Professional Documents

Culture Documents

MKP 3366 y 2

Uploaded by

Vincent Don KasambalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MKP 3366 y 2

Uploaded by

Vincent Don KasambalaCopyright:

Available Formats

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

Interference Suppression Film Capacitors

MKP Radial Potted Type

FEATURES

• Compliant with IEC 60381-14: AMD1 grade IIB

for pitch ≥ 15 mm

- THB: 85 °C, 85 % RH, 500 h at URAC

• Compliant with IEC 60381-14: AMD1 grade IA

for pitch < 15 mm

- THB: 40 °C, 93 % RH, 21 days at URAC

• Material categorization:

for definitions of compliance please see

www.vishay.com/doc?99912

APPLICATIONS

Y2 class

For Y2 electromagnetic interference suppression between

line and ground applications (50 Hz / 60 Hz) with a maximum

mains voltage of 300 VAC.

For application limitations refer to section “Application

Notes”.

QUICK REFERENCE DATA

Capacitance range (E12 series) 0.001 μF to 0.047 μF (preferred values according to E6)

Capacitance tolerance ± 20 %; ± 10 %

55/105/56/C for product volumes ≤ 1750 mm3

Climatic testing class according to EN60068-1

55/105/56/B for product volumes > 1750 mm3

Rated AC voltage 300 VAC; 50 Hz to 60 Hz

Permissible DC voltage 1000 VDC

Maximum application temperature 105 °C

IEC 60384-14:2013

IEC 60384-14:2013 / AMD1:2016

Reference standards EN 60384-14:2013 + AMD1:2016

IEC 60065 requires, pass. flamm. class B for volumes > 1750 mm3

UL 60384-14

Dielectric Polypropylene film

Electrodes Metallized film

Series construction (for > 10 mm pitch)

Construction

Triple construction (for > 7.5 mm and 10 mm pitch)

Encapsulation Plastic case, epoxy resin sealed, flame retardant UL-class 94 V-0

Leads Tinned wire

Marking C-value; tolerance; rated voltage; sub-class; manufacturer’s type designation;

code for dielectric material; manufacturer location; year and week

Note

• For more detailed data and test requirements, contact: rfi@vishay.com

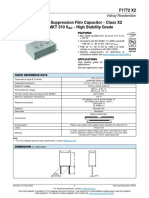

DIMENSIONS in millimeters

l w

lt

P ± 0.4 Ø dt

Revision: 17-Jan-2023 1 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

COMPOSITION OF CATALOG NUMBER

TYPE AND PITCHES MULTIPLIER

336 6 10.0 mm (nF)

CAPACITANCE

Y2 15.0 mm 0.1 2

(numerically)

1 3

Example:

103 = 10 x 1 = 10 nF

BFC2 336 6X XX X

2222(*) 336 6X XX X

(*) Old ordering code

TYPE PACKAGING LEAD CONFIGURATION C-TOL. PREFERRED TYPES

336 6 Lead length 3.5 mm + 1 mm/- 0.5 mm (pitch = 10 mm) or

BFC2 336 60...

Loose in box 3.5 mm ± 0.3 mm (pitch = 15 mm) ± 20 %

Y2 Lead length 25.0 mm ± 2.0 mm BFC2 336 66...

TYPE PACKAGING LEAD CONFIGURATION C-TOL. ON REQUEST

Lead length 3.5 mm + 1 mm/- 0.5 mm (pitch = 10 mm) or

BFC2 336 61...

Loose in box 3.5 mm ± 0.3 mm (pitch = 15 mm) ± 10 %

336 6

Lead length 25.0 mm ± 2.0 mm BFC2 336 67...

Y2

H = 18.5 mm; P0 = 12.7 mm; ± 20 % BFC2 336 63...

Taped on reel (1)

reel diameter 500 mm ± 10 % BFC2 336 64...

Note

(1) For detailed tape specification refer to packaging information: www.vishay.com/doc?28139

SPECIFIC REFERENCE DATA

DESCRIPTION VALUE

Rated AC voltage (URAC) 300 V

Permissible DC voltage (URDC) 1000 V

at 10 kHz

Tangent of loss angle

≤ 20 x 10-4

Rated voltage pulse slope (dU/dt)R at 420 VDC 200 V/μs

R between leads, for C ≤ 0.33 μF at 100 V; 1 min > 15 000 MΩ

R between leads and case; 100 V; 1 min > 30 000 MΩ

Withstanding (DC) voltage (cut off current 10 mA) (1); rise time ≤ 1000 V/s 3400 V; 1 min

Withstanding (AC) voltage between leads and case 2100 V; 1 min

Note

(1) See “Voltage Proof Test for Metalized Film Capacitors”: www.vishay.com/doc?28169

Revision: 17-Jan-2023 2 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

ELECTRICAL DATA AND ORDERING CODE

CATALOG NUMBER BFC2 336 6..... AND PACKAGING

REEL

LOOSE IN BOX

DIMENSIONS (500 mm) (1)(2)

URAC CAP. MASS

wxhxl

(V) (μF) (g) (3) lt = 3.5 mm + 1 mm/- 0.5 mm (10 mm) lt = 25.0 mm ± 2.0 mm

H = 18.5 mm;

(mm) OR 3.5 mm ± 0.3 mm (= 15 mm) P0 = 12.7 mm

LAST 5 DIGITS OF LAST 5 DIGITS OF LAST 5 DIGITS OF

SPQ SPQ SPQ

CATALOG NUMBER CATALOG NUMBER CATALOG NUMBER

PITCH = 10.0 mm ± 0.4 mm; dt = 0.6 mm ± 0.06 mm; C-TOL. = ± 20 %

0.0010 60102 66102 63102

0.0015 60152 66152 63152

4.0 x 10.0 x 12.5 0.6 1250 1400

0.0022 60222 66222 63222

1000

0.0033 60332 66332 63332

0.0047 60472 66472 63472

5.0 x 11.0 x 12.5 0.82 1000 1100

0.0068 60682 66682 63682

PITCH = 15.0 mm ± 0.4 mm; dt = 0.6 mm ± 0.06 mm; C-TOL. = ± 20 %

0.0068 69005 69009 69006

5.0 x 11.0 x 17.5 1.0 1100

0.010 60103 1000 66103 1000 63103

0.015 6.0 x 12.0 x 17.5 1.4 60153 66153 63153 900

PITCH = 15.0 mm ± 0.4 mm; dt = 0.8 mm ± 0.08 mm; C-TOL. = ± 20 %

0.022 7.0 x 13.5 x 17.5 1.8 60223 66223 63223 800

750 500

0.033 8.5 x 15.0 x 17.5 2.4 60333 66333 63333 650

0.047 10.0 x 16.5 x 17.5 3.0 60473 500 66473 450 63473 600

PITCH = 10.0 mm ± 0.4 mm; dt = 0.6 mm ± 0.06 mm; C-TOL. = ± 10 %

0.0010 61102 67102 64102

0.0012 61122 67122 64122

0.0015 61152 67152 64152

0.0018 61182 67182 64182

300 4.0 x 10.0 x 12.5 0.6 1000 1250 1400

0.0022 61222 67222 64222

0.0027 61272 67272 64272

0.0033 61332 67332 64332

0.0039 61392 67392 64392

0.0047 61472 67472 64472

5.0 x 11.0 x 12.5 1.1 1000 1000 1100

0.0056 61562 67562 64562

PITCH = 15.0 mm ± 0.4 mm; dt = 0.80 mm ± 0.08 mm; C-TOL. = ± 10 %

0.0056 69001 69007 69003

0.0068 61682 67682 64682

0.0082 5.0 x 11.0 x 17.5 1.0 61822 67822 64822 1100

0.010 61103 1000 67103 1000 64103

0.012 61123 67123 64123

0.015 61153 67153 61153

6.0 x 12.0 x 17.5 1.4 900

0.018 61183 67183 64183

PITCH = 15.0 mm ± 0.4 mm; dt = 0.80 mm ± 0.08 mm; C-TOL. = ± 10 %

0.022 7.0 x 13.5 x 17.5 1.8 61223 67223 64223 800

0.027 61273 750 67273 500 64273

8.5 x 15.0 x 17.5 2.4 650

0.033 61333 67333 64333

0.039 61393 67393 61393

10.0 x 16.5 x 17.5 3.0 500 450 600

0.047 61473 67473 64473

Notes

• SPQ = Standard packing quantity

(1) H = in-tape height; P = sprocket hole distance; for detailed specifications refer to packaging information: www.vishay.com/doc?28139

0

(2) Reel diameter = 365 mm is available on request

(3) Weight for short lead product only

Revision: 17-Jan-2023 3 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

APPROVALS

SAFETY APPROVALS Y2 VOLTAGE VALUE FILE NUMBERS LINKS

EN 60384-14 (ENEC)

300 VAC 1 nF to 47 nF ENEC16/FI/21/01065 www.vishay.com/doc?28204

(= IEC 60384-14 ed-4 (2013))

UL 60384-14 300 VAC 1 nF to 47 nF E354331

www.vishay.com/doc?28189

CSA-E384-14 300 VAC 1 nF to 47 nF E354331

CB-test-certificate 300 VAC 1 nF to 47 nF FI-39831/A1 www.vishay.com/doc?28203

The ENEC-approval together with the CB-certificate replace all national marks of the following countries (they have already signed the

ENEC-agreement): Austria; Belgium; Czech. Republic; Denmark; Finland; France; Germany; Greece; Hungary; Ireland; Italy; Luxembourg;

Netherlands; Norway; Portugal; Slovenian; Spain; Switzerland and United Kingdom.

MOUNTING

Normal Use

The capacitors are designed for mounting on printed-circuit boards. The capacitors packed in bandoleers are designed for

mounting in printed-circuit boards by means of automatic insertion machines.

For detailed tape specifications refer to packaging information: www.vishay.com/doc?28139

Specific Method of Mounting to Withstand Vibration and Shock

In order to withstand vibration and shock tests, it must be ensured that the stand-off pips are in good contact with the

printed-circuit board:

• The capacitors shall be mechanically fixed by the leads

Space Requirements on Printed Circuit Board

The maximum space for length (Imax.), width (wmax.), and height (hmax.) of film capacitors to take in account on the printed circuit

board is shown in the drawings.

• For products with pitch ≤ 15 mm, Δw = Δl = 0.3 mm; Δh = 0.1 mm

Eccentricity defined as in drawing. The maximum eccentricity is smaller than or equal to the lead diameter of the product

concerned.

wmax. = W + Δ

Eccentricity

Imax. = I + Δ CBA116

hmax. = h + Δ

Seating plane

SOLDERING CONDITIONS

For general soldering conditions and wave soldering profile, we refer to the application note:

“Soldering Guidelines for Film Capacitors”: www.vishay.com/doc?28171

Storage Temperature

Tstg = -25 °C to +35 °C with RH maximum 75 % without condensation

Ratings and Characteristics Reference Conditions

Unless otherwise specified, all electrical values apply to an ambient temperature of 23 °C ± 1 °C, an atmospheric pressure of

86 kPa to 106 kPa and a relative humidity of 50 % ± 2 %.

For reference testing, a conditioning period shall be applied over 96 h ± 4 h by heating the products in a circulating air oven at

the rated temperature and a relative humidity not exceeding 20 %.

Revision: 17-Jan-2023 4 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

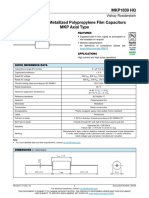

CHARACTERISTICS

Axis Title Axis Title

4 10000 1000 10000

2 Typical

Dissipation Factor (x 10-4)

1000 100 1000

0

ΔC/C (%)

2nd line

2nd line

2nd line

1st line

1st line

2nd line

-2

100 10 10 nF < C ≤ 47 nF 100

-4 C ≤ 10 nF

Minimum

-6 10 1 10

-60 -40 -20 0 20 40 60 80 100 10 100 1000 10 000 100 000

Ambient Temperature (°C) Frequency (Hz)

Capacitance as a function of ambient temperature Tangent of loss angle as a function of frequency

(typical curve) (typical curve)

Axis Title Axis Title

1000 10000 100 10000

1 nF

100 4.7 nF

Frequency (MHz)

1000 1000

Impedance (Ω)

47 nF

10

2nd line

2nd line

2nd line

1st line

2nd line

1st line

10 nF Y2

10

1

100 100

0.1

0.01 10 1 10

10 000 100 000 1M 10M 100M 1 10 100

Frequency (Hz) Capacitance (nF)

Impedance as a function of frequency Resonant frequency as a function of capacitance

(typical curve) (typical curve)

Axis Title Axis Title

1000 10000 1000 10000

100

47 nF

AC Current (mA)

1000 1000

AC Voltage (V)

2nd line

2nd line

2nd line

2nd line

1st line

1st line

10 nF

100 10

100 4.7 nF 100

1

1 nF

Tamb ≤ 105 °C Tamb ≤ 105 °C

10 10 0.1 10

10 100 1000 10 000 100 000 10 100 1000 10 000 100 000

Frequency (Hz) Frequency (Hz)

Max. RMS voltage as a function of frequency Max. RMS current as a function of frequency

Revision: 17-Jan-2023 5 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

Axis Title

1 000 000 10000

1000

2nd line

1st line

RC (s)

100 000

100

10 000 10

0 20 40 60 80 100

Tamb (°C)

Insulation resistance as a function of ambient temperature

(typical curve)

APPLICATION NOTES

• For Y2 electromagnetic interference suppression between line and ground (50 Hz / 60 Hz) with a maximum mains voltage of

300 VAC ± 10 % instability

• For capacitors connected in parallel, normally the proof voltage and possibly the rated voltage must be reduced. For

information depending of the capacitance value and the number of parallel connections contact: rfi@vishay.com

• These capacitors are not intended for continuous pulse applications. For these situations, capacitors of the AC and pulse

program must be used

• The maximum ambient temperature must not exceed 105 °C

• Rated voltage pulse slope:

if the pulse voltage is lower than the rated voltage, the values of the specific reference data can be multiplied by 420 VDC and

divided by the applied voltage

Revision: 17-Jan-2023 6 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

INSPECTION REQUIREMENTS

General Notes

Sub-clause numbers of tests and performance requirements refer to the “Sectional Specification, Publication

IEC 60384-14 ed-4 (2013) and Specific Reference Data.”

GROUP C INSPECTION REQUIREMENTS

SUB-CLAUSE NUMBER AND TEST CONDITIONS PERFORMANCE REQUIREMENTS

SUB-GROUP C1A PART OF SAMPLE

OF SUB-GROUP C1

4.1 Dimensions (detail) As specified in chapters “General data” of this

specification

Initial measurements Capacitance

Tangent of loss angle at 10 kHz

4.3 Robustness of terminations Tensile: load 10 N; 10 s No visible damage

Bending: load 5 N; 4 x 90°

4.4 Resistance to soldering heat No pre-drying

Method: 1A

Solder bath: 260 °C

Duration: 10 s

4.19 Component solvent resistance Isopropylalcohol at room temperature

Method: 2

Immersion time: 5 min ± 0.5 min

Recovery time:

Min. 1 h, max. 2 h

4.4.2 Final measurements Visual examination No visible damage

Legible marking

Capacitance |ΔC/C| ≤ 5 % of the value measured initially

Tangent of loss angle Increase of tan δ:≤ 0.008

Compared to values measured initially

Insulation resistance As specified in section “Insulation Resistance” of

this specification

SUB-GROUP C1B PART OF SAMPLE

OF SUB-GROUP C1

Initial measurements Capacitance

Tangent of loss angle at 10 kHz

4.20 Solvent resistance of the marking Isopropylalcohol at room temperature No visible damage

Method: 1 Legible marking

Rubbing material: cotton wool

Immersion time: 5 min ± 0.5 min

4.6 Rapid change of temperature θA = - 55 °C

θB = + 105 °C

5 cycles

4.6.1 Inspection Duration t = 30 min

Revision: 17-Jan-2023 7 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

GROUP C INSPECTION REQUIREMENTS

SUB-CLAUSE NUMBER AND TEST CONDITIONS PERFORMANCE REQUIREMENTS

SUB-GROUP C1B PART OF SAMPLE

OF SUB-GROUP C1

4.7 Vibration Visual examination No visible damage

Mounting: See section “Mounting” of this

specification

Procedure B4

Frequency range: 10 Hz to 55 Hz.

Amplitude: 0.75 mm or

Acceleration 98 m/s2

(whichever is less severe)

Total duration 6 h

4.7.2 Final inspection Visual examination No visible damage

4.9 Shock Mounting: see section “Mounting” for

more information

Pulse shape: half sine

Acceleration: 490 m/s2

Duration of pulse: 11 ms

4.9.2 Final measurements Visual examination No visible damage

Capacitance |ΔC/C| ≤ 5 % of the value measured initially

Tangent of loss angle Increase of tan δ:

≤ 0.008

Compared to values measured initially

Insulation resistance As specified in section “Insulation Resistance” of

this specification

SUB-GROUP C1 COMBINED SAMPLE

OF SPECIMENS OF SUB-GROUPS

C1A AND C1B

4.11 Climatic sequence

4.11.1 Initial measurements Capacitance

Measured in 4.4.2 and 4.9.2

Tangent of loss angle:

Measured initially in C1A and C1B

4.11.2 Dry heat Temperature: 105 °C

Duration: 16 h

4.11.3 Damp heat cyclic

Test Db

First cycle

4.11.4 Cold Temperature: - 55 °C

Duration: 2 h

4.11.5 Damp heat cyclic

Test Db

remaining cycles

Revision: 17-Jan-2023 8 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

GROUP C INSPECTION REQUIREMENTS

SUB-CLAUSE NUMBER AND TEST CONDITIONS PERFORMANCE REQUIREMENTS

SUB-GROUP C1 COMBINED SAMPLE

OF SPECIMENS OF SUB-GROUPS

C1A AND C1B

4.11.6 Final measurements Visual examination No visible damage

Legible marking

Capacitance |ΔC/C| ≤ 5 % of the value measured in 4.11.1.

Tangent of loss angle Increase of tan δ:

≤ 0.008

Compared to values measured in 4.11.1.

Voltage proof No permanent breakdown or flash-over

2250 VDC; 1 min between term.

Insulation resistance ≥ 50 % of values specified in section “Insulation

resistance” of this specification

SUB-GROUP C2

4.12 Damp heat steady state 56 days, 40 °C, 90 % to 95 % RH no load

capacitance

4.12.1 Initial measurements Capacitance

Tangent of loss angle at 10 kHz

4.12.3 Final measurements Visual examination No visible damage

Legible marking

Capacitance |ΔC/C| ≤ 5 % of the value measured in 4.12.1.

Tangent of loss angle Increase of tan δ:

≤ 0.007

Compared to values measured in 4.12.1.

Voltage proof No permanent breakdown or flash-over

2250 VDC; 1 min between term.

Insulation resistance ≥ 50 % of values specified in section “Insulation

resistance” of this specification

SUB-GROUP C3

4.13.1 Initial measurements Capacitance

Tangent of loss angle at 10 kHz

4.13 Impulse voltage 3 successive impulses, full wave, peak No selfhealing breakdowns or flashover

voltage:

5 kV

Max. 24 pulses

4.14 Endurance Duration: 1000 h

1.7 URAC at 105 °C

Once in every hour the voltage is

increased to 1000 VRMS for 0.1 s via

resistor of 47 Ω ± 5 %

Revision: 17-Jan-2023 9 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

GROUP C INSPECTION REQUIREMENTS

SUB-CLAUSE NUMBER AND TEST CONDITIONS PERFORMANCE REQUIREMENTS

SUB-GROUP C3

4.14.7 Final measurements Visual examination No visible damage

Legible marking

Capacitance |ΔC/C| ≤ 10 % compared to values measured in

4.13.1.

Tangent of loss angle Increase of tan δ:

≤ 0.007

Compared to values measured in 4.13.1.

Voltage proof No permanent breakdown or flash-over

2250 VDC;

1 min between terminations

Insulation resistance ≥ 50 % of values specified in section “Insulation

resistance” of this specification

SUB-GROUP C4

4.15 Charge and discharge 10 000 cycles

(50 c/s) charge to UR half sinewave

Duration: 5 ms

Discharge resistance:

420 V DC

R = ---------------------------------------------------

-

1.5 x C ( ( dU )/ ( dt ) )

Rmin. = 2.2 Ω

4.15.1 Initial measurements Capacitance

Tangent of loss angle at 10 kHz

4.15.3 Final measurements Capacitance |ΔC/C| ≤ 10 % compared to values measured in

4.15.1.

Tangent of loss angle Increase of tan δ:

≤ 0.008

Compared to values measured in 4.15.1.

Insulation resistance ≥ 50 % of values specified in section “Insulation

resistance” of this specification

SUB-GROUP C5

4.16 Radio frequency characteristic Resonance frequency As specified in section “Resonant frequency” of

this specification. ± 10 %

SUB-GROUP C6

4.17 Passive flammability Bore of gas jet: Ø 0.5 mm After removing test flame from capacitor, the

Class B Fuel: Butane capacitor must not continue to burn for more than

Test duration for actual volume V in mm3: 10 s. No burning particle must drop from the

V ≤ 250: 10 s sample.

250 < V ≤ 500: 20 s

500 < V ≤ 1750: 30 s

V > 1750: 60 s

One flame application

12 mm

~ 8 mm

45.0°

Revision: 17-Jan-2023 10 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Not for New Designs - Alternative Device: MKP338 6 Y2

MKP336 6 Y2

www.vishay.com

Vishay BCcomponents

GROUP C INSPECTION REQUIREMENTS

SUB-CLAUSE NUMBER AND TEST CONDITIONS PERFORMANCE REQUIREMENTS

SUB-GROUP C7

4.18 Active flammability 20 x 5 kV discharges on the test capacitor The cheese cloth around the capacitors shall not

connected to UR burn with a flame.

No electrical measurements are required.

SUB-GROUP ADD6

(FOR PITCH ≥ 15 mm)

A.6 Damp heat steady state with load RH: 85 %, temp.: 85 °C

Load: 300 VAC, duration: 500 h

A.6.1 Initial measurements Capacitance

Tangent of loss angle: at 10 kHz

A.6.2 Final measurements Visual examination No visible damage

Legible marking

Capacitance |ΔC/C| ≤ 10 % of the value measured in A.6.1

Tangent of loss angle Increase of tan δ ≤ 0.024

Compared to values measured in A.6.1

No permanent breakdown or flash-over

Insulation resistance ≥ 50 % of values specified in section “Insulation

Resistance” of this specification

SUB-GROUP ADD7

A.7 Damp heat steady state with load RH: 40 %, temp.: 93 °C;

Load: 300 VAC, duration: 21 days

A.7.1 Initial measurements Capacitance

Tangent of loss angle: at 10 kHz

A.7.2 Final measurements Visual examination No visible damage

Legible marking

Capacitance |ΔC/C| ≤ 10 % of the value measured in A.7.1

Tangent of loss angle Increase of tan δ ≤ 0.024

Compared to values measured in A.7.1

No permanent breakdown or flash-over

Insulation resistance ≥ 50 % of values specified in section “Insulation

Resistance” of this specification

Revision: 17-Jan-2023 11 Document Number: 28115

For technical questions, contact: rfi@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay's knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer's responsibility to validate that a particular product

with the properties described in the product specification is suitable for use in a particular application. Parameters provided in

datasheets and / or specifications may vary in different applications and performance may vary over time. All operating

parameters, including typical parameters, must be validated for each customer application by the customer's technical experts.

Product specifications do not expand or otherwise modify Vishay's terms and conditions of purchase, including but not limited

to the warranty expressed therein.

Hyperlinks included in this datasheet may direct users to third-party websites. These links are provided as a convenience and

for informational purposes only. Inclusion of these hyperlinks does not constitute an endorsement or an approval by Vishay of

any of the products, services or opinions of the corporation, organization or individual associated with the third-party website.

Vishay disclaims any and all liability and bears no responsibility for the accuracy, legality or content of the third-party website

or for that of subsequent links.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

© 2023 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED

Revision: 01-Jan-2023 1 Document Number: 91000

You might also like

- Vishay f1772x2Document13 pagesVishay f1772x2rogerNo ratings yet

- CapacitorDocument17 pagesCapacitorjuliolocNo ratings yet

- MKP1847C AC Filtering: Vishay RoedersteinDocument17 pagesMKP1847C AC Filtering: Vishay RoedersteinJuan GarciaNo ratings yet

- Vishay 339M SpecDocument20 pagesVishay 339M SpecDino KaoNo ratings yet

- S SeriesDocument11 pagesS Series380665791408maksNo ratings yet

- WKO Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 440 V, Class Y2, 300 VDocument5 pagesWKO Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 440 V, Class Y2, 300 VYoseph TsegayeNo ratings yet

- CRCW-HP E3: Vishay DraloricDocument10 pagesCRCW-HP E3: Vishay DraloricMohendra PatiNo ratings yet

- WKP Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 VDocument5 pagesWKP Series EMI Suppression Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 Vakeem alturkiNo ratings yet

- SMDY1 Series AC Line Rated Ceramic Disc Capacitors Class X1, 760 V, Class Y1, 500 VDocument7 pagesSMDY1 Series AC Line Rated Ceramic Disc Capacitors Class X1, 760 V, Class Y1, 500 Vumut bayNo ratings yet

- 20 VLDocument5 pages20 VLUmair RaisNo ratings yet

- P6ke ADocument6 pagesP6ke Aafshar.ordybeheshtNo ratings yet

- VY1 Series EMI Suppression Safety Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 VDocument8 pagesVY1 Series EMI Suppression Safety Capacitor, Ceramic Disc, Class X1, 760 V, Class Y1, 500 VheribertosfaNo ratings yet

- DC DC AC AC: Vishay Cera-MiteDocument4 pagesDC DC AC AC: Vishay Cera-MiteAnonymous oyUAtpKNo ratings yet

- 440L Series: AC ACDocument1 page440L Series: AC ACAutor AutorNo ratings yet

- MKP1839 HQ: Vishay RoedersteinDocument13 pagesMKP1839 HQ: Vishay RoedersteinSTE ABMCNo ratings yet

- Dseries 1762011Document10 pagesDseries 1762011fatahillah ataNo ratings yet

- WKO Series: AC ACDocument4 pagesWKO Series: AC ACGeorge GryphoneNo ratings yet

- B43876S9478M 1 - Ed5Document3 pagesB43876S9478M 1 - Ed5Mauricio BaronNo ratings yet

- WYO Series: AC ACDocument4 pagesWYO Series: AC ACtaha aliNo ratings yet

- Vishay k3020pDocument8 pagesVishay k3020progerNo ratings yet

- DatasheetDocument5 pagesDatasheetAliTronic1972No ratings yet

- MKP1848S DC-Link: Vishay RoedersteinDocument15 pagesMKP1848S DC-Link: Vishay RoedersteinRaphael Santos do NascimentoNo ratings yet

- SM6S10 Thru SM6S36A: High Temperature Stability and High Reliability ConditionsDocument5 pagesSM6S10 Thru SM6S36A: High Temperature Stability and High Reliability ConditionsStuxnetNo ratings yet

- Ceramic CapacitorDocument8 pagesCeramic CapacitorparapNo ratings yet

- Revitex VAC40: Sleevings For Thermal, Electrical, Mechanical & Emi ApplicationsDocument2 pagesRevitex VAC40: Sleevings For Thermal, Electrical, Mechanical & Emi ApplicationsJesus VerduzcoNo ratings yet

- EPCOS Switching Spark Gap, 230V Breakdown Voltage, 300A, 25Hz Max. Switching Frequency, 2000000Document4 pagesEPCOS Switching Spark Gap, 230V Breakdown Voltage, 300A, 25Hz Max. Switching Frequency, 2000000Mansoor AsifNo ratings yet

- SM8 Transient SupressorDocument5 pagesSM8 Transient SupressorSergio ReyesNo ratings yet

- SMC 3 K 22 CaDocument5 pagesSMC 3 K 22 CaTodorosss JjNo ratings yet

- SS32 Thru SS36: Vishay General SemiconductorDocument4 pagesSS32 Thru SS36: Vishay General SemiconductorMantenimiento AsistelNo ratings yet

- Vishay Intertech P6KE10CA E3 73 - C1666663Document6 pagesVishay Intertech P6KE10CA E3 73 - C1666663asam youssefNo ratings yet

- Byv 26 DGPDocument5 pagesByv 26 DGPmuhammedasifNo ratings yet

- Capacitor - Data Sheet - CircutorDocument6 pagesCapacitor - Data Sheet - CircutorMd.SafwanNo ratings yet

- SM8S10A Thru SM8S43A: High Temperature Stability and High Reliability ConditionsDocument5 pagesSM8S10A Thru SM8S43A: High Temperature Stability and High Reliability ConditionsSumitomo ExcavatorNo ratings yet

- Limit Switches: General CharacteristicsDocument17 pagesLimit Switches: General CharacteristicsIonica VladNo ratings yet

- SM8A27T: High Temperature Stability and High Reliability ConditionsDocument5 pagesSM8A27T: High Temperature Stability and High Reliability ConditionsmohanNo ratings yet

- Wima MP 3-X2: Metallized Paper (MP) RFI-Capacitors Class X2 PCM 10 MM To 27.5 MMDocument4 pagesWima MP 3-X2: Metallized Paper (MP) RFI-Capacitors Class X2 PCM 10 MM To 27.5 MMFirdaus HanipahNo ratings yet

- 2CDS253001R0324Document5 pages2CDS253001R0324Alma Leon AcostaNo ratings yet

- Surge ArresterDocument4 pagesSurge Arresterizaqui bernardoNo ratings yet

- Esh3B, Esh3C, Esh3D: Vishay General SemiconductorDocument6 pagesEsh3B, Esh3C, Esh3D: Vishay General Semiconductorbalajiboss005No ratings yet

- CrmaDocument4 pagesCrmavahid hajihasaniNo ratings yet

- Elettrotek Kabel GAALFLEXDocument2 pagesElettrotek Kabel GAALFLEXIvan NikodijevicNo ratings yet

- VOW135, VOW136: Vishay SemiconductorsDocument10 pagesVOW135, VOW136: Vishay Semiconductorspeter manthraNo ratings yet

- CVTC VFD - Flexible Motor Supply Cable: XLPE/PVC, Low-Voltage Power, Al/Polyester/AI + TC Braid ShieldedDocument2 pagesCVTC VFD - Flexible Motor Supply Cable: XLPE/PVC, Low-Voltage Power, Al/Polyester/AI + TC Braid ShieldedIbrahim ElkhatibNo ratings yet

- NRJCAT21025EN Minera-EcoDesign 200821Document12 pagesNRJCAT21025EN Minera-EcoDesign 200821Hendri AskoroNo ratings yet

- TNPW E3-1761965Document15 pagesTNPW E3-1761965João JoséNo ratings yet

- Epcos CapacitorDocument8 pagesEpcos CapacitorcoronaqcNo ratings yet

- Typ KFCDocument5 pagesTyp KFCBrunomartinezsk2No ratings yet

- 1N6267 Fagor PDFDocument8 pages1N6267 Fagor PDFHyacinthe Bertrand RazafindramenaNo ratings yet

- 440L Series: Vishay Cera-MiteDocument6 pages440L Series: Vishay Cera-MiteBashir MtwaklNo ratings yet

- Pressure Transmitters: PXT-K SeriesDocument2 pagesPressure Transmitters: PXT-K Serieskarim karimNo ratings yet

- 4x2.5GV+Sch and 7x2.5GV+SchDocument1 page4x2.5GV+Sch and 7x2.5GV+SchalaNo ratings yet

- Specification of Branch Connector (Y)Document5 pagesSpecification of Branch Connector (Y)Kalyanaraman RamakrishnanNo ratings yet

- S202M-K6UC: Miniature Circuit Breaker - S200MUC - 2P - K - 6 AmpereDocument5 pagesS202M-K6UC: Miniature Circuit Breaker - S200MUC - 2P - K - 6 AmpereLucas CruzNo ratings yet

- E WIMA MP 3-Y2 3R-Y2-1375650Document9 pagesE WIMA MP 3-Y2 3R-Y2-1375650Ilton GomesNo ratings yet

- HVR 2537Document7 pagesHVR 2537Damián PastreNo ratings yet

- Sensor de Presión MH-1Document4 pagesSensor de Presión MH-1Sergio Suárez RiesgoNo ratings yet

- 1N4942GP, 1N4944GP, 1N4946GP, 1N4947GP, 1N4948GP: Vishay General SemiconductorDocument4 pages1N4942GP, 1N4944GP, 1N4946GP, 1N4947GP, 1N4948GP: Vishay General Semiconductormalucos123No ratings yet

- VDRH Series: Vishay BccomponentsDocument25 pagesVDRH Series: Vishay BccomponentsAmir SoleimanyNo ratings yet

- Schrack Miniature Power PCB RYII & RYII Reflow Solderable: General Purpose Relays PCB RelaysDocument4 pagesSchrack Miniature Power PCB RYII & RYII Reflow Solderable: General Purpose Relays PCB RelaysWilson Rubiano AlfaroNo ratings yet

- The Cubli: A Reaction Wheel Based 3D Inverted PendulumDocument7 pagesThe Cubli: A Reaction Wheel Based 3D Inverted Pendulumbula69No ratings yet

- 197 204 PDFDocument9 pages197 204 PDFRABAH MESLOUBNo ratings yet

- Adobe Scan Jul 21, 2021Document10 pagesAdobe Scan Jul 21, 2021Thè MâñíñdèrNo ratings yet

- CMOS Digital Integrated Circuits Analysis and Design 4th Edition Kang Solutions Manual 1Document24 pagesCMOS Digital Integrated Circuits Analysis and Design 4th Edition Kang Solutions Manual 1james100% (38)

- Assigment On Work MeasurementDocument5 pagesAssigment On Work Measurementnot youNo ratings yet

- SATR-W-2005 Rev 6 PWHT ReportDocument1 pageSATR-W-2005 Rev 6 PWHT ReportAWAIS RAJANo ratings yet

- Physical Characteristics: Main ArticleDocument20 pagesPhysical Characteristics: Main ArticleEngenharia Clínica HUCFFNo ratings yet

- E 0083 ExtensometersDocument13 pagesE 0083 ExtensometersMohammed Abdul RasheedNo ratings yet

- Assignment 4Document5 pagesAssignment 4LightNo ratings yet

- Stefanescu - Science and Engineering of Casting SolidificationDocument354 pagesStefanescu - Science and Engineering of Casting SolidificationThais FernandesNo ratings yet

- Marine Industries SingaporeDocument34 pagesMarine Industries SingaporeMagesh Varan100% (3)

- Chapter 9. Failure Root Cause PreventionDocument23 pagesChapter 9. Failure Root Cause PreventionAbdirahman Ali mohamudNo ratings yet

- Irregular Flat SlabsDocument17 pagesIrregular Flat SlabsDaniel ReynoldsNo ratings yet

- Power Quality Measurement Under Non-Sinusoidal Condition: September 2011Document25 pagesPower Quality Measurement Under Non-Sinusoidal Condition: September 2011Aman MalikNo ratings yet

- MSCCH 604Document203 pagesMSCCH 604Gourav Biju100% (1)

- Comparative Analysis of A Controller For A Magnetic Ball Levitation SystemDocument10 pagesComparative Analysis of A Controller For A Magnetic Ball Levitation SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- TEGD Lab ManualDocument61 pagesTEGD Lab Manualray malonjaoNo ratings yet

- Analysis of Piston, Connecting Rod and Crank Shaft Assembly: SciencedirectDocument10 pagesAnalysis of Piston, Connecting Rod and Crank Shaft Assembly: Sciencedirectvikek vikumarNo ratings yet

- Me414 Lecture 1 Analysis of Simple StressesDocument19 pagesMe414 Lecture 1 Analysis of Simple StressesILEENVIRUSNo ratings yet

- Math Unit 2Document14 pagesMath Unit 2Jessica MehraNo ratings yet

- St. Francis National High School SF I, Limay, Bataan Third Periodical Test in Science 7 NAME: - YR/SECTIONDocument2 pagesSt. Francis National High School SF I, Limay, Bataan Third Periodical Test in Science 7 NAME: - YR/SECTIONArvin Arne RodrigoNo ratings yet

- Heat-Induced Changes in The Mechanics of A Collagenous Tissue: Isothermal, Isotonic ShrinkageDocument7 pagesHeat-Induced Changes in The Mechanics of A Collagenous Tissue: Isothermal, Isotonic ShrinkageAbdulaziz AlanziNo ratings yet

- Calibration Training SIEMENS VDODocument118 pagesCalibration Training SIEMENS VDOkermanpur.mghNo ratings yet

- Non Destructive TestingDocument10 pagesNon Destructive Testingcheikh ahmedNo ratings yet

- Cambridge International AS & A Level: Mathematics 9709/42Document16 pagesCambridge International AS & A Level: Mathematics 9709/42Hamza Hasan Ellahie(Student)No ratings yet

- Weak Interaction Phy305Document32 pagesWeak Interaction Phy305cifarha venantNo ratings yet

- Parabola Equations - MathBitsNotebook (Geo - CCSS Math) PDFDocument1 pageParabola Equations - MathBitsNotebook (Geo - CCSS Math) PDFRavi KumarNo ratings yet

- Stabilization of Black Cotton Soil Using PDFDocument6 pagesStabilization of Black Cotton Soil Using PDFSushmit KatkaleNo ratings yet

- Elementary Deferential Equation MTH232Document213 pagesElementary Deferential Equation MTH232Dejene GirmaNo ratings yet

- Ecs556 Structural Analysis Assignement Question FinalDocument9 pagesEcs556 Structural Analysis Assignement Question FinalMuhammad IqbalNo ratings yet