Professional Documents

Culture Documents

An Experimental Study On Punching Shear Behavior o

Uploaded by

Mohamed alhaj EmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Experimental Study On Punching Shear Behavior o

Uploaded by

Mohamed alhaj EmadCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/245395797

An Experimental Study on Punching Shear Behavior of Concrete Slabs

Article in Advances in Structural Engineering · April 2009

DOI: 10.1260/136943309788251650

CITATIONS READS

19 2,620

3 authors, including:

A.K.M. Jahangir Alam Khan Mahmud Amanat

Bangladesh University of Engineering and Technology Bangladesh University of Engineering and Technology

6 PUBLICATIONS 34 CITATIONS 55 PUBLICATIONS 292 CITATIONS

SEE PROFILE SEE PROFILE

All content following this page was uploaded by A.K.M. Jahangir Alam on 15 January 2015.

The user has requested enhancement of the downloaded file.

An Experimental Study on Punching Shear Behavior of

Concrete Slabs

by

A.K.M. Jahangir Alam, Khan Mahmud Amanat and Salek M. Seraj

Reprinted from

Advances in Structural Engineering

Volume 12 No. 2 2009

MULTI-SCIENCE PUBLISHING CO. LTD.

5 Wates Way, Brentwood, Essex CM15 9TB, United Kingdom

An Experimental Study on Punching Shear Behavior of

Concrete Slabs

A. K. M. Jahangir Alam1, *, Khan Mahmud Amanat2 and Salek M. Seraj2

1Engineering Office, Bangladesh University of Engineering and Technology (BUET), Dhaka-1000, Bangladesh

2Department of Civil Engineering, Bangladesh University of Engineering and Technology (BUET), Dhaka-1000, Bangladesh

(Received: 30 July 2007; Received revised form: 5 May 2008; Accepted: 2 October 2008)

Abstract: In determining the punching shear capacity of flat slabs, current codes of

practice usually do not consider the effect of boundary restraint against rotation. The

contribution of flexural steel reinforcement is ignored by some of the code provisions.

Present paper is comprised of the test results of 15 model slabs in an effort to ascertain

the influence of boundary restraint, the influence of flexural reinforcement and effect

of thickness of the slabs on their structural behavior and punching load-carrying

capacity. Cracking pattern and load-deflection behavior of the slabs tested have also

been monitored closely. Significant effect of edge restraint on the punching failure

load, resulting in an enhancing of the ultimate punching strength, and effect of flexural

reinforcement on the punching failure load have been noticed. The code-specified

strength of the specimens was calculated in accordance with the American, British,

Canadian, European, and Australian codes. It has been understood that punching shear

is not effectively estimated in some codes. Thus, inclusion of the findings of the study

in the design codes is expected to result in a rational design of structural systems where

punching phenomenon plays a vital role.

Key words: flat slab, punching shear, column, concrete, edge restraint, reinforcement.

1. INTRODUCTION compressive strength of concrete alone. Thus, these codes

Present design rules for punching shear failure of do not take adequate account of the possible role of

reinforced concrete slabs, given in various codes of specimen size and edge restraint. Some codes do not

practice, are largely based on studies of the behavior acknowledge the possible effect of flexural reinforcement

and strength of simply-supported, conventional on the punching shear behavior of reinforced concrete

specimens extending to the nominal line of slabs. Design codes that were primarily based on the

contraflexure (Alam 1997; Kuang and Morley 1992). American code (ACI 318 2005), such as Canadian

The code provisions rely mostly on empirical methods Standard (CSA-A23.3 2004), Australian code (AS 3600

derived from the test results on conventional (Selim and 1994), Bangladesh National Building code (BNBC 1993),

Sebastian 2003) and thin slab specimens (Lovrovich do not reflect the influence of the flexural reinforcement

and McLean 1990). In continuous slab, all panel edges ratio on the punching capacity of slab-column connections.

cannot rotate freely, in contrast to its simply supported British code (BS 8110 1997), European CEB-FIP (1990)

counterpart. As a result, these codes may not properly code and German code (DIN 1045-1 2001) consider the

mimic the punching shear behavior of continuous and effect of flexural reinforcement on the punching shear

actual slab construction. capacity of slabs. Some codes do not take adequate account

Some of the present-day code provisions usually of the possible role of specimen size and slab thickness

specify the punching shear strength as a function of (Lovrovich and McLean 1990; Mitchell et al. 2005).

*Corresponding author. Email address: alamj@buet.ac.bd; Fax: +880-2-8613046; Tel: +880-1711832597.

Advances in Structural Engineering Vol. 12 No. 2 2009 257

An Experimental Study on Punching Shear Behavior of Concrete Slabs

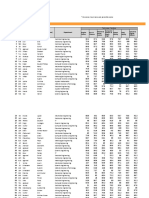

Table 1. Details of reinforced concrete slab specimens

Width of Slab Main bars Extra top

edge beam thickness Reinforcement in each bars in each Edge beam

Slab (b) (h) (ρ) direction direction reinforcement

sample mm mm % No.–mm φ no.–mm φ no.–mm φ

SLAB1 245 80 0.5 15–6 15–6 4–16

SLAB2 245 80 1.0 30–6 30–6 4–16

SLAB3 245 80 1.5 16–10 16–10 4–16

SLAB4 245 60 0.5 11–6 11–6 4–16

SLAB5 245 60 1.0 22–6 22–6 4–16

SLAB6 245 60 1.5 33–6 33–6 4–16

SLAB7 175 80 1.0 30–6 30–6 4–16

SLAB8 175 60 0.5 11–6 11–6 4–16

SLAB9 175 60 1.0 22–6 22–6 4–16

SLAB10 105 80 1.0 30–6 30–6 4–16

SLAB11 105 60 0.5 11–6 11–6 4–16

SLAB12 105 60 1.0 22–6 22–6 4–16

SLAB13 0 80 1.0 30–6 30–6 *3–16

SLAB14 0 60 0.5 11–6 11–6 *3–16

SLAB15 0 60 1.0 22–6 22–6 *3–16

*These reinforcements were provided at the extended bottom section of slab.

All stirrups for edge beam were 6 mm φ @ 88 mm c/c., span = 1200 mm

Test results from simply supported slab specimens do having no edge beams. Width of edge beam, slab

not usually provide an accurate prediction of the thickness and reinforcement ratio were test variable

ultimate load capacity of a slab having lateral restraint. elements for different samples having one or more than

When the slab is restrained against lateral deformation, one variability. Details of the slab samples are given in

this induces large restraining force within the slab and Table 1 and typical plan and sectional details of slabs

between the supports, thus membrane forces are with edge beam are shown in Figure 1. Photographs of

developed (Selim and Sebastian 2003). The enhancement slab sample with reinforcement can be seen in Figures 2

of punching shear capacity can be attributed to the and 3.

presence of in-plane compressive membrane action in

the slab (Kuang and Morley 1992; McLean et al. 1990; 2.2. Materials

Selim and Sebastian 2003). The importance of The concrete used in the specimens consisted of ordinary

compressive membrane stresses due to edge restraint Portland cement, natural sand and crushed stone

was not incorporated into the code formulations, which aggregate with maximum size 10 mm. The water cement

results in conservative prediction. ratio for concrete was 0.45. Both 6 mm and 10 mm

Under the circumstances, the present study diameter steel bars having average yield strength of 421

comprised of a planned series of tests on restrained as MPa were used in the slab panels and stirrup of edge

well as unrestrained slabs, variation of flexural beams. Flexural reinforcement in the edge beam was

reinforcement and slab thickness. Edge restraint was provided by 16 mm diameter steel bars with average

provided by means of edge beams of various dimensions yield strength of 414 MPa. An average cylinder

to mimic the behavior of continuous slabs. The test compressive strength of concrete of 36 MPa at the age of

results obtained from this study will be useful to 28 days was obtained from trial mixes.

evaluate an insight on the punching behavior of

reinforced concrete slabs.

3. TESTING

2. EXPERIMENTAL PROCEDURE The tests were designed to simulate conditions in actual

2.1. Specimen Details structures. Each slab was subjected to concentrated

A total of 15 square reinforced concrete slab specimens loading at the geometric center using a universal testing

were constructed and tested in this study. Twelve of machine. Four steel blocks were used at each corner of

these slabs had edge restraints in the form of edge beam, the slab as support. These blocks confirmed the clear

whereas the other three samples were plain normal slabs span of 1200mm for all samples. During testing, corner

258 Advances in Structural Engineering Vol. 12 No. 2 2009

A.K.M. Jahangir Alam, Khan Mahmud Amanat and Salek M. Seraj

105/175/245 mm 105/175/245 mm

105/175/245 mm

1200 mm

1200 mm

X X

105/175/245 mm

Plan view

60/80 mm

Loading block of size 120mm × 120 mm

4-16 mm ∅ (for edge beam)

120 mm

6 mm ∅ @ 88 mm c/c

6/10 mm ∅ bar

Section x-x

Figure 1. Details of a typical model slab with reinforcement

Figure 3. Photograph of typical model slab reinforcement without

edge beam

Hydraulic jack of capacity 300kN

Load cell at slab center Steel plate of size 120 × 120 mm

Model slab

Square steel block

Structural floor

Figure 2. Photograph of typical model slab reinforcement with

edge beam

Figure 4. Testing set-up

sides of each sample were properly anchored by means through a 20 mm thick steel plate of 120mm × 120mm

of heavy joist, which was connected to structural floor. size, simulating a concentrated load. The applied load

Loading was applied to specimen at an approximately was measured using an accurately calibrated load cell.

constant rate up to the peak load; at the same time Loading was applied to the specimens in increments of

deflections were measured. Failure occurred abruptly in 8.90 kN up to 71.17 kN and then in increments of 4.45 kN

all specimens and loading was stopped after failure. up to failure with measurements of deflections after each

A test rig, consisting mainly of steel girder and 300 kN increment of loading. The testing set up and testing

capacity hydraulic jack was used for the purpose of arrangement is shown in Figures 4 and 5.

loading the slabs of various sizes under loading There was one LVDT at the mid-span to measure

arrangements till failure. The load from the jack was the central slab deflection; one LVDT was placed at

applied to the model slabs at their geometric center the middle span of one of the edge beams to measure

Advances in Structural Engineering Vol. 12 No. 2 2009 259

An Experimental Study on Punching Shear Behavior of Concrete Slabs

Figure 6. Typical cracking pattern on the top surface of a

model slab

Figure 5. Test rig and testing arrangement

the central vertical deflection of the edge beam and four

LVDTs were installed at the corner of edge beams to

assess the performance of the supports. A scale was placed

in each sample for the measurement of crack dimensions.

Figure 7. Typical cracking pattern on the bottom surface of a

4. TEST RESULTS

model slab

All the models underwent punching type of failure with

their inherent brittle characteristics and failed in a

punching shear mode. Most of the slab samples failed 5. DISCUSSIONS

at a load much higher than those predicted by the codes. Test results obtained from this study have been analyzed

The cracking pattern of the top surface of all the slabs and shown in Table 2. It has been found that ultimate

were very much localized and approximately had a size punching shear capacity and behavior of slab samples

of average 120mm x 120mm as shown in Figure 6. The are dependent on restraining action of slab edges,

cracking patterns at the bottom surface of slabs having flexural reinforcement ratio, slab thickness and span-to-

low percentage of reinforcement were more severe than depth ratio of the slab.

those having higher percentages of steel. It has been

noticed that the surface area of cracked zone for the 5.1. Deflection

slabs having wider edge beams were more than those The variation of slab deflection with applied load of all

slabs having smaller edge beams. It has also been slabs is shown in Figure 8. It may be recalled that

observed for all the samples that the deflection at complete load-deflection curves of the entire slab tested

support was negligible, pointing out to the fact that could not be traced due to limitation of available

support fixity was ensured, albeit approximately, instruments.

during the testing of the models. A typical crack pattern It is, however, clear from Figure 8 that central slab

after failure on the bottom surface of slab model is deflections were smaller for the slabs restrained by edge

shown in Figure 7. beams. The value of deflection decreased, in general, as

260 Advances in Structural Engineering Vol. 12 No. 2 2009

A.K.M. Jahangir Alam, Khan Mahmud Amanat and Salek M. Seraj

250 0.14

Load deflection curve for all samples 0.12

Reinforcement ratio = 1%

Non-dimensional strength

200 Slab 1

Slab 2 0.1

Slab 3

Applied load (kN)

Slab 4

150 Slab 5 0.08

Slab 6

Slab 7

Slab 8 0.06

100 Slab 9

h = 80mm

Slab 10

Slab 11 0.04 h = 60mm

Slab 12

50 Slab 13 0.02

Slab 14

Slab 15

0

0 0 50 100 150 200 250 300

0 2 4 6 8 10 12 14 16 18 Width of edge beam (mm)

Deflection at slab center (mm)

Figure 9. Effect of edge restraint for 1.0 percent

Figure 8. Deflection at slab center of all slabs under different reinforcement

loading

Table 2. Test results, non-dimensional and normalized punching shear strength of reinforced concrete slabs

Width

Slab Reinfor- of edge Experimental Cylinder Non- Normalized

thickness cement beam failure load strength dimensional punching shear

(h) ratio (ρ) (b) (Pu) (fc′ ) strength (strength

Slab

sample mm % mm kN MPa (Pu/fc′ b0d) Pu/ f c′ b0d)

SLAB1 80 0.5 245 225.16 38.51 0.1099 0.6820

SLAB2 80 1.0 245 242.09 37.42 0.1216 0.7439

SLAB3 80 1.5 245 142.95 28.19 0.0953 0.5061

SLAB4 60 0.5 245 138.12 38.24 0.1062 0.6569

SLAB5 60 1.0 245 147.59 36.60 0.1186 0.7175

SLAB6 60 1.5 245 130.51 41.95 0.0915 0.5927

SLAB7 80 1.0 175 181.64 32.45 0.1052 0.5994

SLAB8 60 0.5 175 133.27 41.30 0.0949 0.6099

SLAB9 60 1.0 175 115.51 33.14 0.1025 0.5902

SLAB10 80 1.0 105 188.89 37.45 0.0948 0.5802

SLAB11 60 0.5 105 112.88 40.43 0.0821 0.5221

SLAB12 60 1.0 105 115.73 37.04 0.0919 0.5593

SLAB13 80 1.0 0 171.96 37.72 0.0857 0.5263

SLAB14 60 0.5 0 84.73 34.71 0.0718 0.4230

SLAB15 60 1.0 0 91.76 33.03 0.0817 0.4696

the degree of edge restraint increased. Deflection is also increase of width of edge beam as well as flexural

very close in same thickness of slab with different reinforcement of slab.

reinforcement ratios. Although the higher the

reinforcement, the smaller the deflection was observed 5.3. Effect of Edge Restraint

for same loading as shown in these figures. Table 2 shows that there was a definite increase in

punching load of the slab panels as the degree of edge

5.2. Ultimate Load Carrying Capacity restraint increased. This trend is also evident in Figure 9,

Analysis of test result as shown in Table 2, where non- where punching shear capacity increased significantly with

dimensional punching shear strength Pu / fc′ b0d, [where, the increase in the width of edge beams up to 245 mm.

d = effective depth of slab, b0 = 4 * (120 + d)] and The enhancement in the punching load carrying

normalized punching shear strength Pu/ f c′ b0d of each capacity of slabs due to edge continuity may be

specimen have been given. There is a general trend to attributed to the possible influence of in-plane restraint.

increase the load carrying capacity of slabs with the Continuous slabs deflect less than similar simply

Advances in Structural Engineering Vol. 12 No. 2 2009 261

An Experimental Study on Punching Shear Behavior of Concrete Slabs

0.14 5.6. Effect of Span to Depth Ratio

0.12 For smaller span to depth ratio of sample, the slab

h = 60mm

Non-dimensional strength

0.1

deflections at center were smaller than those of higher

span to depth ratio. As shown in Table 2, slabs having

0.08

same flexural reinforcement and edge restraint, non-

0.06 p = 0.5% dimensional strengths are higher for smaller span to

p = 1.0% depth ratio.

0.04

0.02

5.7. Cracks

0 During the tests, the development of cracking and the

0 50 100 150 200 250 300

Width of edge beam (mm) width of cracks were carefully observed and monitored at

various load increments. Cracking on the underside of the

Figure 10. Effect of reinforcement for slab thickness of 60mm

slabs developed as a series of cracks radiating from the

centrally loaded area. As the load increased, the widths of

supported slabs under the action of load. This helps the the cracks increased as expected. For lower level of

slabs having edge continuity to sustain more punching reinforcement (ρ=0.5 percent), numbers of cracks were

load (Alam 1997). Other researchers like Salim and small and more spalling occurred than others. For higher

Sebastian (2003), Kuang and Morley (1992), Lovrovich level of flexural reinforcement (ρ=1.5 percent), cracks

and McLean (1990), McLean et al. (1990) and Rankin were concentrated in the middle portion of the slab.

and Long (1987) also advocated enhancement of Cracking pattern were fine and large in number in

punching shear capacity due to restraint action. Similar case of strongly restrained slabs, for moderately

to the findings of other researchers, compressive restrained slabs such cracks were found to be wider and

membrane forces were, in fact, developed in the slabs fewer in number. In case of strongly restrained slabs,

due to edge restraints. due to the presence of in-plane forces, the width of the

cracks was less and consequently the total energy due to

5.4. Effect of Steel Reinforcement punching was distributed among a large number of fine

As shown in Figure 10, the load-carrying capacity of the cracks (Alam 1997; Kuang and Morley 1992). On the

test slab panels increased with the addition of flexural other hand, in slab having lesser amount of lateral

steel reinforcement. restraint, initially produced cracks could widen and

Some other researchers such as Hallgren (1996), thereby, the total energy was distributed to lesser but

Marzouk and Hussein (1991), Vanderbilt (1972), Dilger wider cracks.

et al. (2005), Gardner (2005) also advocated the

increases in the punching load carrying capacity with 6. COMPARISON OF TEST RESULTS WITH

the increase of flexural reinforcement of slab. DIFFERENT CODE PREDICTIONS

In the present study, non-dimensional strength of The load-carrying capacity of all the slab models as

SLAB3 and SLAB6 having 1.50% flexural obtained from test results as well as from the predictions

reinforcement are lower than similar type of other slabs. of ACI 318 (2005), BS 8110 (1997), CAN3-A23.3

Excessive amount of reinforcement sometimes make (2004) and CEB-FIP (1990) is summarized in Table 3.

structural concrete brittle as reported by Seraj et al. Shear punching capacity by Rankin and Long’s

(1995). The decline in punching strength at higher level (Ranking and Long 1987) method is also included in

of reinforcement may also be due to such effects. Table 3. All terms related to various factor of safety have

However, additional tests are needed to investigate, in been put equal to 1.0. While calculating the predicted

detail, the influence of the flexural reinforcement ratio strength of slabs, actual compressive (cylinder) strength

on punching load capacity of concrete slabs. of concrete on the day of testing have been given as

input, whereas compressive cube strength has been

5.5. Effect of Slab Thickness estimated to be 25 percent higher than its cylinder

As shown in Table 2, although the slab thickness is strength counterpart.

already in the denominator of the expression for It is evident from Table 3, for both 80 mm and 60

dimensionless shear strength, it has been found that mm thick slabs, that the experimental load carrying

punching shear capacity of 80mm thick slabs having capacity is much higher than all the code predictions.

same edge restraint, clear span and reinforcement are American code (ACI 318 2005) has been found to be

higher than those of 60mm slabs. This is also more conservative than the others codes while the

evidenced in Figure 9. European CEB-FIP (1990) code was the least

262 Advances in Structural Engineering Vol. 12 No. 2 2009

A.K.M. Jahangir Alam, Khan Mahmud Amanat and Salek M. Seraj

Table 3. Comparison of load carrying capacity with code predictions

Experi-

mental Predicted ultimate load Experimental failure load

failure in kN /Predicted Load

Slab load ACI BS CAN3- CEB-Rankin Expt. Expt. Expt. Expt. Expt.

models in kN 318 8110 A23.3 FIP& long /ACI /BS /CAN /CEB /Rankin

SLAB1 225.2 108.9 104.8 132.1 139.2 115.2 2.07 2.15 1.70 1.62 1.95

SLAB2 242.1 107.3 132.0 130.2 153.0 135.1 2.25 1.83 1.87 1.59 1.79

SLAB3 143.0 93.2 144.9 113.0 126.7 129.7 1.53 0.99 1.27 1.12 1.10

SLAB4 138.1 69.4 66.6 84.1 89.7 73.4 1.99 2.07 1.64 1.54 1.88

SLAB5 147.6 67.9 83.9 82.3 97.6 85.4 2.17 1.76 1.79 1.51 1.73

SLAB6 130.5 72.7 96.1 88.1 106.9 101.1 1.80 1.36 1.48 1.22 1.29

SLAB7 181.6 100.0 132.0 121.2 139.1 125.8 1.82 1.38 1.50 1.31 1.44

SLAB8 133.3 72.1 66.6 87.4 94.5 76.3 1.85 2.00 1.52 1.41 1.75

SLAB9 115.5 64.6 83.9 78.3 91.3 81.2 1.79 1.38 1.48 1.26 1.42

SLAB10 188.9 107.4 132.0 130.2 153.1 135.1 1.76 1.43 1.45 1.23 1.40

SLAB11 112.9 71.3 66.6 86.5 93.1 75.4 1.58 1.69 1.31 1.21 1.50

SLAB12 115.7 68.3 83.9 82.8 98.4 85.9 1.69 1.38 1.40 1.18 1.35

SLAB13 172.0 107.8 132.0 130.7 158.8 135.6 1.59 1.30 1.32 1.08 1.27

SLAB14 84.7 66.1 66.6 88.1 84.1 69.9 1.28 1.27 0.96 1.01 1.21

SLAB15 91.8 64.5 83.9 78.2 91.1 81.1 1.42 1.09 1.17 1.01 1.13

Average 1.77 1.54 1.46 1.29 1.48

Coefficient of variation 0.148 0.224 0.157 0.153 0.180

conservative. The British code (BS 8110 1997) and the reality as shown in Table 2, it may attain much higher

Canadian code (CAN3-23.3 2004) predictions fell in values. Whereas, only further testing may lead to

between the American and CEB-FIP (1990) codes. The possible modifications in code provisions due to the

trend of results calculated by Rankin and Long method dangerous nature of shear failure, CAN3-A23.3

(Rankin and Long 1987) are near to British and (2004) already uses slightly higher values of 0.4 in a

Canadian code. similar equation.

It appears that for slab samples having 0.5 percent It is also shown in Table 3 that, experimental

reinforcement, load carrying capacity predicted by the punching load carrying capacity of 1% flexural

CEB-FIP (1990) and Canadian codes were closer to the reinforcement is higher than all others of slabs of same

experimental load carrying capacity for slabs having thickness. Punching shear strength capacity with 1.5%

zero restraint. In this case, for restrained slabs, CEB-FIP flexural reinforcement as calculated by British,

(1990) code was, once again, found to be less Canadian and CEB-FIP (1990) codes are close to the

conservative than all other codes. American and British experimental load carrying capacity.

codes, were most conservative in predicting the capacity It is observed that punching shear capacity of slabs

of slabs having ρ = 0.5 percent. They also predicted having 1.0 percent reinforcement and 80mm thickness,

similar conservative punching capacity. load carrying capacity in accordance with British and

It is also evident that the experimental load carrying Canadian codes are very close. It appears that for slab

capacity of the slabs increased with the increase in the samples having 0.5 percent reinforcement, load carrying

degree of edge restraint provided by edge beams of capacity predicted by the European and Canadian codes

larger widths. This restraining action of slabs has not were close and in SLAB14, this is very near to

been taken into consideration in any of the code experimental punching capacity.

provisions. The coefficients of variation of test result with

In view of the fact that ACI 318 (2005) is, perhaps, various codes or methods as shown in the Table 3 are

the most commonly used code in the world and also within 14.8% to 22.4% and indicate the consistency of

seems to form the basis of Bangladesh National test results. According to the coefficient of variation,

Building Code (BNBC), the normalized punching deviation from average value of the ratio of

shear strength using ACI code formula (Pu/0.33 f c′ experimental load carrying capacity and predicted load

b 0 d) for different edge restraints as well as capacity in accordance with American, Canadian and

reinforcement ratios are only 0.33 times f c′ b0d, in CEB are almost similar.

Advances in Structural Engineering Vol. 12 No. 2 2009 263

An Experimental Study on Punching Shear Behavior of Concrete Slabs

From the above discussion, it can be concluded that REFERENCES

the present codes may not be capable of predicting the ACI 318. (2005). Building Code Requirements for Structural Concrete

punching shear strength of reinforced concrete slabs and Commentary, American Concrete Institute, Detroit. USA.

satisfactorily taking into account the effect of edge Alam, A. K. M. J. (1997). Punching Shear Behavior of Reinforcement

restraint. For all the slabs tested, the prediction of ACI Concrete Slabs, MSc. Thesis, Department of Civil Engineering,

318 (2005) is most conservative. On the other hand, Bangladesh University of Engineering & Technology, Dhaka,

although European CEB-FIP codes are very much on Bangladesh.

the conservative side, its prediction of punching failure AS 3600. (1994). Australian Standard: Concrete Structures,

load is better and more economical than the others. Standards Association of Australia, Sydney, Australia.

BNBC (1993). Bangladesh National Building Code, Prepared for

7. CONCLUSIONS Housing and Building Research Institute, Dhaka, Bangladesh.

Punching shear tests on fifteen reinforced concrete slabs BS 8110. (1997). Structural use of Concrete: Part 1: Code of

have been reported in this paper. Twelve of these slabs Practice for Design and Construction, British Standard

were restrained at the edges to simulate continuous slab Institution, London.

construction. The test results provided some basic CEB-FIP (1990). Model Code for Concrete Structures, Comite

experimental information on the behavior of restrained Euro-International du Beton, Cement and Concrete Association,

slabs subjected to concentrated loading. All the slabs London.

failed in a punching mode when subjected to punching CSA-A23.3. (2004). Design of Concrete for Buildings, Canadian

load at the slab centre. The following conclusions may Standards Association, Mississauga, Ontario, Canada.

be derived from the limited experimental work reported Dilger, W., Birkle, G. and Mitchell, D. (2005). “Effect of flexural

in this study: reinforcement on punching shear resistance”, ACI Special

a) Punching shear strengths observed from punching Publication on Punching Shear in Reinforced Concrete Slabs,

tests conducted on the restrained reinforced American Concrete Institute, SP-232-4, pp. 57–74.

concrete slabs have been found to be higher than DIN 1045-1. (2001). Tragwerke aus Beton, Stahlbeton und

the predictions of present-day code provisions. Spannbeton; Teil 1: Bemessung und Konstruktion, DIN-

Present code methods underestimate the punching Deutsches Institut fur Normung, Berlin.

load capacity of slabs as the code provisions are Gardner, N.J. (2005). “ACI 318-05, CS A23.3-04, Eurocode 2

based on tests conducted on simply supported (2003), DIN 1045-1 (2001), BS 8110-97 and CEB-FIP MC 90

slabs with their edges unrestrained. The provisions for punching shear of reinforced concrete flat slabs”,

magnitude of the strength enhancement increases ACI Special Issue on Punching Shear in Reinforced Concrete

with the degree of edge restraint. Slabs, American Concrete Institute, Vol. SP-232-1, pp. 1–22.

b) Whereas the level of flexural reinforcement may Hallgren, M. (1996). Punching Shear Capacity of Reinforced High

have a slightly negative or smaller effect on the Strength Concrete Slabs, PhD Thesis, KTH Stockholm, TRITA-

ultimate punching shear capacity of the heavily BKN. Bull. No. 23, pp. 150.

reinforced slabs, it exerts a positive influence for Kuang, J.S. and Morley, C.T. (1992). “Punching shear behavior of

those lightly reinforced. Although British, restrained reinforced concrete slabs”, ACI Structural Journal,

European CEB-FIP and German codes Vol. 89, No. 1, pp. 13–19.

recognize the influence of percentages of steel, Lovrovich, J.S. and McLean, D.I. (1990). “Punching shear behavior

American, Australian and Canadian codes of slabs with varying span-depth ratios”, ACI Structural Journal,

completely ignore the possible influence of the Vol. 87, No. 5, pp. 507–511.

amount of flexural reinforcement in formulating Marzouk, H. and Hussein, A. (1991). “Experimental investigation on

its equations for punching shear capacity of the behavior of high strength concrete slabs”, ACI Structural

slabs. The provisions of all these codes may, Journal, Vol. 88, No. 6, pp. 701–713.

thus, be reviewed to accommodate the influence McLean, D.I., Phan, L.T., Lew, H.S. and White, R.N. (1990).

of flexural steel more rationally. “Punching shear behavior of light weight concrete slabs and

c) The outcome of the present series of tests may shells”, ACI Structural Journal, Vol. 87, No. 4, pp. 386–392.

become useful for the development of a rational Mitchell, D., Cook, W.D. and Dilger, W. (2005). “Effect of size,

method of analysis. Further experimental geometry and material properties on punching shear resistance”,

research on a wide range of slabs is, of course, ACI Special Issue on Punching Shear in Reinforced Concrete

needed to consolidate the findings. Slabs, American Concrete Institute, SP-232-3, pp. 39–56.

264 Advances in Structural Engineering Vol. 12 No. 2 2009

A.K.M. Jahangir Alam, Khan Mahmud Amanat and Salek M. Seraj

Rankin, G.I.B. and Long, A.E. (1987). “Predicting the enhanced Vanderbilt, M.D. (1972). “Shear strength of continuous plates”,

punching strength of interior slab-column connections”, Journal of Structural Division, ASCE, Vol. 98, No. ST5, pp.

Proceedings of the Institution of Civil Engineers, London, Part 1, 961–973.

Vol. 82, pp. 1165–1186.

Salim, W. and Sebastian, W.M. (2003). “Punching shear failure in NOTATION

reinforced concrete slabs with compressive membrane action”, b width of edge beam

ACI Structural Journal, Vol. 100, No. 4, pp. 471–479. b0 length of perimeter of critical section

Seraj, S.M., Kotsovos, M.D. and Pavlovic, M.N. (1995). “Behavior d effective depth of slab

of high-strength mix reinforced concrete beams”, Journal of h slab thickness

Archives of Civil Engineering, Proceedings of the Polish Pu experimental failure load

Academy of Sciences, Vol. 41, No. 1, pp. 31–67. ρ reinforcement ratio

Advances in Structural Engineering Vol. 12 No. 2 2009 265

View publication stats

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Csec2013 Gen 147Document11 pagesCsec2013 Gen 147김대경No ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- J Jobe 2018 01 006Document23 pagesJ Jobe 2018 01 006noor ayaadNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Effect of Skew On The Behaviour of RC Girder BridgesDocument13 pagesEffect of Skew On The Behaviour of RC Girder BridgesPreeti AgarwalNo ratings yet

- Corrosion and its Consequences for Reinforced Concrete StructuresFrom EverandCorrosion and its Consequences for Reinforced Concrete StructuresNo ratings yet

- Pull-Out Test For Studying Bond Strength inDocument14 pagesPull-Out Test For Studying Bond Strength inحسام رسميNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Tension Field ActionDocument19 pagesTension Field ActionKam LauNo ratings yet

- 30-An Experimental Study of Flexural Cracking in ReinDocument49 pages30-An Experimental Study of Flexural Cracking in ReinJan Van MiddendorpNo ratings yet

- Irjet V8i1007Document5 pagesIrjet V8i1007Diwakar Singh RajputNo ratings yet

- Advances in Ceramic Armor, Bioceramics, and Porous MaterialsFrom EverandAdvances in Ceramic Armor, Bioceramics, and Porous MaterialsJerry C. LaSalviaNo ratings yet

- tmpC1DB TMPDocument12 pagestmpC1DB TMPFrontiersNo ratings yet

- Structural Performance of Steel-Concrete-Steel Sandwich Composite Beams With Channel Steel ConnectorsDocument10 pagesStructural Performance of Steel-Concrete-Steel Sandwich Composite Beams With Channel Steel ConnectorsAshokkumar BhaskaranNo ratings yet

- 08-Self Consolidating ConcreteDocument22 pages08-Self Consolidating ConcreteAnuja KumariNo ratings yet

- Base-Plate Calculation Under Tension.: ArticleDocument24 pagesBase-Plate Calculation Under Tension.: ArticlePanos SpNo ratings yet

- Content ServerDocument10 pagesContent ServerMiena Chigharoe GaneshNo ratings yet

- Effect of Corrosion On Performance of Reinforced Concrete Structure UsingDocument4 pagesEffect of Corrosion On Performance of Reinforced Concrete Structure UsingSyed SohailNo ratings yet

- Punching Shear Strength of Reinforced Concrete Slabs Without Transverse Reinforcement by Aurelio Muttoni PDFDocument16 pagesPunching Shear Strength of Reinforced Concrete Slabs Without Transverse Reinforcement by Aurelio Muttoni PDFNuttawuit BigGyNo ratings yet

- University of Texas Report On Galvanized Slip Coefficients Draft Final 4915Document37 pagesUniversity of Texas Report On Galvanized Slip Coefficients Draft Final 4915Jay ZengNo ratings yet

- Behavior and Simplified Modeling of MechanicalDocument10 pagesBehavior and Simplified Modeling of Mechanicalrizky tri amaliaNo ratings yet

- Bolt Force Transfer MechanismDocument10 pagesBolt Force Transfer Mechanismparthiv_mechmind1987No ratings yet

- Numerical Investigation of TheDocument11 pagesNumerical Investigation of Theqasim.asif9No ratings yet

- Reliability of Corroded Steel Girder BridgesDocument11 pagesReliability of Corroded Steel Girder BridgesAnonymous GRuHWbxJr9No ratings yet

- Effects of Welding Residual Stresses On Fatigue Crack Growth Behaviour in Butt Welds of A Pipeline SteelDocument10 pagesEffects of Welding Residual Stresses On Fatigue Crack Growth Behaviour in Butt Welds of A Pipeline SteelJohan Esteban Garcia PuentesNo ratings yet

- Materials 13 05804 v2Document16 pagesMaterials 13 05804 v2deviationzNo ratings yet

- Balanced Cantilever Shear of SegmentsDocument10 pagesBalanced Cantilever Shear of SegmentsTamaduianu IoanNo ratings yet

- Anchor Stiffness FormulaDocument24 pagesAnchor Stiffness FormulaAhsan SattarNo ratings yet

- Grinding s13296-018-0059-1Document8 pagesGrinding s13296-018-0059-1Md MehtabNo ratings yet

- Affecting Aspects On The Behaviour of Frame Joints: HBRC JournalDocument16 pagesAffecting Aspects On The Behaviour of Frame Joints: HBRC JournalVennela VasupilliNo ratings yet

- Punching Shear Strength of Slabs and Influence of Low Reinforcement RatioDocument40 pagesPunching Shear Strength of Slabs and Influence of Low Reinforcement RatioThai DamNo ratings yet

- Stress Analysis of Mast Structure For Water-Well Drilling MachineDocument8 pagesStress Analysis of Mast Structure For Water-Well Drilling MachineBruno Santos100% (1)

- Presentation Coupler SystemDocument21 pagesPresentation Coupler SystemPralhad Kore100% (1)

- 1 PBDocument4 pages1 PBvenkata369No ratings yet

- Kara & Dundar - 2009 - Effect of Inertia and Deflection of A Reinforced Concrete BeamDocument11 pagesKara & Dundar - 2009 - Effect of Inertia and Deflection of A Reinforced Concrete BeamLaila Monteiro A MeloNo ratings yet

- Final Shaking-Table Tests Shear Walls Openings PDFDocument10 pagesFinal Shaking-Table Tests Shear Walls Openings PDFwjcarrilloNo ratings yet

- Analytical Approach of Anchor Rod Stiffness and Steel-Sap2000Document24 pagesAnalytical Approach of Anchor Rod Stiffness and Steel-Sap2000Vladimir GuamanNo ratings yet

- 2002-4.5 Effect of Shrinkage PDFDocument29 pages2002-4.5 Effect of Shrinkage PDFMy Dad My WorldNo ratings yet

- Design of Anchor Reinforcement For Seismic Shear Loads-SubmissionDocument38 pagesDesign of Anchor Reinforcement For Seismic Shear Loads-SubmissionSarah Perez100% (1)

- The Effect of Lap Splice Length On The Cyclic Lateral Load Behavior of RC MembersDocument21 pagesThe Effect of Lap Splice Length On The Cyclic Lateral Load Behavior of RC Memberskhawaja AliNo ratings yet

- Old Rebar EDR 48Document4 pagesOld Rebar EDR 48JimBobNo ratings yet

- Numerical Analytical Model For Seismic Behavior of Prestre - 2011 - Procedia EngDocument8 pagesNumerical Analytical Model For Seismic Behavior of Prestre - 2011 - Procedia EngabdulghafrNo ratings yet

- ANNAN WSBS14FinalDocument9 pagesANNAN WSBS14Final김대경No ratings yet

- Enhanced Punching Shear MethodDocument4 pagesEnhanced Punching Shear Methodgks6043No ratings yet

- Shot PeeningDocument12 pagesShot PeeningAyrton PabloNo ratings yet

- Effect of Shear Span To Depth Ratio On The Statical Behavior of HSCB Subjected To Transverse LoadingDocument26 pagesEffect of Shear Span To Depth Ratio On The Statical Behavior of HSCB Subjected To Transverse LoadingsanjusamsonNo ratings yet

- Restrengthening of R.C.C Beam by Beam Jacketing: January 2013Document10 pagesRestrengthening of R.C.C Beam by Beam Jacketing: January 2013passion777No ratings yet

- Effect of The Bolt Tightening MethodDocument11 pagesEffect of The Bolt Tightening MethodMarta ParaparNo ratings yet

- Steel StrengthDocument10 pagesSteel StrengthjjNo ratings yet

- Experimental Investigations On CompressiDocument18 pagesExperimental Investigations On Compressiyaj leumas seyerNo ratings yet

- ZhangDocument12 pagesZhangSanjay SinghNo ratings yet

- CEPM - Volume 1 - Issue 1 - Pages 58-67Document10 pagesCEPM - Volume 1 - Issue 1 - Pages 58-67abdulghafrNo ratings yet

- Experimental Study On Shear Behavior of I-Girder With Concrete-Filled Tubular Ange and Corrugated WebDocument23 pagesExperimental Study On Shear Behavior of I-Girder With Concrete-Filled Tubular Ange and Corrugated WebhosseinjamNo ratings yet

- Factors Influencing SplitsetDocument36 pagesFactors Influencing SplitsetAntonio RamosNo ratings yet

- ICRS10 HonnigeDocument7 pagesICRS10 HonnigeSaketh BachuNo ratings yet

- Deep BeamDocument9 pagesDeep BeamDeana WhiteNo ratings yet

- Laboratorio Mecánica de Sólidos TorsionDocument11 pagesLaboratorio Mecánica de Sólidos Torsionjuan salazarNo ratings yet

- Water TableDocument5 pagesWater TableJay DoshiNo ratings yet

- Bayan Ko Linis Ko ProgramDocument43 pagesBayan Ko Linis Ko ProgramCymagne Donna Aquino DelarosaNo ratings yet

- Detailed Lesson Plan - Hand Movements and Gestures in Folk DanceDocument2 pagesDetailed Lesson Plan - Hand Movements and Gestures in Folk DanceJaime MenceroNo ratings yet

- NSF Science and Engineering Indicators 2014Document600 pagesNSF Science and Engineering Indicators 2014Adrian ArizmendiNo ratings yet

- Informal and Formal Letter Writing X E Sem II 2018 - 2019Document15 pagesInformal and Formal Letter Writing X E Sem II 2018 - 2019Oana Nedelcu0% (1)

- Discourse Analysis: Understanding How We Understand.: Ey WordDocument7 pagesDiscourse Analysis: Understanding How We Understand.: Ey WordTommy NickelsonNo ratings yet

- MCQ in Engineering Economics Part 11 ECE Board ExamDocument19 pagesMCQ in Engineering Economics Part 11 ECE Board ExamDaryl GwapoNo ratings yet

- NoteDocument4 pagesNoteMost WonNo ratings yet

- Sample Behavioral Interview QuestionsDocument3 pagesSample Behavioral Interview QuestionssanthoshvNo ratings yet

- Astm D448Document3 pagesAstm D448Mutyaba Johnson100% (5)

- English II Homework Module 6Document5 pagesEnglish II Homework Module 6Yojana DubonNo ratings yet

- Backup Archive and Recovery Archive Users and PermissionsDocument5 pagesBackup Archive and Recovery Archive Users and PermissionsgabilovesadellaNo ratings yet

- Guideline For Grade and Compensation FitmentDocument5 pagesGuideline For Grade and Compensation FitmentVijit MisraNo ratings yet

- UCO 359 Key & Solution 05Document3 pagesUCO 359 Key & Solution 05Anwesha SatpathyNo ratings yet

- UPSC Paper 4 Binder PDFDocument17 pagesUPSC Paper 4 Binder PDFHsis AbedNo ratings yet

- Peranan Dan Tanggungjawab PPPDocument19 pagesPeranan Dan Tanggungjawab PPPAcillz M. HaizanNo ratings yet

- Sri Lanka-ADB Partnership: 1966-2016Document156 pagesSri Lanka-ADB Partnership: 1966-2016Asian Development Bank100% (2)

- Welspun One Logistics Parks: Hazard Risk AssessmentDocument2 pagesWelspun One Logistics Parks: Hazard Risk AssessmentR. Ayyanuperumal AyyanuperumalNo ratings yet

- ExtPascal Advanced Configuration Complete Eng v4Document31 pagesExtPascal Advanced Configuration Complete Eng v4jofreezeNo ratings yet

- Construction Manual California PDFDocument956 pagesConstruction Manual California PDFAlexander Ponce VelardeNo ratings yet

- ParallelDocument4 pagesParallelShanntha JoshittaNo ratings yet

- Psych ManualDocument340 pagesPsych ManualMarius_20100% (1)

- Zerkle Dalcroze Workshop HandoutDocument2 pagesZerkle Dalcroze Workshop HandoutEricDoCarmoNo ratings yet

- BS 8901 SEG Press ReleaseDocument3 pagesBS 8901 SEG Press Releasetjsunder449No ratings yet

- Questions: Comma PlacementDocument8 pagesQuestions: Comma PlacementZarbibi Hussain khelNo ratings yet

- Gad Practical-No - 09Document4 pagesGad Practical-No - 09Amal fanseNo ratings yet

- Gary Molander Syllabus 2014Document3 pagesGary Molander Syllabus 2014AlexGeorgeNo ratings yet

- SIL Working Method ReportDocument35 pagesSIL Working Method ReportEmzy Hussein90% (10)

- Virtually Anywhere Lesson Plan Episodes 1 and 2Document6 pagesVirtually Anywhere Lesson Plan Episodes 1 and 2Elyelson dos Santos GomesNo ratings yet

- Innoventure List of Short Listed CandidatesDocument69 pagesInnoventure List of Short Listed CandidatesgovindmalhotraNo ratings yet

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesFrom EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraRating: 4.5 out of 5 stars4.5/5 (4)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsFrom EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsRating: 4 out of 5 stars4/5 (16)

- Engineering for Kids: Building and Construction Fun | Children's Engineering BooksFrom EverandEngineering for Kids: Building and Construction Fun | Children's Engineering BooksRating: 3 out of 5 stars3/5 (2)

- Transmission Pipeline Calculations and Simulations ManualFrom EverandTransmission Pipeline Calculations and Simulations ManualRating: 4.5 out of 5 stars4.5/5 (10)

- Advanced Design Examples of Seismic Retrofit of StructuresFrom EverandAdvanced Design Examples of Seismic Retrofit of StructuresRating: 1 out of 5 stars1/5 (1)