Professional Documents

Culture Documents

DIA AW 201208 LSR Working at Height

DIA AW 201208 LSR Working at Height

Uploaded by

Carwell AbatayoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIA AW 201208 LSR Working at Height

DIA AW 201208 LSR Working at Height

Uploaded by

Carwell AbatayoCopyright:

Available Formats

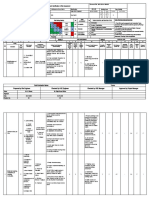

DIA-AW-201208 Aviation July 2012

Working at Height (Life Saving Rule breach)

while conducting lift inspection

Target audience for this alert

Superintendents, Supervisors and Contract Holders

What happened

During an annual lift inspection and whilst the lift was

extended (2.7 m*) the Lift Technician climbed out of the

protected barrier and lowered himself on to the top rung of

the trucks mounted ladder, a distance of 1.37m. As the

ladder did not extened to the full height of the platform, he

was unable to maintain 3 points of contact, see picture.

Why it happened

Failure to recgonise unsafe work practise. The lifted

needed to be rasied, so the inspection could take place. However the only possible way to do this was from switches

located on the lift platform ( this could not be done from ground level). Hence once raised the Lift Technician needed to

get back to the ground.

The Lift Technician was not aware of the specfic requirements of the Shell LSR #6 - Use fall protection equipment when

working outside a protective environment where you can fall over 1.8 meters (6 feet) to keep you safe. * Note: the

Country legal requirement was for Fall protection > 3 M.

The job method statement and Permit did not identify the issue of not being able to operate the Lift from the ground.

Lessons learned

Ensure that supervisors understand the need to oversee contractor work, and all potential unsafe condtions are

highlighted before work starts.

Ensure all staff (employees & contractors) fully understand the requirements of the Shell Life Saving Rules. Especailly if

stricter controls are needed compared to Country requirments

The Method Statement and PTW need to be very explicit about not only what tasks need doing, but how the work is

to be done. This should allow hazards and potential issues to be highlighted and discussed prior to start of work.

Recommendations to be followed

Site Supervisors to check the lifts on trucks and report lifts that cannot be operated by a remote ground control device

to the Regional Engineering Manager.

Supervisors of employees & contractor personnel to ensure persons within their control have attended LSR awareness

session(s), attendance records to be maintained and to check understanding.

Permit Holders and Permit Issues should carryout “Walk-through inspections” of the workplace and the task to be

done to fully understand potential issues and ensure these have been captured in the method statement.

Further information : Contact james.kelly@shell.com or your Regional HSSE Manager for more information.

You might also like

- 1200A and 1200D Electric Power Supplement TPD2144 Production Release V6 0Document91 pages1200A and 1200D Electric Power Supplement TPD2144 Production Release V6 0Mostafa Shanna83% (6)

- Safety Training Cranes and HoistsDocument89 pagesSafety Training Cranes and HoistsJose Antonio García Ruíz100% (3)

- Safe Work Method Statement WorksheetDocument5 pagesSafe Work Method Statement Worksheetgoodspeed_phNo ratings yet

- Example JSA Job Safety AnalysisDocument13 pagesExample JSA Job Safety AnalysisPaulSwinbank100% (4)

- Manitou MLT735 Operatorsmanual PDFDocument178 pagesManitou MLT735 Operatorsmanual PDFnovyNo ratings yet

- ELH-00000-A67 Asphalt Works Section 9 Rev 0Document6 pagesELH-00000-A67 Asphalt Works Section 9 Rev 0Mohamed ChercharNo ratings yet

- JSARA - Fire Detection System InstallationDocument13 pagesJSARA - Fire Detection System InstallationUtku Can KılıçNo ratings yet

- SAMPLE Forklift Safety ProgramDocument5 pagesSAMPLE Forklift Safety Programallan.manaloto23No ratings yet

- RA - Angle GrinderDocument4 pagesRA - Angle GrinderMurugan RajaNo ratings yet

- Project Safety Plan Dammam (Momra)Document74 pagesProject Safety Plan Dammam (Momra)TATATAHERNo ratings yet

- Facility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3Document8 pagesFacility/Plant Location: Description of Work: Contractor:: PCD Project: Water Treatment Facilities - 3AldrinNo ratings yet

- Cold Work Permit: The Following Areas / Items Have Been Inspected by Issuer and ReceiverDocument2 pagesCold Work Permit: The Following Areas / Items Have Been Inspected by Issuer and Receiversindarth raveendrakrishnan100% (6)

- Hse in Drilling OperationsDocument13 pagesHse in Drilling OperationsSamad Ali Siddiqui100% (2)

- DIL AW 201601 Global FallsDocument3 pagesDIL AW 201601 Global Fallsvikrant911100% (1)

- Bucket Truck Safety-PioneerDocument4 pagesBucket Truck Safety-PioneerhazopmanNo ratings yet

- Scissor Lift Truck Safety and Operating ProcedureDocument7 pagesScissor Lift Truck Safety and Operating Procedurenatuan74No ratings yet

- Directional Drill SafetyDocument7 pagesDirectional Drill SafetyMartahan ManurungNo ratings yet

- NR 18 - Aerial Lifts For ConstructionDocument44 pagesNR 18 - Aerial Lifts For ConstructionCPSSTNo ratings yet

- Safe Work Method Statement For Class 1, 2 & 10 Building Projects - B Grade Bricklayers Pty LTDDocument3 pagesSafe Work Method Statement For Class 1, 2 & 10 Building Projects - B Grade Bricklayers Pty LTDsaqib85-999No ratings yet

- Aerial Lift Safety TrainingDocument28 pagesAerial Lift Safety TrainingDarby MorganNo ratings yet

- Steel Shield Temporary Fencing Risk Assessment and Method Statement For ErectionDocument7 pagesSteel Shield Temporary Fencing Risk Assessment and Method Statement For ErectionIrfan Prima AldiNo ratings yet

- Steel Shield Temporary Fencing Risk Assessment and Method Statement For ErectionDocument7 pagesSteel Shield Temporary Fencing Risk Assessment and Method Statement For ErectionIrfan Prima AldiNo ratings yet

- Method Statement and Risk Assessment For Electrical Cable Trench ExcavationDocument8 pagesMethod Statement and Risk Assessment For Electrical Cable Trench Excavationfehmi-fjr469650% (2)

- Rope Access Guide Book Vertical SpecialistDocument23 pagesRope Access Guide Book Vertical Specialistpkannan100% (1)

- METHOD STATEMENT FOR WORKING AT HEIGHT Rev A0Document8 pagesMETHOD STATEMENT FOR WORKING AT HEIGHT Rev A0M.A.N100% (2)

- Century t500 Parts 55145Document482 pagesCentury t500 Parts 55145Luis OrellanaNo ratings yet

- Lifting and RiggingDocument28 pagesLifting and Riggingamanda welchNo ratings yet

- SHOP MANUAL MLT845-120-51900003-Rev.04-11Document164 pagesSHOP MANUAL MLT845-120-51900003-Rev.04-11masaliku 91100% (2)

- Non Complex Method Statement For OffloadingDocument5 pagesNon Complex Method Statement For OffloadingDaniel Cryer100% (1)

- ATT400 Operation Maint 241384Document805 pagesATT400 Operation Maint 241384Hữu Dũng Nguyễn100% (8)

- Lifting and HoistingDocument4 pagesLifting and Hoistingfadhil AbdullahNo ratings yet

- Hazard Identification, Risk Assessment and Risk Control (Hirarc)Document2 pagesHazard Identification, Risk Assessment and Risk Control (Hirarc)Khaty JahNo ratings yet

- Working at Heights Checklist1112222333Document1 pageWorking at Heights Checklist1112222333Shojib khan100% (2)

- ATT400 Parts 241384Document767 pagesATT400 Parts 241384Nguyễn Hữu Dũng86% (7)

- MLT625 75H 51900001 Rev.03 11 PDFDocument173 pagesMLT625 75H 51900001 Rev.03 11 PDFSkalliMoulayAli100% (3)

- Aerial Lift Operations 10.01.16 FinalDocument7 pagesAerial Lift Operations 10.01.16 FinalMohamed KadryNo ratings yet

- R F (H W C) :: Operations & Screening CrushingDocument7 pagesR F (H W C) :: Operations & Screening Crushingkmohamedkeita906No ratings yet

- PM MHMSG502 B3e - L12328a01 PDFDocument475 pagesPM MHMSG502 B3e - L12328a01 PDFFrancisco SandovalNo ratings yet

- LKC - Lifting Risk AssessmentDocument4 pagesLKC - Lifting Risk AssessmentAdam EatonNo ratings yet

- R F (H W C) :: Crushing & Screening Operations BDocument5 pagesR F (H W C) :: Crushing & Screening Operations Bkmohamedkeita906No ratings yet

- Manitou MLT625 operatorsManualT3 PDFDocument173 pagesManitou MLT625 operatorsManualT3 PDFgavinNo ratings yet

- SHE 68 - 9589 - Elevator Work PermitDocument2 pagesSHE 68 - 9589 - Elevator Work PermitciupcicNo ratings yet

- Aerial Lifts Manual 2020Document15 pagesAerial Lifts Manual 2020ahmedNo ratings yet

- MLT 845 E3 - 1Document32 pagesMLT 845 E3 - 1mliugongNo ratings yet

- Ride On Roller ManualDocument9 pagesRide On Roller ManualRonald AranhaNo ratings yet

- Operator Manual Manitou MTL 845 120 LSU - New - 2008Document128 pagesOperator Manual Manitou MTL 845 120 LSU - New - 2008mliugong100% (4)

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- User's Manual ABB GeneratorsDocument268 pagesUser's Manual ABB GeneratorsSebastian Nicușor Părăoanu50% (2)

- Erbe VIO300S Service Manual PDFDocument70 pagesErbe VIO300S Service Manual PDFNikola Nikola100% (1)

- Rescue Boat Code Final Rev 5-13-02.07.13Document166 pagesRescue Boat Code Final Rev 5-13-02.07.13Legend Anbu100% (3)

- Heavy Duty AssignmentDocument15 pagesHeavy Duty AssignmentSurafel MesfinNo ratings yet

- SSW MEWP Cherry PickerDocument2 pagesSSW MEWP Cherry Pickerrossiwidnes78No ratings yet

- Genie Superlift SOP 003Document27 pagesGenie Superlift SOP 003Mauricio SantanaNo ratings yet

- What Kind of Accident Is About To Happen?Document2 pagesWhat Kind of Accident Is About To Happen?Alvin Garcia PalancaNo ratings yet

- Safety Macarale SemnalizareDocument8 pagesSafety Macarale SemnalizareDragos VerdesNo ratings yet

- Crane Safety InstructionsDocument8 pagesCrane Safety InstructionsAnil kumarNo ratings yet

- Binder 1Document6 pagesBinder 1بسام كريمNo ratings yet

- Aerial Lift Manual: Environmental Health & SafetyDocument15 pagesAerial Lift Manual: Environmental Health & SafetykarijosephNo ratings yet

- Escalator PPOP 02.23Document3 pagesEscalator PPOP 02.23Mohamed jemalNo ratings yet

- FCF Minerals Corporation Operation of Roller CompactorsDocument23 pagesFCF Minerals Corporation Operation of Roller CompactorsJela ParadiseNo ratings yet

- Mobile Overhead Crane Operation Method StatementDocument5 pagesMobile Overhead Crane Operation Method StatementRynoNo ratings yet

- LL Slide Pack November 2011Document11 pagesLL Slide Pack November 2011Rauf HuseynovNo ratings yet

- Mobile (Truck) Cranes: Primary HazardsDocument6 pagesMobile (Truck) Cranes: Primary HazardsfiarNo ratings yet

- Sandline Flagging Operation Results in FatalityDocument2 pagesSandline Flagging Operation Results in FatalityReda AL-mesbahNo ratings yet

- SOP For Working at HeightDocument18 pagesSOP For Working at HeightWasim AkramNo ratings yet

- Manlift Training. Cesare Training .Document29 pagesManlift Training. Cesare Training .Wathiq Ghareeb SalmanNo ratings yet

- Aerial Lift and Scaffolding Guidelines 2020Document15 pagesAerial Lift and Scaffolding Guidelines 2020ahmedNo ratings yet

- Vehicle Safety 1002Document6 pagesVehicle Safety 1002Jessabelle RamosNo ratings yet

- DIA-AW - 201103 LTI Manual Handling LadderDocument2 pagesDIA-AW - 201103 LTI Manual Handling LadderCarwell AbatayoNo ratings yet

- DC-AW-2010-02 Incomplete Unloading of EO Rail Tank CarDocument2 pagesDC-AW-2010-02 Incomplete Unloading of EO Rail Tank CarCarwell AbatayoNo ratings yet

- DIA-AA-201019.Punctured Hand RefuellingDocument1 pageDIA-AA-201019.Punctured Hand RefuellingCarwell AbatayoNo ratings yet

- DC AW 2015 7 Grinder IncidentDocument2 pagesDC AW 2015 7 Grinder IncidentCarwell AbatayoNo ratings yet

- Safety in Materials Science LabDocument3 pagesSafety in Materials Science Labmohammad majeedNo ratings yet

- SPI-HSE-GL-02-Work at Height-EHS GuidelinesDocument6 pagesSPI-HSE-GL-02-Work at Height-EHS GuidelinesPraveen NairNo ratings yet

- 3M 3015 VP Vapor Permeable Air Barrier TDS v8!18!17Document4 pages3M 3015 VP Vapor Permeable Air Barrier TDS v8!18!17Hari SantosoNo ratings yet

- NEBOSH International General Certificate in Occupational Health and SafetyDocument20 pagesNEBOSH International General Certificate in Occupational Health and SafetysuleeshNo ratings yet

- Electrical Installations: Technical DescriptionDocument28 pagesElectrical Installations: Technical DescriptionVisitec PowerindoNo ratings yet

- Potsdam Village Police Dept. Blotter Jan. 20, 2018Document4 pagesPotsdam Village Police Dept. Blotter Jan. 20, 2018NewzjunkyNo ratings yet

- Module 20 - Job Hazard Analysis (JHA)Document8 pagesModule 20 - Job Hazard Analysis (JHA)Aviects Avie JaroNo ratings yet

- Al Adaa - OshadDocument17 pagesAl Adaa - Oshadkifes18963No ratings yet

- Process Safety ApiDocument6 pagesProcess Safety ApiLudi D. LunarNo ratings yet

- Management and Health Safety Handover ChecklistDocument2 pagesManagement and Health Safety Handover ChecklistMariam BakariNo ratings yet

- MSDS VN Edge Paint - Defoamer - Updated Dec 16th 22Document4 pagesMSDS VN Edge Paint - Defoamer - Updated Dec 16th 22anggunNo ratings yet

- Unit-2 Disaster ManagementDocument39 pagesUnit-2 Disaster ManagementSrividya KrishnaNo ratings yet

- Resume of Santhirajan PDFDocument3 pagesResume of Santhirajan PDFsanthirajanNo ratings yet

- HIRA For Waterproofing Work at B-Hub ProjectDocument8 pagesHIRA For Waterproofing Work at B-Hub ProjectRajat Kumar MishraNo ratings yet

- VIBRATOR - JSA-042 - Replacement of Vibrator Pump or Double Drive - 26-Apr-15Document7 pagesVIBRATOR - JSA-042 - Replacement of Vibrator Pump or Double Drive - 26-Apr-15hechame TamerhouletNo ratings yet

- Simplexity PRD Template Sept 2022Document12 pagesSimplexity PRD Template Sept 2022Iqra RamzanNo ratings yet

- Construction Occupational Safety & Health (COSH) : Department Order # 13Document72 pagesConstruction Occupational Safety & Health (COSH) : Department Order # 13Joseph Ryan ManandegNo ratings yet

- Gelijkstroomregelaars Mentor MP User Guide en Iss7 0476 0000 07Document194 pagesGelijkstroomregelaars Mentor MP User Guide en Iss7 0476 0000 07Đoàn ThuậnNo ratings yet

- Catalytic Converter & Oxygen Sensor Cleaner: Safety Data SheetDocument10 pagesCatalytic Converter & Oxygen Sensor Cleaner: Safety Data SheetAsadNo ratings yet

- MSDS Nalco PC-191T Anti-ScalantDocument8 pagesMSDS Nalco PC-191T Anti-ScalantKader RahmaniNo ratings yet