Professional Documents

Culture Documents

Spectrasyn Plus™ 3.6: Advanced Polyalphaolefin (Pao) Fluid

Uploaded by

Maram YasserOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spectrasyn Plus™ 3.6: Advanced Polyalphaolefin (Pao) Fluid

Uploaded by

Maram YasserCopyright:

Available Formats

Product Datasheet

SpectraSyn Plus™ 3.6

Advanced Polyalphaolefin (PAO) Fluid

Product Description

SpectraSyn Plus™ Advanced Polyalphaolefin (PAO) provide an optimal combination of volatility and low-temperature fluidity. SpectraSyn Plus™

Advanced PAO products viscosity indices translate into improved flow at low temperatures and increased film thickness at high temperatures.

SpectraSyn Plus™ Advanced PAO provide superior lubrication as the primary basestocks for synthetic lubricants used in passenger car engines,

heavy-duty diesel engines, transmissions, and a variety of industrial applications. SpectraSyn Plus™ Advanced PAO can be used for upgrading

mineral oil or Group III basestocks for improved low temperature and volatility performance.

General

Availability 1 • Africa & Middle East • Europe • North America

• Asia Pacific • Latin America

Revision Date • 07/01/2019

Basics Typical Value (English) Typical Value (SI) Test Based On

Specific Gravity 2 (60.1°F (15.6°C)) 0.816 0.816 ASTM D4052

Appearance (0°F (-18°C)) Bright & Clear Bright & Clear Visual

Color < 0.5 < 0.5 ASTM D1500

Kinematic Viscosity 2 ASTM D445

212°F (100°C) 3.6 cSt 3.6 mm²/s

104°F (40°C) 15.4 cSt 15.4 mm²/s

-40°F (-40°C) 2000 cSt 2000 mm²/s

Viscosity Index 120 120 ASTM D2270

Pour Point < -85 °F < -65 °C ASTM D5950/D97

Flash Point, COC 435 °F 224 °C ASTM D92

Noack Volatility 2 < 17.0 wt% < 17.0 wt% ASTM D5800/DIN

51581

Water < 50 ppm < 50 ppm ASTM D6304

Refractive Index 2 (77°F (25°C)) 1.4530 1.4530 ASTM D1218

Total Acid Number < 0.05 mg KOH/g < 0.05 mg KOH/g ASTM D974 (mod)

Flow Typical Value (English) Typical Value (SI) Test Based On

Apparent Viscosity by Mini-Rotary ASTM D4684

Viscometer 2

-40°F (-40°C) 2060 cP 2060 cP

Brookfield Viscosity 2 (-40°F (-40°C)) 2117 cP 2117 cP ASTM D2983

Cold Cranking Simulator 2 ASTM D5293

-22°F (-30°C) 660 cP 660 cP

-31°F (-35°C) 1050 cP 1050 cP

Thermal Typical Value (English) Typical Value (SI) Test Based On

Density Correction Factor 3 6.48E-4 (g/cm³)/°C 6.48E-4 (g/cm³)/°C ASTM D1250

Fire Point, COC 2 478 °F 248 °C ASTM D92

Evaporation Loss 2 (401°F (205°C), 6.5 hr) 22.6 wt% 22.6 wt% ASTM D972 (mod)

Vapor Pressure 3 (302°F (150°C)) 0.2 mm Hg 0.2 mm Hg ASTM D2879

Performance Typical Value (English) Typical Value (SI) Test Based On

Dielectric Constant 3 (77°F (25°C)) 2.09 2.09 ASTM D924

Dielectric Strength 3 41.5 kV 41.5 kV ASTM D877

High-Temp. High-Shear Viscosity 2 1.14 cP 1.14 cP ASTM D5481

Solubility Typical Value (English) Typical Value (SI) Test Based On

Aniline Point 3 246.2 °F 119.0 °C ASTM D611

Effective Date: 07/01/2019 ExxonMobil Page: 1 of 2

Product Datasheet

SpectraSyn Plus™ 3.6

Advanced Polyalphaolefin (PAO) Fluid

Additional Information

Technical White Mineral Oil, 21 CFR 178.3620(b)

National Sanitation Foundation (NSF) White book, category code H1, Lubricants with incidental food contact

Legal Statement

For detailed Product Stewardship information, please contact Customer Service.

Notes

Typical properties: these are not to be construed as specifications.

1Product may not be available in one or more countries in the identified Availability regions. Please contact your Sales Representative for complete

Country Availability.

2 Single sample or two sample average determinations

3 Calculated

For additional technical, sales and order assistance: www.exxonmobilchemical.com/ContactUs

©2022 ExxonMobil. ExxonMobil, the ExxonMobil logo, the interlocking “X” device and other product or service names used herein are trademarks of

ExxonMobil, unless indicated otherwise. This document may not be distributed, displayed, copied or altered without ExxonMobil's prior written

authorization. To the extent ExxonMobil authorizes distributing, displaying and/or copying of this document, the user may do so only if the document

is unaltered and complete, including all of its headers, footers, disclaimers and other information. You may not copy this document to or reproduce it

in whole or in part on a website. ExxonMobil does not guarantee the typical (or other) values. Any data included herein is based upon analysis of

representative samples and not the actual product shipped. The information in this document relates only to the named product or materials when

not in combination with any other product or materials. We based the information on data believed to be reliable on the date compiled, but we do not

represent, warrant, or otherwise guarantee, expressly or impliedly, the merchantability, fitness for a particular purpose, freedom from patent

infringement, suitability, accuracy, reliability, or completeness of this information or the products, materials or processes described. The user is solely

responsible for all determinations regarding any use of material or product and any process in its territories of interest. We expressly disclaim liability

for any loss, damage or injury directly or indirectly suffered or incurred as a result of or related to anyone using or relying on any of the information in

this document. This document is not an endorsement of any non-ExxonMobil product or process, and we expressly disclaim any contrary implication.

The terms “we,” “our,” "ExxonMobil Product Solutions" and "ExxonMobil" are each used for convenience, and may include any one or more of

ExxonMobil Product Solutions Company, Exxon Mobil Corporation, or any affiliate either directly or indirectly stewarded.

exxonmobilchemical.com

Effective Date: 07/01/2019 ExxonMobil Page: 2 of 2

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Synesstic12 TDSDocument2 pagesSynesstic12 TDScotteNo ratings yet

- Spectrasyn™ 10: Polyalphaolefin (Pao) FluidDocument2 pagesSpectrasyn™ 10: Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- Pao 100Document2 pagesPao 100Антон СтепураNo ratings yet

- Esterex™ TM111: Synthetic FluidDocument2 pagesEsterex™ TM111: Synthetic FluidDinesh babuNo ratings yet

- Hygold 5000Bs: Base Oil Marketing SpecificationDocument1 pageHygold 5000Bs: Base Oil Marketing Specificationsamsoon80100% (1)

- HexaneDocument3 pagesHexaneIan RidzuanNo ratings yet

- Grease PropertiesDocument4 pagesGrease Propertiescarlos sotoNo ratings yet

- OmniGold P220N 2021Document1 pageOmniGold P220N 2021C MoraNo ratings yet

- Spectrasyn Plus™ 5: Advanced Polyalphaolefin (Pao) FluidDocument2 pagesSpectrasyn Plus™ 5: Advanced Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- Nap-Gard 7-2500 PDFDocument2 pagesNap-Gard 7-2500 PDFPietro ViganNo ratings yet

- Hydroseal Globale PDFDocument2 pagesHydroseal Globale PDFPranshu JainNo ratings yet

- OmniGold A3Document1 pageOmniGold A3Eduarda FochezattoNo ratings yet

- Abistir 7120Document2 pagesAbistir 7120Phung LucNo ratings yet

- 750 Naphtenico ErgonDocument2 pages750 Naphtenico ErgonJorge ZegarraNo ratings yet

- L2000 Naftenico ErgonDocument1 pageL2000 Naftenico ErgonJorge ZegarraNo ratings yet

- POLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESDocument3 pagesPOLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESPhuoc Thinh TruongNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Exxonmobil™ Pp7905E1: Polypropylene Impact CopolymerDocument2 pagesExxonmobil™ Pp7905E1: Polypropylene Impact CopolymermosesNo ratings yet

- TDS - Acrylic V045 - From TrinseoDocument3 pagesTDS - Acrylic V045 - From TrinseoVio AmarieiNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- San 330IDocument2 pagesSan 330INguyễn Hồng NamNo ratings yet

- Spectrasyn Elite™ 300: Metallocene Polyalphaolefin (Mpao) FluidDocument2 pagesSpectrasyn Elite™ 300: Metallocene Polyalphaolefin (Mpao) FluidMaram YasserNo ratings yet

- Tds - Master Quench ADocument2 pagesTds - Master Quench ANashrul HakimNo ratings yet

- 4376 Industrial Gear Oil CLP 320Document1 page4376 Industrial Gear Oil CLP 320ralish12No ratings yet

- TDS - PAO4Document1 pageTDS - PAO4KC Lakshmi NarayananNo ratings yet

- Propriedades ABSDocument1 pagePropriedades ABSengmecanica07022013No ratings yet

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENDocument2 pagesFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartNo ratings yet

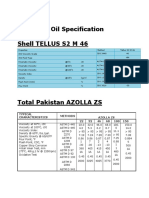

- Specifications For Hydraulic OilDocument3 pagesSpecifications For Hydraulic OilAliya NaseemNo ratings yet

- Data Sheet of Cutback Bitumen MC 30Document1 pageData Sheet of Cutback Bitumen MC 30TanajiNo ratings yet

- Nitronic® 40 Stainless Steel: Chemical CompositionDocument2 pagesNitronic® 40 Stainless Steel: Chemical CompositionBagus WicaksanaNo ratings yet

- Exceed™ 4536PA: Performance PolymerDocument2 pagesExceed™ 4536PA: Performance PolymerSalustraNo ratings yet

- Shear Flat SlabDocument1 pageShear Flat Slabadnan-651358No ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetIVANCHUNo ratings yet

- Cummins G12 Diesel Fuel Oil Use in Aggreko EnginesDocument2 pagesCummins G12 Diesel Fuel Oil Use in Aggreko EnginesAhmed AbdullahNo ratings yet

- Exact™ 3040 Cast: Ethylene-Based Plastomer ResinDocument2 pagesExact™ 3040 Cast: Ethylene-Based Plastomer ResinManuel HerreraNo ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- San 335TDocument2 pagesSan 335TNguyễn Hồng NamNo ratings yet

- MS - Hyprene L1200 7-25-08Document1 pageMS - Hyprene L1200 7-25-08Abe KobNo ratings yet

- Abs Irpc Polimaxx SP100Document2 pagesAbs Irpc Polimaxx SP100countzeroaslNo ratings yet

- SikaAnchorFix2Arctic PdsDocument4 pagesSikaAnchorFix2Arctic PdsDragoș SturzoiuNo ratings yet

- ICHIRO GENBU (ICR-6122 6131) : Product DescriptionDocument2 pagesICHIRO GENBU (ICR-6122 6131) : Product DescriptiondnoaisapsNo ratings yet

- Wpbf4054Imnep Pibiflex 4054 Im Nero: Technical Data SheetDocument2 pagesWpbf4054Imnep Pibiflex 4054 Im Nero: Technical Data SheetankitNo ratings yet

- San 310CTRDocument2 pagesSan 310CTRNguyễn Hồng NamNo ratings yet

- TenCate BT250E-6 DatasheetDocument4 pagesTenCate BT250E-6 DatasheetGregory A KressNo ratings yet

- Shellsol T q7412 AmDocument3 pagesShellsol T q7412 AmRagavendra Prabu GovindarajuNo ratings yet

- Exxsol™ D110: Dearomatized FluidDocument2 pagesExxsol™ D110: Dearomatized FluidAnh TuanNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- Specifications & Properties for Motiva Base OilsDocument1 pageSpecifications & Properties for Motiva Base OilsMassimiliano VolaNo ratings yet

- TDS-Therminol 66Document3 pagesTDS-Therminol 66amir soheil GooyavarNo ratings yet

- Solvay - Halar 513 LCDocument3 pagesSolvay - Halar 513 LCRenan GadioliNo ratings yet

- Shellsol T q7412 PDFDocument3 pagesShellsol T q7412 PDFmeNo ratings yet

- TDS Marlotherm LHDocument2 pagesTDS Marlotherm LHManu Fernandez AfonsoNo ratings yet

- Datasheet Isoparaffinsshellsoltdeurope PDFDocument3 pagesDatasheet Isoparaffinsshellsoltdeurope PDFmeNo ratings yet

- Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCDocument1 pageProperties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCsidsaleemNo ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- Inductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesFrom EverandInductively Coupled Plasma-Mass Spectrometry: Practices and TechniquesNo ratings yet

- Spectrasyn Elite™ 300: Metallocene Polyalphaolefin (Mpao) FluidDocument2 pagesSpectrasyn Elite™ 300: Metallocene Polyalphaolefin (Mpao) FluidMaram YasserNo ratings yet

- Vistalon™ 8731: Ethylene Propylene Diene Terpolymer RubberDocument1 pageVistalon™ 8731: Ethylene Propylene Diene Terpolymer RubberMaram YasserNo ratings yet

- Exceed™ XP 8346CB: Performance PolymerDocument2 pagesExceed™ XP 8346CB: Performance PolymerMaram YasserNo ratings yet

- Vistalon™ 805: Ethylene Propylene Copolymer RubberDocument1 pageVistalon™ 805: Ethylene Propylene Copolymer RubberMaram YasserNo ratings yet

- Vistalon™ 8800: Ethylene Propylene Diene Terpolymer RubberDocument1 pageVistalon™ 8800: Ethylene Propylene Diene Terpolymer RubberMaram YasserNo ratings yet

- Spectrasyn Elite™ 300: Metallocene Polyalphaolefin (Mpao) FluidDocument2 pagesSpectrasyn Elite™ 300: Metallocene Polyalphaolefin (Mpao) FluidMaram YasserNo ratings yet

- Spectrasyn Plus™ 3.6: Advanced Polyalphaolefin (Pao) FluidDocument2 pagesSpectrasyn Plus™ 3.6: Advanced Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- Exceed™ S 9333 Series: Performance PolymerDocument2 pagesExceed™ S 9333 Series: Performance PolymerMaram YasserNo ratings yet

- Exceed XP 7052MLDocument2 pagesExceed XP 7052MLsaied shabanaNo ratings yet

- Exceed™ XP 8656MK: Performance PolymerDocument2 pagesExceed™ XP 8656MK: Performance PolymerCristian RodriguezNo ratings yet

- Exceed™ XP 8346CB: Performance PolymerDocument2 pagesExceed™ XP 8346CB: Performance PolymerMaram YasserNo ratings yet

- Exxon™ Bromobutyl 2222: RubberDocument2 pagesExxon™ Bromobutyl 2222: RubberMaram YasserNo ratings yet

- Exceed XP 7052MLDocument2 pagesExceed XP 7052MLsaied shabanaNo ratings yet

- Exceed™ XP 8656ML: Performance PolymerDocument2 pagesExceed™ XP 8656ML: Performance PolymerCristian RodriguezNo ratings yet

- Excedd XP 8784 Series PDS PDFDocument2 pagesExcedd XP 8784 Series PDS PDFchinchotarngNo ratings yet

- Vistalon™ 8731: Ethylene Propylene Diene Terpolymer RubberDocument1 pageVistalon™ 8731: Ethylene Propylene Diene Terpolymer RubberMaram YasserNo ratings yet

- Exxpro™ 3433: Specialty ElastomerDocument2 pagesExxpro™ 3433: Specialty ElastomerMaram YasserNo ratings yet

- Exxon™ Butyl 065S: RubberDocument2 pagesExxon™ Butyl 065S: RubberMaram YasserNo ratings yet

- Exxon™ Butyl 365S: RubberDocument2 pagesExxon™ Butyl 365S: RubberMaram YasserNo ratings yet

- Exxon™ Chlorobutyl 5066: RubberDocument2 pagesExxon™ Chlorobutyl 5066: RubberMaram YasserNo ratings yet

- Exxon™ Bromobutyl 7211: RubberDocument2 pagesExxon™ Bromobutyl 7211: RubberMaram YasserNo ratings yet

- Exxpro™ 3433: Specialty ElastomerDocument2 pagesExxpro™ 3433: Specialty ElastomerMaram YasserNo ratings yet

- Exxon™ Butyl 065S: RubberDocument2 pagesExxon™ Butyl 065S: RubberMaram YasserNo ratings yet

- Exxon™ Butyl 365S: RubberDocument2 pagesExxon™ Butyl 365S: RubberMaram YasserNo ratings yet

- AP XX Mobil Delvac MX 20W 50Document3 pagesAP XX Mobil Delvac MX 20W 50Maram YasserNo ratings yet

- Maintenance Heavy EquipmentDocument442 pagesMaintenance Heavy EquipmentMaram YasserNo ratings yet

- Exxon™ Butyl 268S: RubberDocument2 pagesExxon™ Butyl 268S: RubberMaram YasserNo ratings yet

- Thermal Physics SLDocument4 pagesThermal Physics SLIBstudent10No ratings yet

- Introduction to Nuclear Medicine TechniquesDocument7 pagesIntroduction to Nuclear Medicine TechniquesMarco Mendoza67% (3)

- AD GT3000 Catalogue en 12-07 CDocument52 pagesAD GT3000 Catalogue en 12-07 CMohamed AlkharashyNo ratings yet

- Natal Chart ReportDocument23 pagesNatal Chart ReportEvelyn WilsonNo ratings yet

- Your Trip: Traveler AgencyDocument2 pagesYour Trip: Traveler AgencydomingosNo ratings yet

- EarlyDocument59 pagesEarlyjrtlimNo ratings yet

- Hardware Catalog No Prices (PTHW0208.1C) PDFDocument11 pagesHardware Catalog No Prices (PTHW0208.1C) PDFAhmed TahaNo ratings yet

- Examination, June/July: ExplainDocument6 pagesExamination, June/July: ExplainSandesh KulalNo ratings yet

- Coumadin WarfarinDocument1 pageCoumadin WarfarinSheri490100% (1)

- Diy AquariumsDocument108 pagesDiy Aquariumshalo_bing100% (2)

- UHF and 5 Gigahertz (60 MM) SHF ISM Radio BandsDocument3 pagesUHF and 5 Gigahertz (60 MM) SHF ISM Radio BandsAnandhu cNo ratings yet

- Soundarya Lahari Translation in EnglishDocument50 pagesSoundarya Lahari Translation in EnglishRanganatha Gowda100% (1)

- JDF Enlistment TestDocument15 pagesJDF Enlistment TestRelando Bailey84% (174)

- A Framework For Developing and Evaluating Utility Substation Cyber Security - Schneider ElectricDocument10 pagesA Framework For Developing and Evaluating Utility Substation Cyber Security - Schneider ElectricHugh cabNo ratings yet

- Procreate User GuideDocument75 pagesProcreate User GuideOmar Páez0% (1)

- De Bonding On Command of Adhesive JointsDocument73 pagesDe Bonding On Command of Adhesive JointsJorge VieiraNo ratings yet

- Identifing Legends and CultureDocument2 pagesIdentifing Legends and CultureHezekaiah AstraeaNo ratings yet

- Serif Business LetterDocument18 pagesSerif Business LetterNeerajha RabindranathNo ratings yet

- Can Bus ScaniaDocument21 pagesCan Bus Scaniajose breno vieira silva96% (25)

- The Relationship of Language Development and Nutritional Status of The Child in The Region South of The City of Kediri Region Public HealthDocument12 pagesThe Relationship of Language Development and Nutritional Status of The Child in The Region South of The City of Kediri Region Public Healthdoddyk kurniawanNo ratings yet

- 2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFDocument59 pages2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFGeorge JhonsonNo ratings yet

- Pharmaceutics Exam 3 - This SemesterDocument6 pagesPharmaceutics Exam 3 - This Semesterapi-3723612100% (1)

- Introduction to NFFHTDocument44 pagesIntroduction to NFFHTTAPASVI BHATTNo ratings yet

- Dry-Heat Destruction of Destruction KineticsDocument5 pagesDry-Heat Destruction of Destruction KineticsFabioEspinolaNo ratings yet

- 07 GU - OC2021 - E03 - 1 GUL UniRAN Configuration 65PDocument65 pages07 GU - OC2021 - E03 - 1 GUL UniRAN Configuration 65PjedossousNo ratings yet

- Spek Dental Panoramic Rotograph EVODocument2 pagesSpek Dental Panoramic Rotograph EVOtekmed koesnadiNo ratings yet

- MSDS Matrix Diluent-2 LISSDocument4 pagesMSDS Matrix Diluent-2 LISSLaboratorium RSI PekajanganNo ratings yet

- Lower Motor Neuron LesionsDocument29 pagesLower Motor Neuron LesionsLoshi ChandrasekarNo ratings yet

- Sulphur VapoursDocument12 pagesSulphur VapoursAnvay Choudhary100% (1)