Professional Documents

Culture Documents

Aqua Ozone Equipment Pos CD Manual

Aqua Ozone Equipment Pos CD Manual

Uploaded by

kuraimund0 ratings0% found this document useful (0 votes)

56 views17 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

56 views17 pagesAqua Ozone Equipment Pos CD Manual

Aqua Ozone Equipment Pos CD Manual

Uploaded by

kuraimundCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 17

ren eeitir ty

ii

Tiorsraae Teoor

POS Series

Swimming Pool Ozone Systems

INSTALLATION & OPERATIONS

MANUAL

TABLE OF CONTENTS

SECTION 1.

GENERAL INFORMATION..

1A. Important Safe Instructions

4B. System Description.

1C. System Specifications.

2A. Location...

2A-1 location Requirements.

2A-2 location for POS System.

2A-3 Dimension & Weight for POS..

2B. Wiring for POS System.

2B-1 Wiring for Main Power Line..

2B-2 Wiring for Remote Control

2B-P Wiring for Oil-less Air Pump.

28-3 Wi

2c.

20-4

2€-P Plumbing for Oil-less Air Pump...4

2€-2 Plumbing for Degas Valve.

.g for Water Boost Pump..

Rb BBB BER RE KBOKHHH OSES

mbing for POS System.

jumbing for Water Boost Pump...4

2C-3 Plumbing by Applications.

2C-3-A Plumbing for Single POS..

2C-3-B Plumbing for Multiple POS.

SECTION 3.

OPERATION

3A. Gener:

3A-1 Instruction..

3B. Normal Opera'

3B-1 System Turn ON.

3B-1-a Turn on Main Power Breaket

3B-1-b Turn ON Power Switch.

3B-1-c Bypass Valve Adjus

3€. System Shut-Down..

3€-1 Daily Shut-Down...

3€-2 Shut-Down for Storage.

SECTION 4.

MAINTENANCE AND SERVICE.

4A. System Overview.

4A-1. Inner & Front View.

Left, Back & Right View.

4D. Standard Replacement Parts Li

APPENDIX: “A”.

CD Ozone & PSA Oxygen Module..

APPEND.

POS SERIES OZONE SYSTEMS

ARE CE LISTED

AQUA

‘Torstar Seour

SECTION 1

General Informa’

1A. IMPORTANT SAFETY INSTRUCTIONS

‘Read this manual completely before installation by qualified electric

7 & plumber,

* Locate ozone system at least 5 feet from walls to achieve enough service clearance & install the system on 2

platform no less than 1 foot above floor to prevent water flooding, plumbing with nonmetallic tubing,

* Connect to a grounded, grounding type receptacle only, follow all applicable electrical codes.

* Warning - To reduce the risk of electrical shock, replace damaged cord immediately.

+ Electric shock hazard. Be sure to turn power OFF and disconnect from power source before any service work is

performed. Failure to do so could result in serious injury or death.

+ Warning - Short term inhalation of high concentrations of ozone and long term inhalation of low concentrations

of ozone can cause serious harmful physiological effects. DO NOT inhale ozone gas produced by this device.

+ For safety, do not store or use gasoline, chemicals or other flammable liquids or vapors near ozone system.

4B. System Description

The POS-CD series are turn-key, skid-mount, air-cooled, CD type ozone/water contacting systems

specifically designed for swimming pool applications. The system incorporates complete CD type

ozone generator, oll-less compressor(s), system operation & function indicating control panel,

ozone injector with bypass valve, water backflow prevention device, PVC contacting vessel with

degas valve, gray epoxy powder coated mild steel cabinet with stainless steel mounting base and

with the main function of full system On/Off remote control, ozone On/Off remote control, 4-20mA

ozone output auto adjusting PID control & ozone safe interlock. The water boost pump, ORP

controller & ozone destructor are optional

1€.Systom Specifications

SPECIFICATION POS-10 POS-20 POS-30 POS-40

Ozone Output 10g/hr | ——20g/hr | «30a 40g/he

Matched Pool Volume* | Upto450M3 | _Upto900M3_| _Upto13500M3_| Upto 1S00N3,

Eavipped Compressor one one ano wo

aby (60LPM@2bar) | (60LPM@2bar) | (120LPM@2bar)_ | (120LPM@2bar)

(Flow @ Pressure)

Water Inlet: 1.5'750mm | Inlet: 1.5°/50mm | Inlet: 5%/50mm | tnlet: 1.5°/50mm

Connection Size | Outlet: 1.5"/50mm | Outlet:1.5"/50mm | Outlet:1.5°/50mm | Outlet: 1.5°/50mm

Power Requirement ** | 120/240V 60/S0HZ | 120/240V 60/S0Hz | 120/240v 60/50HZ | 120/240V 60/50Hz

(Single Phase) 450W 000w 10s0w 1200

Optional Water Boost

2M3.@4omHead | 2M3@40OmHead | 2M3.@4omHead | 23 @ 4om Head

Pump Requirement | |

Optional ORP Controlled | ___ Option Option Option Option

Note: “* “For indoor hotel pool with middle bather load & chlorine as secondary sanitizer only.

Not include ozone boost water pump’s power consumption.

AQUA

SECTION 2

System Installation

2A.Location

2A-1Location Req

ments

Ambient Temp: 5°C - 38°C, indoor use only.

Ventilation: Room should provide 6 air changes per hour minimum.

Protection from weather elements must be provided for outdoor installations. Operating outside of

the recommended temperature ranges may result in damage not covered under the manufacturer's

warranty.

2A-2 Location for POS System

POS system is designed for floor mounting and must be located a dry, clean, free-dust, water proof

in door. The system must be kept away from fire source and many other heavily oxidation source. It

is recommended that the space around POS system is at least 5 feet to achieve enough service

clearance & POS system must be installed on a platform no less than 1 foot above floor to prevent

water flooding,

2A-3 Dimension & Weight for POS System

Note: size in mm

POS System Weight:

Net:95Kg Gross: 115Kg

External

Oil-less Compressor Weight:

Net:12.5Kg Gross: 15Kg

736 32 (per compressor)

2B. Wiring for POS System

2B-4 Wiring for Main Power Line

‘TWousraiac Srour

Use two at least 2.5mm2 copper wires one end to

connect with the terminals locate on top of main

power breaker, another end connect with the main

power line.

Note: You must use another one at least 1.0mm2

copper wires as a ground wire one end to connect

with the metal chassis inner of POS cabinet and

another end to connect with external ground.

2B-2 Wiring for Remote Control (For oRP remote contro! connection, please see “Appendix D” )

The POS's remote control terminals were shorted by

short circuit wires at factory to set POS system in basic

working function; to use full remote control functions,

please learn the definition of terminals 2s follow:

#1, #2: Remote Contro!—Whole system ON/OFF

43, #4: Ozone Control-—-Only ozone section ON/OFF

5, 6: 4-20

wuto adjust ozone output level by

external 4-20mA feedback signal.

The POS-10/20 (POS-30/40) is equipped with one (two) external “OP-2" oll-less air pumps). For wiring oll-less air

pump(s) as follow: 1). Locate oil-less air pump(s) beside of POS ; 2). Insert the plug of cil-less air pump into the

socket locate on the right side of POS labeled with “Air Pump Socket”.

ay

‘TWousrarac Sroor

2B-3 Wiring for Ozone Water Boost Pump

Note: The recommended ozone water boost pump model of CH2-40 (for POS-4/6/8UV) & CH4-40 (For POS-30/40),

watts in 550/750w, brand in GRUNDFOS

ecre Cable for Wat

2C-1 Plumbing for Water Boost Pump

PVC Hard Pipe

2C-P Plumbing for Oit-

Air Pump ( {use extomal compressed air source, please see “Appendix I" )

Use OD 8mm compressed air hose, one end connect with the connector locate on the right side of POS labeled

with “ Compressed Air Inlet”; another end connect with the connector located side of OP-2 oll-ess air pumps.

AQUA

————

2C-2 Plumbing for Degas Valve

Due to reduce the package size to keep freight in low, the degas valve was removed and located on the rear of,

POS system; for degas valve re-installation, please follow up the steps below:

2C-3 Plumbing by Applications

POS are full integrated ozone systems for varies water treatment applications, the typical plumbing for swimming.

pool as follow:

2C-3-A Plumbing for Single POS

MAIN RETURN LINE

——

“

:

ele TT

oat

i

8

Note: — Waterline --- SignalCable ~— Ozone Gas Line

1, *#"is isolation valve.

2. “WATER BOOST PUMP” should be synchronization

with "MAIN RECIRCULATION PUMP”.

‘Wousrnin. Sroor,

2C-3-B Plumbing for Mul

ee

Tivosraaw trou

SECTION 3

Operation

3A.General

Open the isolation valves before ozone water boost water pump & after POS system and allows whole system to

be filled with water and the exclusion of the air inside to avoid the pump running dry and water hammer occurs.

3A-1 Instruction

3A-2-a Main Power Breaker 3A-2-b Power Switch

FLOWMETER: Indicating oxygen flow though out the system range around 8-10L/Min

PRESSURE: Indicating the pressure at ozone output port range around -5 inkig

OZONE OUTPUT: Regulating ozone output range within 10-100%

SYSTEM STATUS:

LED bar graph: Indicating ozone output level as reference

Main Power: Indicating the main power was supplied to system

system ON: Indicating of POS system turned ON

Ozone ON: Indicating of POS system production ozone

Remote OFF: Indicating of POS in suspend state

AQUA

Tas eerAcSOTT

3B. Normal Operation

3B-1 System Turn ON

3-1-a Turn ON the main power breaker 3B-1-b Turn ON the power switch

3B-1-c Bypass Valve Adjusting

Keeping pressure gauge pointer within middle of green zone by follow steps:

‘Wousrniae Seour

3C. System Shut-Down

3641 Daily Shut-Down:

1. Turn Power Switch OFF

2. Open POS's Door and Turn Main Power Breaker OFF, then close & lock POS's door

3-2 Shut-Down for Storage

1, Shut down POS as Daily Shut-Down above

2. Open the system drain valve locates at right bottom of contacting vessel to empty the stored water.

SECTION 4

Maintenance and Service

4A. System Overview

4A1. Inner & Front View (POS-40)

ie ai

L

Les] #1 46] #8)

Inner Front

Item Parts Name Item ene

aL Control Panel #8 Cooling Fan

#2 Power Switch #9 Main Power Breaker

3 Cooling Air Filter, #10 Power Distribution PCB |

4 Door Lock LL PDM Regulating PCB

45, ‘Mount Base #12 Double-deck power supply

46 Ozone Module 13 Door Safe Switch

7 PSA Oxygen Module

10

ay

42-2. Left, Back & Right View

a4 ne.

as

a7

#16 ns;

Left Back Right

item Parts Name Item Parts Name

1 Ozone Off-gas Valve #11 | Water inlet Connection Port

#2 Water Boost Pump Power Connection Box | #12 __| Water Outlet Connection Port

#8 CORP Probe Cable Threading Box #13 | Water Drain Hose

4 Ozone Destructor #14 | Compressed air inlet #1

5S Water Auto Drain Valve #15 | Compressed Air Inlet #2

#6 System Drain Valve #16 _| Air Pump Socket #1

#7 Water Inlet Pressure Gauge #27 _| Air Pump Socket #2

#8 Water Outlet Pressure Gauge #18 __| Panel Window for ORP Controller

#9 Bypass Valve #19 __| Blind Plate for Power Cable Gland

#10 | Venturi injector

48. Preventative Maintenance Schedul

DAIL

Check POS system for proper operation;

. Make sure any warning indicator light is illuminated;

. Make sure LED bar graph for ozone output;

. Make sure ozone water boost pump is running and no leakage;

‘Make sure the pressure gauge pointer within middle of green zone;

Make sure if ozone destructor is getting warm (if equipped)

1

1

2

3, Make sure flow meter is indicating proper air flow (6-8L/min);

4

.

6

MONTHLY:

1. Shut off POS;

2. Clean inside and outside of POS;

2a. Use compresses air spraying:

2d. Use dry & soft cloth cleani

2c. Use the bush brushing dust on the face of inner components.

3. Clean air pump inside & outside;

4, Cleaning filter elements location on the POS's door & on each side of OP-2 air pump

uu

AQ

‘Woetraise Seour

Appendix: C

Pneumatic 3-in-1 Assembly

If use end user’s compressed air source to feed POS, the optional “Pneumatic 3-in-1 Assembly” should

bbe ordered from manufacturer and its installation & connection should be done as shown below:

AQUA

‘Wousrniac Sroor,

Appendix: D

ORP Controller & Probe Installations

POS systems were designed to use the optional ORP controller/probe model in BL982411 from HANNA

instruments Inc.; for complete the instalation, please follow up the following steps:

ea

‘Trovsraae Srour

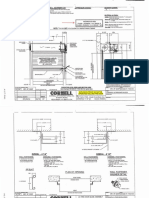

Appendix: E

System Electrical Wiring Diagram

Appendix: E (Cont.)

System Electrical Wiring Diagram

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Fire Safety and Evacuation Plan TemplateDocument19 pagesFire Safety and Evacuation Plan Templatekuraimund100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- OPW Fire Cutoff ValveDocument3 pagesOPW Fire Cutoff ValvekuraimundNo ratings yet

- Pipe Strap For Uninsulated CS PipesDocument1 pagePipe Strap For Uninsulated CS PipeskuraimundNo ratings yet

- RAK Compact Disable Wash BasinDocument1 pageRAK Compact Disable Wash BasinkuraimundNo ratings yet

- Ball Float ValveDocument2 pagesBall Float ValvekuraimundNo ratings yet

- VSR Series: Vane-Type Waterflow SwitchDocument1 pageVSR Series: Vane-Type Waterflow SwitchkuraimundNo ratings yet

- RAKTherm Reinforced Piping SystemsDocument13 pagesRAKTherm Reinforced Piping SystemskuraimundNo ratings yet

- Pneumatic Test For Clean Agent (From NFPA 2001 (2018) )Document1 pagePneumatic Test For Clean Agent (From NFPA 2001 (2018) )kuraimundNo ratings yet

- Inst Symbols P ID FunctionDocument37 pagesInst Symbols P ID FunctionkuraimundNo ratings yet

- GROHE Specification Sheet 38745001Document1 pageGROHE Specification Sheet 38745001kuraimundNo ratings yet

- Crane FS Balancing Valve IOMDocument2 pagesCrane FS Balancing Valve IOMkuraimundNo ratings yet

- Standard Sewer DetailsDocument59 pagesStandard Sewer DetailsPhanhai KakaNo ratings yet

- Review of The WaterMark Certification SchemeDocument107 pagesReview of The WaterMark Certification SchemekuraimundNo ratings yet

- Avk Support Bush Series 05/08: Mounting Instruction / Montagevejledning Einbauanleitung / Instruction de MontageDocument2 pagesAvk Support Bush Series 05/08: Mounting Instruction / Montagevejledning Einbauanleitung / Instruction de MontagekuraimundNo ratings yet

- GH Motor - Roller Shutter DoorDocument2 pagesGH Motor - Roller Shutter DoorkuraimundNo ratings yet

- F4001ED Safe-Air Tester ManualDocument28 pagesF4001ED Safe-Air Tester ManualkuraimundNo ratings yet

- RMC Thermal Balancing ValvesDocument2 pagesRMC Thermal Balancing ValveskuraimundNo ratings yet