Professional Documents

Culture Documents

Astm B139M

Uploaded by

ferrer0000Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm B139M

Uploaded by

ferrer0000Copyright:

Available Formats

AMERICAN SOCIETY FOR TESTING AND MATERIALS

Designation:B 139M - 95 100 Barr Harbor Dr., West Conshohocken, PA 19429

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

METRIC II not listed in the current combined index, will appear in the next edition

Standard Specification for

Phosphor Bronze Rod, Bar, and Shapes [Metric]’

This standard is issued under the fixed designation B I39M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapprowl. A

superscript epsilon (c) indicates an editorial change since the last revision or reapproval.

1. Scope* appearing in Specification B 249M. In case of conflict, this

1.1 This specification establishes the requirements for specification shall prevail.

phosphor bronze rod, bar, and shapes.

4. Ordering Information

1.2 The values stated in Sl units are the standard.

1.3 This specification is the companion to inch-pound 4.1 Contracts and purchase orders for product under this

Specification B 139. specification should include the following information:

4.1.1 ASTM designation and year of issue (for example,

B 139M - XX),

2. Referenced Documents

4.1.2 Copper Alloy UNS No. designation (for example,

2.1 ASTM Standards. c5 1OOO),

B 249M Specification for General Requirements for 4.1.3 Product temper (for example, H04-see Section 7),

Wrought Copper and Copper-Alloy Rod, Bar, Shapes, 4.1.4 Form: cross section such as round, hexagon, square,

and Forgings (Metric)* etc.,

B 601 Practice for Temper Designations for Copper and 4.1.5 Diameter or distance between parallel surfaces,

Copper Alloys-Wrought and Cast* 4.1.6 Edge Contours,

E 62 Test Methods for Chemical Analysis of Copper and 4.1.7 Quantity: total weight each copper alloy, temper,

Copper Alloys (Photometric Method)3 form, and size, and

E 478 Test Methods for Chemical Analysis of Copper 4.1.8 When product is purchased for an agency of the

Alloys” US. Government (Section IO).

4.2 The following options are available and should be

specified in the contract or purchase order when required:

3. General Requirements

4.2.1 Piston-finish for rod and shafting (Section 9),

3.1 The following sections of Specification B 249M con- 4.2.2 Certification (Specification B 249M), and

stitutes a part of this specification. 4.2.3 Test report (Specification B 249M).

3.1.1 Terminology. -

3.1.2 Materials and Manufacture. 5. Material and Manufacture

3.1.3 Workmanship, Finish and Appearance.

5.1 Material:

3.1.4 Sampling. 5.1.1 The material of manufacture shall be cast billets of

3.1.5 Number of Tests and Retests. Copper Alloy UNS No. C5 1000, C52100, C52400, C53400,

3.1.6 Specimen Preparation. or C54400 and of such soundness as to be suitable for

3.1.7 Test Methods. extrusion.

3.1.8Significance of Numerical Limits.

3.1.9Inspection. NOTE l-Copper Alloy UNS Nos. C51000, C52 100, and CS2400 are

suitable for structural applications, pump parts, rods, bolts, gears, and

3.1.10 Rejection and Rehearing.

similar applications.

3.1.11 Certification. NOTE 2-Copper Alloys UNS Nos. C53400 and C54400 are free

3.1.12Test Reports. machining and are suitable for screw-machine products.

3.1.13 Packaging and Package Marking.

3.2 In addition, when a section with a title identical to 6. Chemical Composition

that referenced in 3.1 above appears in this specification, it 6.1 The material shall conform to the requirements in

contains additional information which supplements that Table 1 for the Copper Alloy UNS No. designation specified

in the ordering information.

’ This specification is under the jurisdiction of ASTM Committee B-S on

6.1.1 These limits do not preclude the presence of other

Copper and Copper Alloys and is the direct responsibility of Subcommittee 805.02 elements. Limits may be established and analysis required

on Rods. Bars, and Shapes. for unnamed elements by agreement between the manufac-

Current edition approved Sept. 10, 1995. Published November 1995. Originally

turer and the purchaser.

published as B I39M - 80. Last previous edition B 139M - 90.

2 Annuul Book o$ASTM Sumdurds, Vol 02.0 I. 6.2 Copper may be taken as the difference between the

‘Ann& Book o!ASTM Smndurds, Vol 03.05. sum of all elements analyzed and 100 %.

* A Summary of Changes section appears at the end of this specification.

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

ASTM BL39ll 95 m 0759530 0571879 250 D

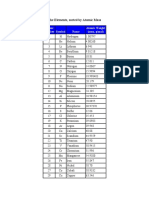

TABLE 1 Chemical Requirements

Copper Alloy UNS No.

Element, w

c51000 C52100 C52400 c53400 c54400

Tin 4.2-5.8 7.0-9.0 9.0-l 1 .o 3.5-5.8 3.5-4.5

Phosphorus 0.03-0.35 0.03-0.35 0.03-0.35 0.03-0.35 0.01-0.50

Iron, max 0.10 0.10 0.10 0.10 0.10

Lead 0.05 max 0.05 max 0.05 max 0.8-l .2 3.5-4.5

Zinc 0.30 max 0.20 max 0.20 max 0.30 max 1.5-4.5

Copper remainder remainder remainder remainder remainder

6.3 When all elements in Table 1 for the Copper Alloy titled paragraphs of Specification B 249M:

UNS No. named in the ordering information are deter- 11.1.1 Diameter or Distance Between Parallel Surfaces:

mined, the sum of results shall be 99.5 5%min. I 1. I. 1. I Rod: Round, Hexagonal, Octagonal-Table 2.

11.1. I .2 Piston-Finish Rod-Table 3.

7. Temper 1 I. 1.1.3 Bar: Rectangular and Sqzrare-Tables 9 and I I.

7. I Rod and Bar: 1 I. 1.2 Shapes.

7.1.1 The tempers, as defined in Practice B 601, for rod 11.1.2.1 The dimensional tolerances for shapes shall be

and bar produced to this specification are identified in Table subject to agreement between the manufacturer and the

2. purchaser and the agreement shall be a part of the contract or

7.2 Shapes. purchase order.

7.2.1 The temper for shapes is subject to agreement I 1. I .3 Lenglh:

between the manufacturer and the purchaser and the agree- 1I. 1.3.1 Rod, Bar, and Shapes-Tables 13 and 15.

ment shall be a part of the contract or purchase order. 11.1.4 Straightness:

1 I. 1.4.1 Rod and Bar-Table 16.

8. Mechanical Property Requirements 1 1. I .4.2 Shafting Rod-Table 17.

8.1 Tensile Requirements: 11.1.4.3 Pisron-Finish Rod-The tolerance is subject to

8.1. I Rod and Bar: agreement between the manufacturer and the purchaser and

8.1.1.1 Rod and bar shall conform to the requirements the agreement shall be a part of the contract or purchase

prescribed in Table 2 for the specified Copper Alloy UNS order.

No. designation, temper, cross-section, and size. I I. 1.5 Edge Contours:

8. I .2 Shapes: 11.1S. 1 Refer to paragraph titled “Edge Contours”.

8. I .2. I The requirements for shapes shall be subject to

agreement between the manufacturer and the purchaser and 12. Test Methods

the agreement shall be a part of the contract or purchaser 12.1 Chemical Analysis:

order. 12. I. 1 Chemical composition shall be determined, in case

of disagreement, as follows:

9. Piston-Finish Element Test Method

9.1 When specified in the contract or purchase order, Copper E 478

round rod over 12 mm in diameter shall be furnished as Iron E 478

Lead E 478 (AA)

piston-finished rod or shafting.

Zinc c2 % E 478 (AA)

>2 56 E 478 (Titrimetric)

10. Purchases for U.S. Government Tin E 478 (Titrametric)

Phosphorus E 62

10.1 When specified in the contract or purchase order,

product purchased for agencies of the U.S. Government shall 12.1.2 Test method(s) for the determination of element(s)

conform to the special government regulations in the Supple- required by contractual or purchase order agreement shall be

mental Requirements section of Specification B 249M. as agreed upon between the manufacturer or supplier and the

purchaser.

I 1. Dimensions, Mass, and Permissible Variations

11.1 The dimensions and tolerances for product furnished 13. Keywords

under this specification shall conform to the requirements of 13.1 phosphor bronze bar; phosphor bronze rod; phos-

the following tables and related paragraphs, and referenced phor bronze shapes

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

ASTM BL39M 95 m 0759530 0571880 T72 -

TABLE 2 Tensile Reauirements for Rod and Bar

Temper Diameter or Distance Between Parallel Tensile Strength, MPa

Elongation4 min. %

Standard Name Surfaces, mm min max

Copper Alloy UNS No. C51000

060 soft anneal Rod: Round under 6 275 400 .

HO4 hard Rod: Round under 6 550 680 ...

Round and hexagonal:

6 to 12, inci 465 13

over 12 to 25, incl 415 15

over 25 380 .. 16

Bar: Square and rectangular:

6 to 9, incl 415 . . 10

over 9 380 . 15

HO8 spring Rod: Round:

0.65 to 1.6, inch 790 .

over 1.8 to 3. incl 760 ..

over 3 to 6, incl 725 i;

over 6 to 9, incl 690 5.0

over 9 to 12, incl 620 I 9.0

Copper Alloy UNS No. C52100

060 soft anneal Rod: Round under 6 365 470

HO4 hard Rod: Round under 6 720 1030

Round and hexagonal:

6 to 12, incl 585 12

over 12 to 25, incl 515 15

over 25 415 ..I 20

Ear: Square and rectangular:

6 to 9, incl 470 10

over 9 415 15

Copper Alloy UNS No. C52400

080 soft anneal Rod: Round under 6 415 515

HO4 hard Rod: Round under 6 725 1100

Round and hexagonal:

6 to 12. incl 655 ... 10

over 12 to 25, incl 585 . 12

over 25 480 . 15

Bar: Square and rectangular:

6 to 9, incl 525 ... 10

over 9 480 .. 15

Copper Alloy UNS No. C53400

HO4 hard Rod: Round and hexagonal:

1.6 to 6, incl 450 8

over 6 to 12, incl 415 10

over 12 to 25, incl 380 . 12

over 25 345 15

Rod: Square and rectangular:

6 to 9. incl 380 . 10

over 9 345 . 15

Copper Alloy UNS No. C54400

HO4 hard Rod: Round and hexagonal:

1.6 to 6, incl 450 . . 8

over 6 to 12, incl 415 10

over 12 to 25, incl 380 12

over 25 345 .. 15

Bar: Square and rectangular:

6 to 9. incl 380 10

over 9 345 .. 15

* Elongation values are based on a gage length of 5.65 times the square root of the area for dimensions greater than 2.5 mm,

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

ASTM i3139M 95 m 0759530 057~~8~ 909 m

SUMMARY OF CHANGES

This section identifies the location of selected changes to this specification that have been incorporated

since the 1990 issue as follows:

(1) Permitted alloys for manufacture relocated from the (3) The temper column of Table 2 revised; no change in

Scope section to the Materials and Manufacture section. temper designations.

(2) The specific section of Specification B 249M which (4) Individual test methods identified for determining

constitute a part of this specification identified. chemical composition in case of dispute.

The American Society for Tesfmg and Mater/a& fakes no poWon respeclmg fhe vabdify ol any pafenr rights asserted in connecllon

wilh any item menlmned in fhis sfandard. Users of fhis standard are expressly adnsed fhat deferminaf/on of the vakd!fy 01 any such

patent righfs, and the risk of infringement 01 such righfs, are entire/y Ihe/r own responsibility.

This standard is subjecf lo revlslon at any time by the responsible technical committee and must be revIewed every five years and

if not revised, either reapproved or withdrawn. Your commenfs are innted either for revision of fhis standard or for add/tiona/ standards

and should be addressed lo ASTM Headquarters. Your comments will receive careful consideration at a meefing ol the respons/b/a

technical commiltee, which you may attend. If you be/ thal :~our comments have not received a lair hearing you should make your

views known lo the ASTM Committee on Standards. 100 Barr Harbor Drive, West Conshohocken, PA 19428.

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

You might also like

- Astm B139Document5 pagesAstm B139Jamil SalmanNo ratings yet

- BS en 763Document6 pagesBS en 763raviraj londheNo ratings yet

- Astm B 140 B140M-2007Document4 pagesAstm B 140 B140M-2007Ramsi AnkziNo ratings yet

- Copper-Beryllium Alloy Rod and Bar: Standard Specification ForDocument5 pagesCopper-Beryllium Alloy Rod and Bar: Standard Specification ForAyvid HgnisNo ratings yet

- Naval Brass Rod, Bar, and Shapes: Standard Specification ForDocument7 pagesNaval Brass Rod, Bar, and Shapes: Standard Specification ForHoang Duy PhuongNo ratings yet

- Copper Alloy Sand Castings For Valve ApplicationDocument6 pagesCopper Alloy Sand Castings For Valve ApplicationROHITNo ratings yet

- Astm B 98M-98Document5 pagesAstm B 98M-98Fa ChNo ratings yet

- Astm B 138 - B 138M - 06Document4 pagesAstm B 138 - B 138M - 06Ramsi AnkziNo ratings yet

- Naval Brass Rod, Bar, and Shapes: Standard Specification ForDocument7 pagesNaval Brass Rod, Bar, and Shapes: Standard Specification Formanuel floresNo ratings yet

- PDFsam - B 379 - 11Document5 pagesPDFsam - B 379 - 11mike.jensen0581No ratings yet

- Aluminum Bronze Sheet, Strip, and Rolled Bar: Standard Specification ForDocument4 pagesAluminum Bronze Sheet, Strip, and Rolled Bar: Standard Specification Forbenedick barquinNo ratings yet

- Astm 66Document3 pagesAstm 66Adams Ribeiro100% (1)

- B455Document3 pagesB455basha100% (1)

- Copper-Beryllium Alloy (UNS Nos. C17000 and C17200) Forgings and ExtrusionsDocument4 pagesCopper-Beryllium Alloy (UNS Nos. C17000 and C17200) Forgings and ExtrusionsMaxNo ratings yet

- Copper Alloy Permanent Mold Castings For General ApplicationsDocument3 pagesCopper Alloy Permanent Mold Castings For General ApplicationsJonicus-DextoreNo ratings yet

- Naval Brass Rod, Bar, and Shapes: Standard Specification ForDocument7 pagesNaval Brass Rod, Bar, and Shapes: Standard Specification ForAlejandro ValdesNo ratings yet

- Phosphor Bronze Rod, Bar, and Shapes: Standard Specification ForDocument5 pagesPhosphor Bronze Rod, Bar, and Shapes: Standard Specification FormahfuzNo ratings yet

- Aluminum Bronze Sheet, Strip, and Rolled Bar: Standard Specification ForDocument4 pagesAluminum Bronze Sheet, Strip, and Rolled Bar: Standard Specification ForGreg YeeNo ratings yet

- Astm B19Document6 pagesAstm B19Davor IbarraNo ratings yet

- Copper-Beryllium Alloy Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForDocument12 pagesCopper-Beryllium Alloy Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForRajendra ChoudharyNo ratings yet

- Astm b169Document4 pagesAstm b169ANIL100% (1)

- Phosphor Bronze Wire: Standard Specification ForDocument3 pagesPhosphor Bronze Wire: Standard Specification Forbenedick barquinNo ratings yet

- Copper-Zinc-Silicon Alloy Rod: Standard Specification ForDocument3 pagesCopper-Zinc-Silicon Alloy Rod: Standard Specification ForVictor VillegasNo ratings yet

- Astm B148 09 PDFDocument5 pagesAstm B148 09 PDFRamana NatesanNo ratings yet

- Aluminum-Bronze Sand Castings: Standard Specification ForDocument5 pagesAluminum-Bronze Sand Castings: Standard Specification ForIsma RioNo ratings yet

- Brass Rod, Bar, and Shapes: Standard Specification ForDocument7 pagesBrass Rod, Bar, and Shapes: Standard Specification ForMuthuswamyNo ratings yet

- ASTM5Document1,227 pagesASTM5Guatavo91No ratings yet

- Copper-Cobalt-Beryllium Alloy and Copper-Nickel-Beryllium Alloy Plate, Sheet, Strip, and Rolled BarDocument4 pagesCopper-Cobalt-Beryllium Alloy and Copper-Nickel-Beryllium Alloy Plate, Sheet, Strip, and Rolled BarLuigi HernándezNo ratings yet

- ASTM B121 Leaded Brass Sheet PlateDocument4 pagesASTM B121 Leaded Brass Sheet Platestrip1100% (2)

- Copper-Nickel-Zinc Alloy (Nickel Silver) and Copper-Nickel Rod and BarDocument5 pagesCopper-Nickel-Zinc Alloy (Nickel Silver) and Copper-Nickel Rod and Barabdulkadir aliNo ratings yet

- Astm B 134 B134M-08Document7 pagesAstm B 134 B134M-08Chung LeNo ratings yet

- Composition Bronze or Ounce Metal Castings: Standard Specification ForDocument3 pagesComposition Bronze or Ounce Metal Castings: Standard Specification Formanuel floresNo ratings yet

- Bronze Castings For Steam Locomotive Wearing PartsDocument3 pagesBronze Castings For Steam Locomotive Wearing PartsFierro Huerta Guillermo IsraelNo ratings yet

- Bronze Castings For Steam Locomotive Wearing PartsDocument3 pagesBronze Castings For Steam Locomotive Wearing PartsedwinbadajosNo ratings yet

- Astm B505Document7 pagesAstm B505Syed Shoaib RazaNo ratings yet

- Astm B505 (C93700) PDFDocument7 pagesAstm B505 (C93700) PDFSyed Shoaib RazaNo ratings yet

- Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)Document6 pagesCartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)Hoang Duy PhuongNo ratings yet

- B 21 - B 21M - 14Document8 pagesB 21 - B 21M - 14Ahmed BilalNo ratings yet

- Astm B206Document4 pagesAstm B206BhanuNo ratings yet

- B 938 - 04 - Cu Be AlloyDocument4 pagesB 938 - 04 - Cu Be Alloyvelu.gNo ratings yet

- B271M PDFDocument6 pagesB271M PDFmahantmtechNo ratings yet

- Bronze Castings For Steam Locomotive Wearing PartsDocument3 pagesBronze Castings For Steam Locomotive Wearing PartsIsmail TpNo ratings yet

- Copper-Nickel-Zinc Alloy (Nickel Silver) and Copper-Nickel Rod and BarDocument5 pagesCopper-Nickel-Zinc Alloy (Nickel Silver) and Copper-Nickel Rod and BarmahfuzNo ratings yet

- Astm B16-10Document5 pagesAstm B16-10Francisco Villasmil OlivaresNo ratings yet

- Free-Cutting Brass Rod, Bar and Shapes For Use in Screw MachinesDocument5 pagesFree-Cutting Brass Rod, Bar and Shapes For Use in Screw MachinesInfinita PersistenciaNo ratings yet

- Astm B411B411M-14Document3 pagesAstm B411B411M-14Gabriel Perez CruzNo ratings yet

- Astm B 505 PDFDocument8 pagesAstm B 505 PDFprodn123No ratings yet

- PDFsam - B 441 - 16Document4 pagesPDFsam - B 441 - 16mike.jensen0581No ratings yet

- Astm B16 2010Document5 pagesAstm B16 2010brunobassottiNo ratings yet

- Naval Brass Rod, Bar, and Shapes: Standard Specification ForDocument8 pagesNaval Brass Rod, Bar, and Shapes: Standard Specification Foranurag yadavNo ratings yet

- Copper-Nickel-Tin Spinodal Alloy Strip: Standard Specification ForDocument6 pagesCopper-Nickel-Tin Spinodal Alloy Strip: Standard Specification ForDanZel DanNo ratings yet

- Astm B 135-02Document6 pagesAstm B 135-02christianguilleminNo ratings yet

- Copper-Zinc-Tin and Copper-Zinc-Tin-Iron-Nickel Alloys Plate, Sheet, Strip, and Rolled BarDocument6 pagesCopper-Zinc-Tin and Copper-Zinc-Tin-Iron-Nickel Alloys Plate, Sheet, Strip, and Rolled BarmithileshNo ratings yet

- Copper-Beryllium Alloy Rod and Bar: Standard Specification ForDocument5 pagesCopper-Beryllium Alloy Rod and Bar: Standard Specification ForJyothishNo ratings yet

- Astm B22Document4 pagesAstm B22J.J. Engineering100% (2)

- Copper-Beryllium Alloy Rod and Bar: Standard Specification ForDocument5 pagesCopper-Beryllium Alloy Rod and Bar: Standard Specification ForIbtisam Abud100% (2)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- BCD Sor 16 07 2012Document225 pagesBCD Sor 16 07 2012Chikodi UGDNo ratings yet

- Dimension Stone CladdingDocument15 pagesDimension Stone CladdingHusen ZahranNo ratings yet

- Concrete Plant OperationsDocument28 pagesConcrete Plant OperationsJuned Hamid Khan100% (2)

- Sinus Jevi Duct Heaters 1Document6 pagesSinus Jevi Duct Heaters 1EIJAZ SONS International FZENo ratings yet

- StepCoolingTestofCr MoSteel PDFDocument4 pagesStepCoolingTestofCr MoSteel PDFvijaya kumarNo ratings yet

- Astm A755 CCLDocument5 pagesAstm A755 CCLMahendra DhamalNo ratings yet

- PB Impax Supreme English160604175245Document8 pagesPB Impax Supreme English160604175245Filipe BastosNo ratings yet

- Asme Section Viii Div 1 2 3Document73 pagesAsme Section Viii Div 1 2 3Sakthi Pk100% (3)

- 1 Rigid PavementsDocument5 pages1 Rigid PavementsUmar FarooqNo ratings yet

- TOPIC The Differences Between Pure Metals and Alloys. Content: Pure Metals: - Concept - Physical Property - Uses of Pure MetalsDocument31 pagesTOPIC The Differences Between Pure Metals and Alloys. Content: Pure Metals: - Concept - Physical Property - Uses of Pure MetalsSinh LeNo ratings yet

- Sa 311Document5 pagesSa 311singaravelan narayanasamyNo ratings yet

- Pickling Procedure 20 - 08Document2 pagesPickling Procedure 20 - 08Siriepathi SeetharamanNo ratings yet

- Isoria 10 Type Leaflet 8444Document16 pagesIsoria 10 Type Leaflet 8444Stefaan JacobsNo ratings yet

- Assembly In-Process Inspection ChecklistDocument2 pagesAssembly In-Process Inspection ChecklistRonnel Leano100% (1)

- Dynamicevolutionofgrainstructureandmicro Texturealongawelding PDFDocument13 pagesDynamicevolutionofgrainstructureandmicro Texturealongawelding PDF1rubena1No ratings yet

- Moen Install GuideDocument2 pagesMoen Install GuideMichael JohnsonNo ratings yet

- 1mm Special Edition E FolderDocument41 pages1mm Special Edition E FolderManish SharmaNo ratings yet

- Sikagrout 215 M Pds enDocument3 pagesSikagrout 215 M Pds enfikryh_2No ratings yet

- Retail colorchart-REYNOBONDDocument8 pagesRetail colorchart-REYNOBONDJonathanNo ratings yet

- Carriage ChartDocument10 pagesCarriage ChartSuperintending Engineer IPH Circle SundernagarNo ratings yet

- Iron Industry of PakistanDocument39 pagesIron Industry of PakistanSaad Javed78% (9)

- AA-036322-001 - Anchor Bolt DetailsDocument1 pageAA-036322-001 - Anchor Bolt DetailsGaurav BedseNo ratings yet

- Bostrig Type P VFD 2kVDocument3 pagesBostrig Type P VFD 2kVEnrique MartínezNo ratings yet

- Cables TheoryDocument15 pagesCables TheorytceterexNo ratings yet

- Usa Astm C936 (M) 13Document3 pagesUsa Astm C936 (M) 13Eko Agus SetyonoNo ratings yet

- Documents - Pub Ss9208 Rev 48 Production Acceptance CriteriaDocument64 pagesDocuments - Pub Ss9208 Rev 48 Production Acceptance CriteriaflyinzeskyNo ratings yet

- 1.boq - RC Work For Office (Part 3) - LattanavongDocument2 pages1.boq - RC Work For Office (Part 3) - LattanavongKu BờmNo ratings yet

- The ElementsDocument4 pagesThe ElementsHaider AliNo ratings yet

- 1 3 14Document1 page1 3 14منير أحمدNo ratings yet

- 01-Pet Eng Design - PTE - 470 - IntroductionDocument30 pages01-Pet Eng Design - PTE - 470 - IntroductionHassan KhalifeNo ratings yet