Professional Documents

Culture Documents

Amputation

Uploaded by

Ra sa0 ratings0% found this document useful (0 votes)

14 views2 pagesAmputation safety

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAmputation safety

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pagesAmputation

Uploaded by

Ra saAmputation safety

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

Fring Safety Toies

ety Talk Safety Pro Blo Members Are Become a Member

Amputations

Click here to print an ad-free version ofthis safety talk!

Amputations in the Workplace Safety Talk

‘Amputations are a very serious health and safety concern inthe workplace. OSHA reports there is an average of

sn amputations that occur in US workplaces every single day. This reported number has resulted from OSHA

siting employers to report serious injuries starting in 201S. This average does not include 28 states and

itories that have their own health and safety programs. The number could be even higher due to employers.

knowing about the new reporting rule or those whe purposely avoid reporting these types of injuries to

a

‘ethan 90 percent of the amputations involved fingers, but there were also amputations of the hands, toes,

_ and other body parts. There are many hazards in the workplace that can result in amputations.

emmon Locations Where Amputations Occur

(source OSHA.gov)

Point of operation- This is where a machine is performing work on a material. Some examples of points of,

operation include a razor cutting fabric, a mechanical press bending metal, or a drillbit cutting holes in metal

sheeting.

Power transmission apparatuses- Includes machine components that transmit energy. Some examples include

pulleys, belts, chains, flywheels, cams, gears, and connecting rods.

‘Other machinery parts: Any machinery part that moves with enough force ta cut flesh and bone Is hazard that

‘ean result in an amputation. This would include any parts that reciprocate, rotate, or traverse moving parts

Safeguards Against Amputations

Elimination- Eliminate any hazards that can cause an amputation injury to avoid the possibilty ofthe injury

‘occurring to any individual

Engineering controls: Where there are moving parts, ensure there is proper guarding around the hazard, Use

barriers or fences to keep individuals out af areas where there are many moving parts or machinery. Use safety

devices that shut off the machine if person enters a dangerous area, Other safety devices, such as ones that wll

not allow a machine to function unless the operator's hands are in a safe position, can also be effective in

preventing amputation injuries.

‘Administrative controls- Employees should be trained on recognizing the hazards in their workplace that cause

“amputations, A lock-out/tag-out program ls anather example of an administrative control to prevent injury when

servicing equipment that has moving parts.

Want

safety resol

instead of

Personal precautions- Do not stick your hands where you cannot see ther, Do not bypass guards or work on live

‘equipment. Also, avoid wearing loose clothing or jewelry that could pull your fingers or other body parts into

moving equipment,

‘Summary

{Be aware of the different hazards that can cause amputation injuries in the workplace.

Focus en eliminating as many of these hazards as possible, then look to use effective

engineering controls to protect yourself and coworkers from amputation injuries. Not every

single hazard may be eliminated in your workplace, so always be aware of your

surroundings and never put yourself n a situation where an injury is more likely to occur.

Discussion points:

1. What are tasks we complete here that an amputation injury is a risk?

2. How can we eliminate or mitigate these risks?

Join the Free Email List and Get 10 Member Talks!

Fat Name

you want downloadable PDFS of al ofthe talks? Join as a member and get all ofthe 250+ free talks as well

5 ‘as 300+ additional talks in PFs that are easy to download and print!

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Collins CSEC® Physics Workbook Answers PDFDocument16 pagesCollins CSEC® Physics Workbook Answers PDFRa sa100% (3)

- Collins CSEC® Physics Workbook Answers PDFDocument16 pagesCollins CSEC® Physics Workbook Answers PDFRa sa100% (3)

- Biological Hazards - Wearing Face MasksDocument3 pagesBiological Hazards - Wearing Face MasksRa saNo ratings yet

- OSHA Training Toolbox Talk: Cutting, Welding, & Compressed Gas Safety - Care of Torch HosesDocument2 pagesOSHA Training Toolbox Talk: Cutting, Welding, & Compressed Gas Safety - Care of Torch HosesRa saNo ratings yet

- Biological Hazards - Intro To Bacteria and VirusesDocument2 pagesBiological Hazards - Intro To Bacteria and VirusesRa saNo ratings yet

- Biological Hazards - Primary Modes of Bacteria and Virus TransmissionDocument2 pagesBiological Hazards - Primary Modes of Bacteria and Virus TransmissionRa saNo ratings yet

- OSHA Training Toolbox Talk: Cutting, Welding, & Compressed Gas Safety - Torch AssemblyDocument3 pagesOSHA Training Toolbox Talk: Cutting, Welding, & Compressed Gas Safety - Torch AssemblyRa saNo ratings yet

- OSHA Training Toolbox Talk: Cutting, Welding, & Compressed Gas SafetyDocument2 pagesOSHA Training Toolbox Talk: Cutting, Welding, & Compressed Gas SafetyRa saNo ratings yet

- SEA Language Arts and Creative Writing (2012.2013)Document37 pagesSEA Language Arts and Creative Writing (2012.2013)Ra saNo ratings yet

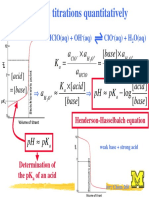

- Acid-Base Titrations Quantitatively: Acid A Base A A A K Acid K A Base Acid PK PHDocument5 pagesAcid-Base Titrations Quantitatively: Acid A Base A A A K Acid K A Base Acid PK PHRa saNo ratings yet

- SEA 2011 Language ArtsDocument16 pagesSEA 2011 Language ArtsRa saNo ratings yet

- SEA Grammar 2015Document28 pagesSEA Grammar 2015Ra saNo ratings yet

- Proximity Trace: in The Time of COVID-19 - How Will You Maintain Safe Working Distances?Document2 pagesProximity Trace: in The Time of COVID-19 - How Will You Maintain Safe Working Distances?Ra saNo ratings yet

- !"5) JK5JLJK5M 5) NjolnnmDocument17 pages!"5) JK5JLJK5M 5) NjolnnmRa saNo ratings yet

- Phase Boundaries: Vapor PressureDocument7 pagesPhase Boundaries: Vapor PressureRa saNo ratings yet

- CRV MANUAL (001-144) (001-054) .Ja - en PDFDocument54 pagesCRV MANUAL (001-144) (001-054) .Ja - en PDFRa saNo ratings yet

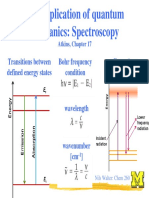

- The Application of Quantum Mechanics: SpectrosDocument7 pagesThe Application of Quantum Mechanics: SpectrosRa saNo ratings yet

- Jap 2018 CRV MANUAL (235-390) (102-156) .Ja - enDocument55 pagesJap 2018 CRV MANUAL (235-390) (102-156) .Ja - enRa saNo ratings yet