Professional Documents

Culture Documents

Model: 55EOZCJ (60 HZ) 45EFOZCJ (50 HZ) : 3-Phase Diesel

Uploaded by

sebastianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model: 55EOZCJ (60 HZ) 45EFOZCJ (50 HZ) : 3-Phase Diesel

Uploaded by

sebastianCopyright:

Available Formats

Model: 55EOZCJ (60 Hz)

45EFOZCJ (50 Hz)

3-Phase Diesel

Marine Generator Set

Generator Features

D Engine is Environmental Protection Agency (EPA)

Tier III compliant (60 Hz model only) or EU Stage V

(50 Hz model only)

D The unique Fast-Responser X excitation system

delivers excellent voltage response and short-circuit

capability using a rare-earth permanent magnet-excited

alternator

D The brushless, rotating-field alternator has broadrange

reconnectability

D Remote control connector

D Class H insulation

D Reconnectable voltage

D One- or three-phase reconnectable alternator

D Voltage regulation of ±0.5%

D Frequency regulation of 0.5%

D Heat exchanger cooled configuration includes a wet

exhaust bend

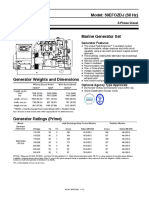

Generator Weights and Dimensions D Keel cooled configuration includes a dry exhaust bend

Generator Set Optional Agency Type Approvals

HX/KC* RAD* D Det Norske Veritas- Germanischer Lloyd (DNV- GL)

Weight, kg (lb.)

D China Classification Society (CCS)

Wet 961 (2119) 984 (2169) D Lloyd’s Register

Dry 934 (2059) 957 (2109) D Bureau Veritas (BV)

Length, mm (in.) 1549 (60.97) 1884 (74.15) D American Bureau of Shipping (ABS)

Width, mm (in.) 738 (29.04) 827 (32.57) Agency requirements:

Height, mm (in.) 961 (37.82) 1465 (57.68)

d Extra senders, exhaust blankets, and double wall

fuel lines with leak alarm

* HX/KC = Heat Exchanger/Keel Cooled Model d 3 separate Type Approval documents for engine,

* RAD = Radiator Model alternator, and Decision-Makerr 3500 controller

Above dimension excludes exhaust outlet. Refer to appropriate ADV for detailed dimensions.

Generator Ratings (Prime)

Model Heat Exchanger/Keel Cooled Models Radiator Models

Generator

(Alternator) Voltage Hz Ph Amps Rated kW/kVA Amps Rated kW/kVA

120/208 60 3 191 55.0/69.0 191 55.0/69.0

120/240 60 3 165 55.0/69.0 165 55.0/69.0

55EOZCJ 120/240 60 1 221 53.0/53.0 221 53.0/53.0

(4P8X) 127/220 60 3 180 55.0/69.0 180 55.0/69.0

139/240 60 3 165 55.0/69.0 165 55.0/69.0

277/480 60 3 83 55.0/69.0 83 55.0/69.0

110/190 50 3 171 45.0/56.0 171 45.0/56.0

110/220 50 3 148 45.0/56.0 148 45.0/56.0

115/230 50 1 196 45.0/45.0 196 45.0/45.0

45EFOZCJ

120/208 50 3 142 41.0/51.0 142 41.0/51.0

(4P8X)

220/380 50 3 86 45.0/56.0 86 45.0/56.0

230/400 50 3 79 44.0/55.0 79 44.0/55.0

240/416 50 3 71 41.0/51.0 71 41.0/51.0

RATINGS: Ratings per ISO 3046, ISO 8528-1, and Kohler ISO rating guideline 2.14. Obtain technical information bulletin (TIB-101) on ratings guidelines for complete ratings definitions.

Availability is subject to change without notice. Kohler Co. reserves the right to change the design or specifications without notice and without any obligation or liability whatsoever.

Contact your local Kohler generator set distributor for availability.

10% overload capacity one hour in twelve hours.

G2-162 (55EOZCJ) 7/20n

Application Data

Engine Lubrication

Engine Specifications 60 Hz 50 Hz Lubricating System 60 Hz 50 Hz

Type Inline, 4-cycle Oil pan capacity with filter, L (U.S. qt.) 14 (15)

Number of cylinders 4 Type Pressure

Firing order 1-3-4-2

Aspiration Turbocharged Operation Requirements

Displacement, L (cu. in.) 4.5 (275)

Air Requirements 60 Hz 50 Hz

Bore and stroke, mm (in.) 106 x 127 (4.17 x 5.00)

Engine combustion air requirements,

Compression ratio 16:1 m3/min. (cfm) 6.1 (215) 4.2 (148)

Combustion system Direct injection Max. air intake restriction, kPa (in. H2O) 6.25 (25) 6.25 (25)

Rated rpm 1800 1500 Cooling air required for generator set at

Maximum power at rated rpm, HP 99 82 50_C (122_F) ambient, m3/min. (cfm)

HX/KC* 18.12 (640) 15.72 (555)

Cylinder block material Cast iron RAD* 135.9 (4800) 113.3 (4000)

Cylinder head material Cast iron Exhaust flow, m3/min. (cfm) 14.74 (521) 10.51 (371)

Piston rings 2 compression/1 oil Exhaust temp., _C (_F) 452 (846) 482 (900)

Crankshaft material Forged steel Max. allowed exhaust backpressure,

Connecting rod material Forged steel kPa (in. H2O) 7.5 (30) 7.5 (30)

Governor type Electronic isochronous Fuel Consumption 60 Hz 50 Hz

Diesel, Lph (gph) at % load

Engine Electrical 100% 17.64 (4.66) 14.04 (3.71)

Engine Electrical System 60 Hz 50 Hz 75% 13.66 (3.61) 10.67 (2.82)

Battery, voltage 12- or 24-volt spec 50% 9.65 (2.55) 7.34 (1.94)

isolated ground, standard

25% 5.67 (1.50) 3.97 (1.05)

Battery, charging (12 volt) 75 amp

Battery, charging (24 volt) 50 amp

Engine Features

Battery, recommendation (min., 12 volt) 625 CCA

D One-side serviceability of fuel system, lubrication system, and air

Starter motor Gear-reduction type cleaner

D Low oil pressure cutout

Cooling

D High water temperature cutout

Cooling System 60 Hz 50 Hz D Loss of coolant cutout

Capacity, L (U.S. qt.) (approx.), HX/KC* 14 (15) D Overcrank cutout

RAD* 24.6 (26)

D Belt guard

Cooling type, HX* Heat exchanger

RAD* Radiator D Optional digital gauge

Seawater pump type, HX/KC* John Deere gear driven D Disposable oil filter

Seawater pump suction lift, D Extended oil drain

maximum, m (ft.), HX/KC* 3.0 (10.0)

D PTO options: 12- or 24-volt electric clutch

Heat rejected to jacket water at rated kW,

kW (Btu/min.) 80 (4548) 70 (3984)

Engine water pump flow, Lpm (gpm) 117 (30.9) 82.9 (21.9)

Controller Features

D A graphical display and pushbutton/rotary selector dial provide

Seawater pump flow, Lpm (gpm), HX/KC* 90 (24) 76 (20) easy, local data access.

D Measurements are selectable in metric or English units.

Fuel

D The controller supports Modbusr protocol with serial bus (RS-485)

Fuel System 60 Hz 50 Hz or Ethernet networks.

Fuel recommendation Diesel fuel specified to D Scrolling display shows critical data at a glance.

EN 590 or ASTM D975

D Graphical display of power metering (kW, kVA, V, I, PF, and VAR).

Fuel shutoff solenoid Electric

D Integrated hybrid voltage regulator.

Fuel injection system High Pressure

Common Rail (HPCR) D Built-in alternator thermal overload protection.

Fuel pump priming Mechanical Modbusr is a registered trademark of Schneider Electric.

Maximum recommended fuel lift, m (ft.) 2.4 (7.9)

* HX = Heat Exchanger, KC = Keel Cooled, RAD = Radiator Model

G2-162 (55EOZCJ) 7/20n

Decision-Makerr 3500 Alternator Specifications

Paralleling Controller Alternator Specifications

Specifications Alternator

Manufacturer Kohler

Type 4-pole, rotating-field

Provides advanced control, system monitoring, and system diagnostics for Exciter type Brushless, rare-earth

optimum performance and compatibility. The Decision-Makerr 3500 permanent-magnet

controller uses a patented hybrid voltage regulator and unique software Number of leads 12, reconnectable

logic to manage alternator thermal overload protection features normally

requiring additional hardware. Additional features include: Voltage regulator Solid state, volts/Hz

D AC Output Voltage Regulator Adjustment. The voltage adjustment Insulation: NEMA MG1

provides a maximum adjustment of ±10% of the system voltage. Material Class H

D Alarm Silence. The controller can be set up to silence the alarm horn Temperature rise 115_C

only when in the AUTO mode for NFPA-110 application or Always for

user convenience. Bearing: number, type 1, sealed

D Alternator Protection. The controller provides generator set overload Coupling Flexible disc

and short circuit protection matched to each alternator for the Amortisseur windings Full

particular voltage/phase configuration.

Voltage regulation, no load to full load ±0.5%

D Automatic Restart. The controller automatic restart feature initiates

the start routine and recrank after a failed start attempt. One-step load acceptance per NFPA 110 100% of rating

Peak motor starting kVA: (35% dip for voltages below)

D Cyclic Cranking. The controller has programmable cyclic cranking. 480 V, 400 V 4P8X (12 lead) 261 (60 Hz), 218 (50 Hz)

D ECM Diagnostics. The controller displays engine ECM fault code

descriptions to help in engine troubleshooting.

D Engine Start Aid. The configurable starting aid feature provides

Alternator Features

customized control for an optional engine starting aid. D NEMA MG1, IEEE, and ANSI standards compliance for temperature

D Event Logging. The controller keeps a record (up to 1000 entries) for rise and motor starting.

warning and shutdown faults. This fault information becomes a stored D Capable of sustained line-to-neutral short circuit current of up to 300%

record of system events and can be reset. of the rated current for up to 2 seconds. Capable of sustained short

D Historical Data Logging. Total number of successful starts of the circuit current of up to 300% of the rated current for up to 10 seconds

generator is recorded and displayed. for 3 phase connections. (IEC 60092-301 short-circuit performance.)

D Integrated Hybrid Voltage Regulator. The voltage regulator provides D Sustained short-circuit current enabling downstream circuit breakers to

±0.5% no-load to full-load RMS voltage regulation with three-phase trip without collapsing the alternator field.

sensing.

D Self-ventilated and dripproof construction.

D Lamp Test. Press the alarm silence/lamp test button to verify

functionality of the indicator lights. D Vacuum-impregnated windings with epoxy varnish for dependability

and long life.

D LCD Display. Adjustable contrast for improving visibility.

D Superior voltage waveform from a two-thirds pitch stator and skewed

D Measurement Units. The controller provides selection of English or rotor.

metric displays.

D Power Metering. Controller graphical display provides voltage, Optional Accessories

current, power factor, kW, kVA, and kVAR.

D Circuit breakers

D Programming Access (USB). Provides software upgrades and

diagnostics with PC software tools. D Remote digital display

D Remote Reset. The remote reset function supports acknowledging D Remote monitoring, start/stop panel with wiring harness for

and resetting faults and allows restarting of the generator set without connection to the generator controller

going to the master control switch off/reset position.

D Duplex fuel filter

D Run Time Hourmeter. The generator set run time is displayed.

D Siphon break

D Time Delay Engine Cooldown (TDEC). The TDEC provides a time

delay before the generator set shuts down. D Remote connection/extension harness

D Time Delay Engine Start (TDES). The TDES provides a time delay D Oil level indicator (high/low)

before the generator set starts.

D Low coolant level indicator

D Voltage Selection Menu. This menu provides the capability to switch

the generator output voltage. NOTE: Generator set output leads may D Electric front clutch power takeoff (PTO)

require reconnection. 12- or 24- volt

D Paralleling Functions:

D Bus sensing

D First on logic

D Synchronizing

D Communication based isochronous load sharing

D Droop load sharing

D External controlled load sharing via analog bias signals

G2-162 (55EOZCJ) 7/20n

KOHLER CO., Kohler, Wisconsin 53044 USA

Phone 920-457-4441, Fax 920-459-1646

For the nearest sales and service outlet in the

US and Canada, phone 1-800-544-2444

KOHLERPower.com

ADV-8501-B

DISTRIBUTED BY:

NOTE: Dimensions are shown in mm [in.].

NOTE: This drawing is provided for reference only and is not

intended for installation planning. Contact your local

distributor for more detailed information.

E 2013 Kohler Co. All rights reserved.

G2-162 (55EOZCJ) 7/20n

You might also like

- Kohler 100efozcjDocument6 pagesKohler 100efozcjoppa FadlyNo ratings yet

- Kohler Generator g2166Document4 pagesKohler Generator g2166philipNo ratings yet

- Kohler 80efozcjDocument4 pagesKohler 80efozcjoppa FadlyNo ratings yet

- Kohler 50 PDFDocument4 pagesKohler 50 PDFĐại DươngNo ratings yet

- Model: 50EFOZCJ (50 HZ) : 3-Phase DieselDocument4 pagesModel: 50EFOZCJ (50 HZ) : 3-Phase DieselĐại DươngNo ratings yet

- 50EFOZDJ Technical DataDocument4 pages50EFOZDJ Technical DataĐặng MinhNo ratings yet

- Marine Generator Set OverviewDocument4 pagesMarine Generator Set OverviewDavid GPNo ratings yet

- Kohler Moteur Johndeere 50EFOZDDocument4 pagesKohler Moteur Johndeere 50EFOZDzirra82No ratings yet

- Marine Generator Set Specs and FeaturesDocument4 pagesMarine Generator Set Specs and FeaturessebastianNo ratings yet

- Kohler 35EFKOZD SpecificationsDocument4 pagesKohler 35EFKOZD SpecificationsKelvin YuenNo ratings yet

- 1000REOZDEDocument4 pages1000REOZDELanh TranNo ratings yet

- Kohler 24 Specs SheetDocument4 pagesKohler 24 Specs Sheetabduallah muhammadNo ratings yet

- Kohler Marine 70efozd PDFDocument4 pagesKohler Marine 70efozd PDFĐại DươngNo ratings yet

- Kholer Generator 750REOZMD Spec SheetDocument4 pagesKholer Generator 750REOZMD Spec SheetNicholas BrennanNo ratings yet

- 28EOZD 60 Hz Marine Generator Set 1-Phase DieselDocument4 pages28EOZD 60 Hz Marine Generator Set 1-Phase DieselĐại DươngNo ratings yet

- Model: 10EOZD 9efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 10EOZD 9efozd: 60 HZ 50 HZ 1-Phase DieselTeszt Sdj100% (1)

- Model: 23EOZD 20efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 23EOZD 20efozd: 60 HZ 50 HZ 1-Phase DieselMaksym KlymenkoNo ratings yet

- 1500REOZDBDocument4 pages1500REOZDBRodrigoNo ratings yet

- Model: 15.5EOZD 13efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 15.5EOZD 13efozd: 60 HZ 50 HZ 1-Phase Dieselabduallah muhammadNo ratings yet

- Kohler 2000ROZD4 Spec SheetDocument4 pagesKohler 2000ROZD4 Spec SheetKhaled KamelNo ratings yet

- 40REOZT Towable Generator Sets Provide Reliable PowerDocument4 pages40REOZT Towable Generator Sets Provide Reliable Powerrendi valentinoNo ratings yet

- Koin 080T310Document4 pagesKoin 080T310PHAM THANH TUNo ratings yet

- Model: 6EKOD 5efkod: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 6EKOD 5efkod: 60 HZ 50 HZ 1-Phase Dieselyeng menNo ratings yet

- 6EKOD SpecificationsDocument4 pages6EKOD SpecificationsEfrain FlorezNo ratings yet

- Kohler 800rozmc SpecDocument4 pagesKohler 800rozmc Speclilama45-1No ratings yet

- Kohler 12.5EDocument4 pagesKohler 12.5EMike JacobsNo ratings yet

- Reozjc: Standard Features Ratings RangeDocument4 pagesReozjc: Standard Features Ratings RangeJulio CesarNo ratings yet

- Model: 11EKOZD 9efkozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 11EKOZD 9efkozd: 60 HZ 50 HZ 1-Phase DieselEdgar MaldonadoNo ratings yet

- Model: 500EOZCS (60 HZ) 450EFOZCS (50 HZ) : 3-Phase DieselDocument4 pagesModel: 500EOZCS (60 HZ) 450EFOZCS (50 HZ) : 3-Phase DieselPato DuhaldeNo ratings yet

- Kohler 45RZ Generator Ratings and SpecificationsDocument4 pagesKohler 45RZ Generator Ratings and SpecificationsRebecca Winfrey100% (1)

- Kohler 80RZG Spec SheetDocument4 pagesKohler 80RZG Spec SheetRomanvi1980No ratings yet

- Kohler 50rozj Spec SheetDocument4 pagesKohler 50rozj Spec SheetRomanvi1980No ratings yet

- Kohler 30REOZJB John Deere 3029TF150 Spec Sheet PDFDocument4 pagesKohler 30REOZJB John Deere 3029TF150 Spec Sheet PDFEric LaguipoNo ratings yet

- KohleerDocument6 pagesKohleerJuan RenteriaNo ratings yet

- Kohler 125rzg Spec SheetDocument4 pagesKohler 125rzg Spec SheetRomanvi1980No ratings yet

- Ratings Range: Tier 2 EPA-Certified For Stationary Emergency ApplicationsDocument6 pagesRatings Range: Tier 2 EPA-Certified For Stationary Emergency ApplicationsBryan FrancoNo ratings yet

- Reozje: ModelDocument4 pagesReozje: ModelLuis LunarNo ratings yet

- Kohler 60RZ Spec SheetDocument4 pagesKohler 60RZ Spec SheetRomanvi1980No ratings yet

- 125 RZG Technical Data Sheet - Prime DutyDocument4 pages125 RZG Technical Data Sheet - Prime DutyAdewunmi OlufemiNo ratings yet

- Cummins Data Sheet C550D5Document3 pagesCummins Data Sheet C550D5fahad pirzadaNo ratings yet

- Thong So Ky ThuatDocument6 pagesThong So Ky ThuatBảo GiaNo ratings yet

- Model:: Residential GasDocument4 pagesModel:: Residential Gasapelectric100% (1)

- Kohler 150RZGB Spec SheetDocument4 pagesKohler 150RZGB Spec SheetRomanvi1980No ratings yet

- 63530b32af2a5a8cd858fc94 Kohler 80REOZJB GeneratorDocument4 pages63530b32af2a5a8cd858fc94 Kohler 80REOZJB GeneratorYennifer HernandezNo ratings yet

- 3-Phase Diesel Marine Generator Set Ratings and SpecsDocument4 pages3-Phase Diesel Marine Generator Set Ratings and SpecsBrillyanNo ratings yet

- Model:: Gas 110 - 600 VDocument4 pagesModel:: Gas 110 - 600 VTomás GonzalezNo ratings yet

- Reozjd: ModelDocument4 pagesReozjd: ModelluislunarNo ratings yet

- Cat C32: Diesel Generator SetsDocument5 pagesCat C32: Diesel Generator SetsKhaled KamelNo ratings yet

- Kohler Model13ERGDocument4 pagesKohler Model13ERGWilliamBrown6No ratings yet

- AUIRFB4610 AUIRFS4610: V 100V R Typ. 11m Max. 14m I 73ADocument13 pagesAUIRFB4610 AUIRFS4610: V 100V R Typ. 11m Max. 14m I 73ATomi OzzyNo ratings yet

- Caterpillar Specification SheetsDocument9 pagesCaterpillar Specification Sheetsavinash_1229No ratings yet

- Cat C32: Diesel Generator SetsDocument6 pagesCat C32: Diesel Generator SetsJean Claude EidNo ratings yet

- Caterpillar XQ1000 Containerized Diesel Generator SetDocument10 pagesCaterpillar XQ1000 Containerized Diesel Generator SetMacAllister MachineryNo ratings yet

- Cat C32: Diesel Generator SetsDocument6 pagesCat C32: Diesel Generator Setsavinash_1229No ratings yet

- 14resa (L) Spec Sheet 2019Document6 pages14resa (L) Spec Sheet 2019angelNo ratings yet

- Tassili Motors genset specificationsDocument4 pagesTassili Motors genset specificationsbachir zouizaiNo ratings yet

- Kohler 10REOD/REOZD Compact Diesel Generator SpecsDocument4 pagesKohler 10REOD/REOZD Compact Diesel Generator SpecsGalindez JoséNo ratings yet

- SS9 CPGKDocument4 pagesSS9 CPGKYahya SaifanNo ratings yet

- Irfz 46 NsDocument14 pagesIrfz 46 Nstecnicogato27No ratings yet

- DSEA109 Data SheetDocument2 pagesDSEA109 Data SheetGustavo PereiraNo ratings yet

- DVR DSEA109-Operator-ManualDocument62 pagesDVR DSEA109-Operator-ManualBasaveswar KorlaNo ratings yet

- Installation and Service Instructions: PB/F - PB/FL Type PowercubeDocument32 pagesInstallation and Service Instructions: PB/F - PB/FL Type PowercubeqweNo ratings yet

- Marine Generator Set Specs and FeaturesDocument4 pagesMarine Generator Set Specs and FeaturessebastianNo ratings yet

- Singe Page BrochureDocument2 pagesSinge Page BrochuresebastianNo ratings yet

- AGN026 - B - Harmonic Voltage Distortion PDFDocument11 pagesAGN026 - B - Harmonic Voltage Distortion PDFquang_dtd09No ratings yet

- DSE8620 MKII: GensetDocument2 pagesDSE8620 MKII: GensetsebastianNo ratings yet

- Operation: Marine Generator SetsDocument152 pagesOperation: Marine Generator Setsabduallah muhammadNo ratings yet

- DSE8005 Data SheetDocument1 pageDSE8005 Data SheetsebastianNo ratings yet

- Dse8610 Mkii Data SheetDocument2 pagesDse8610 Mkii Data Sheetali rifNo ratings yet

- DSE8620 Data SheetDocument2 pagesDSE8620 Data SheetRoberto SubuyucNo ratings yet

- Tad1351Ge: 12.78 Liter, In-Line 6 CylinderDocument2 pagesTad1351Ge: 12.78 Liter, In-Line 6 Cylinderjulio cesar navaNo ratings yet

- AGN 025 - Non Linear LoadsDocument9 pagesAGN 025 - Non Linear LoadsthainarimeNo ratings yet

- Generadores Marinos Comerciales-2Document7 pagesGeneradores Marinos Comerciales-2sebastianNo ratings yet

- Generadores Marinos ComercialesDocument9 pagesGeneradores Marinos ComercialessebastianNo ratings yet

- Catalogo de RepuestosDocument2 pagesCatalogo de RepuestossebastianNo ratings yet

- Wartsila 32 Product Guide PDFDocument268 pagesWartsila 32 Product Guide PDFAlexander AcureroNo ratings yet

- NPC Small Power Utilities Group Power Plant UnitsDocument9 pagesNPC Small Power Utilities Group Power Plant UnitsJaapar HassanNo ratings yet

- MFI Control System Schematic DiagramsDocument2 pagesMFI Control System Schematic DiagramsJesús GINo ratings yet

- 1106D-E70TA PerkinsDocument2 pages1106D-E70TA PerkinsRuben Espinoza CruzNo ratings yet

- New Engine Mercedes 260 Model 177Document17 pagesNew Engine Mercedes 260 Model 177along15102002No ratings yet

- Chapter 13 SERVICE DATA: 13.1 Maintenance ScheduleDocument62 pagesChapter 13 SERVICE DATA: 13.1 Maintenance ScheduleAuxiliar Mantenimiento EcaNo ratings yet

- PGP/PGM600: Service ManualDocument20 pagesPGP/PGM600: Service ManualARTMehr Eng. GroupNo ratings yet

- MANFuelsDocument52 pagesMANFuelsJezrell JaravataNo ratings yet

- Tutorial Problems for Mechanics and ThermodynamicsDocument3 pagesTutorial Problems for Mechanics and ThermodynamicsChloe OlazoNo ratings yet

- JE493ZDB DIESEL ENGINE PARTS CATALOGUEDocument16 pagesJE493ZDB DIESEL ENGINE PARTS CATALOGUENoor Sa'adahNo ratings yet

- Market Analysis of Uk FuelDocument16 pagesMarket Analysis of Uk FuelYeshua ResearchNo ratings yet

- Powerkit Esp/Prp Diesel EngineDocument3 pagesPowerkit Esp/Prp Diesel EngineBradNo ratings yet

- Diesel Generator Fuel Consumption Chart in LitresDocument1 pageDiesel Generator Fuel Consumption Chart in LitresAnkur mittalNo ratings yet

- tAD1341/1342/1343ge-B: 308/343/366 KW (419/466/498 HP) at 1500 RPM, 335/395/406 KW (456/537/552 HP) at 1800 RPMDocument2 pagestAD1341/1342/1343ge-B: 308/343/366 KW (419/466/498 HP) at 1500 RPM, 335/395/406 KW (456/537/552 HP) at 1800 RPMMOAMMEDNo ratings yet

- Steam PDFDocument467 pagesSteam PDFRavi Bhaskar100% (1)

- Lab 31Document8 pagesLab 31net fliNo ratings yet

- Common Rail System (CRS) : Subaru Ee20 EngineDocument47 pagesCommon Rail System (CRS) : Subaru Ee20 EngineJose Manuel PichardoNo ratings yet

- 12 - ServicingDocument18 pages12 - ServicingEsang AkanNo ratings yet

- Tae 16me345Document4 pagesTae 16me345MICHEL RAJ MechNo ratings yet

- (SSANGYONG) - Manual - de - Taller - SSANGYONG - Actyon - 2012 D20DTRDocument182 pages(SSANGYONG) - Manual - de - Taller - SSANGYONG - Actyon - 2012 D20DTRpatricioNo ratings yet

- I.C. Engine Lubrication Systems ExplainedDocument6 pagesI.C. Engine Lubrication Systems ExplainedBALAMBAL RNo ratings yet

- Noss Matrix P-119-1Document1 pageNoss Matrix P-119-1eizz88No ratings yet

- Shell Gadinia 30: Performance, Features & BenefitsDocument2 pagesShell Gadinia 30: Performance, Features & BenefitsfrancisNo ratings yet

- Hitachi-Man B&W Diesel Engine Service Data: Exhaust Valve Condition and Recommendation On M/E Low-Load OperationDocument5 pagesHitachi-Man B&W Diesel Engine Service Data: Exhaust Valve Condition and Recommendation On M/E Low-Load Operationg arvNo ratings yet

- Fundamentals of Oil Gas Accounting by Charlotte J Wright and Rebecca A GallunDocument36 pagesFundamentals of Oil Gas Accounting by Charlotte J Wright and Rebecca A Gallunmajid.alsuwaidi97860% (1)

- PowerKit 6M26 Series Diesel Engine SpecsDocument2 pagesPowerKit 6M26 Series Diesel Engine SpecsDuc Thao VuNo ratings yet

- Once Jane Lifted Her Pen and Made A Start, Writing The Essay Became EasyDocument13 pagesOnce Jane Lifted Her Pen and Made A Start, Writing The Essay Became EasysheejasamNo ratings yet

- MEPC25 Automobile Engineering Assignment: Submitted By: M K Jaiganesh 111118068Document25 pagesMEPC25 Automobile Engineering Assignment: Submitted By: M K Jaiganesh 111118068jaiNo ratings yet

- Model DE Electronically Controlled Diesel Fuel Injection Pump Operation and Instruction ManualDocument60 pagesModel DE Electronically Controlled Diesel Fuel Injection Pump Operation and Instruction ManualjiovanniNo ratings yet

- MG D16 1500/1800 rpm diesel engine technical dataDocument8 pagesMG D16 1500/1800 rpm diesel engine technical dataMicroTech. Corp.No ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)