Professional Documents

Culture Documents

Extra Credit 3

Extra Credit 3

Uploaded by

testOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Extra Credit 3

Extra Credit 3

Uploaded by

testCopyright:

Available Formats

AJITPAL SINGH

12/18/2015

Injector Nozzle Cleaning

Clogged fuel injectors have probably led to more unnecessary top overhauls. The reason is

because the symptoms can be very misleading. The engine is not producing as much power as plugs may

be getting engine oil fouled, and oil consumption may be up, as is the fuel flow indication on the gauge.

The engine is probably idling rough too. These are all classic signs of cylinder wear, and cylinders may be

pulled unnecessarily. That said, running a partially clogged injector too long can fry a cylinder and

therefore not to ignore any abnormal type of individual EGT indications. Nozzles get clogged from heat

after shutdown, evaporating the less volatile fuel components in the lines, and forming a scummy

varnish deposit. This deposit can coat the inside of the nozzles which have a very critical inside diameter.

Finding the clogged is done by checking the sump screen and the injector body filter screen. In some

systems the screen is spring-loaded so it can allow bypassing if it is seriously clogged.

There are a number of symptoms to watch for and simple checks for this problem. By using the

multi-probe CHT/EGT indicators, it will be different than normal. A classic way to check this issue is by

doing a cold cylinder check. Another way to know is when a clogged nozzle will be dribbling fuel out the

bleed hole. The stream should have no side shoots coming off and should be symmetrical. Nozzle care is

also another important step as performed maintenance. Cleaning of the nozzles should be accomplished

every 100 hours of annually or any time symptoms arise. If unusually dirt operating conditions exist,

more frequent cleaning may be required. Frequent cleaning prevents the nozzles from becoming stuck

or even seized into place from maintenance inattention. Nozzles should be soaked in acetone for 20

minutes and blown dry with compressed air. The nozzles are to be torqued according to the

maintenance manual specific settings. Over-torqued installation of nozzles may cause cylinder cracks.

When securing the nozzles, the fuel line should not be twisted. Always check injector lines for leaks such

as fuel stains, as well as nicks or dents or chafing. Any extra bends that were not designed in from the

factory may cause problems. For turbo nozzles and shrouds they should be stain free.

You might also like

- 3406E and C15 Marine Engines-Maintenance IntervalsDocument21 pages3406E and C15 Marine Engines-Maintenance Intervalswoulkan100% (2)

- 1y 2y 3y 4yDocument5 pages1y 2y 3y 4yBeloforte100% (2)

- AjusteDocument3 pagesAjusteAmy MurrayNo ratings yet

- 3406E+and+C15+Marine+Engines Maintenance+IntervalsDocument21 pages3406E+and+C15+Marine+Engines Maintenance+IntervalsJason McLaughlin100% (2)

- Ger 4618Document4 pagesGer 4618Jessica SandersNo ratings yet

- SB 214020Document7 pagesSB 214020Hamilton MirandaNo ratings yet

- DIY Clogged Intake Manifold Cleaning VW TDI of Carbon Build Up, 1998, 1999, 2000, 2001, 2002, and 2003 PDFDocument1 pageDIY Clogged Intake Manifold Cleaning VW TDI of Carbon Build Up, 1998, 1999, 2000, 2001, 2002, and 2003 PDFSuciu FlorinNo ratings yet

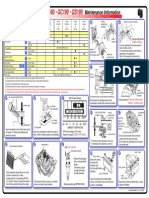

- GC135 GC160 GC190 GS190: Maintenance InformationDocument1 pageGC135 GC160 GC190 GS190: Maintenance InformationGoran MojsilovicNo ratings yet

- Hydraulic Press MaintenanceDocument5 pagesHydraulic Press Maintenancedanaytesfu27No ratings yet

- Amt 646 Midterm 2Document14 pagesAmt 646 Midterm 2Tyron CastroNo ratings yet

- FReelander Head Gasket InstructionsDocument4 pagesFReelander Head Gasket Instructionscottage garage100% (3)

- Fuel Injection Valve Condition: Service Letter SL2016-628/KELDocument4 pagesFuel Injection Valve Condition: Service Letter SL2016-628/KELVitalii KorolNo ratings yet

- Symptoms of A Blown Head GasketDocument5 pagesSymptoms of A Blown Head GasketSandeep Swami G Elugu100% (2)

- 10 - Failure Analysis GuidebookDocument32 pages10 - Failure Analysis GuidebookAnurag Dureja50% (2)

- Diagnosing Misfires: Steady MisfireDocument3 pagesDiagnosing Misfires: Steady MisfireDawood SubedarNo ratings yet

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument4 pagesQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioHamilton miranda100% (1)

- The Purpose of The Head GasketDocument19 pagesThe Purpose of The Head Gasketmrcamre.plcNo ratings yet

- Wet SumpingDocument3 pagesWet SumpingBimal Amarnath MenonNo ratings yet

- TT-17-015 Turbocharger Oil DepositsDocument6 pagesTT-17-015 Turbocharger Oil DepositsVictor MontesdeocaNo ratings yet

- Piston Ring & CylinderDocument8 pagesPiston Ring & CylinderahmedalgaloNo ratings yet

- Engine Block Cleaning ProcedureDocument7 pagesEngine Block Cleaning ProcedureKamal PakdamanNo ratings yet

- SME 2455 Presentation: Marine Ic Enginnering-IiDocument9 pagesSME 2455 Presentation: Marine Ic Enginnering-IiIsmail Jabe UllahNo ratings yet

- MTQ Iload Turbo InstructionsDocument2 pagesMTQ Iload Turbo InstructionsAdrian ClinceNo ratings yet

- Calibracion de Valvulas D399Document82 pagesCalibracion de Valvulas D399Reynol Rivas80% (5)

- Dawg Scooter ManualDocument26 pagesDawg Scooter ManualStephanie Parker100% (2)

- Fuel Injection Nozzles: Test/ExchangeDocument3 pagesFuel Injection Nozzles: Test/ExchangePedro SchembriNo ratings yet

- Pruebas y Ajustes.Document79 pagesPruebas y Ajustes.Francisco Wilson Bezerra FranciscoNo ratings yet

- Service Manual Generic Xor 125Document96 pagesService Manual Generic Xor 125chicharro88100% (2)

- Maintenance Items For Special Attention SI1080C PDFDocument3 pagesMaintenance Items For Special Attention SI1080C PDFDavid OrtizNo ratings yet

- Adly 50gtc Service ManualDocument86 pagesAdly 50gtc Service ManualAnna RyanNo ratings yet

- Engine Assembly ProceduresDocument9 pagesEngine Assembly Proceduresashishkhurana93100% (1)

- Oil ConsumptionDocument6 pagesOil ConsumptionprashantNo ratings yet

- MG HG ReplacementDocument16 pagesMG HG ReplacementChrisBeller45No ratings yet

- Fuel Injector CleaningDocument12 pagesFuel Injector Cleaningapi-26140644100% (1)

- An Engine Compression Test Is The Most Practical Way To Learn About The Mechanical Condition of Your EngineDocument10 pagesAn Engine Compression Test Is The Most Practical Way To Learn About The Mechanical Condition of Your EngineJAYSON CANDELARIANo ratings yet

- Mailhot - User Guide G2-235-8.7-5A REV 1 (Mack)Document15 pagesMailhot - User Guide G2-235-8.7-5A REV 1 (Mack)Ignacio Rifo NochezNo ratings yet

- Mercedes Benz 190Document4 pagesMercedes Benz 190jesse55lv50% (2)

- ExpertDocument301 pagesExpertEngine Tuning Up100% (2)

- Fitting Steering Pump SpidDocument15 pagesFitting Steering Pump SpidJuan GarcNo ratings yet

- Centrifugal Pump Checklist 2023Document7 pagesCentrifugal Pump Checklist 2023Caesar MutizeNo ratings yet

- Overhaul (Top End) 3508Document7 pagesOverhaul (Top End) 3508Randy jr macielNo ratings yet

- PEHP6001 - Good Oil SampleDocument2 pagesPEHP6001 - Good Oil SampleAndre Paul MektronikNo ratings yet

- Assessment Sheet: Student ID: Unit Code & NameDocument17 pagesAssessment Sheet: Student ID: Unit Code & NameheshanNo ratings yet

- Diesel Engine ProblemsDocument4 pagesDiesel Engine ProblemsArvind Sangeeta KothariNo ratings yet

- QuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service ManualDocument21 pagesQuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service Manualshashiraj50% (2)

- Atc70-125 1985 and Earlier Servicemanual OcrDocument32 pagesAtc70-125 1985 and Earlier Servicemanual Ocr80sDweebNo ratings yet

- 1.6 Hdi Carbon IssuesDocument44 pages1.6 Hdi Carbon IssuesMark Tranter86% (7)

- Replacing The Volvo Oil Trap and Oil Pan SumpDocument6 pagesReplacing The Volvo Oil Trap and Oil Pan SumpsaifrulNo ratings yet

- Reasons For Engine Oil ConsumptionDocument6 pagesReasons For Engine Oil ConsumptionKavanNo ratings yet

- Class 2 Oral Questions & AnswersDocument26 pagesClass 2 Oral Questions & Answersprashant manhasNo ratings yet

- Jeppesen Oral QsDocument47 pagesJeppesen Oral QsDavid DoughtyNo ratings yet

- Motor Maintenance - SCHEDULED ROUTINE CARE: Bearing LubricationDocument7 pagesMotor Maintenance - SCHEDULED ROUTINE CARE: Bearing LubricationRM HaroonNo ratings yet

- ENP-652 Cylinder Boss Wear and RepairDocument7 pagesENP-652 Cylinder Boss Wear and RepaireparodiesNo ratings yet

- Juego de Valvulas 3046Document3 pagesJuego de Valvulas 3046Alejandro ValenzuelaNo ratings yet