) Yer.

°Vh,v: modification factor for member thickness in elation anchor embedment depth

ACIB1B-14 (17,5.2.8) Yh

Vb: basie concrete breakout strength, of single anchor is calculated as smaller of

Eg, ACI318-14 (17.5.2.2a) & Fg. ACIBI8-14 (17.5.2.26)

‘Vb= (0.6*(leida) “0.2*/da)* a*Fe"*(cal) “1.5= (0.64(250/16) °0.24V16)*1*30*S10°1.5=262.35kn

Eq, ACI3IS-14(17.5.2.2a)...controls

Vb=3.7#)* Vocal 1 S=3,7*1*V30°5101.5=253.4kn ACISIB-14 (17.5.2.26),

\Vebg=875000/1 1704501 40,9*1,2"1"262.35=211,81kn

Used 6 factor for castin headed studs with supplementary einforeement, Condition A applies =0.75,

Therefor 6 Vebg=0.75*211.81=158.86> 0.5*143-7.15kn 50 ol

+ Peyout

Nominal pryout strength is ealeulated from Eg. ACIS18-1¢ (17.5.3.1)

#Vepg=kep*Nepg Eq. ACIBI8-14 (17.53.16)

Nepe~ Nebe.

kep=2 (hell

250mm>2,5mmn)

Nobg-AnciAncotVee™Ped*entWep.n"Nb_ACI318-14 (17.42.15)

‘Anco= 9*hefP=9*250°=562500mm? —ACIBI8-14 (17.4.2,le)

‘Ane=(cal-+1 Sheff)*b-(510+1.5*250)*1000-885000mn

"Yee: modification factor for anchor groups loaded eccentrcally in tension

Fr the anchor group the load is

YWee=1 ACIBI8-14(17.4.2.4)

“Wed modification factor for cast-in anchor edge effect; four anchors i

Tension are located elose tothe edge; ACI3IS14 (17.4.2.5b)

‘e,n: modification faetor for concrete condition at service load levels,

Assume member is cracked. ACISI8-14 (17.4.2.6) Yen=1

‘Yep.n: modification factor for post installed anchors in un eracked concrete

Without supplementary reinforcement to control splitting. ACIB18-14 (17.4.2.7) Fep.a=1

Nb: basic concrete breakout strength, either caleulate from Eg. ACIB18-14 (17.4.2.2a)

Nb=Ke*y-4yFe'*heff*1 5=101*\/30425001,5=216,506kn

‘Nebg-885000/562500°1*1*1*1*216,506-340.63kn

Used 6 factor for a cast-in headed studs with supplementary reinforcement, Condition A applies =0.75,

‘Therefor g Vebg-0.75"340.63-255.47Kn> 14.3kn $0 Ok.

+ Interaction of tension and shear Fores

Nebo , Weng

+

ain im

<1

2628 | 7.5

27724" 156.86

0.14< 12 So ok

9. CHECK STABILITIES

+ Resisting moment MR=34,38*240,625~28,6*2%(2.45~0,625) =218.865kn.m

otal reaction for back footings

lasrs3s 3.1567.15+3.] =28.6kn

Total reaction fr font footing

[2.1964 302.11y268.3718.394.22), =| =|

34.38kn

‘Overturing frontline

+ Driving moment Ml

2.4148kn.m (from ETABS)

aoa

Factor of safety against for overturning with consider load combination (0,6DL4W)

FS(ov) = SMR — 26218865 4595150 Sook

MD 824148

410. FOOTING:

Soil pressure under footing

38, 3kn/m2 < 150kn/m2

tty poe

4 +

+ +

+ +

i _ Lt

Fi a

+ +

EE BES

prods *

4 a

boy +

4 3

ot vt

4 4

+ +

Lol ee

Minimum reinforcement for footing 0,0018*D*d-0.0018*700*1000~1260mm? (6T16 E.W-top & bottom)

11. COMPUTER SOFTWARE OUTPUT (ETABS):

MOMENTS AND SHEAR DIAGRAMS:

12. CHECK LATERAL DEFLECTION

iy | —s.0 ae 20.58 mm so ok

ner Dts

recat Hane

Data Cote

See

Seaton Stace

Secu Posey Souee

Sec: Eo

Sten Oreos

Taal ech

Too ange th

Top Frye Tacks

Wes Taree

Botan Rrge id

Botan Rage Mckrese

Fe Pada

Genet Data

Paty Nene

Daa Ca

Secten Shane

Secten Posey Sauce

‘ce: Une Detred

Secten Dera

Taleo

Tet ian

Farce Thekoene

Web Mckee

eat

16 2

3

ost Sow tats.

Ses

Peo ote

rae = ian a

‘rey Oak

to o-

as =

ss =

rot =

as =

Son Stn Peete eo

se 2

Moyo Nein

Sea

Povety Moste

= otyShow Moser

Cet Ott

Stow etn Poets ee]

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- إصلاح المباني القائمة المتضررةDocument61 pagesإصلاح المباني القائمة المتضررةأبو نادر100% (1)

- Marine Construction 2Document10 pagesMarine Construction 2أبو نادرNo ratings yet

- كمية الاعمدة زون A1 الجزاء 2Document1 pageكمية الاعمدة زون A1 الجزاء 2أبو نادرNo ratings yet

- CONCRETE REPAIR CH 23 SIDDIQUI - Part2Document67 pagesCONCRETE REPAIR CH 23 SIDDIQUI - Part2أبو نادرNo ratings yet

- Retrofit of Reinforced Concrete - Part1Document264 pagesRetrofit of Reinforced Concrete - Part1أبو نادرNo ratings yet

- Wall SamDocument8 pagesWall Samأبو نادرNo ratings yet

- Nezar Al Wafaai's ResumeDocument1 pageNezar Al Wafaai's Resumeأبو نادرNo ratings yet

- STAIRSDocument1 pageSTAIRSأبو نادرNo ratings yet

- 60 Park AR STAIR-SHAHED ModelDocument1 page60 Park AR STAIR-SHAHED Modelأبو نادرNo ratings yet

- مناطق الصب2Document1 pageمناطق الصب2أبو نادرNo ratings yet

- حساب كميات برج - الفغيمDocument37 pagesحساب كميات برج - الفغيمأبو نادرNo ratings yet

- محاضرة البلاطات اللاحقة الشد م. حلمي سكريDocument29 pagesمحاضرة البلاطات اللاحقة الشد م. حلمي سكريأبو نادرNo ratings yet

- WWW Hilti Co UkDocument6 pagesWWW Hilti Co Ukأبو نادرNo ratings yet

- حساب كميات برج - رعدDocument37 pagesحساب كميات برج - رعدأبو نادرNo ratings yet