Professional Documents

Culture Documents

WKP Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 V

Uploaded by

akeem alturkiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WKP Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 V

Uploaded by

akeem alturkiCopyright:

Available Formats

WKP Series

www.vishay.com

Vishay Roederstein

EMI Suppression Capacitor, Ceramic Disc,

Class X1, 760 VAC, Class Y1, 500 VAC

FEATURES

• Complying with IEC 60384-14

• High reliability

• Wide range of different leadstyles

• Singlelayer AC disc safety capacitors

• Material categorization: for definitions of

compliance please see www.vishay.com/doc?99912

APPLICATIONS

• X1, Y1 according to IEC 60384-14

• Line-to-line filtering (Class X)

LINKS TO ADDITIONAL RESOURCES • Line-to-ground filtering (Class Y)

• EMI / RFI suppression and filtering

3D 3D

3D Models • Primary and secondary coupling (SMPS)

DESIGN

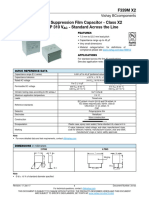

QUICK REFERENCE DATA The capacitors consist of ceramic disc both sides of which

DESCRIPTION VALUE are silver plated. Connection leads are made of tinned

Ceramic Class 1 2 copper having diameters of 0.6 mm or 0.8 mm.

Y5S, Y5S, The capacitors may be supplied with straight or kinked

Ceramic Dielectric N750 N750 Y5T, Y5T, leads having a lead spacing of 10.0 mm or 12.5 mm.

Y5U Y5U

Voltage (VAC) 500 760 500 760 Coating is made of blue colored flame retardant epoxy resin

in accordance with UL 94 V-0.

Min. Capacitance (pF) 33 47

Max. Capacitance (pF) 33 4700 CAPACITANCE RANGE

Mounting Radial

33 pF to 4.7 nF

OPERATING TEMPERATURE RANGE TOLERANCE ON CAPACITANCE

-40 °C to +125 °C (1) ± 10 %, ± 20 %

Note

(1) For explanation about the difference of operating temperature RATED VOLTAGE

range and temperature characteristic of capacitance please see • X1: 760 VAC, 50 Hz (IEC 60384-14)

www.vishay.com/doc?48299 760 VAC, 50 Hz / 60 Hz (US/UL/CSA 60384-14)

TEMPERATURE CHARACTERISTICS • Y1: 500 VAC, 50 Hz (IEC 60384-14)

500 VAC, 50 Hz / 60 Hz (US/UL/CSA 60384-14)

Class 1: N750

Class 2: Y5S, Y5T, Y5U TEST VOLTAGE

• 4000 VAC, 50 Hz, 2 s Component test (100 %)

SECTIONAL SPECIFICATIONS

• 4000 VAC, 50 Hz, 60 s Random sampling test (destructive)

Climatic category (according to EN 60068-1)

• 4000 VAC, 50 Hz, 60 s Voltage proof of coating (destructive)

Class 1: 40 / 125 / 21

Class 2: 40 / 125 / 21 INSULATION RESISTANCE AT 500 VDC

≥ 10 000 MΩ (60 s)

APPROVALS

IEC 60384-14 DISSIPATION FACTOR

UL 60384-14 Class 1: max. 0.5 % (1 kHz)

CSA E60384-14 Class 2: max. 2.5 % (1 kHz)

Revision: 28-Jan-2022 1 Document Number: 22206

For technical questions, contact: slcap@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

WKP Series

www.vishay.com

Vishay Roederstein

DIMENSIONS in millimeters

Dmax. Smax.

3.0 max.

V

F

30 - 3

or 10 ± 1

Ø d ± 0.05

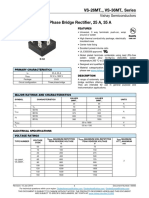

TECHNICAL DATA

LEAD LEAD PART NUMBER

BODY BODY WIDTH (1)

CAPACITANCE (2) CAPACITANCE SPACING (1) DIAMETER (1) MISSING DIGITS

DIAMETER THICKNESS V (mm)

C (pF) TOLERANCE F (mm) d (mm) SEE ORDERING

DMAX. (mm) SMAX. (mm) ± 0.5 mm

± 1 mm ± 0.05 mm CODE BELOW

N750

± 10 %,

33 8.0 6.0 12.5 0.6 1.9 WKP330#CP###KR

± 20 %

Y5S

47 WKP470#CP###KR

± 10 %,

68 8.0 6.0 12.5 0.6 2.3 WKP680#CP###KR

± 20 %

100 WKP101#CP###KR

Y5T

150 ± 10 %, WKP151#CP###KR

8.0 6.0 12.5 0.6 2.3

220 ± 20 % WKP221#CP###KR

Y5U

330 WKP331#CP###KR

8.0

470 0.6 2.5 WKP471#CP###KR

680 9.0 WKP681#CP###KR

1000 10.0 WKP102#CP###KR

± 10 %,

1500 12.0 6.0 12.5 WKP152#CP###KR

± 20 %

2200 13.0 WKP222#CP###KR

0.8 2.7

3300 15.0 WKP332#CP###KR

3900 16.0 WKP392#CP###KR

4700 18.0 WKP472#CP###KR

Notes

(1) Standard lead configuration, other lead spacing and diameter available on request

(2) Capacitance values from 1 nF to 4.7 nF: the alternative usage of smaller VKP series is recommended for new application.

ORDERING CODE

# 7th digit Capacitance tolerance ± 10 % = K, ± 20 % = M

### 10th to 12th digit Lead configuration See “General Information” www.vishay.com/doc?22001

Example WKP 222 M CP ED0 K R

Capacitance Lead RoHS

Series Tolerance code Voltage code Internal code

value configuration compliant

Revision: 28-Jan-2022 2 Document Number: 22206

For technical questions, contact: slcap@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

WKP Series

www.vishay.com

Vishay Roederstein

MARKING

WKP

IEC 384-14

760~X1 760 500 250~

500~Y1 X1 Y1

33p M WKP 2n2 M

WKP 33 pF to 1.5 nF WKP 2.2 nF to 4.7 nF

APPROVALS

IEC 60384-14 - Safety tests

This approval together with CB test certificate substitutes all national approvals.

CB Certificate (www.vishay.com/doc?22214)

Y1-capacitor: CB test certificate: US-26549-UL 33 pF to 4.7 nF 500 VAC

X1-capacitor: CB test certificate: US-26549-UL 33 pF to 4.7 nF 760 VAC

Minimum thickness of insulation: 0.4 mm

VDE (www.vishay.com/doc?22216)

Y1-capacitor: VDE marks approval: 136493 33 pF to 4.7 nF 500 VAC

X1-capacitor: VDE marks approval: 136493 33 pF to 4.7 nF 760 VAC

DIN EN 60384-14 (VDE 0565-1-1)

Minimum thickness of insulation: 0.4 mm

Underwriters Laboratories Inc. / Canadian Standards Association (www.vishay.com/doc?22215)

Y1-capacitor: UL-test certificate: E183844 33 pF to 4.7 nF 500 VAC

X1-capacitor: UL-test certificate: E183844 33 pF to 4.7 nF 760 VAC

UL 60384-14, CSA E60384-14

Minimum thickness of insulation: 0.4 mm

AC CURRENT VS. VOLTAGE (typical) IMPEDANCE VS. FREQUENCY (typical)

5000 10

I (μA)

Z (Ω)

4000 4.7 nF

1

3000 3.3 nF

68 pF

100 pF

150 pF

220 pF

330 pF

470 pF

680 pF

1000 pF

2000

1500 pF

2.2 nF

2200 pF

0.1

3300 pF

3900 pF

4700 pF

1000 1.0 nF

470 pF

0 0.01

0 500 1000 1500 2000 2500 3000 3500 4000 1 10 100 1000

UR (V~) f (MHz)

Revision: 28-Jan-2022 3 Document Number: 22206

For technical questions, contact: slcap@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

WKP Series

www.vishay.com

Vishay Roederstein

STORAGE

The capacitors must not be stored in a corrosive atmosphere, where sulphide or chloride gas, acid, alkali or salt are present.

Exposure of the components to moisture, should be avoided. The solderability of the leads is not affected by storage of up to

24 months (temperature +10 °C to +35 °C, relative humidity up to 60 %). Class 2 ceramic dielectric capacitors are also subject

to aging, see www.vishay.com/doc?22001.

SOLDERING

SOLDERING SPECIFICATIONS

Soldering test for capacitors with wire leads: (according to IEC 60068-2-20, solder bath method)

SOLDERABILITY RESISTANCE TO SOLDERING HEAT

Soldering temperature 235 °C ± 5 °C 260 °C ± 5 °C

Soldering duration 2 s ± 0.5 s 10 s ± 1 s

Distance from component body ≥ 2 mm ≥ 5 mm

SOLDERING RECOMMENDATIONS

Soldering of the component should be achieved using a Sn60/40 type or a silver-bearing Sn62/36/2Ag type solder. Ceramic

capacitors are very sensitive to rapid changes in temperature (thermal shock) therefore the solder heat resistance specification

(see Soldering Specifications table) should not be exceeded. Subjecting the capacitor to excessive heating may result in thermal

shocks that can crack the ceramic body. Similarly, excessive heating can cause the internal solder junction to melt.

CLEANING

The components should be cleaned immediately following the soldering operation with vapor degreasers.

SOLVENT RESISTANCE

The coating and marking of the capacitors are resistant to the following test method: IEC 60068-2-45 (method XA).

MOUNTING

If a defined product stop is required for mounting on a PCB, a mechanically formed product stop (kinked or inline wire) or a

mounting tool should be used.

We do not recommend modifying the lead terminals, e.g. bending or cropping. This action could break the coating or crack the

ceramic insert. If however, the lead must be modified in any way, we recommend support of the lead with a clamping fixture

next to the coating.

OPERATING VOLTAGE

In case the voltage is applied to the circuit, starting as well as stopping, may generate irregular voltage for a transit period

because of resonance or switching. Be sure to use a capacitor with a rated voltage range that includes these irregular voltages.

OPERATING TEMPERATURE AND SELF-GENERATED HEAT

Keep the surface temperature of a capacitor below the upper limit of its rated operating temperature range. Be sure to take into

account the heat generated by the capacitor itself. When the capacitor is used in a high frequency, pulse, or similar application,

it may have self-generated heat due to dielectric dissipation.

Temperature increase due to self-generated heating should not exceed 20 °C while operating at an atmosphere temperature of

25 °C.

When measuring, the surface temperature, make sure that the capacitor is not affected by radiant, conductive and convective

heat by its surroundings. Excessive heat may lead to thermo-mechanical deterioration of the capacitor's characteristics and

reliability.

RELATED DOCUMENTS

General Information www.vishay.com/doc?22001

CB Test Certificate www.vishay.com/doc?22214

VDE Marks Approval www.vishay.com/doc?22216

UL Test Certificate www.vishay.com/doc?22215

Revision: 28-Jan-2022 4 Document Number: 22206

For technical questions, contact: slcap@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay's knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer's responsibility to validate that a particular product

with the properties described in the product specification is suitable for use in a particular application. Parameters provided in

datasheets and / or specifications may vary in different applications and performance may vary over time. All operating

parameters, including typical parameters, must be validated for each customer application by the customer's technical experts.

Product specifications do not expand or otherwise modify Vishay's terms and conditions of purchase, including but not limited

to the warranty expressed therein.

Hyperlinks included in this datasheet may direct users to third-party websites. These links are provided as a convenience and

for informational purposes only. Inclusion of these hyperlinks does not constitute an endorsement or an approval by Vishay of

any of the products, services or opinions of the corporation, organization or individual associated with the third-party website.

Vishay disclaims any and all liability and bears no responsibility for the accuracy, legality or content of the third-party website

or for that of subsequent links.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

© 2023 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED

Revision: 01-Jan-2023 1 Document Number: 91000

You might also like

- Datasheet Compact NSX DC 100-630A 3P 4 - ENDocument5 pagesDatasheet Compact NSX DC 100-630A 3P 4 - ENlezellerNo ratings yet

- RCC Chimneys - CICIND Code PDFDocument23 pagesRCC Chimneys - CICIND Code PDFVasanth KumarNo ratings yet

- WKO Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 440 V, Class Y2, 300 VDocument5 pagesWKO Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 440 V, Class Y2, 300 VYoseph TsegayeNo ratings yet

- WKO Series: AC ACDocument4 pagesWKO Series: AC ACGeorge GryphoneNo ratings yet

- VY1 Series EMI Suppression Safety Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 VDocument8 pagesVY1 Series EMI Suppression Safety Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 VheribertosfaNo ratings yet

- WKP 239882Document5 pagesWKP 239882gastronomicaNo ratings yet

- 440L Series: AC ACDocument1 page440L Series: AC ACAutor AutorNo ratings yet

- 20 VLDocument5 pages20 VLUmair RaisNo ratings yet

- WYO Series: AC ACDocument4 pagesWYO Series: AC ACtaha aliNo ratings yet

- SMDY1 Series AC Line Rated Ceramic Disc Capacitors Class X1, 760 V, Class Y1, 500 VDocument7 pagesSMDY1 Series AC Line Rated Ceramic Disc Capacitors Class X1, 760 V, Class Y1, 500 Vumut bayNo ratings yet

- S SeriesDocument11 pagesS Series380665791408maksNo ratings yet

- Dseries 1762011Document10 pagesDseries 1762011fatahillah ataNo ratings yet

- 440L Series AC Line Rated Disc CapacitorsDocument6 pages440L Series AC Line Rated Disc CapacitorsBashir MtwaklNo ratings yet

- Ceramic CapacitorDocument8 pagesCeramic CapacitorparapNo ratings yet

- Ceramic Capacitors: Vy1, Vy1 Compact, and Vy2Document4 pagesCeramic Capacitors: Vy1, Vy1 Compact, and Vy2Faraz ElectronicNo ratings yet

- F Series Ceramic Disc DC Capacitors, Class 1, Class 2, Low Loss (0.2 %), 500 V, 1 KV, 2 KV, and 3 KVDocument8 pagesF Series Ceramic Disc DC Capacitors, Class 1, Class 2, Low Loss (0.2 %), 500 V, 1 KV, 2 KV, and 3 KVHECHO EN MEXICO 2.0No ratings yet

- DC DC AC AC: Vishay Cera-MiteDocument4 pagesDC DC AC AC: Vishay Cera-MiteAnonymous oyUAtpKNo ratings yet

- MKP 3366 y 2Document12 pagesMKP 3366 y 2Vincent Don KasambalaNo ratings yet

- Vishay f1772x2Document13 pagesVishay f1772x2rogerNo ratings yet

- CapacitorDocument17 pagesCapacitorjuliolocNo ratings yet

- Pha Surge Suppressor Capacitors: Vishay ESTADocument7 pagesPha Surge Suppressor Capacitors: Vishay ESTAAndes PutraNo ratings yet

- DWB - Molded Case Circuit BreakersDocument68 pagesDWB - Molded Case Circuit BreakersHélio SousaNo ratings yet

- S202M-K6UC: Miniature Circuit Breaker - S200MUC - 2P - K - 6 AmpereDocument5 pagesS202M-K6UC: Miniature Circuit Breaker - S200MUC - 2P - K - 6 AmpereLucas CruzNo ratings yet

- S202M-C4UC: Miniature Circuit Breaker - S200MUC - 2P - C - 4 AmpereDocument5 pagesS202M-C4UC: Miniature Circuit Breaker - S200MUC - 2P - C - 4 AmpereLucas CruzNo ratings yet

- Ceramic Disc Capacitors Class 1 and 2, 1 KV To 50 KV, General PurposeDocument3 pagesCeramic Disc Capacitors Class 1 and 2, 1 KV To 50 KV, General PurposeIman AkbariNo ratings yet

- The Right Molded Case Circuit Breaker for Your ApplicationDocument56 pagesThe Right Molded Case Circuit Breaker for Your Applicationwil alfNo ratings yet

- Vishay 715c-ktDocument7 pagesVishay 715c-ktrogerNo ratings yet

- SafetydnDocument5 pagesSafetydnDigital ModelsNo ratings yet

- Low profile Schottky rectifiers for inverters and convertersDocument4 pagesLow profile Schottky rectifiers for inverters and convertersMantenimiento AsistelNo ratings yet

- ZOV Series - High Energy Varistors: DescriptionDocument4 pagesZOV Series - High Energy Varistors: DescriptionIgor PNo ratings yet

- EMI Suppression KEMETDocument2 pagesEMI Suppression KEMETavo638No ratings yet

- SS32, SS33, SS34, SS35, SS36: Vishay General SemiconductorDocument4 pagesSS32, SS33, SS34, SS35, SS36: Vishay General SemiconductorHla Swe OoNo ratings yet

- AC03 Safety (AC03..CS) : Vishay DraloricDocument3 pagesAC03 Safety (AC03..CS) : Vishay Draloricyenassiri278No ratings yet

- Product Data Sheet: Circuit Breaker Compact NSX100F - TMD - 16 A - 3 Poles 2dDocument3 pagesProduct Data Sheet: Circuit Breaker Compact NSX100F - TMD - 16 A - 3 Poles 2dagustin_agustin33No ratings yet

- Vishay Intertech P6KE10CA E3 73 - C1666663Document6 pagesVishay Intertech P6KE10CA E3 73 - C1666663asam youssefNo ratings yet

- SD47ADocument3 pagesSD47Aasif.binance1988No ratings yet

- Description Appearance: 600 Watt Transient Voltage SuppressorDocument5 pagesDescription Appearance: 600 Watt Transient Voltage SuppressorFOOD FUSIONNo ratings yet

- MKP1847C AC Filtering: Vishay RoedersteinDocument17 pagesMKP1847C AC Filtering: Vishay RoedersteinJuan GarciaNo ratings yet

- Limit Switches: General CharacteristicsDocument17 pagesLimit Switches: General CharacteristicsIonica VladNo ratings yet

- S202M-K16UC: Miniature Circuit Breaker - S200MUC - 2P - K - 16 AmpereDocument5 pagesS202M-K16UC: Miniature Circuit Breaker - S200MUC - 2P - K - 16 AmpereMary RoshmaNo ratings yet

- MKP1848S DC-Link: Vishay RoedersteinDocument15 pagesMKP1848S DC-Link: Vishay RoedersteinRaphael Santos do NascimentoNo ratings yet

- P6ke ADocument6 pagesP6ke Aafshar.ordybeheshtNo ratings yet

- Description Appearance: Voidless-Hermetically Sealed Fast Recovery Glass RectifiersDocument3 pagesDescription Appearance: Voidless-Hermetically Sealed Fast Recovery Glass RectifiersRenato Almeida AmorimNo ratings yet

- Vishay 339M SpecDocument20 pagesVishay 339M SpecDino KaoNo ratings yet

- MPRXCX Flexiship 6 - 10kv EngDocument3 pagesMPRXCX Flexiship 6 - 10kv EngFaziNo ratings yet

- Miniature Circuit Breaker - S200 - 1P - C - 16 Ampere: Product-DetailsDocument5 pagesMiniature Circuit Breaker - S200 - 1P - C - 16 Ampere: Product-DetailsHector SuarezNo ratings yet

- Solarflex - X H1Z2Z2-K: 1500 V DC, EN 50618Document2 pagesSolarflex - X H1Z2Z2-K: 1500 V DC, EN 50618Solar ProjectsNo ratings yet

- Product Data Sheet: Circuit Breaker Compact NSX100F - TMD - 50 A - 3 Poles 3dDocument3 pagesProduct Data Sheet: Circuit Breaker Compact NSX100F - TMD - 50 A - 3 Poles 3dMuhammad SaeedNo ratings yet

- How To Install PSIM PDFDocument5 pagesHow To Install PSIM PDFPavan Singh TomarNo ratings yet

- Schneider Electric - ComPact-NSX - LV429642Document4 pagesSchneider Electric - ComPact-NSX - LV429642ayyalu samyNo ratings yet

- MG LV429632Document3 pagesMG LV429632abdulkawi alasharyNo ratings yet

- S203-C16 Circuit Breaker DetailsDocument5 pagesS203-C16 Circuit Breaker DetailsYsabel AliagaNo ratings yet

- Vishay Bccomponents: FeaturesDocument12 pagesVishay Bccomponents: Featuresndfgdfs oishdfNo ratings yet

- DIODES Vs 36mtseriesDocument7 pagesDIODES Vs 36mtserieshocine gherbiNo ratings yet

- SS12, SS13, SS14, SS15, SS16: Vishay General SemiconductorDocument4 pagesSS12, SS13, SS14, SS15, SS16: Vishay General Semiconductormarcoteran007No ratings yet

- Miniature Circuit Breaker - S200 - 3P - C - 63 Ampere: Product-DetailsDocument5 pagesMiniature Circuit Breaker - S200 - 3P - C - 63 Ampere: Product-DetailsCesar Augusto Navarro SalasNo ratings yet

- S201-C4 Miniature Circuit Breaker DetailsDocument6 pagesS201-C4 Miniature Circuit Breaker Detailserick valenciaNo ratings yet

- Capacitor - Data Sheet - CircutorDocument6 pagesCapacitor - Data Sheet - CircutorMd.SafwanNo ratings yet

- VS-GBPC.. Series: Vishay SemiconductorsDocument7 pagesVS-GBPC.. Series: Vishay SemiconductorsMohamed ReyadNo ratings yet

- Compact NSX100N Circuit BreakerDocument3 pagesCompact NSX100N Circuit BreakerLucia TrifanNo ratings yet

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- CS23-08io2_CS23-12io2_CS23-16io2Document3 pagesCS23-08io2_CS23-12io2_CS23-16io2akeem alturkiNo ratings yet

- Yamaha 02Rv2E ManualDocument398 pagesYamaha 02Rv2E Manualkris_marNo ratings yet

- User Manual Ibc10Document8 pagesUser Manual Ibc10akeem alturkiNo ratings yet

- Getting Started With AnyDesk-1Document7 pagesGetting Started With AnyDesk-1akeem alturkiNo ratings yet

- 3.063 Polymer Physics: "Soft Matter"Document519 pages3.063 Polymer Physics: "Soft Matter"akeem alturkiNo ratings yet

- B1 Brochure 4522 962 93921 3D-RA 2013 05Document4 pagesB1 Brochure 4522 962 93921 3D-RA 2013 05akeem alturkiNo ratings yet

- Cynergy3 D S v3Document4 pagesCynergy3 D S v3akeem alturkiNo ratings yet

- Maintenance and User S Guide: Downloaded From Manuals Search EngineDocument4 pagesMaintenance and User S Guide: Downloaded From Manuals Search Engineakeem alturkiNo ratings yet

- Adafruit Guide Excellent SolderingDocument30 pagesAdafruit Guide Excellent Solderingakeem alturkiNo ratings yet

- Schmitt Trigger FinalDocument4 pagesSchmitt Trigger Finalsidd14feb92No ratings yet

- 1 Shane Fitzsimons - TATA SonsDocument8 pages1 Shane Fitzsimons - TATA Sonsvikashs srivastavaNo ratings yet

- Materiality of Cultural ConstructionDocument3 pagesMateriality of Cultural ConstructionPaul YeboahNo ratings yet

- Design Steel Concrete Composite StructuresDocument1 pageDesign Steel Concrete Composite StructuresDinuSkyNo ratings yet

- Namatacan HS Report on Regional Diagnostic AssessmentDocument13 pagesNamatacan HS Report on Regional Diagnostic AssessmentDonnabelle MedinaNo ratings yet

- Activity No.1 in GED 103Document2 pagesActivity No.1 in GED 103Kenneth HerreraNo ratings yet

- Government of India Sponsored Study on Small Industries Potential in Sultanpur DistrictDocument186 pagesGovernment of India Sponsored Study on Small Industries Potential in Sultanpur DistrictNisar Ahmed Ansari100% (1)

- Modular Kitchen AnalysisDocument3 pagesModular Kitchen AnalysisGhanithan SubramaniamNo ratings yet

- Liquefaction of Soil in KathmanduDocument9 pagesLiquefaction of Soil in Kathmanduajay shresthaNo ratings yet

- Python Quals PytestDocument4 pagesPython Quals PytestAnkit RathoreNo ratings yet

- Homework FileDocument18 pagesHomework FiledariadybaNo ratings yet

- PHD Thesis - Dalong Zhao-ZnO TFT Thin Film Passivation - Noise Analysis, Hooge ParameterDocument169 pagesPHD Thesis - Dalong Zhao-ZnO TFT Thin Film Passivation - Noise Analysis, Hooge Parameterjiaxin zhangNo ratings yet

- Eugene A. Nida - Theories of TranslationDocument15 pagesEugene A. Nida - Theories of TranslationYohanes Eko Portable100% (2)

- Impact of Government Expenditure On Human Capital Development (1990-2022)Document55 pagesImpact of Government Expenditure On Human Capital Development (1990-2022)malijessica907No ratings yet

- Lecture 8: Dynamics Characteristics of SCR: Dr. Aadesh Kumar AryaDocument9 pagesLecture 8: Dynamics Characteristics of SCR: Dr. Aadesh Kumar Aryaaadesh kumar aryaNo ratings yet

- D 4 Development of Beam Equations: M X V XDocument1 pageD 4 Development of Beam Equations: M X V XAHMED SHAKERNo ratings yet

- Lamosa CatalogoDocument51 pagesLamosa CatalogoSofi SamareitesNo ratings yet

- M-2 AIS Installation Manual ContentDocument57 pagesM-2 AIS Installation Manual ContentAdi PrasetyoNo ratings yet

- Alfa Laval DecanterDocument16 pagesAlfa Laval DecanterAKSHAY BHATKARNo ratings yet

- PR1 Module 2Document12 pagesPR1 Module 2Ervin GonzalesNo ratings yet

- SRFP 2015 Web List PDFDocument1 pageSRFP 2015 Web List PDFabhishekNo ratings yet

- A Phenomenological Research Design IllustratedDocument15 pagesA Phenomenological Research Design IllustratedMATEI100% (1)

- Fif-12 Om Eng Eaj23x102Document13 pagesFif-12 Om Eng Eaj23x102Schefer FabianNo ratings yet

- Development of Science in Africa - CoverageDocument2 pagesDevelopment of Science in Africa - CoverageJose JeramieNo ratings yet

- AGWA Guide GlazingDocument96 pagesAGWA Guide GlazingMoren AlfonsoNo ratings yet

- Sketch 5351a Lo LCD Key Uno 1107Document14 pagesSketch 5351a Lo LCD Key Uno 1107nobcha aNo ratings yet

- Review of Train Wheel Fatigue LifeDocument15 pagesReview of Train Wheel Fatigue Lifeabdurhman suleimanNo ratings yet

- Time: 3 Hours Total Marks: 100: Printed Page 1 of 2 Sub Code: KEE302Document2 pagesTime: 3 Hours Total Marks: 100: Printed Page 1 of 2 Sub Code: KEE302AvinäshShärmaNo ratings yet

- Xerox University Microfilms: 300 North Zeeb Road Ann Arbor, Michigan 48106Document427 pagesXerox University Microfilms: 300 North Zeeb Road Ann Arbor, Michigan 48106Muhammad Haris Khan KhattakNo ratings yet