Professional Documents

Culture Documents

LNG 320231

Uploaded by

Green Michaels0 ratings0% found this document useful (0 votes)

16 views5 pagesPumps Maintenance

Original Title

Lng 320231

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPumps Maintenance

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views5 pagesLNG 320231

Uploaded by

Green MichaelsPumps Maintenance

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

Technical Documentation

Operation, Maintenance, Mounting and

Disassembly Instructions for the

Series L3NG Screw Pump

© 186 5177Ie:rev.9

oo

Beee) L3NG

os

Contents

1. General . Page 1

4.1. Application Page 1

1.2. Information about the Product Page 1

1.2.1. Addressing of the Manual Page 1

1.22. Manufacturing Page 1

1.23. Name, Types and Size Page 1

1.2.4. Serial Number and Type Plate Page 1

1.25. Date of Manual Execution Page 1

1.26. Change Notes and Manual Numbers Page 1

1.27. Copy Rights Page 1

1.28. Technical Documentation and Data Sheet Page 1

1.29. Customer Service Page 1

1.2.10. Quality Assurance and Quality testing Page 1

4.2.11. Warranty Page 1

2. Safety . Page 2

2.4. General Rules and Advice Page 2

2.2. Dangers of not observing the Safety Advice Page 2

2.3. Safety conscious Working Page 2

2.4. Warning and Advice signs Page 2

25. Safety Advice for the Operator Page 2

2.8. Safety Advice for the Service, Inspection and Mounting Page 2

2.7. Denial of Modifications and Changes without Approval Page 2

2.8. Unallowable Running Conditions Page 2

2.9. Other Operations and Safely Hazards Page 2

3. Transport and Intermediate Storage Page 3

3.1. Safely Measures Page 3

3.2. Transport Precautions Page 3

3.3. Unpacking Page 3

3.4, Intermediate Storage Page 3

3.5. Preservation Page 3

3.5.1. Aging of Preservation Page 3

3.5.2. Re-Preservation Page 3

3.5.3, Removal of the Preservation Page 3

3.6. Protecting from the Environment Page 3

4, Description of the Pump Page 4

4.1, General Description Page 4

4.2, Assembly and Operation Page 4

4.3, Construction of the Parts Page 4

43.1, Pump casing Page 4

4.3.2. Spindle Set Page 4

4.3.3. Shaft Seal Page 4

4.3.4, Casing Gasketing Page 4

435. Bearing Page 4

4.38, End Cover Page 4

423.7. Drive Side Cover Page 4

43.8. Pressure Relief Valve Page 4

4.3.9, Nozzles Page 4

4.3.10, Drive and Shaft coupling Page 5

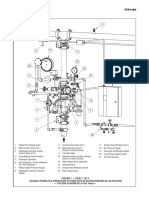

4.4, Dimensioning and Geometry Page 5

4.4.1, Standard Overall and Single Dimension Drawings Page 5

4.4.2. Standard Assembly Drawings Page 5

E 185517I¢:r0%.3

Paget

oo

Lolstritz agi -3NG

os

4.4.3. Standard Sectional Drawings Page 5

45, Execution Modifications .. a ce Page 5

4.5.1. Type key Page 5

4.5.2. Standard Material of Construction Page 5

46. Operating Page 5

4.6.1. General Operation Fields Page 5

4.6.2. Temperature- and Pressure Limitations Page 5

4.6.3, Performance Data and Speeds ce Page 5

4.6.3.1. Performance Tables Page 5

4.6.3.2. Power Consumption Diagrams Page 5

4.6.4, Installation Page 5

4.6.4.1. Necessary Space for Operation and Maintenance Page 5

4.6.4.2. Allowable Environmental Influences Page 5

4.6.4.3. Base, Foundation and Anchoring Page 6

4.6.4.4. Suction and Discharge Piping Page 6

4.6.45. Support Connections Page 6

5. Mounting and Installation ceeseeeeees Page 7

5.1. Tools: Page 7

5.2. Initial Installation of the Pump Page 7

5.3. Initial Installation of the Pump Unit Page 7

6. Start up - Shut down . cieeeeeee Page 8

6.1. Technical Documentation Page &

6.2, Pipes schematic and Measuring Points .... co Page &

6.3, Preparation for Start up... o ce : Page 8

64. Startup Page 8

6.5. Shut down of the Pump Page 8

66. Re-starting Page 8

67, Stil stand - co Page &

6.7.1, Shut down for up to 3 Months Page 8

6.7.2. Shut down from 3 to 6 Months Page 8

6.7.3. Shut down for more than 6 Months Page 8

6.8, Operation Supervision ... o ce : Page 8

6.9, Bearing of the Power Rotor : : Page 9

7. Maintenance Page 10

7.4. General Page 10

7.2. Maintenance and Inspection Page 10

7.3. Disassembly and Assembly Page 10

7.3.1. General Precaution Page 10

7.3.2. Customer Service / Personal | Danger Page 10

7.3.3. Disassembly and Assembly Advice Page 10

7.3.4, Necessary Assembly Tools, Page 10

7.4. Disassembly of the Pump Page 10

7.5. Assembly of the Pump Page 11

7.8. Spare Parts Page 12

8 Trouble Shooting Page 13,

8.1, Table to define Reason and solving of Problems Page 13

82. Torque Requirements Page 14

8.3. Allowable Pipe Forces and Moments Page 14

84. Changes to the technical Documentation Page 14

9, Drawings, Data Sheets and Appendix ... Page 14

Appendix

E 185517I¢:r0%.3 Paget

Lelstritz

4. General

4.4. Application

“This sew pump is used for pumping olor ther ubicting mesa

pressures up 1 18 bar.

4.2. Information about the Product

4124. Addressing ofthe Manuat

‘This manval was made forthe pump series L SN.

Foralarexectonscifernt anal are vali. They may be ordered

from tha manufacturer separately et on hand

4122, Manufacturing

‘The manufacturer ofthe serew pump type L3NG.

LLEISTRITZ Purmpen GmbH

resiging inthe

Federal Republle of Germany

90459 Numberg, Merigrafenstrate 29-39

or 0014 Nimberg, Postfach 30 44

DIN- Pars, accessrios an adettonal pars are purchased tom

sub-supplers.

4.23, Names, Types and Sizes

Name: Three-rotor screw pump

Type: L3NG.

Sizes: 20,25, 32, 38, 45,52, 60, 70, 80,80, 100, 112,125, 140,160,

480,200, 225, 250 and 275

For adationalinermaton see te type key.

4.24. Seri Number and Type Pate

Each units equipped wih a standard ype plate, which shows the

manufacturersseral number and ype key. Enlarged ype plates are

‘valanle on request

4.25, Date of Manual Execution

Dated October 17,1204,

“octal and design changes. improvements ana amendmonts may

be made wihout nate.

4126. Change Notes and Manual Numbers

[executes changes ae listed onthe fal page of his manual, The

‘ype of change, date, exeotor and proof reader are noted

foro! sraings,

12.7. Copy Rights

‘Al manuals, documents and dravings ar copy righted according to

owas

4.28, Technical Documentation and Data Sheet

Forin depth explanations see the folowing chapters:

Safely raptor 2

“Transport ané Storage Onapter 3.

Description of ne Pump Chapeer 4

Mounting and nsaaion Crapeer 5

Mounting al Start-up aré Shut down Captor 6

Maintenance Onapter 7

Trouble Shooting Cnapter 6

Drawings and documents Chapter 8

4129. Customer Service

Ir senda s required or questons need o be answsred pase contact

‘urheadquarters or someone in ou sales organization,

412.10. quality Assurance and Qualiy testing

‘complex qalty assurance eytem guaranties high quay stands

levels for Lest sorew pumps. Te qualy assurance, accoraing 0

DIN 1S0 900%, covers al production sap, whieh ara necessary to fd

lal he quality requirments forts product.

‘ua assurance measures (.0. sie, ype of test and caritication)

ae issued by he purchase in wing, ndusing the necessary fos

fang document. Prot t shipment all puns are rgorousy tested

‘ny ums whicn full the confirmed tet data willbe shipped

Use of nis manual wi halp to assure a vouble tae operation an fl

tow perormance, The proa lst data onthe bench flows the go

fal est recommendations fo rlary postive dsslacement ures per

OMA 24284,

“W" por DIN 55360 P18,

4.24. Warranty

(ur bit for defects of rine goods i outed incur every and

ayant condtons, which ar part of o Sales Condtons and Tors.

Damages which may occur a result of disregard of the insrton

‘manualand eplacamentconstons are not covered under waranty.

‘taleter date operation canons change, or example diferent rod

uct, viscosity, tmparature, speed alt condton, hase conions

have to be reviewed and acknowledges by LEISTRITZ fro other

agroomentshave boon made with LEISTRITZ he delvered pumps

can oly be disassembled and mode by LEISTRITZ or LEISTRITZ~

Service Representatives. Otherwise the waranty for occured d=

292s wl bo vices.

E185 51770; rov 5

1 of Page 14

Leistrit=

2. Safety

24. General Rules and Advice

‘This manual includes general rules which have tobe observes for

rstalaton oparaton and maininanco, Theor this aval has to

be read bets nsalaon and operation bythe inal, as wel as by

the respansble specialstuser, thas a be made avalaoe atthe

te forreference ata later date

22, Dangers of not observing the Safety Advice

Ignoring to safety advice can endanger people, the environment and

the pump unt. For example

DDamageto the pump unts or cen functons of these uns, can en

anger personnel trough electric, mechanical and chemical i=

‘ences, endangering he envionment by leakage of harmful prod

eds and eter pola,

23, Safety conscious Working

‘Tho saety ules sedi his manual applicable prventve practices

‘2 wel as intemal safety les of the user always have o be flowed

24. Waring and Advice Signs

nts manual safety symbol are mentoned which can hap to prevent

_secidonts fo poronnel. A goneral safely sign iderdfes hazard which

vil endanger he unt an ts function,

“The word ‘Aten is neradin ha otto not these acstionl ac-

‘oe signs andi lala crt onthe un

Attention

For example

Direction of Ration and Flow

Elctncal Curent Waring

Marking ofthe Nozzles (let, cult rows)

Marking Vent and Drain Opening

"No ruby" sign and thors

25. Safety Advice for the Operator

aie leal dl)

“Hot or extremly cold machine pats are potential dangers and must

be protected against access.

Coupling guards, which protect he exo coupling and shaft fom

‘806s, shall NOT be remaved uring running ft equiprent.

“Leakage of hazardous produts a he sea, by suchas, explosive,

Tox or hot ie ret be collected and drained oa sate place not

to endanger operating personnal and the envionment.

[All general rules oflaw, applicable he ste nave tobe flowed

28, Safety Advice forthe Service, Inspection and Mounting

‘The entre scope of serio, inclusng inspection and

mounting, has be done by an auto2ed peda, who

has knomledge ofthis manval, Any work onthe machine

ion allowed whon tho units standing stil, The shut

down of the unt described inthe manual has to be fo.

lowed

Immectatly atte end of any work al safety and protec

tion devices have to be instlas completely. 2efore

start-up, pins mentioned under 6.4 have be oloned,

2:7, Denial of Modifications and Changes without Approval

(Changes ot mofcations onthe unt which have net bn confirmed

by Leitz, are not atowes,

2.8. Unallowable Running Conditions

“Te operational safety ofthe devared unt Is only assured by operat

ing according tothe confirms design and data Units should rot be

used under aferen operating conatons without the manufacturers

approval The Imitation of he perfomance data sheets should never

be exceeded, Safoty hazards may resuli they are exceeded.

29. Other Operations and Safety Hazards

‘Allpacking material of he pump orth unit shal only be

removed sect before the installation of te pu.

[No foreign paricles ar allowed to ener the pump!

‘The danger ofan accident tntaltion and mounting of

the unithas tobe observed at any tine.

Balance stably always has to be exiting, assembly

parts have tobe secured again ling

Loose pats have tobe secures by proper moans.

‘Te pump unt isnt alowed tobe lowered or ited by the

power supply Ines bythe piping.

‘Connecting he power supp Ineo he Motor state has

tobe done an Elecrician and folowing the electrical iy

‘outol he mole sup. Proper dmensioning fhe nes

has tobe cbservd.Allcangers by electcal energy have

tobe alminated. NEMAYVDA rules andthe rues of eo

al Energy and Supply eorpany have tobe observed as

wal

Vig) MIKK

185 517716; 3

Page 2 of Page 4

You might also like

- 5 FPSDocument2 pages5 FPSGreen MichaelsNo ratings yet

- Unit 1 - FPSDocument3 pagesUnit 1 - FPSGreen MichaelsNo ratings yet

- BCG Report2021 2Document2 pagesBCG Report2021 2Green MichaelsNo ratings yet

- Prelim - Feb - Report 2023 - 2Document4 pagesPrelim - Feb - Report 2023 - 2Green MichaelsNo ratings yet

- 2 FPSDocument3 pages2 FPSGreen MichaelsNo ratings yet

- Detailed SumDocument4 pagesDetailed SumGreen MichaelsNo ratings yet

- Intro ABDocument4 pagesIntro ABGreen MichaelsNo ratings yet

- Gis BRG Rep 001 2013Document2 pagesGis BRG Rep 001 2013Green MichaelsNo ratings yet

- 200-FPS 2378Document2 pages200-FPS 2378Green MichaelsNo ratings yet

- RDY Inst Rep 2008Document1 pageRDY Inst Rep 2008Green MichaelsNo ratings yet

- Preliminary02 Bearing 2 2012Document1 pagePreliminary02 Bearing 2 2012Green MichaelsNo ratings yet

- Prelim01 Bearing 1 2011Document1 pagePrelim01 Bearing 1 2011Green MichaelsNo ratings yet

- Final 03 BRG 3 2012Document1 pageFinal 03 BRG 3 2012Green MichaelsNo ratings yet

- Preliminary02 - Bearing 2 - 2012Document1 pagePreliminary02 - Bearing 2 - 2012Green MichaelsNo ratings yet

- RDY Inst Rep 2008Document1 pageRDY Inst Rep 2008Green MichaelsNo ratings yet

- 2012BRG Rep FINDocument1 page2012BRG Rep FINGreen MichaelsNo ratings yet

- Prelim01 - Bearing 1 - 2011Document1 pagePrelim01 - Bearing 1 - 2011Green MichaelsNo ratings yet

- PreliminaryReport 02026.3Document4 pagesPreliminaryReport 02026.3Green MichaelsNo ratings yet

- Toolbox / Safety TalksDocument2 pagesToolbox / Safety TalksGreen MichaelsNo ratings yet

- PreliminaryReport 02026.4Document5 pagesPreliminaryReport 02026.4Green MichaelsNo ratings yet

- Risk Assessment and Rating FormDocument10 pagesRisk Assessment and Rating FormGreen MichaelsNo ratings yet

- Worksheet 8: Algebraic Expressions (Term 2) Grade 8 MathematicsDocument2 pagesWorksheet 8: Algebraic Expressions (Term 2) Grade 8 MathematicsGreen MichaelsNo ratings yet

- Wessels Development (2009)Document176 pagesWessels Development (2009)Green MichaelsNo ratings yet

- Twelopele Afrika and Projects (PTY) LTD MONITORING AND REVIEW PLANDocument2 pagesTwelopele Afrika and Projects (PTY) LTD MONITORING AND REVIEW PLANGreen MichaelsNo ratings yet

- Twelopele Afrika PPE INSPECTION CHECKLISTDocument2 pagesTwelopele Afrika PPE INSPECTION CHECKLISTGreen MichaelsNo ratings yet

- 2070-1-14 - Copy - Borehole - Water - Treatment PDFDocument99 pages2070-1-14 - Copy - Borehole - Water - Treatment PDFGreen MichaelsNo ratings yet

- Employ Literature To Evaluate Proposed Solutions and Mantain Continuous ImprovementDocument1 pageEmploy Literature To Evaluate Proposed Solutions and Mantain Continuous ImprovementGreen MichaelsNo ratings yet

- 1.final - SHEQ AssignmentDocument12 pages1.final - SHEQ AssignmentGreen MichaelsNo ratings yet

- SHEQFC-02 Process Flow Rev 0 01032014Document4 pagesSHEQFC-02 Process Flow Rev 0 01032014Green MichaelsNo ratings yet

- Harry Potter and The Philosopher's Stone by J. K. Rowling Chapter QuestionsDocument1 pageHarry Potter and The Philosopher's Stone by J. K. Rowling Chapter QuestionsGreen MichaelsNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)