Professional Documents

Culture Documents

Swenn Screw TDS

Uploaded by

rimshadtpOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Swenn Screw TDS

Uploaded by

rimshadtpCopyright:

Available Formats

Metal Fixing

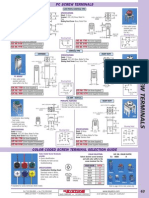

2.5 Self-Drilling/Tapping Screws - Technical Data Sheet

Screws

Ultimate Tensile Breaking Load, kgf [kN]

Ø # 6 (3.5 mm) Ø # 8 (4.2 mm) Ø # 10 (4.8 mm) Ø # 12 (5.5 mm) Ø # 14 (6.3 mm)

Hex Washer Head Carbon Steel Self-Drilling Screws

550 [5.4] 792 [7.8] 1034 [10.1] 1358 [13.3] 1781 [17.5]

Hex Washer Head Bi-metal Stainless Steel Self-Drilling Screws

476 [4.7] 686 [6.7] 896 [8.8] 1176 [11.5] 1543 [15.1]

Hex Washer Head SS 410 Stainless Steel Self-Drilling Screws

677 [6.6] 975 [9.6] 1274 [12.5] 1673 [16.4] 2195 [21.5]

Torsional Strength, Nm, Minimum

Ø # 6 (3.5 mm) Ø # 8 (4.2 mm) Ø # 10 (4.8 mm) Ø # 12 (5.5 mm) Ø # 14 (6.3 mm)

Hex Washer Head Carbon Steel Self-Drilling Screws

2.8 4.8 7.0 10.9 17.0

Hex Washer Head Bi-metal Stainless Steel Self-Drilling Screws

2.7 4.7 6.9 10.9 16.9

Hex Washer Head SS 410 Stainless Steel Self-Drilling Screws

3.0 5.1 7.5 11.0 17.5

Single Shear Strength, kgf [kN]

Ø # 6 (3.5 mm) Ø # 8 (4.2 mm) Ø # 10 (4.8 mm) Ø # 12 (5.5 mm) Ø # 14 (6.3 mm)

Hex Washer Head Carbon Steel Self-Drilling Screws

418 [4.1] 531 [5.2] 663 [6.5] 847 [8.3] 1378 [13.5]

Hex Washer Head Bi-metal Stainless Steel Self-Drilling Screws

388 [3.8] 500 [4.9] 653 [6.4] 806 [7.9] 1337 [13.1]

Hex Washer Head SS 410 Stainless Steel Self-Drilling Screws

428 [4.2] 592 [5.8] 796 [7.8] 1030 [10.1] 1347 [13.2]

Double Shear Strength, kgf [kN]

Ø # 6 (3.5 mm) Ø # 8 (4.2 mm) Ø # 10 (4.8 mm) Ø # 12 (5.5 mm) Ø # 14 (6.3 mm)

Hex Washer Head Carbon Steel Self-Drilling Screws

450 [4.4] 571 [5.6] 663 [6.5] 867 [8.5] 1378 [13.5]

Hex Washer Head Bi-metal Stainless Steel Self-Drilling Screws

408 [4.0] 500 [4.9] 674 [6.6] 816 [8.0] 1347 [13.2]

Hex Washer Head SS 410 Stainless Steel Self-Drilling Screws

428 [4.2] 612 [6.0] 816 [8.0] 1071 [10.5] 1408 [13.8]

Note:

1. These data are the results of laboratory testing conducted in controlled laboratory environment and conditions.

2. The technical parameters are of ultimate designation

3. The data tabulated are minimum and/or average values.

It Matters

Specific job site conditions should be taken into consideration when using

this information and accordingly data may vary.

Unless otherwise noted, load values based upon testing conducted in

accordance with AISI S905

Calculations to evaluate the test results and to determine the characteristic

fastener strength are made in accordance with Section F1 of AISI S100.

SW-CT2016-MFS

Coming together is beginning, Keeping together is progress, Working together is Success !!

Page 12 of 46

www.swenn-inc.com | T: 1 941331 2331 | E: info@swenn-inc.com

Metal Fixing

2.5 Self-Drilling/Tapping Screws - Technical Data Sheet

Screws

Pull Out Load, kN

Thickness of Steel member not in contact with head or washer, ga (mm)

Screw Diameter

20 (0.912) 18 (1.214) 16 (1.519) 14 (1.897) 12 (2.657) 10 (3.416) 8 (4.176) 5 (5.314) 3 (6.073)

#6 [3.5 mm] 1.22 1.63 2.03 2.54 3.56 - - - -

#8 [4.2 mm] 1.47 1.95 2.44 3.05 4.27 5.49 - - -

#10 [4.8 mm] 1.67 2.23 2.79 3.48 4.88 6.27 7.67 - -

#12 [5.5 mm] 1.92 2.55 3.20 3.99 5.59 7.19 8.79 11.18 12.78

#14 [6.3 mm] 2.20 2.93 3.66 4.57 6.40 8.23 10.06 12.81 14.63

Note:

1. The Values are based on test sheet of Tensile strength of member not in contact with head or washer, Fu = 450 MPa. For Steel with Fu=350 MPa, multiply values by 0.78 For Steel with Fu=310 MPa, multiply values

by 0.68.

2. Pull out Load values based upon calculations done in accordance with Section E4 of the AISI S100.

3. Load values are based upon testing conducted in accordance with AISI S905. These data are the results of laboratory testing conducted in controlled laboratory environment and conditions.

4. AISI S100 recommends a safety factor Ω= 3.0 be applied for ASD, a factor Φ = 0.5 be applied for LRFD design or a factor Φ = 0.4 be applied for LSD design.

Pull Over Load, kN

Thickness of Steel member in contact with head or washer, ga (mm)

Washer or Head Diameter

26 (0.455) 25 (0.531) 24 (0.607) 22 (0.759) 20 (0.912) 18 (1.214) 16 (1.519) 14 (1.897) 12 (2.657)

16 mm 4.91 5.73 6.56 8.20 9.85 13.11 - - -

19 mm 5.84 6.81 7.78 9.73 11.70 - - - -

Note:

1. The Values are based on test sheet of Tensile strength of member not in contact with head or washer, Fu = 450 MPa. For Steel with Fu=350 MPa, multiply values by 0.78 For Steel with Fu=310 MPa, multiply values

by 0.68.

2. Pull over Load values based upon calculations done in accordance with Section E4 of the AISI S100.

3. Load values are based upon testing conducted in accordance with AISI S905. These data are the results of laboratory testing conducted in controlled laboratory environment and conditions.

4. AISI S100 recommends a safety factor Ω= 3.0 be applied for ASD, a factor Φ = 0.5 be applied for LRFD design or a factor Φ = 0.4 be applied for LSD design.

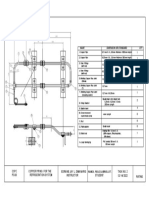

Turning Lever to Pull-out

Gauge to Measure Pull-out

Pull-out Test:

Load

Typical Stand to mount on subject

Arrangement

Clamp to hold the screw

Pull-out Schematic Screw fastened into test plate Pull-over Schematic

It Matters

Pull-out is a failure mode where fasteners are pulled free from support.

Pull-over is a failure mode where a steel sheet is pulled over the fastener

head (i.e. the fastener head is pulled through the steel sheet).

The Pull-out and Pull-over modes shall be identified when loading induces

tension in the shank of fastener that connects steel as thin as 0.38 mm to

structural support members.

SW-CT2016-MFS

There is no art to find the mind’s construction in the face !!

Page 13 of 46

www.swenn-inc.com | T: 1 941331 2331 | E: info@swenn-inc.com

Metal Fixing

2.5 Self-Drilling/Tapping Screws - Technical Data Sheet

Screws

Pull Out Load, kN

Thickness of Steel member not in contact with head or washer, ga (mm)

Screw Diameter

20 (0.912) 18 (1.214) 16 (1.519) 14 (1.897) 12 (2.657) 10 (3.416) 8 (4.176) 5 (5.314) 3 (6.073)

#6 [3.5 mm] 1.22 1.63 2.03 2.54 3.56 - - - -

#8 [4.2 mm] 1.47 1.95 2.44 3.05 4.27 5.49 - - -

#10 [4.8 mm] 1.67 2.23 2.79 3.48 4.88 6.27 7.67 - -

#12 [5.5 mm] 1.92 2.55 3.20 3.99 5.59 7.19 8.79 11.18 12.78

#14 [6.3 mm] 2.20 2.93 3.66 4.57 6.40 8.23 10.06 12.81 14.63

Note:

1. The Values are based on test sheet of Tensile strength of member not in contact with head or washer, Fu = 450 MPa. For Steel with Fu=350 MPa, multiply values by 0.78 For Steel with Fu=310 MPa, multiply values

by 0.68.

2. Pull out Load values based upon calculations done in accordance with Section E4 of the AISI S100.

3. Load values are based upon testing conducted in accordance with AISI S905. These data are the results of laboratory testing conducted in controlled laboratory environment and conditions.

4. AISI S100 recommends a safety factor Ω= 3.0 be applied for ASD, a factor Φ = 0.5 be applied for LRFD design or a factor Φ = 0.4 be applied for LSD design.

Pull Over Load, kN

Thickness of Steel member in contact with head or washer, ga (mm)

Washer or Head Diameter

26 (0.455) 25 (0.531) 24 (0.607) 22 (0.759) 20 (0.912) 18 (1.214) 16 (1.519) 14 (1.897) 12 (2.657)

16 mm 4.91 5.73 6.56 8.20 9.85 13.11 - - -

19 mm 5.84 6.81 7.78 9.73 11.70 - - - -

Note:

1. The Values are based on test sheet of Tensile strength of member not in contact with head or washer, Fu = 450 MPa. For Steel with Fu=350 MPa, multiply values by 0.78 For Steel with Fu=310 MPa, multiply values

by 0.68.

2. Pull over Load values based upon calculations done in accordance with Section E4 of the AISI S100.

3. Load values are based upon testing conducted in accordance with AISI S905. These data are the results of laboratory testing conducted in controlled laboratory environment and conditions.

4. AISI S100 recommends a safety factor Ω= 3.0 be applied for ASD, a factor Φ = 0.5 be applied for LRFD design or a factor Φ = 0.4 be applied for LSD design.

Turning Lever to Pull-out

Gauge to Measure Pull-out

Pull-out Test:

Load

Typical Stand to mount on subject

Arrangement

Clamp to hold the screw

Pull-out Schematic Screw fastened into test plate Pull-over Schematic

It Matters

Pull-out is a failure mode where fasteners are pulled free from support.

Pull-over is a failure mode where a steel sheet is pulled over the fastener

head (i.e. the fastener head is pulled through the steel sheet).

The Pull-out and Pull-over modes shall be identified when loading induces

tension in the shank of fastener that connects steel as thin as 0.38 mm to

structural support members.

SW-CT2016-MFS

There is no art to find the mind’s construction in the face !!

Page 13 of 46

www.swenn-inc.com | T: 1 941331 2331 | E: info@swenn-inc.com

You might also like

- Operations and Maintenance Manual TemplateDocument21 pagesOperations and Maintenance Manual Templaterimshadtp100% (5)

- Strength of Materials (S.O.M.) Model Question Paper (Q.P.) SolutionDocument16 pagesStrength of Materials (S.O.M.) Model Question Paper (Q.P.) SolutionProf. P. H. Jain93% (14)

- Anchor Bolts (Make-Hilti) PDFDocument4 pagesAnchor Bolts (Make-Hilti) PDFShino UlahannanNo ratings yet

- Report On NYC First Responder 9-11 AccountsDocument59 pagesReport On NYC First Responder 9-11 AccountsChiodo72No ratings yet

- Facebook, Twitter and Google Data Analysis Using Hadoop PDFDocument6 pagesFacebook, Twitter and Google Data Analysis Using Hadoop PDFAbdifatah OsmanNo ratings yet

- Testing-Drill Screw SpecificationsDocument3 pagesTesting-Drill Screw SpecificationsJerry Huang100% (1)

- BIE Technical DatasDocument4 pagesBIE Technical DatasTran The AnhNo ratings yet

- TDS Self Drilling Screws GeneralDocument1 pageTDS Self Drilling Screws Generalgraziella njeimNo ratings yet

- Assembly Part Number Example: 4 in (100 MM), Group 1Document2 pagesAssembly Part Number Example: 4 in (100 MM), Group 1RICHARDNo ratings yet

- UL MASTECO ALARM VALVE Instruction ManualDocument4 pagesUL MASTECO ALARM VALVE Instruction ManualNguyễn Thống NhấtNo ratings yet

- Keystone 8196 Datasheet PDFDocument1 pageKeystone 8196 Datasheet PDFraj06740No ratings yet

- Guideline For ScrewDocument10 pagesGuideline For ScrewIsboNo ratings yet

- 4 Fasteners: Hybrid Wood and Steel Details-Builder's GuideDocument24 pages4 Fasteners: Hybrid Wood and Steel Details-Builder's GuidetribleprinceNo ratings yet

- Series 45316 Flanged Globe ValveDocument4 pagesSeries 45316 Flanged Globe ValveEmmanuelNo ratings yet

- EvolutionTekDatasheet PDFDocument1 pageEvolutionTekDatasheet PDFRobNo ratings yet

- Self Drilling Screws: DescriptionDocument2 pagesSelf Drilling Screws: DescriptionPaulNo ratings yet

- Fivalco Catalog HPWDocument1 pageFivalco Catalog HPWeisen htbNo ratings yet

- FT BIE en Rev6Document7 pagesFT BIE en Rev6Mohd AzharNo ratings yet

- Self Tapping Screw 6336Document2 pagesSelf Tapping Screw 6336Dinesh GanapathyNo ratings yet

- Valv Check Aleum DGC Riser CheckDocument1 pageValv Check Aleum DGC Riser CheckYopoGas Ingenieria & ServiciosNo ratings yet

- Arita KatalogDocument58 pagesArita KatalogHasanah MYNo ratings yet

- 758T Brass Ball Valve - Spec Sheet: Features & BenefitsDocument2 pages758T Brass Ball Valve - Spec Sheet: Features & Benefitscarlos lolaNo ratings yet

- Russian Steel Structure 1Document3 pagesRussian Steel Structure 1RamNo ratings yet

- Nut (Hardware) : Bolts & Screws NutsDocument13 pagesNut (Hardware) : Bolts & Screws NutsIDTR JamshedpurNo ratings yet

- Hilti CatalogDocument13 pagesHilti CatalogYongHan KwongNo ratings yet

- Pontiac V8 EngineDocument19 pagesPontiac V8 Engineroberto100% (1)

- Sharpe Series-13 ValvesDocument4 pagesSharpe Series-13 ValvesluchitocapoNo ratings yet

- Series 25316 Flanged Check ValveDocument4 pagesSeries 25316 Flanged Check ValveRahesh MNo ratings yet

- 0 0 WO Euro Tabbladen - InddDocument1 page0 0 WO Euro Tabbladen - Inddrakhikishore143No ratings yet

- Integral Needle Valves SINV WebDocument5 pagesIntegral Needle Valves SINV WebMEK MarineNo ratings yet

- Torque SpecDocument1 pageTorque SpecRahulNo ratings yet

- Tek - General Product CatalogDocument12 pagesTek - General Product CatalogRick HenbidNo ratings yet

- B7 Butterfly Valve - Wafer Style - : Spec SheetDocument1 pageB7 Butterfly Valve - Wafer Style - : Spec SheetParthibanNo ratings yet

- 316 Stainless Steel Button Head Hex Drive Screws: M3.5 X 0.6mm Thread, 6mm LongDocument2 pages316 Stainless Steel Button Head Hex Drive Screws: M3.5 X 0.6mm Thread, 6mm LongYossi JerasiNo ratings yet

- Dynabolt® Sleeve Anchors: Technical DataDocument1 pageDynabolt® Sleeve Anchors: Technical DataCoco Aryan TundyNo ratings yet

- MD Cabinet DoorsDocument4 pagesMD Cabinet DoorsKamel NaitNo ratings yet

- Brass Ball Valve (BBV) V0816Document1 pageBrass Ball Valve (BBV) V0816Saiful Islam SagorNo ratings yet

- DBB Vb04 Series, Ms-02-210 r2Document4 pagesDBB Vb04 Series, Ms-02-210 r2herysyam1980No ratings yet

- Acc 0910 Cutting Grinding Brushing Gb-EnDocument7 pagesAcc 0910 Cutting Grinding Brushing Gb-EnannedierNo ratings yet

- Spring Return HandelDocument1 pageSpring Return Handelvaitheeswaran PNo ratings yet

- Bolt Strength in Working and Limit StateDocument1 pageBolt Strength in Working and Limit Statemsn sastryNo ratings yet

- STPE600 - Dadi A ProiezioneDocument17 pagesSTPE600 - Dadi A ProiezioneLucaNo ratings yet

- K-823-A, SCVDocument1 pageK-823-A, SCVamir shokrNo ratings yet

- V GAVETA - Grooved Resilient OSY Gate ValveDocument1 pageV GAVETA - Grooved Resilient OSY Gate ValveGabriel TapiaNo ratings yet

- V GAVETA - Grooved Resilient OSY Gate Valve - Ficha TécnicaDocument1 pageV GAVETA - Grooved Resilient OSY Gate Valve - Ficha TécnicaGabriel TapiaNo ratings yet

- Bearings & Misc PR ListDocument2 pagesBearings & Misc PR ListengineeringNo ratings yet

- StdrillserratedDocument2 pagesStdrillserratedSaul AguilarNo ratings yet

- Ramos Copper Piping For The Refrigeration System Layout2Document1 pageRamos Copper Piping For The Refrigeration System Layout2Piolo Gabrielle RamosNo ratings yet

- SSC-400 Bill of Materials R0ADocument3 pagesSSC-400 Bill of Materials R0AMartin DanzeNo ratings yet

- Self Drill Screw With Flange WurthDocument4 pagesSelf Drill Screw With Flange WurthentosektosNo ratings yet

- ProValve Knife Gate ValveDocument12 pagesProValve Knife Gate ValveHarry HonchoNo ratings yet

- Bi-Metal Tek Screw: Product DatasheetDocument1 pageBi-Metal Tek Screw: Product Datasheetbravo deltafoxNo ratings yet

- Karasto: Cuadro de Roscas: Roscas para Tubos Whitworth (Cilindricas) - Según DIN 259 (ISO 228)Document2 pagesKarasto: Cuadro de Roscas: Roscas para Tubos Whitworth (Cilindricas) - Según DIN 259 (ISO 228)Nestor OliNo ratings yet

- Asme Ansi b16.11 Fittings DimensionDocument23 pagesAsme Ansi b16.11 Fittings DimensionHarish Chandra Singh0% (1)

- Asme Ansi b16.11 Fittings DimensionDocument23 pagesAsme Ansi b16.11 Fittings DimensionAlvaro Enrique MuñozNo ratings yet

- Valves GaugeDocument2 pagesValves GaugeAbu Bilal AbdillahNo ratings yet

- FLO DS 0006 Wafer Butterfly ValvesDocument4 pagesFLO DS 0006 Wafer Butterfly ValvesShubhajit ChakrabortyNo ratings yet

- Mol-Lean Oil Surge VesselDocument8 pagesMol-Lean Oil Surge VesselImranNo ratings yet

- F0111 300 Data SheetDocument1 pageF0111 300 Data SheetSehoon OhNo ratings yet

- CS Ball Valve TM-590Document1 pageCS Ball Valve TM-590Hector Dario Tobon BenjumeaNo ratings yet

- Lugged Butterfly Valve 2-12 PDFDocument1 pageLugged Butterfly Valve 2-12 PDFThomasFrenchNo ratings yet

- John Crane Gland Nut Tightening TorqueDocument2 pagesJohn Crane Gland Nut Tightening TorqueWinston TohNo ratings yet

- ASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedDocument33 pagesASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedpaulamuisesNo ratings yet

- Joseph Hernandez: Development With An Organization of Repute in India or AbroadDocument2 pagesJoseph Hernandez: Development With An Organization of Repute in India or AbroadrimshadtpNo ratings yet

- HS Butyl TDSDocument2 pagesHS Butyl TDSrimshadtpNo ratings yet

- Tech Data - Epdm Foam SheetDocument1 pageTech Data - Epdm Foam SheetrimshadtpNo ratings yet

- Hammerfix N: The Hammer-In Plug For A Simple, Fast and Economical InstallationDocument2 pagesHammerfix N: The Hammer-In Plug For A Simple, Fast and Economical InstallationrimshadtpNo ratings yet

- Comparison ISO 9001-2015 With ISO 9001 - 2008 EDITIONDocument3 pagesComparison ISO 9001-2015 With ISO 9001 - 2008 EDITIONrimshadtpNo ratings yet

- UNS S41000 (Type SS 410) : SS 304 Bonded To 3mm Non-Conductive Grey EPDM WasherDocument1 pageUNS S41000 (Type SS 410) : SS 304 Bonded To 3mm Non-Conductive Grey EPDM WasherrimshadtpNo ratings yet

- Self-Drillingscrewjt3-12-5.5: Industrial Lightweight ConstructionDocument2 pagesSelf-Drillingscrewjt3-12-5.5: Industrial Lightweight ConstructionrimshadtpNo ratings yet

- Dimension:: Blind RivetsDocument1 pageDimension:: Blind RivetsrimshadtpNo ratings yet

- 2014 Mazda 6 30305Document576 pages2014 Mazda 6 30305rimshadtpNo ratings yet

- Bolt Tightening ReportDocument2 pagesBolt Tightening Reportrimshadtp67% (3)

- Arshad Ibrahim: Sales / Marketing OfficerDocument2 pagesArshad Ibrahim: Sales / Marketing OfficerrimshadtpNo ratings yet

- Method - Statement - Damaged Paint Repair RahulDocument11 pagesMethod - Statement - Damaged Paint Repair RahulrimshadtpNo ratings yet

- Paint Damage Repair ProcedureDocument48 pagesPaint Damage Repair Procedurerimshadtp100% (1)

- Site Paint Repair Procedure IntumescentDocument4 pagesSite Paint Repair Procedure Intumescentrimshadtp100% (3)

- Since The Beginning of The 20 Century, Between Tradition and InnovationDocument6 pagesSince The Beginning of The 20 Century, Between Tradition and InnovationrimshadtpNo ratings yet

- Fire Safety Maintenance ChecklistDocument2 pagesFire Safety Maintenance Checklistrimshadtp100% (1)

- QP-REG-Q-001 - Rev. 4-77-78Document2 pagesQP-REG-Q-001 - Rev. 4-77-78rimshadtpNo ratings yet

- Alt - Abbott ArchitectDocument12 pagesAlt - Abbott Architectحيدر كاملNo ratings yet

- Building Square Footage Worksheet: Let's Get StartedDocument3 pagesBuilding Square Footage Worksheet: Let's Get StartedMhathung KikonNo ratings yet

- Yharnam Shadows (Beta) - Printer FriendlyDocument32 pagesYharnam Shadows (Beta) - Printer FriendlyLeandro NetoNo ratings yet

- Final Output HRMDocument3 pagesFinal Output HRMDanilo MaglinteNo ratings yet

- 02 - House Load and Load Rejection (CNK 12 M Ove Oi 202C) +Document7 pages02 - House Load and Load Rejection (CNK 12 M Ove Oi 202C) +Your FriendNo ratings yet

- Customer Information CenterDocument4 pagesCustomer Information CenterCiochina Cihodari LilianaNo ratings yet

- Epic AP Calculus Formul Sheet AB Derivatives Limits IntegralsDocument2 pagesEpic AP Calculus Formul Sheet AB Derivatives Limits IntegralsZacharyNo ratings yet

- Bianca Armand Resume 2012Document1 pageBianca Armand Resume 2012Christy GilbertNo ratings yet

- Understanding Blockchain Technology: August 2018Document8 pagesUnderstanding Blockchain Technology: August 2018Dhana SekarNo ratings yet

- French Revolution CourseDocument5 pagesFrench Revolution CoursebhagyalakshmipranjanNo ratings yet

- Personal Protective Equipment ProceduresDocument7 pagesPersonal Protective Equipment ProceduresIbrahim Azam IbrahimNo ratings yet

- Wheat Flour MillDocument1 pageWheat Flour MillRAHUL SHARMANo ratings yet

- Numerical Metods Chapter 1 & 2Document35 pagesNumerical Metods Chapter 1 & 2Naren Sundararajan100% (1)

- Hinari 2021Document11 pagesHinari 2021Ivan PerezNo ratings yet

- Maths Investigation On Linear Factored FormDocument2 pagesMaths Investigation On Linear Factored Formapi-221530271No ratings yet

- Points To Remember: Ms. Reema Khosla: Life ProcessesDocument2 pagesPoints To Remember: Ms. Reema Khosla: Life ProcessesjanviNo ratings yet

- Office of Surveillance Commissioners - PROCEDURES AND GUIDANCE (2008)Document46 pagesOffice of Surveillance Commissioners - PROCEDURES AND GUIDANCE (2008)alex4368No ratings yet

- Lab 4.2.3: Basic DOS Commands: Estimated Time: 30 Minutes ObjectiveDocument5 pagesLab 4.2.3: Basic DOS Commands: Estimated Time: 30 Minutes ObjectiveHamzaSpahijaNo ratings yet

- Debugger TricoreDocument145 pagesDebugger TricoreTihomir VincicNo ratings yet

- Karmachari Sancahie KoshDocument9 pagesKarmachari Sancahie KoshSabeen budhathokiNo ratings yet

- Geoffrey Farthing - Channelling and Ascension InThe Light of TheosophyDocument6 pagesGeoffrey Farthing - Channelling and Ascension InThe Light of Theosophydoggy7No ratings yet

- Local Government in The United StatesDocument108 pagesLocal Government in The United StatesAlexandru FlorinNo ratings yet

- International Organization For Standardization Payment CardsDocument10 pagesInternational Organization For Standardization Payment CardsSankalp MathurNo ratings yet

- Office of The District & Sessions Judge, Ludhiana: Public NoticeDocument8 pagesOffice of The District & Sessions Judge, Ludhiana: Public NoticeharishNo ratings yet

- Group 08Document8 pagesGroup 08Varun Nanda100% (1)

- Namrata-PERIPHERAL NERVE SURGERYDocument58 pagesNamrata-PERIPHERAL NERVE SURGERYHarnoor BediNo ratings yet

- Salesforce Communities Managers GuideDocument80 pagesSalesforce Communities Managers Guidem naohNo ratings yet