Professional Documents

Culture Documents

Kohler 100efozcj

Uploaded by

oppa FadlyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kohler 100efozcj

Uploaded by

oppa FadlyCopyright:

Available Formats

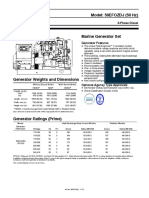

Model: 125EOZCJ (60 Hz)

100EFOZCJ (50 Hz)

3-Phase Diesel

Marine Generator Set

Generator Features

D Engine is Environmental Protection Agency (EPA)

Tier III compliant (60 Hz model only)

D The unique Fast-Responser X excitation system

delivers excellent voltage response and short-circuit

capability using a rare-earth permanent magnet-excited

alternator

D The brushless, rotating-field alternator has broadrange

reconnectability

D Remote control connector

D Class H insulation

D Reconnectable voltage

D One- or three-phase reconnectable alternator

D Voltage regulation of 0.5%

D Frequency regulation of 0.5%

D Heat exchanger cooled configuration includes a wet

exhaust bend

D Keel cooled configuration includes a dry exhaust bend

Generator Weights and Dimensions Optional Agency Type Approvals

Generator Set D Det Norske Veritas- Germanischer Lloyd (DNV- GL)

HX/KC* RAD* D China Classification Society (CCS)

D Lloyd’s Register

Weight, kg (lb.) D Bureau Veritas (BV)

Wet 1495 (3295) 1557 (3433)

D American Bureau of Shipping (ABS)

Dry 1458 (3215) 1509 (3327)

Agency requirements:

Length, mm (in.) 2068 (81.43) 2466 (97.10) d Extra senders, exhaust blankets, and double wall

Width, mm (in.) 893 (35.16) 1129 (44.45) fuel lines with leak alarm

d 3 separate Type Approval documents for engine,

Height, mm (in.) 1003 (39.47) 1475 (58.07)

alternator, and Decision-Makerr 3500 controller

* HX/KC = Heat Exchanger/Keel Cooled Model D IMO Tier III Exempt models offered in 118/147 kW/kVA

* RAD = Radiator Model (60 Hz) and 99/124 kW/kVA (50 Hz) options.

Above dimension excludes exhaust outlet. Refer to appropriate ADV for detailed dimensions.

G2-166 (125EOZCJ) 10/22j

Generator Ratings (Prime)

Model Heat Exchanger/Keel Cooled Models Radiator Models

Generator

(Alternator) Voltage Hz Ph Amps Rated kW/kVA Amps Rated kW/kVA

120/208 60 3 434 125/156 434 125/156

120/240 60 3 376 125/156 376 125/156

125EOZCJ

127/220 60 3 410 125/156 410 125/156

(4R13X)

139/240 60 3 376 125/156 376 125/156

277/480 60 3 188 125/156 188 125/156

110/190 50 3 380 100/125 380 100/125

120/208 50 3 347 100/125 347 100/125

100EFOZCJ 110/220 50 3 328 100/125 328 100/125

(4R13X) 220/380 50 3 190 100/125 190 100/125

230/400 50 3 180 100/125 180 100/125

240/416 50 3 173 100/125 173 100/125

120/208 60 3 410 118/147 410 118/147

120/240 60 3 355 118/147 355 118/147

125EOZCJ *

127/220 60 3 388 118/147 388 118/147

(4R13X)

139/240 60 3 355 118/147 355 118/147

277/480 60 3 178 118/147 178 118/147

110/190 50 3 377 99/124 377 99/124

120/208 50 3 344 99/124 344 99/124

100EFOZCJ * 110/220 50 3 325 99/124 325 99/124

(4R13X) 220/380 50 3 189 99/124 189 99/124

230/400 50 3 179 99/124 179 99/124

240/416 50 3 172 99/124 172 99/124

RATINGS: Ratings per ISO 3046, ISO 8528-1, and Kohler ISO rating guideline 2.14. Obtain technical information bulletin (TIB-101) on ratings guidelines for complete ratings definitions.

Availability is subject to change without notice. Kohler Co. reserves the right to change the design or specifications without notice and without any obligation or liability whatsoever.

Contact your local Kohler generator set distributor for availability.

10% overload capacity one hour in twelve hours.

* IMO Tier III Exempt model

G2-166 (125EOZCJ) 10/22j

Application Data

Engine Lubrication

Engine Specifications 60 Hz 50 Hz Lubricating System 60 Hz 50 Hz

Type Inline, 4-cycle Oil pan capacity with filter, L (U.S. qt.) 19.0 (20.0)

Number of cylinders 6 Type Pressure

Firing order 1-5-3-6-2-4

Aspiration Turbocharged and Operation Requirements

aftercooled

Displacement, L (cu. in.) 6.8 (415) Air Requirements 60 Hz 50 Hz

Bore and stroke, mm (in.) 107 x 127 (4.21 x 5.00) Engine combustion air requirements,

m3/min. (cfm) 15.0 (529) 10.0 (353)

Compression ratio 16.7:1

Max. air intake restriction, kPa (in. H2O) 6.25 (25) 6.25 (25)

Combustion system Direct injection

Cooling air required for generator set at

Rated rpm 1800 1500 50_C (122_F) ambient, m3/min. (cfm)

Maximum power at rated rpm, HP 223 187 HX/KC* 24.35 (860) 21.10 (745)

RAD* 736 (26000) 614 (21700)

Cylinder block material Cast iron

Exhaust flow, m3/min. (cfm) 32 (1123) 23 (828)

Cylinder head material Cast iron

Exhaust temp., _C (_F) 373 (703.4) 454 (849.2)

Piston rings 2 compression/1 oil

Max. allowed exhaust backpressure,

Crankshaft material Forged steel kPa (in. H2O) 7.5 (30) 7.5 (30)

Connecting rod material Forged steel

Fuel Consumption 60 Hz 50 Hz

Governor type Electric isochronous

Diesel, Lph (gph) at % load

100% 39.5 (10.4) 31.1 (8.2)

Engine Electrical

75% 31.2 (8.2) 23.6 (6.2)

Engine Electrical System 60 Hz 50 Hz

50% 21.4 (5.7) 16.6 (4.4)

Battery, voltage 12- or 24-volt spec

isolated ground, standard 25% 12.7 (3.4) 9.4 (2.5)

Battery, charging (12 volt) 75 amp

Battery, charging (24 volt) 50 amp Engine Features

Battery, recommendation (min., 12 volt) 925 CCA D One-side serviceability of fuel system, lubrication system, and air

cleaner

Starter motor Gear-reduction type

D Low oil pressure cutout

Cooling D High water temperature cutout

D Loss of coolant cutout

Cooling System 60 Hz 50 Hz

D Overcrank cutout

Capacity, L (U.S. qt.) (approx.), HX/KC* 19.0 (20.0)

RAD* 50.3 (53.16) D Belt guard

Cooling type, HX* Heat exchanger D Optional digital gauge

RAD* Radiator

D Disposable oil filter

Seawater pump type, HX/KC* John Deere gear driven

D Extended oil drain

Seawater pump suction lift,

D PTO options: 12- or 24-volt electric clutch

maximum, m (ft.), HX/KC* 3.0 (10.0)

Heat rejected to jacket water at rated kW,

kW (Btu/min.) 195 (11088) 149 (8498) Controller Features

Engine water pump flow, Lpm (gpm) 194 (51.2) 160.5 (42.4) D A graphical display and pushbutton/rotary selector dial provide

easy, local data access.

Seawater pump flow, Lpm (gpm), HX/KC* 173 (45.7) 125 (33)

D Measurements are selectable in metric or English units.

Fuel D The controller supports Modbusr protocol with serial bus (RS-485)

or Ethernet networks.

Fuel System 60 Hz 50 Hz

D Scrolling display shows critical data at a glance.

Fuel recommendation Diesel fuel specified to

D Graphical display of power metering (kW, kVA, V, I, PF, and VAR).

EN 590 or ASTM D975

D Integrated hybrid voltage regulator.

Fuel shutoff solenoid Electric

Fuel injection system High Pressure D Built-in alternator thermal overload protection.

Common Rail (HPCR)

Modbusr is a registered trademark of Schneider Electric.

Fuel pump priming Self Priming

Maximum recommended fuel lift, m (ft.) 2.4 (7.9)

* HX = Heat Exchanger, KC = Keel Cooled, RAD = Radiator Model

G2-166 (125EOZCJ) 10/22j

Decision-Makerr 3500

Paralleling Controller

Provides advanced control, system monitoring, and system diagnostics for

optimum performance and compatibility. The Decision-Makerr 3500

controller uses a patented hybrid voltage regulator and unique software

logic to manage alternator thermal overload protection features normally

requiring additional hardware. Additional features include:

D AC Output Voltage Regulator Adjustment. The voltage adjustment

provides a maximum adjustment of 10% of the system voltage.

D Alarm Silence. The controller can be set up to silence the alarm horn

only when in the AUTO mode for NFPA-110 application or Always for

user convenience.

D Alternator Protection. The controller provides generator set overload

and short circuit protection matched to each alternator for the

particular voltage/phase configuration.

D Automatic Restart. The controller automatic restart feature initiates

the start routine and recrank after a failed start attempt.

D Cyclic Cranking. The controller has programmable cyclic cranking.

D ECM Diagnostics. The controller displays engine ECM fault code

descriptions to help in engine troubleshooting.

D Engine Start Aid. The configurable starting aid feature provides

customized control for an optional engine starting aid.

D Event Logging. The controller keeps a record (up to 1000 entries) for

warning and shutdown faults. This fault information becomes a stored

record of system events and can be reset.

D Historical Data Logging. Total number of successful starts of the

generator is recorded and displayed.

D Integrated Hybrid Voltage Regulator. The voltage regulator provides

0.5% no-load to full-load RMS voltage regulation with three-phase

sensing.

D Lamp Test. Press the alarm silence/lamp test button to verify

functionality of the indicator lights.

D LCD Display. Adjustable contrast for improving visibility.

D Measurement Units. The controller provides selection of English or

metric displays.

D Power Metering. Controller graphical display provides voltage,

current, power factor, kW, kVA, and kVAR.

D Programming Access (USB). Provides software upgrades and

diagnostics with PC software tools.

D Remote Reset. The remote reset function supports acknowledging

and resetting faults and allows restarting of the generator set without

going to the master control switch off/reset position.

D Run Time Hourmeter. The generator set run time is displayed.

D Time Delay Engine Cooldown (TDEC). The TDEC provides a time

delay before the generator set shuts down.

D Time Delay Engine Start (TDES). The TDES provides a time delay

before the generator set starts.

D Voltage Selection Menu. This menu provides the capability to switch

the generator output voltage. NOTE: Generator set output leads may

require reconnection.

D Paralleling Functions:

D Bus sensing

D First on logic

D Synchronizing

D Communication based isochronous load sharing

D Droop load sharing

D External controlled load sharing via analog bias signals

G2-166 (125EOZCJ) 10/22j

Alternator Specifications

Alternator Specifications

Specifications Alternator

Manufacturer Kohler

Type 4-pole, rotating-field

Exciter type Brushless, rare-earth

permanent-magnet

Number of leads 12, reconnectable

Voltage regulator Solid state, volts/Hz

Insulation: NEMA MG1

Material Class H

Temperature rise 115_C

Bearing: number, type 1, sealed

Coupling Flexible disc

Amortisseur windings Full

Voltage regulation, no load to full load 0.5%

One-step load acceptance per NFPA 110 100% of rating

Peak motor starting kVA: (35% dip for voltages below)

480 V, 380 V 4R13X (12 lead) 540 (60 Hz), 425 (50 Hz)

Alternator Features

D NEMA MG1, IEEE, and ANSI standards compliance for temperature

rise and motor starting.

D Capable of sustained line-to-neutral short circuit current of up to 300%

of the rated current for up to 2 seconds. Capable of sustained short

circuit current of up to 300% of the rated current for up to 10 seconds

for 3 phase connections. (IEC 60092-301 short-circuit performance.)

D Sustained short-circuit current enabling downstream circuit breakers to

trip without collapsing the alternator field.

D Self-ventilated and dripproof construction.

D Vacuum-impregnated windings with epoxy varnish for dependability

and long life.

D Superior voltage waveform from a two-thirds pitch stator and skewed

rotor.

Optional Accessories

D Circuit breakers

D Remote digital display

D Remote monitoring, start/stop panel with wiring harness for

connection to the generator controller

D Duplex fuel filter

D Siphon break

D Remote connection/extension harness

D Oil level indicator (high/low)

D Low coolant level indicator

G2-166 (125EOZCJ) 10/22j

KOHLER CO., Kohler, Wisconsin 53044 USA

Phone 920-457-4441, Fax 920-459-1646

For the nearest sales and service outlet in the

US and Canada, phone 1-800-544-2444

KOHLERPower.com

ADV-8508-A

DISTRIBUTED BY:

NOTE: Dimensions are shown in mm [in.].

NOTE: This drawing is provided for reference only and is not

intended for installation planning. Contact your local

distributor for more detailed information.

E 2014 Kohler Co. All rights reserved.

G2-166 (125EOZCJ) 10/22j

You might also like

- Model: 55EOZCJ (60 HZ) 45EFOZCJ (50 HZ) : 3-Phase DieselDocument4 pagesModel: 55EOZCJ (60 HZ) 45EFOZCJ (50 HZ) : 3-Phase DieselsebastianNo ratings yet

- Kohler Generator g2166Document4 pagesKohler Generator g2166philipNo ratings yet

- Kohler 80efozcjDocument4 pagesKohler 80efozcjoppa FadlyNo ratings yet

- Kohler 50 PDFDocument4 pagesKohler 50 PDFĐại DươngNo ratings yet

- Model: 50EFOZCJ (50 HZ) : 3-Phase DieselDocument4 pagesModel: 50EFOZCJ (50 HZ) : 3-Phase DieselĐại DươngNo ratings yet

- 50EFOZDJ Technical DataDocument4 pages50EFOZDJ Technical DataĐặng MinhNo ratings yet

- Marine Generator Set OverviewDocument4 pagesMarine Generator Set OverviewDavid GPNo ratings yet

- Kohler Moteur Johndeere 50EFOZDDocument4 pagesKohler Moteur Johndeere 50EFOZDzirra82No ratings yet

- Kohler Marine 70efozd PDFDocument4 pagesKohler Marine 70efozd PDFĐại DươngNo ratings yet

- 1000REOZDEDocument4 pages1000REOZDELanh TranNo ratings yet

- Marine Generator Set Specs and FeaturesDocument4 pagesMarine Generator Set Specs and FeaturessebastianNo ratings yet

- Kohler 35EFKOZD SpecificationsDocument4 pagesKohler 35EFKOZD SpecificationsKelvin YuenNo ratings yet

- Kholer Generator 750REOZMD Spec SheetDocument4 pagesKholer Generator 750REOZMD Spec SheetNicholas BrennanNo ratings yet

- 28EOZD 60 Hz Marine Generator Set 1-Phase DieselDocument4 pages28EOZD 60 Hz Marine Generator Set 1-Phase DieselĐại DươngNo ratings yet

- Kohler 24 Specs SheetDocument4 pagesKohler 24 Specs Sheetabduallah muhammadNo ratings yet

- Model: 10EOZD 9efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 10EOZD 9efozd: 60 HZ 50 HZ 1-Phase DieselTeszt Sdj100% (1)

- Model: 23EOZD 20efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 23EOZD 20efozd: 60 HZ 50 HZ 1-Phase DieselMaksym KlymenkoNo ratings yet

- Model: 6EKOD 5efkod: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 6EKOD 5efkod: 60 HZ 50 HZ 1-Phase Dieselyeng menNo ratings yet

- 6EKOD SpecificationsDocument4 pages6EKOD SpecificationsEfrain FlorezNo ratings yet

- Kohler 2000ROZD4 Spec SheetDocument4 pagesKohler 2000ROZD4 Spec SheetKhaled KamelNo ratings yet

- Model: 500EOZCS (60 HZ) 450EFOZCS (50 HZ) : 3-Phase DieselDocument4 pagesModel: 500EOZCS (60 HZ) 450EFOZCS (50 HZ) : 3-Phase DieselPato DuhaldeNo ratings yet

- 1500REOZDBDocument4 pages1500REOZDBRodrigoNo ratings yet

- Reozjc: Standard Features Ratings RangeDocument4 pagesReozjc: Standard Features Ratings RangeJulio CesarNo ratings yet

- Model: 15.5EOZD 13efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 15.5EOZD 13efozd: 60 HZ 50 HZ 1-Phase Dieselabduallah muhammadNo ratings yet

- Kohler 60RZ Spec SheetDocument4 pagesKohler 60RZ Spec SheetRomanvi1980No ratings yet

- Kohler 800rozmc SpecDocument4 pagesKohler 800rozmc Speclilama45-1No ratings yet

- 40REOZT Towable Generator Sets Provide Reliable PowerDocument4 pages40REOZT Towable Generator Sets Provide Reliable Powerrendi valentinoNo ratings yet

- Kohler 45RZ Generator Ratings and SpecificationsDocument4 pagesKohler 45RZ Generator Ratings and SpecificationsRebecca Winfrey100% (1)

- Model: 11EKOZD 9efkozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 11EKOZD 9efkozd: 60 HZ 50 HZ 1-Phase DieselEdgar MaldonadoNo ratings yet

- Koin 080T310Document4 pagesKoin 080T310PHAM THANH TUNo ratings yet

- KohleerDocument6 pagesKohleerJuan RenteriaNo ratings yet

- Kohler 30REOZJB John Deere 3029TF150 Spec Sheet PDFDocument4 pagesKohler 30REOZJB John Deere 3029TF150 Spec Sheet PDFEric LaguipoNo ratings yet

- Reozje: ModelDocument4 pagesReozje: ModelLuis LunarNo ratings yet

- Kohler 125rzg Spec SheetDocument4 pagesKohler 125rzg Spec SheetRomanvi1980No ratings yet

- Kohler 12.5EDocument4 pagesKohler 12.5EMike JacobsNo ratings yet

- Ratings Range: Tier 2 EPA-Certified For Stationary Emergency ApplicationsDocument6 pagesRatings Range: Tier 2 EPA-Certified For Stationary Emergency ApplicationsBryan FrancoNo ratings yet

- Kohler 80RZG Spec SheetDocument4 pagesKohler 80RZG Spec SheetRomanvi1980No ratings yet

- Kohler 50rozj Spec SheetDocument4 pagesKohler 50rozj Spec SheetRomanvi1980No ratings yet

- Cummins Data Sheet C550D5Document3 pagesCummins Data Sheet C550D5fahad pirzadaNo ratings yet

- 63530b32af2a5a8cd858fc94 Kohler 80REOZJB GeneratorDocument4 pages63530b32af2a5a8cd858fc94 Kohler 80REOZJB GeneratorYennifer HernandezNo ratings yet

- Thong So Ky ThuatDocument6 pagesThong So Ky ThuatBảo GiaNo ratings yet

- 125 RZG Technical Data Sheet - Prime DutyDocument4 pages125 RZG Technical Data Sheet - Prime DutyAdewunmi OlufemiNo ratings yet

- Caterpillar Specification SheetsDocument9 pagesCaterpillar Specification Sheetsavinash_1229No ratings yet

- Cat C32: Diesel Generator SetsDocument5 pagesCat C32: Diesel Generator SetsKhaled KamelNo ratings yet

- CM20180320 15806 02586Document5 pagesCM20180320 15806 02586Ignacio LucasNo ratings yet

- Low NoiseDocument13 pagesLow Noiseh81757442352166No ratings yet

- Model:: Residential GasDocument4 pagesModel:: Residential Gasapelectric100% (1)

- Reozjd: ModelDocument4 pagesReozjd: ModelluislunarNo ratings yet

- Model:: Gas 110 - 600 VDocument4 pagesModel:: Gas 110 - 600 VTomás GonzalezNo ratings yet

- SS26-CPGK - Hoja de Especificacion C20D6Document4 pagesSS26-CPGK - Hoja de Especificacion C20D6johanNo ratings yet

- Diesel Generator Set X2.5 Series Engine: 15 kVA - 28 kVA 50 HZ 10.8 KW - 20 KW 60 HZDocument4 pagesDiesel Generator Set X2.5 Series Engine: 15 kVA - 28 kVA 50 HZ 10.8 KW - 20 KW 60 HZabera alemayehuNo ratings yet

- Cat C32: Diesel Generator SetsDocument6 pagesCat C32: Diesel Generator SetsJean Claude EidNo ratings yet

- Cat C32: Diesel Generator SetsDocument6 pagesCat C32: Diesel Generator Setsavinash_1229No ratings yet

- 300reozd S60Document4 pages300reozd S60David J SandersNo ratings yet

- Grupo eDocument4 pagesGrupo eJhousep steven Mesia gonzalesNo ratings yet

- Planta Elect. Cat 3512Document5 pagesPlanta Elect. Cat 3512MauricioNo ratings yet

- SS9 CPGKDocument4 pagesSS9 CPGKYahya SaifanNo ratings yet

- Diesel Generator Sets: FeaturesDocument5 pagesDiesel Generator Sets: FeaturesBilel Ben SlamaNo ratings yet

- CM20180320 16121 49538Document5 pagesCM20180320 16121 49538Ignacio LucasNo ratings yet

- Programmable Logic Controllers PLC Timer FunctionsDocument9 pagesProgrammable Logic Controllers PLC Timer FunctionsElisha MbiseNo ratings yet

- Growth Product Manager Nanodegree Program SyllabusDocument14 pagesGrowth Product Manager Nanodegree Program SyllabusWardell JonesNo ratings yet

- CD4047BC Low Power Monostable/Astable Multivibrator: General DescriptionDocument10 pagesCD4047BC Low Power Monostable/Astable Multivibrator: General DescriptionFlavio SilvaNo ratings yet

- DTS 600 GDO Installation ManualDocument12 pagesDTS 600 GDO Installation Manualpiesang007No ratings yet

- Iec 62443 3 2 2020Document12 pagesIec 62443 3 2 2020steveNo ratings yet

- Check If Folder Exists Using Excel VBADocument6 pagesCheck If Folder Exists Using Excel VBAYamini ShindeNo ratings yet

- 8:1 Mux VHDL CodeDocument5 pages8:1 Mux VHDL CodeRishikesh Jatekar60% (5)

- BIM Methodology & GuideDocument120 pagesBIM Methodology & GuideaminazmNo ratings yet

- Tour 2020Document238 pagesTour 2020David López CallejaNo ratings yet

- Designing With AR and VRDocument30 pagesDesigning With AR and VRPigmy LeeNo ratings yet

- UVSS - Installation GuideDocument17 pagesUVSS - Installation GuideMubasher SaeedNo ratings yet

- Keysight 34450A Programmers Reference PDFDocument311 pagesKeysight 34450A Programmers Reference PDFkrishnaprasad pNo ratings yet

- Dialog Utility 11.1 InstallDocument12 pagesDialog Utility 11.1 Installulil ikbalNo ratings yet

- Quotation For CCTVDocument4 pagesQuotation For CCTVefficient officeNo ratings yet

- Civil EngineeringDocument16 pagesCivil EngineeringYashpal GangeshwarNo ratings yet

- Delock Usb-C™, Hdmi or Mini Displayport To 4K Hdmi Adapter Cable 1.8 MDocument3 pagesDelock Usb-C™, Hdmi or Mini Displayport To 4K Hdmi Adapter Cable 1.8 MMihanikNo ratings yet

- Lecture 8 Stack ApplicationsDocument79 pagesLecture 8 Stack ApplicationsAbdullah TahirNo ratings yet

- Sample Music License - Royalty Free Music LibraryDocument2 pagesSample Music License - Royalty Free Music LibraryFawaz OguntolaNo ratings yet

- Openshift Container Platform 4.6Document34 pagesOpenshift Container Platform 4.6Chinni MunniNo ratings yet

- Hospital Management System - TutorialsDuniyaDocument67 pagesHospital Management System - TutorialsDuniyaFizza JafferyNo ratings yet

- UC Berkeley DigitalTransformation Brochure 14 May 20 V14Document17 pagesUC Berkeley DigitalTransformation Brochure 14 May 20 V14Brayan CigueñasNo ratings yet

- Cybersecurity Chapter 1 QuizDocument7 pagesCybersecurity Chapter 1 QuizJenny Marcela Perez BolivarNo ratings yet

- Digital Crime Money Loundering Simulation TrainingsDocument1 pageDigital Crime Money Loundering Simulation TrainingsmarijalazaNo ratings yet

- Ten Project Proposals in Artificial Intelligence: January 2008Document35 pagesTen Project Proposals in Artificial Intelligence: January 2008Manas MallickNo ratings yet

- Result Management System: Student Maagement Exam ManagementDocument7 pagesResult Management System: Student Maagement Exam ManagementDIPALI SONTAKINo ratings yet

- Computer Organization Chapter 8 Short NoteDocument31 pagesComputer Organization Chapter 8 Short NoteMeskatul Islam2100% (1)

- SLSU Lucban Campus Class SchedulesDocument4 pagesSLSU Lucban Campus Class SchedulesChristian Paul CasidoNo ratings yet

- Outdoor Integrated Cabinet ICC710-HA1-C7 (01075400) Datasheet 03 - (20201031)Document2 pagesOutdoor Integrated Cabinet ICC710-HA1-C7 (01075400) Datasheet 03 - (20201031)Odai Kiwan100% (1)

- Dissertation Logbook TemplateDocument8 pagesDissertation Logbook TemplateBuyPapersOnlineCheapSingapore100% (1)

- Dealing With Dual Inheritance HierarchiesDocument12 pagesDealing With Dual Inheritance HierarchiessanjeevprNo ratings yet