Professional Documents

Culture Documents

SRU-mini Operating Manual

Uploaded by

Clint Bryan VirayCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SRU-mini Operating Manual

Uploaded by

Clint Bryan VirayCopyright:

Available Formats

Translation of the original manual

Assembly and Operating Manual

SRU

Pneumatic Rotary Unit

Imprint

Imprint

Copyright:

This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights

reserved.

Technical changes:

We reserve the right to make alterations for the purpose of technical improvement.

Document number: 389439

Version: 13.00 | 19/09/2022 | en

Dear Customer,

thank you for trusting our products and our family-owned company, the leading

technology supplier of robots and production machines.

Our team is always available to answer any questions on this product and other solutions.

Ask us questions and challenge us. We will find a solution!

Best regards,

Your SCHUNK team

Customer Management

Tel. +49-7133-103-2503

Fax +49-7133-103-2189

cmg@de.schunk.com

Please read the operating manual in full and keep it close to the product.

2 13.00 | SRU | Assembly and Operating Manual | en | 389439

Table of Contents

Table of Contents

1 General.................................................................................................................... 5

1.1 About this manual ................................................................................................ 5

1.1.1 Presentation of Warning Labels ............................................................... 5

1.1.2 Applicable documents .............................................................................. 6

1.1.3 Sizes .......................................................................................................... 6

1.1.4 Variants..................................................................................................... 6

1.2 Warranty .............................................................................................................. 6

1.3 Scope of delivery .................................................................................................. 7

1.3.1 Accessory pack.......................................................................................... 7

1.4 Accessories ........................................................................................................... 8

1.4.1 Seal kit ...................................................................................................... 8

2 Basic safety notes ................................................................................................... 9

2.1 Intended use......................................................................................................... 9

2.2 Not intended use .................................................................................................. 9

2.3 Constructional changes ........................................................................................ 9

2.4 Spare parts ......................................................................................................... 10

2.5 Environmental and operating conditions ........................................................... 10

2.6 Personnel qualification....................................................................................... 10

2.7 Personal protective equipment.......................................................................... 11

2.8 Notes on safe operation ..................................................................................... 11

2.9 Transport ............................................................................................................ 12

2.10 Malfunctions....................................................................................................... 12

2.11 Disposal .............................................................................................................. 13

2.12 Fundamental dangers......................................................................................... 13

2.12.1 Protection during handling and assembly .............................................. 13

2.12.2 Protection during commissioning and operation ................................... 14

2.12.3 Protection against dangerous movements............................................. 14

2.12.4 Protection against electric shock............................................................ 15

2.13 Notes on particular risks..................................................................................... 16

3 Technical data......................................................................................................... 18

3.1 Type key.............................................................................................................. 18

3.2 Basic data ........................................................................................................... 19

4 Design and description............................................................................................ 20

4.1 Design ................................................................................................................. 20

4.2 Description ......................................................................................................... 20

5 Assembly ................................................................................................................ 21

5.1 Assembling and connecting................................................................................ 21

5.2 Connections........................................................................................................ 23

5.2.1 Mechanical connection........................................................................... 23

5.2.2 Pneumatic connection............................................................................ 25

13.00 | SRU | Assembly and Operating Manual | en | 389439 3

Table of Contents

5.3 Settings ............................................................................................................... 26

5.3.1 Adjustment of the end positions ............................................................ 26

5.3.2 Adjustment of the central position (Variant M) ..................................... 27

5.4 Installing the sensors .......................................................................................... 28

5.4.1 Overview of sensors ............................................................................... 28

5.4.2 Mounting MMS 22 magnetic switch....................................................... 29

5.4.3 Mounting MMS 22-PI1 programmable magnetic switch........................ 30

6 Commissioning ....................................................................................................... 31

6.1 Setting the speed................................................................................................ 31

6.2 Adjustment of the shock absorber stroke .......................................................... 32

6.2.1 Shock absorber stroke (variant H) .......................................................... 33

6.2.2 Shock absorber stroke (variant S)........................................................... 34

7 Troubleshooting ..................................................................................................... 35

7.1 Product does not move ...................................................................................... 35

7.2 Product does not travel through the entire stroke ............................................ 35

7.3 Product rotates jerkily ........................................................................................ 36

7.4 Torque diminishes? ............................................................................................ 36

8 Maintenance .......................................................................................................... 37

8.1 Notes .................................................................................................................. 37

8.2 Maintenance interval ......................................................................................... 37

8.3 Lubricants/Lubrication points (basic lubrication) ............................................... 38

8.4 Disassembly and assembly ................................................................................. 38

8.4.1 Dismantle product .................................................................................. 38

8.4.2 Notes for assembly ................................................................................. 39

8.4.3 Tightening torque for screws.................................................................. 39

8.4.4 Assembly drawing................................................................................... 40

9 Translation of original declaration of incorporation ................................................ 43

10 Annex to Declaration of Incorporation .................................................................... 44

4 13.00 | SRU | Assembly and Operating Manual | en | 389439

General

1 General

1.1 About this manual

This manual contains important information for a safe and

appropriate use of the product.

This manual is an integral part of the product and must be kept

accessible for the personnel at all times.

Before starting work, the personnel must have read and

understood this operating manual. Prerequisite for safe working is

the observance of all safety instructions in this manual.

In addition to these instructions, the documents listed

under } 1.1.2 [/ 6] are applicable.

NOTE: The illustrations in this manual are intended to provide a

basic understanding and may deviate from the actual version.

1.1.1 Presentation of Warning Labels

To make risks clear, the following signal words and symbols are

used for safety notes.

DANGER

Danger for persons!

Non-observance will inevitably cause irreversible injury or death.

WARNING

Dangers for persons!

Non-observance can lead to irreversible injury and even death.

CAUTION

Dangers for persons!

Non-observance can cause minor injuries.

CAUTION

Material damage!

Information about avoiding material damage.

13.00 | SRU | Assembly and Operating Manual | en | 389439 5

General

1.1.2 Applicable documents

• General terms of business *

• Catalog data sheet of the purchased product *

• Assembly and operating manuals of the accessories *

• For ATEX versions: Supplementary sheet "Installation and

operating instructions - EX" *

The documents labeled with an asterisk (*) can be downloaded

from schunk.com.

1.1.3 Sizes

This operating manual applies to the following sizes:

• SRU 8

• SRU 10

• SRU 12

• SRU 14

1.1.4 Variants

This operating manual applies to the following variations:

• SRU with elastomer dampening (S)

• SRU with hydraulic dampening (H)

• SRU without dampening (W)

• SRU With pneumatic center positioning (M)

• SRU With fluid feed-through

• SRU explosion-protected version (Ex)

1.2 Warranty

If the product is used as intended, the warranty is valid for 24

months from the ex-works delivery date under the following

conditions:

• Observe the specified maintenance and lubrication intervals

• Observe the ambient conditions and operating conditions

Parts touching the workpiece and wear parts are not included in

the warranty.

6 13.00 | SRU | Assembly and Operating Manual | en | 389439

General

1.3 Scope of delivery

The scope of delivery includes

• Pneumatic Rotary Unit SRU in the version ordered

• Assembly and Operating Manual

• Accessory pack

1.3.1 Accessory pack

Content of the accessory pack:

• 2 x centering sleeves for mounting

• 2 x O-rings for hose-free direct connection

• 2 x locking screws for hose connections

• 2 x cylinder pin

ID.-No. of the accessory pack

Accessory pack for Variants ID number

W/H/S 1004955

SRU 8 W/H/S-2 1004956

SRU 10 W/H/S-M 1004957

W/H/S-M-2 1004958

SRU 12 5524552

W/H/S 1004959

SRU 12 W/H/S-4 1004960

SRU 14 W/H/S-M 1004961

W/H/S-M-4 1004962

13.00 | SRU | Assembly and Operating Manual | en | 389439 7

General

1.4 Accessories

A wide range of accessories are available for this product

For information regarding which accessory articles can be used

with the corresponding product variants, see catalog data sheet.

1.4.1 Seal kit

ID.-No. of the seal kit

Seal kit for Variants ID number

W/H/S 5517914

SRU 8 W/H/S-M 5517915

SRU 10 W/H/S-2/4 5517916

W/H/S-2/4 5517917

W/H/S 5517918

SRU 12 W/H/S-M 5517919

W/H/S-2/4 5517920

W/H/S-2/4 5517921

W/H/S 5517922

SRU 14 W/H/S-M 5517923

W/H/S-2/4 5517924

W/H/S-2/4 5517925

Contents of the sealing kit, } 8.4.4 [/ 40].

8 13.00 | SRU | Assembly and Operating Manual | en | 389439

Basic safety notes

2 Basic safety notes

2.1 Intended use

The product may only be used for swiveling permissible

attachment parts or workpieces.

• The product may only be used within the scope of its technical

data, } 3 [/ 18].

• When implementing and operating components in safety-

related parts of the control systems, the basic safety principles

in accordance with DIN EN ISO 13849-2 apply. The proven safety

principles in accordance with DIN EN ISO 13849-2 also apply to

categories 1, 2, 3 and 4.

• The product is intended for installation in a machine/automated

system. The applicable guidelines for the machine/automated

system must be observed and complied with.

• The product is intended for industrial and industry-oriented use.

• Appropriate use of the product includes compliance with all

instructions in this manual.

2.2 Not intended use

Inappropriate use includes using the product as a cutting tool or

drilling tool, for example.

• Any utilization that exceeds or differs from the appropriate use

is regarded as misuse.

2.3 Constructional changes

Implementation of structural changes

By conversions, changes, and reworking, e.g. additional threads,

holes, or safety devices can impair the functioning or safety of the

product or damage it.

• Structural changes should only be made with the written

approval of SCHUNK.

13.00 | SRU | Assembly and Operating Manual | en | 389439 9

Basic safety notes

2.4 Spare parts

Use of unauthorized spare parts

Using unauthorized spare parts can endanger personnel and

damage the product or cause it to malfunction.

• Use only original spare parts or spares authorized by SCHUNK.

2.5 Environmental and operating conditions

Required ambient conditions and operating conditions

Incorrect ambient and operating conditions can make the product

unsafe, leading to the risk of serious injuries, considerable material

damage and/or a significant reduction to the product's life span.

See also Link Daten Umgebungs- und Einsatzbedingungen.

2.6 Personnel qualification

Inadequate qualifications of the personnel

If the personnel working with the product is not sufficiently

qualified, the result may be serious injuries and significant

property damage.

• All work may only be performed by qualified personnel.

• Before working with the product, the personnel must have read

and understood the complete assembly and operating manual.

• Observe the national safety regulations and rules and general

safety instructions.

The following personal qualifications are necessary for the various

activities related to the product:

Trained electrician Due to their technical training, knowledge and experience, trained

electricians are able to work on electrical systems, recognize and

avoid possible dangers and know the relevant standards and

regulations.

Qualified personnel Due to its technical training, knowledge and experience, qualified

personnel is able to perform the delegated tasks, recognize and

avoid possible dangers and knows the relevant standards and

regulations.

Instructed person Instructed persons were instructed by the operator about the

delegated tasks and possible dangers due to improper behaviour.

Service personnel of Due to its technical training, knowledge and experience, service

the manufacturer personnel of the manufacturer is able to perform the delegated

tasks and to recognize and avoid possible dangers.

10 13.00 | SRU | Assembly and Operating Manual | en | 389439

Basic safety notes

2.7 Personal protective equipment

Use of personal protective equipment

Personal protective equipment serves to protect staff against

danger which may interfere with their health or safety at work.

• When working on and with the product, observe the

occupational health and safety regulations and wear the

required personal protective equipment.

• Observe the valid safety and accident prevention regulations.

• Wear protective gloves to guard against sharp edges and

corners or rough surfaces.

• Wear heat-resistant protective gloves when handling hot

surfaces.

• Wear protective gloves and safety goggles when handling

hazardous substances.

• Wear close-fitting protective clothing and also wear long hair in

a hairnet when dealing with moving components.

2.8 Notes on safe operation

Incorrect handling of the personnel

Incorrect handling and assembly may impair the product's safety

and cause serious injuries and considerable material damage.

• Avoid any manner of working that may interfere with the

function and operational safety of the product.

• Use the product as intended.

• Observe the safety notes and assembly instructions.

• Do not expose the product to any corrosive media. This does

not apply to products that are designed for special

environments.

• Eliminate any malfunction immediately.

• Observe the care and maintenance instructions.

• Observe the current safety, accident prevention and

environmental protection regulations regarding the product's

application field.

13.00 | SRU | Assembly and Operating Manual | en | 389439 11

Basic safety notes

2.9 Transport

Handling during transport

Incorrect handling during transport may impair the product's

safety and cause serious injuries and considerable material

damage.

• When handling heavy weights, use lifting equipment to lift the

product and transport it by appropriate means.

• Secure the product against falling during transportation and

handling.

• Stand clear of suspended loads.

2.10 Malfunctions

Behavior in case of malfunctions

• Immediately remove the product from operation and report the

malfunction to the responsible departments/persons.

• Order appropriately trained personnel to rectify the

malfunction.

• Do not recommission the product until the malfunction has

been rectified.

• Test the product after a malfunction to establish whether it still

functions properly and no increased risks have arisen.

12 13.00 | SRU | Assembly and Operating Manual | en | 389439

Basic safety notes

2.11 Disposal

Handling of disposal

The incorrect handling of disposal may impair the product's safety

and cause serious injuries as well as considerable material and

environmental harm.

• Follow local regulations on dispatching product components for

recycling or proper disposal.

2.12 Fundamental dangers

General

• Observe safety distances.

• Never deactivate safety devices.

• Before commissioning the product, take appropriate protective

measures to secure the danger zone.

• Disconnect power sources before installation, modification,

maintenance, or calibration. Ensure that no residual energy

remains in the system.

• If the energy supply is connected, do not move any parts by

hand.

• Do not reach into the open mechanism or movement area of

the product during operation.

2.12.1 Protection during handling and assembly

Incorrect handling and assembly

Incorrect handling and assembly may impair the product's safety

and cause serious injuries and considerable material damage.

• Have all work carried out by appropriately qualified personnel.

• For all work, secure the product against accidental operation.

• Observe the relevant accident prevention rules.

• Use suitable assembly and transport equipment and take

precautions to prevent jamming and crushing.

Incorrect lifting of loads

Falling loads may cause serious injuries and even death.

• Stand clear of suspended loads and do not step into their

swiveling range.

• Never move loads without supervision.

• Do not leave suspended loads unattended.

13.00 | SRU | Assembly and Operating Manual | en | 389439 13

Basic safety notes

2.12.2 Protection during commissioning and operation

Falling or violently ejected components

Falling and violently ejected components can cause serious injuries

and even death.

• Take appropriate protective measures to secure the danger

zone.

• Never step into the danger zone during operation.

2.12.3 Protection against dangerous movements

Unexpected movements

Residual energy in the system may cause serious injuries while

working with the product.

• Switch off the energy supply, ensure that no residual energy

remains and secure against inadvertent reactivation.

• Never rely solely on the response of the monitoring function to

avert danger. Until the installed monitors become effective, it

must be assumed that the drive movement is faulty, with its

action being dependent on the control unit and the current

operating condition of the drive. Perform maintenance work,

modifications, and attachments outside the danger zone

defined by the movement range.

• To avoid accidents and/or material damage, human access to

the movement range of the machine must be restricted. Limit/

prevent accidental access for people in this area due through

technical safety measures. The protective cover and protective

fence must be rigid enough to withstand the maximum possible

movement energy. EMERGENCY STOP switches must be easily

and quickly accessible. Before starting up the machine or

automated system, check that the EMERGENCY STOP system is

working. Prevent operation of the machine if this protective

equipment does not function correctly.

14 13.00 | SRU | Assembly and Operating Manual | en | 389439

Basic safety notes

2.12.4 Protection against electric shock

Possible electrostatic energy

Components or assembly groups may become electrostatically

charged. When the electrostatic charge is touched, the discharge

may trigger a shock reaction leading to injuries.

• The operator must ensure that all components and assembly

groups are included in the local potential equalisation in

accordance with the applicable regulations.

• While paying attention to the actual conditions of the working

environment, the potential equalisation must be implemented

by a specialist electrician according to the applicable

regulations.

• The effectiveness of the potential equalisation must be verified

by executing regular safety measurements.

13.00 | SRU | Assembly and Operating Manual | en | 389439 15

Basic safety notes

2.13 Notes on particular risks

DANGER

Risk of fatal injury from suspended loads!

Falling loads can cause serious injuries and even death.

• Stand clear of suspended loads and do not step within their

swiveling range.

• Never move loads without supervision.

• Do not leave suspended loads unattended.

• Wear suitable protective equipment.

WARNING

Risk of injury from objects falling and being ejected!

Falling and ejected objects during operation can lead to serious

injury or death.

• Take appropriate protective measures to secure the danger

zone.

WARNING

Risk of injury due to unexpected movements!

If the power supply is switched on or residual energy remains in

the system, components can move unexpectedly and cause

serious injuries.

• Before starting any work on the product: Switch off the power

supply and secure against restarting.

• Make sure, that no residual energy remains in the system.

WARNING

Risk of injury from sharp edges and corners!

Sharp edges and corners can cause cuts.

• Use suitable protective equipment.

WARNING

Risk of burns through contact with hot surfaces!

Surfaces of components can heat up severely during operation.

Skin contact with hot surfaces causes severe burns to the skin.

• For all work in the vicinity of hot surfaces, wear safety gloves.

• Before carrying out any work, make sure that all surfaces have

cooled down to the ambient temperature.

16 13.00 | SRU | Assembly and Operating Manual | en | 389439

Basic safety notes

WARNING

Risk of injury from parts coming loose!

If the shock absorbers are faulty, the product can become

damaged. Parts coming loose in this way can lead to injuries.

• Regularly check the components for wear and damage.

WARNING

Risk of injury if the condition or behavior of the product is

undefined!

Cutting off the compressed air supply in an uncontrolled manner

could lead to undefined states and behavior. This may cause

personal injury or material damage.

• The operator must define suitable emergency stop and

restarting strategies.

✓ Emergency stop strategies: e.g. by means of controlled shut

down

✓ Restarting strategies: e.g. using pressure build-up valves or

suitable valve switching sequences

13.00 | SRU | Assembly and Operating Manual | en | 389439 17

Technical data

3 Technical data

3.1 Type key

SRU mini-8 - W- M - 4 - EX-

Size

8 12 10 14

Dampening method

S = speed W = soft H = hard

Center position

– = no M = pneumatic

Fluid feed-through

– = no 2 = 2 channels 4 = 2 channels

Explosion-protected version

– = no EX

18 13.00 | SRU | Assembly and Operating Manual | en | 389439

Technical data

3.2 Basic data

Operating data

SRU 8, 10, 12, 14

Designation S/H/W

Angle of rotation [°] 180

End position adjustability [°]

Min. -3

Max. +90

Repeatability [mm] < 0.07

Pressure medium Compressed air, compressed air

quality according to

ISO 8573-1: 7:4:4

Nominal operating pressure [bar] 6

Min. pressure [bar] 4.5

Max. pressure [bar] 8

More technical data is included in the catalog data sheet.

Whichever is the latest version.

Ambient conditions and operating conditions

SRU 8, 10, 12, SRU 8, 10, 12,

14 14

Designation variant S/H variant W

Ambient temperature [°C]

min. +5 +5

max. +60 +90

Relative air humidity [%]

min. 35

max. (free from condensation) 85

Protection class IP * 65

Noise emission [dB(A)] ≤ 70

* For use in dirty ambient conditions (e.g. sprayed water, vapors,

abrasion or processing dust) SCHUNK offers corresponding

product options as standard. SCHUNK also offers customized

solutions for special applications in dirty ambient conditions.

13.00 | SRU | Assembly and Operating Manual | en | 389439 19

Design and description

4 Design and description

4.1 Design

Pneumatic Rotary Unit, variant "S" displayed

1 Pinion

2 Main air connections

3 Housing with grooves for sensors

4 Shock absorbers

5 Sleeve for adjusting the end positions

4.2 Description

The product is a pneumatic miniature swivel unit for rotating and

swiveling movements with various options.

• Hydraulic dampening (variant H)

• Elastomer dampening (variant S)

• Without dampening (variant W)

• Pneumatic center position (variant M)

• Fluid feed-through

20 13.00 | SRU | Assembly and Operating Manual | en | 389439

Assembly

5 Assembly

5.1 Assembling and connecting

DANGER

Danger of explosion in potentially explosive areas!

• Observe supplementary sheet for products with explosion-

resistant versions "SRU -...-EX".

WARNING

Risk of injury due to unexpected movements!

If the power supply is switched on or residual energy remains in

the system, components can move unexpectedly and cause

serious injuries.

• Before starting any work on the product: Switch off the power

supply and secure against restarting.

• Make sure, that no residual energy remains in the system.

CAUTION

Material damage due to faulty settings and assembly.

If the end position is approached too aprubtly, the product may

be damaged.

• Ensure the turning / swiveling movement is carried out

without bouncing or bumping.

• Therefore provide sufficient throttling and damping.

• Please observe the information in the catalog data sheet.

CAUTION

Material damage due to opened exhaust air throttle valves!

If during first actuation the exhaust throttle valves are open, the

product may move in an uncontrolled manner.

• Close the exhaust air throttle valves completely before

applying pressure.

NOTE

• Observe the requirements for the compressed air

supply, } 3 [/ 18].

• In case of compressed air loss (cutting off the energy line), the

product loses its dynamic effects and does not remain in a

secure position. However, the use of a SDV-P pressure

maintenance valve is recommended in this case in order to

maintain the dynamic effect for some time.

13.00 | SRU | Assembly and Operating Manual | en | 389439 21

Assembly

1. Screw the product to the machine/system, } 5.2.1 [/ 23].

✓ Use centering sleeves.

✓ Observe the tightening torque for the mounting screws, see

the following table.

2. Fasten attachment with two cylindrical pins and two fastening

screws to the pinion, } 5.2.1 [/ 23].

IMPORTANT! Insert the cylindrical pins by hand. Do not

hammer the pinion.

3. In the main air connections "A" and "B", screw in throttle

valves and connect compressed air lines, } 5.2.2 [/ 25].

OR with hose-free direct connection:

✓ Mount throttle valves in the supply lines "a" and "b".

✓ Use O-rings from the accessory pack.

4. Check that all of the throttle valves are closed.

5. Screw in locking screws in open and not required air

connections where appropriate.

6. Adjust end positions, } 5.3.1 [/ 26].

7. Adjust center position if necessary, } 5.3.2 [/ 27]

8. Mount sensor if necessary, } 5.4 [/ 28].

9. Adjust swiveling speed, } 6.1 [/ 31].

10. Adjust shock absorber stroke, } 6.2 [/ 32].

22 13.00 | SRU | Assembly and Operating Manual | en | 389439

Assembly

5.2 Connections

5.2.1 Mechanical connection

Evenness of the The values apply to the whole mounting surface to which the

mounting surface product is mounted.

Requirements for evenness of the mounting surface (Dimensions in mm)

Edge length Permissible unevenness

< 100 < 0.02

> 100 < 0.05

Mounting The module can be mounted from the top, from the bottom or

from the side.

Assembly options

13.00 | SRU | Assembly and Operating Manual | en | 389439 23

Assembly

Mounting material

SRU

Item Designation 8 10 12 14

91 Centering sleeves Ø5 Ø5 Ø6 Ø6

92 Screws for fastening from M2.5 / M2.5 / M3 / M3 /

above (output side) 25 25 35 35

deep deep deep deep

Max. tightening torque [Nm] 0.75 0.75 1.3 1.3

1 Screws for fastening from M3 / M3 / M4 / M4 /

below (underside) 4.5 4.5 6 6

deep deep deep deep

Max. tightening torque [Nm] 1.3 1.3 3 3

2 Screws for fastening on the M3 / M3 / M4 / M4 /

side 4.5 4.5 6 6

deep deep deep deep

Max. tightening torque [Nm] 1.3 1.3 3 3

3 Screws for fastening the M3 / M3 / M4 / M4 /

adapter plate 4 deep 4 deep 5 deep 5 deep

Max. tightening torque [Nm] 1.3 1.3 3 3

93 Cylindrical pin for securing Ø3 x 8 Ø3 x 8 Ø4 x 8 Ø4 x 8

the adapter plate

24 13.00 | SRU | Assembly and Operating Manual | en | 389439

Assembly

5.2.2 Pneumatic connection

CAUTION

Avoid causing damage by approaching the end positions softly.

• Attach the one-way control valve to the product when

connecting to the center position.

Air connections

Thread diameter of the air connections

SRU

Item Designation 8 10 12 14

1 Thread diameter hose M3

connection (A ; B ; C)

2 Thread diameter hose-free M3

direct connection on base side

(a ; b ; c)

A Hose connection für swiveling clockwise

B Hose connection für swiveling counter-clockwise

C Hose connection for swiveling in center position

Further information on the hose-free direct connection contains

the catalog data sheet.

13.00 | SRU | Assembly and Operating Manual | en | 389439 25

Assembly

5.3 Settings

5.3.1 Adjustment of the end positions

Connection B

Connection A

Variant W

Stop A

Stop B

Connection B Connection A

Variant H or variant S

Stop A

Stop B

Adjustment of the end positions

1. Apply pressure to connection A until the rotary unit has

reached its end position.

2. Loosen the lock nut (40) at stop B.

3. Set the end position with sleeve B (5) and stop B (15).

4. Hold sleeve B (5) and stop B (15) tight and tighten the lock nut (40).

5. Check the end positions.

6. Apply pressure to connection B until the rotary unit has

reached its end position.

7. Loosen the lock nut (40) at stop A.

8. Set the end position with sleeve A (5) and stop A (15).

9. Hold sleeve A (5) and stop A (15) tight and tighten the lock nut

(40).

10. Check the end positions.

NOTE

When the lock nut (40) is loosened, air can escape at the sleeve

(5) and at the stop (15). This is due to the design and is normal.

26 13.00 | SRU | Assembly and Operating Manual | en | 389439

Assembly

5.3.2 Adjustment of the central position (Variant M)

Adjustment of the central position

1. Depressurize connections A and B.

2. Apply air pressure to connection C.

3. Loosen the lock nuts (54) of the stop spindles (25).

4. Unscrew stop A2 as far as possible.

5. Turn the pinion clockwise and keep it pressed against stop A1.

6. Turn stop A1 until the desired central position has been

reached.

7. Turn stop A2 until there is no more play in the pinion in the

central position.

8. Retighten the lock nuts (54) of the stop spindles (25).

9. Rotate several times to check the correct setting of the central

position.

13.00 | SRU | Assembly and Operating Manual | en | 389439 27

Assembly

5.4 Installing the sensors

DANGER

Danger of explosion in potentially explosive areas!

• Observe supplementary sheet for products with explosion-

resistant versions "SRU -...-EX".

NOTE

Observe the assembly and operating manual of the sensor for

mounting and connecting.

The product is prepared for the use of sensors.

• For the exact type designations of suitable sensors, please see

catalog datasheet and } 5.4.1 [/ 28].

• For technical data for the suitable sensors, see assembly and

operating manual and catalog datasheet.

– The assembly and operating manual and catalog datasheet

are included in the scope of delivery for the sensors and are

available at schunk.com.

• Information on handling sensors is available at schunk.com or

from SCHUNK contact persons.

5.4.1 Overview of sensors

SRU

Designation 8 10 12 14

Magnetic switch MMS 22 X X X X

Programmable magnetic switch MMS 22-PI1 X X X X

28 13.00 | SRU | Assembly and Operating Manual | en | 389439

Assembly

5.4.2 Mounting MMS 22 magnetic switch

CAUTION

Material damage due to an incorrect tightening torque!

If the threaded pin is tightened with an incorrect tightening

torque, the product may be damaged.

• Observe a maximum tightening torque of 10 Ncm for the set-

screws.

Two groves have been worked into the housing to mount the

sensors.

1. Connect sensor and secure cable, see the Sensor Assembly and

Operating Manual.

2. Apply air pressure to connection "A" (4).

✓ Pinion (2) swivels towards the end position.

3. Insert or screw the first sensor (1) into the groove (5).

4. Move the sensor along the groove until it actuates.

5. Tighten set screw (8).

✓ Tightening torque: 10 Ncm

6. Bleed connection "A" (4).

7. Actuate connection "B" (3).

✓ Pinion (2) swivels into the other end position.

8. Insert or screw the second sensor (1) into the groove (6).

9. Move the sensor along the groove until it actuates.

10. Tighten set screw (8).

✓ Tightening torque: 10 Ncm

11. Check the switching position and test its function.

Center position Rotate unit in the center position and mount sensor analogously.

variant

13.00 | SRU | Assembly and Operating Manual | en | 389439 29

Assembly

5.4.3 Mounting MMS 22-PI1 programmable magnetic switch

CAUTION

Material damage due to an incorrect tightening torque!

If the threaded pin is tightened with an incorrect tightening

torque, the product may be damaged.

• Observe a maximum tightening torque of 10 Ncm for the set-

screws.

Two groves have been worked into the housing to mount the

sensors.

1. Connect sensor and secure cable, see the Sensor Assembly and

Operating Manual.

2. Apply air pressure to connection "A" (4).

✓ Pinion (2) swivels towards the end position.

3. Hold teaching tool to the sensor (1) until the sensor flashes.

4. Insert or screw the sensor (1) into the groove (5), until the

sensor flashes rapidly.

5. Tighten set screw (8).

✓ Tightening torque: 10 Ncm

6. Bleed connection "A" (4).

7. Actuate connection "B" (3).

✓ Pinion (2) swivels into the other end position.

8. Repeat steps for the second sensor.

9. Check the switching position and test its function.

Center position Rotate unit in the center position and mount sensor analogously.

variant

30 13.00 | SRU | Assembly and Operating Manual | en | 389439

Commissioning

6 Commissioning

CAUTION

Damage to the rotary module possible!

The rotary module can be damaged if it arrives too abruptly in

the end position.

• The rotary motion must reach the end position without jerk or

bounce.

• Therefore flow control valves and shock absorbers must be

used, } 6.1 [/ 31] and } 6.2 [/ 32].

• Please observe the information in the catalog pages.

6.1 Setting the speed

CAUTION

Material damage due to erroneous settings!

If the end position is approached too hard, the product may be

damaged.

• Adjust exhaust throttle valve and shock absorber so that the

movement is braked smoothly.

1. Close exhaust throttle valve completely.

2. Open exhaust throttle valve until the product starts to move.

3. Continue to open the exhaust throttle valve incrementally until

the movement decelerates smoothly.

✓ If the speed is too low, the product will brake too soon and

the end position will be reached too slowly.

✓ If the speed is too high, the product will impact against the

end position and the shock absorber will be overloaded.

NOTE

A smooth motion may also be too slow in many use-cases. Further

settings can be made via the shock absorbers, } 6.2 [/ 32].

13.00 | SRU | Assembly and Operating Manual | en | 389439 31

Commissioning

6.2 Adjustment of the shock absorber stroke

NOTE

When received from the factory, the unit is set to utilize the

maximum shock absorber stroke.

Movement

End position

Target position

Damping

Time T

Target time

The shock absorber stroke is too long and the end position is

reached too slowly.

Movement

End position

Target position

Damping

Time T

Target time

The shock absorber stroke is too short and the unit arrives in the

end position too abruptly.

Movement

End position

Target position

Damping

Time T

Target time

Optimal shock absorber stroke.

32 13.00 | SRU | Assembly and Operating Manual | en | 389439

Commissioning

6.2.1 Shock absorber stroke (variant H)

ConnectionB

ConnectionA

Stop B

Stop A

Adjusting the shock absorber

Adjusting the 1. Apply air pressure to connection A.

dampening for 2. Loosen the counter nut (46) from the stop B, by holding the

end position 0° sleeve (5).

3. Unscrew the shock absorber (49) to decrease dampening and

swiveling time.

4. Load and rotate the product to check the shock absorption

effect.IMPORTANT! The end position must be reached

gently, } 6.2 [/ 32].

5. Hold on to the sleeve (5) and shock absorber (49) and tighten

the counter nut (46).

Adjusting the 1. Apply air pressure to connection B.

dampening for 2. Loosen the counter nut (46) from the stop A, by holding the

end position 180° sleeve (5).

3. Unscrew the shock absorber (49) to decrease dampening and

swiveling time.

4. Load and rotate the product to check the shock absorption

effect. IMPORTANT! The end position must be reached

gently, } 6.2 [/ 32].

5. Hold on to the sleeve (5) and shock absorber (49) and tighten

the counter nut (46).

NOTE

Air can escape from the shock absorber (49) if the counter nut

(40) is loosened. This is normal and part of the design.

13.00 | SRU | Assembly and Operating Manual | en | 389439 33

Commissioning

6.2.2 Shock absorber stroke (variant S)

ConnectionB

ConnectionA

Stop B

Stop A

Adjustment of the shock absorber

Pos. X SRU

10 12 14

Maximum screw-in depth of the shock 20.5 24 34

absorber [mm]

Setting the shock 1. Apply air pressure to connection A.

absorption for 2. Loosen lock nut (46) on stop B, providing counter support for

end position 0° the sleeve (61).

3. Unscrew the shock absorber (69) to decrease shock absorption

and rotation time.

4. Load and swivel module to check damping effect.

IMPORTANT! The end position must be approached

softly,} 6.2 [/ 32]

5. Hold sleeve (61) and shock absorber (69) tight and retighten

the lock nut (46).

Setting the shock 1. Apply air pressure to connection B.

absorption for 2. Loosen lock nut (46) on stop A, providing counter support for

end position 180° the sleeve (61).

3. Unscrew the shock absorber (69) to decrease shock absorption

and rotation time.

4. Load and swivel module to check damping effect.

IMPORTANT! The end position must be approached

softly,} 6.2 [/ 32]

5. Hold sleeve (61) and shock absorber (69) tight and retighten

the lock nut (46) firmly.

NOTE

When the lock nut (40) is loosened, air can escape at the shock

absorber (49). This is due to the design and is normal.

34 13.00 | SRU | Assembly and Operating Manual | en | 389439

Troubleshooting

7 Troubleshooting

7.1 Product does not move

Possible cause Corrective action

Pressure drops below minimum. Check air supply.

} 5.2.2 [/ 25]

Compressed air lines switched. Check compressed air lines.

} 5.2.2 [/ 25]

Proximity switch defective or set incorrect. Readjust or change sensor.

Unused air connections open. Close unused air connections.

Flow control valve closed. Open the flow control valve.

Component part defective. Replace component or send it to SCHUNK

for repair.

7.2 Product does not travel through the entire stroke

Possible cause Corrective action

Accumulation of dirt between stop / sleeve Clean and if necessary re-lubricate.

and pistons. } 8 [/ 37]

End positions are adjusted incorrectly. Adjust end position.

} 5.3.1 [/ 26]

Pressure drops below minimum. Check air supply.

} 3 [/ 18]

Mounting surface is not sufficiently flat. Check the evenness of the mounting surface.

} 5.2.1 [/ 23]

Component part defective. Send product with a SCHUNK repair order or

dismantle product.

13.00 | SRU | Assembly and Operating Manual | en | 389439 35

Troubleshooting

7.3 Product rotates jerkily

Possible cause Corrective action

Too little grease in the mechanical guiding Clean and lubricate product., } 8 [/ 37]

areas.

Compressed air lines blocked. Check compressed air lines of damage.

Mounting surface is not sufficiently flat. Check the evenness of the mounting surface.

One-way flow control valve is missing or Install and adjust one-way flow control

adjustet incorrectly. valve.

Loading too large. Check the permissible weight., } 5.2.1 [/ 23]

7.4 Torque diminishes?

Possible cause Corrective action

Compressed air can escape. Check seals, if necessary, disassemble the

product and replace seals. } 8.4.1 [/ 38]

Too much grease in the mechanical Clean and lubricate product.

movement space. } 8 [/ 37]

Pressure drops below minimum. Check air supply.

} 5.2.2 [/ 25]

36 13.00 | SRU | Assembly and Operating Manual | en | 389439

Maintenance

8 Maintenance

8.1 Notes

DANGER

Danger of explosion in potentially explosive areas!

• Observe supplementary sheet for products with explosion-

resistant versions "SRU -...-EX".

Original spare parts

Use only original spare parts of SCHUNK when replacing spare and

wear parts.

8.2 Maintenance interval

CAUTION

Material damage due to hardening lubricants!

Lubricants harden more quickly at temperatures above 60°C,

leading to possible product damage.

• Reduce the lubricant intervals accordingly.

Interval Maintenance work

(million cycles)

for SRU 8 - 14

2 Clean all parts thoroughly, check for damage

and wear, if necessary replace seals and

wearing parts, } 8.4 [/ 38].

• Position of the wearing

parts, } 8.4.4 [/ 40]

• Seal kit, } 1.4.1 [/ 8]

2 Treat all grease areas with lubricant.

Oil or grease external steel

parts. } 8.3 [/ 38].

2 For H variant:

Check that the shock absorber is working, if

necessary replace the shock

absorber, } 8.4 [/ 38].

2 For S variant:

Check that the elastomer is working, if

necessary replace the

elastomer, } 8.4 [/ 38].

13.00 | SRU | Assembly and Operating Manual | en | 389439 37

Maintenance

8.3 Lubricants/Lubrication points (basic lubrication)

SCHUNK recommends the lubricants listed.

During maintenance, treat all greased areas with lubricant. Thinly

apply lubricant with a lint-free cloth.

Lubricant point Lubricant

The teeth and the pinion Toothgood 1

All seals Sealgood 1

8.4 Disassembly and assembly

8.4.1 Dismantle product

Position of the item numbers } 8.4.4 [/ 40]

1. Remove the compressed air hoses.

2. Unscrew the screws (34) and remove the cover 1 (3).

3. Unscrew the screws (60) and remove the cover 2 (14).

4. Mark the installation position of the piston (2) and the pinion

(6 / 16).

5. Version with media feed-through: Unscrew the screws (41) and

remove the cover (18).

6. Disassemble the safety ring (33) on the pinion.

7. Type SRU 8 and Type SRU 10: Remove the washer (7).

8. Press the pinion (6 / 16) upward out of the housing (1).

9. Servicing the module.

WARNING

Risk of injury due to unexpected movements!

If the power supply is switched on or residual energy remains in

the system, components can move unexpectedly and cause

serious injuries.

• Before starting any work on the product: Switch off the power

supply and secure against restarting.

• Make sure, that no residual energy remains in the system.

38 13.00 | SRU | Assembly and Operating Manual | en | 389439

Maintenance

8.4.2 Notes for assembly

Assembly takes place in the opposite order to disassembly.

Observe the following:

• Unless otherwise specified, secure all screws and nuts with

Loctite no. 243 and tighten with the appropriate tightening

torque.} 8.4.3 [/ 39]

CAUTION

Material damage due to incorrect assembly!

The O-rings (42) can become damaged during assembly.

• Install the cover for the internal air feed-through (18)

carefully.

• The cover for the internal air feed-through (18) can be

installed rotated by 180°, if required.

8.4.3 Tightening torque for screws

Position of the item numbers } 8.4.4 [/ 40]

Specified in Nm

Item SRU

8 10 12 14

34 0.75 0.75 1.3 1.3

41 0.75 0.75 1.3 1.3

60 0.75 0.75 1.3 1.3

13.00 | SRU | Assembly and Operating Manual | en | 389439 39

Maintenance

8.4.4 Assembly drawing

The following figures are example images.

They serve for illustration and assignment of the spare parts.

Variations are possible depending on size and variant.

* Wearing part, replace during maintenance. Included in the

seal kit. Seal kit can only be ordered completely.

** only for SRU 8 and SRU 10

Assembly of swivel unit

40 13.00 | SRU | Assembly and Operating Manual | en | 389439

Maintenance

Assembly of fluid feed-through and hydraulic damping

Assembly of swivel unit with center position

13.00 | SRU | Assembly and Operating Manual | en | 389439 41

Maintenance

Assembly of swivel unit with damper elastomer damping

42 13.00 | SRU | Assembly and Operating Manual | en | 389439

Translation of original declaration of incorporation

9 Translation of original declaration of incorporation

in terms of the Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of

the Council on machinery.

Manufacturer/ SCHUNK GmbH & Co. KG Clamping and gripping technology

Distributor Bahnhofstr. 106 - 134

D-74348 Lauffen/Neckar

We hereby declare that on the date of the declaration the following partly completed

machine complied with all basic safety and health regulations found in the directive

2006/42/EC of the European Parliament and of the Council on machinery. The declaration

is rendered invalid if modifications are made to the product.

Product designation: Pneumatic Rotary Unit / SRU / pneumatic

ID number 0356810 ... 0356877 0356930 ... 0356973

The partly completed machine may not be put into operation until conformity of the

machine into which the partly completed machine is to be installed with the provisions of

the Machinery Directive (2006/42/EC) is confirmed.

Applied harmonized standards, especially:

EN ISO 12100:2010 Safety of machinery - General principles for design -

Risk assessment and risk reduction

The manufacturer agrees to forward on demand the relevant technical documentation for

the partly completed machinery in electronic form to national authorities.

The relevant technical documentation according to Annex VII, Part B, belonging to the

partly completed machinery, has been created.

Person authorized to compile the technical documentation:

Robert Leuthner, Address: see manufacturer's address

Lauffen/Neckar, September 2022 p.p. Ralf Winkler; Head of Technology & Engineering,

Mechanics Gripping Systems

13.00 | SRU | Assembly and Operating Manual | en | 389439 43

Annex to Declaration of Incorporation

10 Annex to Declaration of Incorporation

according 2006/42/EG, Annex II, No. 1 B

1.Description of the essential health and safety requirements pursuant to 2006/42/EC,

Annex I that are applicable and that have been fulfilled with:

Product designation Pneumatic Rotary Unit

Type designation SRU

ID number 0356810 ... 0356877 0356930 ... 0356973

To be provided by the System Integrator for the overall machine ⇓

Fulfilled for the scope of the partly completed machine ⇓

Not relevant ⇓

1.1 Essential Requirements

1.1.1 Definitions X

1.1.2 Principles of safety integration X

1.1.3 Materials and products X

1.1.4 Lighting X

1.1.5 Design of machinery to facilitate its handling X

1.1.6 Ergonomics X

1.1.7 Operating positions X

1.1.8 Seating X

1.2 Control Systems

1.2.1 Safety and reliability of control systems X

1.2.2 Control devices X

1.2.3 Starting X

1.2.4 Stopping X

1.2.4.1 Normal stop X

1.2.4.2 Operational stop X

1.2.4.3 Emergency stop X

1.2.4.4 Assembly of machinery X

1.2.5 Selection of control or operating modes X

1.2.6 Failure of the power supply X

1.3 Protection against mechanical hazards

1.3.1 Risk of loss of stability X

1.3.2 Risk of break-up during operation X

1.3.3 Risks due to falling or ejected objects X

1.3.4 Risks due to surfaces, edges or angles X

1.3.5 Risks related to combined machinery X

1.3.6 Risks related to variations in operating conditions X

44 13.00 | SRU | Assembly and Operating Manual | en | 389439

Annex to Declaration of Incorporation

1.3 Protection against mechanical hazards

1.3.7 Risks related to moving parts X

1.3.8 Choice of protection against risks arising from moving parts X

1.3.8.1 Moving transmission parts X

1.3.8.2 Moving parts involved in the process X

1.3.9 Risks of uncontrolled movements X

1.4 Required characteristics of guards and protective devices

1.4.1 General requirements X

1.4.2 Special requirements for guards X

1.4.2.1 Fixed guards X

1.4.2.2 Interlocking movable guards X

1.4.2.3 Adjustable guards restricting access X

1.4.3 Special requirements for protective devices X

1.5 Risks due to other hazards

1.5.1 Electricity supply X

1.5.2 Static electricity X

1.5.3 Energy supply other than electricity X

1.5.4 Errors of fitting X

1.5.5 Extreme temperatures X

1.5.6 Fire X

1.5.7 Explosion X

1.5.8 Noise X

1.5.9 Vibrations X

1.5.10 Radiation X

1.5.11 External radiation X

1.5.12 Laser radiation X

1.5.13 Emissions of hazardous materials and substances X

1.5.14 Risk of being trapped in a machine X

1.5.15 Risk of slipping, tripping or falling X

1.5.16 Lightning X

1.6 Maintenance

1.6.1 Machinery maintenance X

1.6.2 Access to operating positions and servicing points X

1.6.3 Isolation of energy sources X

1.6.4 Operator intervention X

1.6.5 Cleaning of internal parts X

13.00 | SRU | Assembly and Operating Manual | en | 389439 45

Annex to Declaration of Incorporation

1.7 Information

1.7.1 Information and warnings on the machinery X

1.7.1.1 Information and information devices X

1.7.1.2 Warning devices X

1.7.2 Warning of residual risks X

1.7.3 Marking of machinery X

1.7.4 Instructions X

1.7.4.1 General principles for the drafting of instructions X

1.7.4.2 Contents of the instructions X

1.7.4.3 Sales literature X

The classification from Annex 1 is to be supplemented from here

forward.

2 Supplementary essential health and safety requirements for certain X

categories of machinery

2.1 Foodstuffs machinery and machinery for cosmetics or pharmaceutical X

products

2.2 Portable hand-held and/or guided machinery X

2.2.1 Portable fixing and other impact machinery X

2.3 Machinery for working wood and material with similar physical X

characteristics

3 Supplementary essential health and safety requirements to offset X

hazards due to the mobility of machinery

4 Supplementary essential health and safety requirements to offset X

hazards due to lifting operations

5 Supplementary essential health and safety requirements for machinery X

intended for underground work

6 Supplementary essential health and safety requirements for machinery X

presenting particular hazards due to the lifting of persons

46 13.00 | SRU | Assembly and Operating Manual | en | 389439

Translation of the original manual

13.00 | SRU | Assembly and Operating Manual | en | 389439

SCHUNK GmbH & Co. KG

Clamping and gripping technology

Bahnhofstr. 106 - 134

© 2022 SCHUNK GmbH & Co. KG

D-74348 Lauffen/Neckar

Tel. +49-7133-103-0

Fax +49-7133-103-2399

info@de.schunk.com

schunk.com

Folgen Sie uns I Follow us

09-2022

You might also like

- SRU-Plus 20-60Document88 pagesSRU-Plus 20-60Ernesto SanchezNo ratings yet

- MPZ Operating ManualDocument48 pagesMPZ Operating Manualweslley.luzNo ratings yet

- Schunk EGP 44Document48 pagesSchunk EGP 44Györk Attila KrasznaiNo ratings yet

- Baxi 200 Combi 2 Installation ManualDocument84 pagesBaxi 200 Combi 2 Installation ManualGas engineerNo ratings yet

- JUMO VariTRON 500 Operating ManualDocument110 pagesJUMO VariTRON 500 Operating ManualNatiqNo ratings yet

- 905 Titrando Metrohm User ManualDocument53 pages905 Titrando Metrohm User ManualFelipe CadenaNo ratings yet

- Umfluxus Wdv2-1enDocument193 pagesUmfluxus Wdv2-1engelealdo souza ferreiraNo ratings yet

- UMFLUXUS_F808V2-2ENDocument171 pagesUMFLUXUS_F808V2-2ENGeorge BermúdezNo ratings yet

- 88968004EN Manual 896 Professional Detector - ConductivityDocument40 pages88968004EN Manual 896 Professional Detector - ConductivityKhalid ZghearNo ratings yet

- EPP-360 Plasma Power Source 0558007676Document46 pagesEPP-360 Plasma Power Source 0558007676martin_jaitmanNo ratings yet

- Main Eco Compact Combi User GuideDocument36 pagesMain Eco Compact Combi User Guide1030sqrpioNo ratings yet

- Installation, User and Service Manual: POWER HT+ 1.130 POWER HT+ 1.150 POWER HT+ 1.200 POWER HT+ 1.250Document136 pagesInstallation, User and Service Manual: POWER HT+ 1.130 POWER HT+ 1.150 POWER HT+ 1.200 POWER HT+ 1.250Victor alejandro Escalona LarenasNo ratings yet

- 890 Titrando: ManualDocument46 pages890 Titrando: ManualAhmad HamdounNo ratings yet

- H560 Haematology AnalyserDocument200 pagesH560 Haematology Analyserfuwjigfuwjig_4935018No ratings yet

- Installation and Commissioning Instructions ELK-3, 420 KV: High Voltage Products, SwitchgearDocument260 pagesInstallation and Commissioning Instructions ELK-3, 420 KV: High Voltage Products, SwitchgearPathompong BoonraungrodNo ratings yet

- ESE Power Generator: Translation of The Original Oper-Ating ManualDocument64 pagesESE Power Generator: Translation of The Original Oper-Ating ManualDaniel Muratalla100% (1)

- Ins 1Document80 pagesIns 1daniel raduNo ratings yet

- Inm4840 PDFDocument24 pagesInm4840 PDFw_sallumNo ratings yet

- XV-102 Touch Display: ManualDocument81 pagesXV-102 Touch Display: ManualcristianomtzNo ratings yet

- 5db697c820cca Sample Preparation Operating Manual CryoCube F740hi Hiw I Iw MinDocument118 pages5db697c820cca Sample Preparation Operating Manual CryoCube F740hi Hiw I Iw MinKrzysiek PrądzińskiNo ratings yet

- Integral Shaft Support ManualDocument80 pagesIntegral Shaft Support ManualBill NevisNo ratings yet

- 860 KF Thermoprep: ManualDocument59 pages860 KF Thermoprep: ManualKarla CalderónNo ratings yet

- H360 Haematology AnalyserDocument196 pagesH360 Haematology Analyserfuwjigfuwjig_4935018100% (1)

- Sam Electronics 1100 PDFDocument308 pagesSam Electronics 1100 PDFArjunroyEdward100% (4)

- IEM User ManualDocument80 pagesIEM User ManualSas Volta Sr.No ratings yet

- 2 Finger 85 141105Document81 pages2 Finger 85 141105Pham LongNo ratings yet

- HART® Connection Systems: MTL Hart Interfacing SolutionsDocument36 pagesHART® Connection Systems: MTL Hart Interfacing SolutionsShahzad JamesNo ratings yet

- RAGF - S.M. Desfibrilador Marca Nihon Kohden Modelo TEC5500Document123 pagesRAGF - S.M. Desfibrilador Marca Nihon Kohden Modelo TEC5500Tania RomeroNo ratings yet

- Manual Técnico Do Monitor B850 GEDocument180 pagesManual Técnico Do Monitor B850 GETecnico GutterresNo ratings yet

- GE Healthcare CARESCAPE Monitor B450 Service Manual: Software Version 2 Hardware Version B450-01Document244 pagesGE Healthcare CARESCAPE Monitor B450 Service Manual: Software Version 2 Hardware Version B450-01Guillermo Alberto CampetellaNo ratings yet

- Power Focus 4000Document428 pagesPower Focus 4000Cesar ChaconNo ratings yet

- UMFLUXUS F72xV2-0ENDocument237 pagesUMFLUXUS F72xV2-0ENAccNo ratings yet

- Remove PDFDocument246 pagesRemove PDFJhon LopezNo ratings yet

- Tec7600 7700 SM - ADocument178 pagesTec7600 7700 SM - AElectromedicina CatanNo ratings yet

- KROHNE WATER LEVEL. MA - OPTISYS-SLM - 2100 - 200730 - 4002737306 - R06 - enDocument96 pagesKROHNE WATER LEVEL. MA - OPTISYS-SLM - 2100 - 200730 - 4002737306 - R06 - enEma LhtNo ratings yet

- Turck Pressure SensorDocument31 pagesTurck Pressure SensorW0549160No ratings yet

- 14NL013-MNL-1410 (FT)Document144 pages14NL013-MNL-1410 (FT)hyarub9No ratings yet

- MGA21324 - DefiMonitor XD - GB - JDocument102 pagesMGA21324 - DefiMonitor XD - GB - JJulio Benancio ZuluagaNo ratings yet

- Manual Hmi SewDocument64 pagesManual Hmi SewASTECHNo ratings yet

- 905 Titrando ManualDocument55 pages905 Titrando Manualjoseph dela cruzNo ratings yet

- R59770277 01 ReferenceGuideDocument171 pagesR59770277 01 ReferenceGuideСерёга СергоNo ratings yet

- Scale Manual 66828-2-En - GB-1202Document72 pagesScale Manual 66828-2-En - GB-1202Tayyab Bashir100% (1)

- Barco UserGuide R5905724 01 ICMP-Web-Commander-user-guideDocument55 pagesBarco UserGuide R5905724 01 ICMP-Web-Commander-user-guideeeyyee GsNo ratings yet

- On-Load Tap-Changer VACUTAP® VR I HD Voltage Regulator TAPCON 230 AVTDocument156 pagesOn-Load Tap-Changer VACUTAP® VR I HD Voltage Regulator TAPCON 230 AVTsherifmoussaNo ratings yet

- Radarpilot, Chartradar, Multipilot 1100 Soft. 5.1.x-Technical ManualDocument336 pagesRadarpilot, Chartradar, Multipilot 1100 Soft. 5.1.x-Technical Manualartur.damascenoNo ratings yet

- 810278001ENDocument126 pages810278001ENwaqiuddinNo ratings yet

- Umfluxus F401v2-2enDocument160 pagesUmfluxus F401v2-2enmuhammad adibNo ratings yet

- MCT Tnu1 V1 2 en - WDocument169 pagesMCT Tnu1 V1 2 en - Wعبد الله عبد الحيNo ratings yet

- Galaxy 48 R/48 S CO Incubators: Operating ManualDocument92 pagesGalaxy 48 R/48 S CO Incubators: Operating ManualGenlajt DOOELNo ratings yet

- Bag Filter Cleaning Control Unit Scheuch PM-ADocument119 pagesBag Filter Cleaning Control Unit Scheuch PM-AAhmad Dagamseh100% (2)

- EN-TM Machine V4.50 CC300Document230 pagesEN-TM Machine V4.50 CC300Dinh Thi TruongNo ratings yet

- MAN 2848-40-42 Operation ManualDocument100 pagesMAN 2848-40-42 Operation ManualTesta Bonaventura Vincenzo100% (3)

- Operating Instruction: MAN Industrial Diesel Engines D2862 LE221/223/231/233Document86 pagesOperating Instruction: MAN Industrial Diesel Engines D2862 LE221/223/231/233Camilo PuentesNo ratings yet

- Mastercycler Pro: Register Your Instrument!Document118 pagesMastercycler Pro: Register Your Instrument!Dung ChuNo ratings yet

- Nihon Khoden SM TEC5500BDocument123 pagesNihon Khoden SM TEC5500BCarlos CortesNo ratings yet

- im_flexim_umfluxus_f72xv2-1enDocument237 pagesim_flexim_umfluxus_f72xv2-1enGeorge BermúdezNo ratings yet

- 83055416Document72 pages83055416amiromara15No ratings yet

- XC-K Oil: Installation and Maintenance InstructionDocument64 pagesXC-K Oil: Installation and Maintenance Instructiondaboo sanatNo ratings yet

- Window BlindsDocument10 pagesWindow BlindsClint Bryan VirayNo ratings yet

- Plant MOR - Hydro.template - Annex A.3Document4 pagesPlant MOR - Hydro.template - Annex A.3Clint Bryan VirayNo ratings yet

- IT TRADER (Marketing) Duties and ResponsibilitiesDocument2 pagesIT TRADER (Marketing) Duties and ResponsibilitiesClint Bryan VirayNo ratings yet

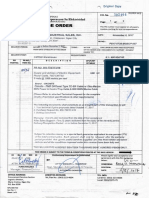

- PO - 302404 - TSD - Electric Equipt. Power CableDocument3 pagesPO - 302404 - TSD - Electric Equipt. Power CableClint Bryan VirayNo ratings yet

- Plant MOR - Wind.template AnnexA.5Document2 pagesPlant MOR - Wind.template AnnexA.5Clint Bryan VirayNo ratings yet

- 2019 UniformDocument10 pages2019 UniformClint Bryan VirayNo ratings yet

- Contract Outside Caterer - SimpronsDocument1 pageContract Outside Caterer - SimpronsClint Bryan VirayNo ratings yet

- MFSR Sample - Annex CDocument2 pagesMFSR Sample - Annex CClint Bryan VirayNo ratings yet

- Aksyon Barangay Kontra Dengue: Structure ofDocument1 pageAksyon Barangay Kontra Dengue: Structure ofClint Bryan VirayNo ratings yet

- SAMPLE FORMAT Preliminaries UPDATEDDocument10 pagesSAMPLE FORMAT Preliminaries UPDATEDClint Bryan VirayNo ratings yet

- 46,000 107,200 Total Foods: MinimumDocument2 pages46,000 107,200 Total Foods: MinimumClint Bryan VirayNo ratings yet

- Aksyon Barangay Kontra Dengue: Structure ofDocument1 pageAksyon Barangay Kontra Dengue: Structure ofClint Bryan VirayNo ratings yet

- CS Form No. 212 Attachment - Work Experience Sheet CVLADocument4 pagesCS Form No. 212 Attachment - Work Experience Sheet CVLAClint Bryan VirayNo ratings yet

- CBCV List of Activities Issues and ConcernsDocument3 pagesCBCV List of Activities Issues and ConcernsClint Bryan VirayNo ratings yet

- Verbs and NounsDocument2 pagesVerbs and NounsClint Bryan VirayNo ratings yet

- Plant MOR - Geothermal.template - Annex A.2Document4 pagesPlant MOR - Geothermal.template - Annex A.2Clint Bryan VirayNo ratings yet

- Test 1Document1 pageTest 1Clint Bryan VirayNo ratings yet

- Aircon OverallDocument13 pagesAircon OverallClint Bryan VirayNo ratings yet

- Single Bike Generator InstructionsDocument5 pagesSingle Bike Generator InstructionsLovely GreenNo ratings yet

- ScriptDocument1 pageScriptClint Bryan VirayNo ratings yet

- Pedal Power Lores PDFDocument143 pagesPedal Power Lores PDFClint Bryan VirayNo ratings yet

- The Sloppy Genie GeeDocument2 pagesThe Sloppy Genie GeeClint Bryan VirayNo ratings yet

- Polymer Exchange Membrane Fuel Cell VehicleDocument13 pagesPolymer Exchange Membrane Fuel Cell VehicleClint Bryan VirayNo ratings yet

- GreaseDocument44 pagesGreaseClint Bryan Viray100% (2)

- Filipino Polvoron Cookie RecipeDocument1 pageFilipino Polvoron Cookie RecipeClint Bryan VirayNo ratings yet

- Mass KG M KG M Exact Density Calculated Density Exact DensityDocument3 pagesMass KG M KG M Exact Density Calculated Density Exact DensityClint Bryan VirayNo ratings yet

- Polymer Exchange Membrane Fuel Cell VehicleDocument13 pagesPolymer Exchange Membrane Fuel Cell VehicleClint Bryan VirayNo ratings yet

- Part A - Exercises: © Festo Didactic GMBH & Co. KG - 541091Document128 pagesPart A - Exercises: © Festo Didactic GMBH & Co. KG - 541091Franklin BosiNo ratings yet

- Two Phase Flow and Heat Transfer - Assignment 3Document11 pagesTwo Phase Flow and Heat Transfer - Assignment 3Joel Jr Rudinas (Remodulator)No ratings yet

- Mastering Automotive Wiring Harness in CATIA V5 Through Illustrative ExamplesDocument101 pagesMastering Automotive Wiring Harness in CATIA V5 Through Illustrative Examplesarun.nagarkarNo ratings yet

- 7.K-75-010 Series 439D Vibrating Bells 10-6-14 PDFDocument2 pages7.K-75-010 Series 439D Vibrating Bells 10-6-14 PDFmaryNo ratings yet

- ME 346: Heat Transfer: Instructor: Ankit JainDocument29 pagesME 346: Heat Transfer: Instructor: Ankit JainDeepankar Sakya KusumaNo ratings yet

- Transformer DifferentialDocument40 pagesTransformer Differentialshahrizal7100% (1)

- 4.0 Xterra 2006Document48 pages4.0 Xterra 2006AUTOMOTRIZ TIPO SPCANo ratings yet

- Kubota Mobile Light TowerDocument1 pageKubota Mobile Light TowerabrhamtNo ratings yet

- Bifpcl Question Solve - 2015: R 5+3+2 10 V 20+20 40 Sor 10 P 40 / (4 X 10)Document7 pagesBifpcl Question Solve - 2015: R 5+3+2 10 V 20+20 40 Sor 10 P 40 / (4 X 10)Mazharul HaqueNo ratings yet

- Eccentric Vibratory Mills - Theory and Practice: Eberhard Gock, Karl-Eugen KurrerDocument9 pagesEccentric Vibratory Mills - Theory and Practice: Eberhard Gock, Karl-Eugen KurrerNikita BogdanovNo ratings yet

- Jura Impressa S7, S9 DiagramDocument19 pagesJura Impressa S7, S9 DiagrampolyfaxNo ratings yet

- Statistical Handbook of JapanDocument213 pagesStatistical Handbook of JapanFaidzul FerdauesNo ratings yet

- PN JunctionDocument71 pagesPN JunctionNeha Prashant VermaNo ratings yet

- Shri - Vinod.C.H Shri - Sanjeev Kumar Shri - Rajagopalan SivasankaranDocument6 pagesShri - Vinod.C.H Shri - Sanjeev Kumar Shri - Rajagopalan SivasankaranAmit KrNo ratings yet

- Altair 4 X PowerpointDocument29 pagesAltair 4 X PowerpointMartin UribeNo ratings yet

- Monbukagakusho Physics 2010 SolutionDocument26 pagesMonbukagakusho Physics 2010 SolutionIskandar Setiadi100% (11)

- RMU Test ReportDocument3 pagesRMU Test ReportGANESH K75% (4)

- Durapac-Cylinder-Single Acting High Tonnage Locking CollarDocument4 pagesDurapac-Cylinder-Single Acting High Tonnage Locking CollarBùi Văn HợpNo ratings yet

- UHP Triplex Pump: Ultrabar30Document2 pagesUHP Triplex Pump: Ultrabar30Frederik CañabiNo ratings yet

- TLEEIM Grade9 QTR3 Module1 Part1 Lighting Fixtures and Lamps Modular 1Document23 pagesTLEEIM Grade9 QTR3 Module1 Part1 Lighting Fixtures and Lamps Modular 1Lorde FloresNo ratings yet

- Rr210205 Electro Mechanics IDocument8 pagesRr210205 Electro Mechanics ISrinivasa Rao GNo ratings yet

- Boiler Commissioning StepsDocument22 pagesBoiler Commissioning StepsSaurabh Kumar100% (1)

- Test 3 AtomicDocument4 pagesTest 3 AtomicRajeev GangwarNo ratings yet

- Tut 8Document1 pageTut 8Chandra Shekhar BishnoiNo ratings yet

- Bazooka November 2023 CompressedDocument152 pagesBazooka November 2023 Compressedanjus5sudha5vinu5No ratings yet

- SPE GCS Well Integrity SymposiumDocument18 pagesSPE GCS Well Integrity SymposiumAshish AmarNo ratings yet

- Searox SL 320: Marine Slab 60Document1 pageSearox SL 320: Marine Slab 60Novan AndriantoNo ratings yet

- Exhaust Pipe Dia & Back Pressure Calculations - TCS TrivandrumDocument6 pagesExhaust Pipe Dia & Back Pressure Calculations - TCS Trivandrummazumdar_satyajitNo ratings yet

- Manual MicrozoneDocument4 pagesManual MicrozoneEduardo PucNo ratings yet

- On Writing Well (William Zinsser)Document150 pagesOn Writing Well (William Zinsser)Onder Y.100% (4)