Professional Documents

Culture Documents

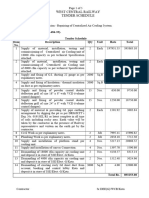

Concrete Work Temperature Limits

Uploaded by

Bernice KohOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Work Temperature Limits

Uploaded by

Bernice KohCopyright:

Available Formats

Concrete Temperature Limits

Temperature control for concrete shall comply with the following requirements:

a) The Contractor shall employ effective means such as shading the aggregates, precooling mixing water

and adding flaked ice to ensure the temperature of concrete prior to and including the time at which it is

placed shall not exceed 30 oC.

b) After the concrete has been placed, its peak temperature in any part of the structure shall not be permitted

to rise above 75 oC.

c) After the concrete has been placed, the maximum temperature difference between a point at the centre

of a concrete section and the adjacent surface shall not be greater than 20 oC times the shortest distance,

in metres, between the concrete section centre and the surface.

d) The Contractor shall employ effective means such as insulation, selection of appropriate pour cycle

times, or heating/cooling as necessary, to ensure that at any time within 14 days after the concrete has

been placed, the temperature differential between any point in the freshly placed concrete of any

structural element at a distance of 600mm from a construction joint and the corresponding point 600mm

from the construction joint in the adjacent previously placed structural element, shall not exceed 20 oC.

Concrete Temperature Measurement

a) The initial placing temperature of the concrete shall be measured by inserting a calibrated probe-type

thermometer, with a ±1oC accuracy, into each delivery of the concrete at the time of discharge from the

vehicle transporting it or not later than 15 minutes thereafter.

b) The temperature of the hydrating concrete shall be measured for each pour until 14 days after pouring

using a sufficient number of calibrated thermocouples within a ± 2oC accuracy.

c) The thermocouples shall be suitably robust to withstand concrete placing, and be adequately protected

and firmly fixed in position on the reinforcement cage.

d) The output of the thermocouples shall be continuously recorded using an automated data logger. The

power supply to the data logger shall be non-interruptible and the equipment shall be maintained and

checked at least twice per day to ensure that they are operating satisfactorily.

e) The thermocouples shall be calibrated in conjunction with the working and backup data logger(s) and

the calibration results shall be submitted at least 3 days prior to incorporation within the Works.

f) After installation of the thermocouples within the pour and immediately prior to concreting, the

thermocouples shall be checked by comparing the relative ambient temperature readings. Any damaged

or malfunctioned thermocouple shall be replaced prior to the commencement of concreting.

g) After the placing of concrete, the temperature readings shall be taken at a maximum of hourly intervals

for the initial 7 days after placing. The monitoring frequency can be reduced to 12 ±1 hours thereafter

until 14 days after placing or until the maximum temperature is less than 15 oC above the daily minimum

ambient temperature.

h) The output from the data loggers shall be down loaded daily by the Contractor. A copy of the data shall

be given to the SO immediately after down loading in an agreed electronic and hard copy format.

i) Within 7 days from the completion of the temperature monitoring period the Contractor shall submit a

report. The report shall include the individual tabulated temperature results and calculated values

indicating compliance, as required by this Particular Specification, for all maximum and differential

temperature measurements. The report shall be presented in both tabulated and graphical format and shall

include all thermocouples within the same measurement plane on the same graph to ensure that the

temperature differentials between the core, surface and ambient are readily discernible.

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- HVAC Duct Work Installation Method StatementDocument3 pagesHVAC Duct Work Installation Method StatementSudath Kularathna100% (1)

- HVAC Duct Work Installation Method StateDocument3 pagesHVAC Duct Work Installation Method StateAlexander GomezNo ratings yet

- WO - RCC (Building Work, Only Labour With Shuttering)Document12 pagesWO - RCC (Building Work, Only Labour With Shuttering)Tushar Doshi100% (4)

- MEP Back To Back Contract AgreementDocument4 pagesMEP Back To Back Contract AgreementAnonymous a3K3WgNo ratings yet

- General Construction Guidelines - Jul2018Document12 pagesGeneral Construction Guidelines - Jul2018luigi firmalinoNo ratings yet

- Methodology For Mass ConcreteDocument5 pagesMethodology For Mass ConcreteGobinda NayekNo ratings yet

- PQC Methodology-2Document7 pagesPQC Methodology-2venkateswara rao Pothina100% (1)

- Work OrderDocument16 pagesWork Orderalankar realitiesNo ratings yet

- Mass ConcreteDocument20 pagesMass ConcreteDhanushka Srimal100% (1)

- HVAC Duct Work Installation Method StatementDocument4 pagesHVAC Duct Work Installation Method StatementMohamed ElarabiNo ratings yet

- 05-14 QCS 2014Document7 pages05-14 QCS 2014Raja Ahmed HassanNo ratings yet

- Portals - 0 - Flooring WO (Blank Format)Document11 pagesPortals - 0 - Flooring WO (Blank Format)Amit manna100% (1)

- Auxiliary Boiler MSDocument10 pagesAuxiliary Boiler MSsharif339No ratings yet

- Fire Protection SystemsDocument26 pagesFire Protection Systemsmahdi_gNo ratings yet

- Method Statement Installation of PPR Water SupplyFINALDocument5 pagesMethod Statement Installation of PPR Water SupplyFINALmengineering75% (4)

- Hvac Duct Work Installation Method StatementDocument3 pagesHvac Duct Work Installation Method StatementSamer Ali0% (1)

- HVACDocument16 pagesHVACroinbanerjiNo ratings yet

- Technical Specification For HVAC 1of 2Document39 pagesTechnical Specification For HVAC 1of 2abramNo ratings yet

- MD1 0 T 052 05 00114 CDocument20 pagesMD1 0 T 052 05 00114 Chunkenx01100% (1)

- Scope of Work Elevator LiftDocument5 pagesScope of Work Elevator LiftKUMARJITNo ratings yet

- Low Pressure Steam Curing of Precast UnitsDocument4 pagesLow Pressure Steam Curing of Precast Unitsdash1991No ratings yet

- Particular Specification For Reinforced Massive Concrete StructuresDocument4 pagesParticular Specification For Reinforced Massive Concrete StructureskarfungNo ratings yet

- Particular Specification For Reinforced Massive Concrete StructuresDocument4 pagesParticular Specification For Reinforced Massive Concrete StructuresMengthuyNo ratings yet

- SSP 500 - Mass Concrete - 9!16!14Document3 pagesSSP 500 - Mass Concrete - 9!16!14dicky1969No ratings yet

- Mass Foundations ConcreteDocument7 pagesMass Foundations ConcreteChris RetardoNo ratings yet

- Pre Heat & PWHT of PipingDocument2 pagesPre Heat & PWHT of PipingHarish GandhiNo ratings yet

- CITY WALK (RESI 1 & 2) - Project Specific Details - REV 3 (17-12-2019)Document4 pagesCITY WALK (RESI 1 & 2) - Project Specific Details - REV 3 (17-12-2019)FarisNo ratings yet

- Procedure For REINFORCED MASS CONCRETE 01Document4 pagesProcedure For REINFORCED MASS CONCRETE 01Adnan ArshidNo ratings yet

- Assignment Nicmar/Code OfficeDocument27 pagesAssignment Nicmar/Code Officepoonam_ceNo ratings yet

- Sprinkler Fire Department Notes - 2022 Code - 202306282026331951Document2 pagesSprinkler Fire Department Notes - 2022 Code - 202306282026331951Juan José Jaramillo PeñaNo ratings yet

- HVAC Duct Work Installation Method StateDocument3 pagesHVAC Duct Work Installation Method StateMuhammadYounusNo ratings yet

- Idoc - Pub - Hvac Duct Work Installation Method StatementDocument3 pagesIdoc - Pub - Hvac Duct Work Installation Method StatementAsharudeen CbNo ratings yet

- NCP 23Document18 pagesNCP 23Junaid Mohd100% (3)

- Scope of The TenderDocument6 pagesScope of The Tendernaveenkumar.k.h kumar.k.hNo ratings yet

- 057521Document20 pages057521M.Senthil VelavanNo ratings yet

- TTender Schedule EL-50-67-2020-21Document5 pagesTTender Schedule EL-50-67-2020-21kaygupta301102No ratings yet

- Amc Ac VCB DGDocument9 pagesAmc Ac VCB DGbalaji bNo ratings yet

- HDPE Tender DocumentDocument4 pagesHDPE Tender Documentabhijithaval100% (1)

- Audible & Vibratory Pavement MarkingDocument4 pagesAudible & Vibratory Pavement MarkingRoslan 'Abok' KamarudinNo ratings yet

- Assignment Nicmar/Code Office Name:Of Assignment at Code Officeproject Name: Plumeria Garden Greater Noida U.P.Scope of WorkDocument15 pagesAssignment Nicmar/Code Office Name:Of Assignment at Code Officeproject Name: Plumeria Garden Greater Noida U.P.Scope of WorksupriyaghanbahadurNo ratings yet

- 03051Document2 pages03051JojolasNo ratings yet

- Gas Supplies To Multi Occupancy Residential BuildingsDocument8 pagesGas Supplies To Multi Occupancy Residential BuildingsBGRLNo ratings yet

- Gas Supplies To Multi Occupancy Residential Buildings 03092020Document8 pagesGas Supplies To Multi Occupancy Residential Buildings 03092020Ram ChaitanyaNo ratings yet

- Iv. Special Conditions of This TenderDocument22 pagesIv. Special Conditions of This TenderMuhammed AnasNo ratings yet

- Thermal Control in ConcreteDocument14 pagesThermal Control in ConcreteDeshapriyaNo ratings yet

- 2021-03-12 - Special ConditionDocument11 pages2021-03-12 - Special ConditionMAULIK RAVALNo ratings yet

- Statement of WorkDocument7 pagesStatement of WorkCha PaineNo ratings yet

- Maximum Fresh Concrete Temperature Requirements (MMSP Project)Document3 pagesMaximum Fresh Concrete Temperature Requirements (MMSP Project)Tin ZawNo ratings yet

- Mass Foundations Concrete and Temperature Control MoniteringDocument20 pagesMass Foundations Concrete and Temperature Control MoniteringAnte DaboNo ratings yet

- Multi Indoor Unit VRFDocument18 pagesMulti Indoor Unit VRFVu SonNo ratings yet

- Hot Weather ConcretingDocument10 pagesHot Weather ConcretingIm ChinithNo ratings yet

- Geotechnical Instrumentation SpecDocument6 pagesGeotechnical Instrumentation SpecMOHD ASMIROLNo ratings yet

- Specification For Instrumentation and Monitoring of Reclamation WorksDocument13 pagesSpecification For Instrumentation and Monitoring of Reclamation Worksjinwook75No ratings yet

- 0 +RFQ+ (ACU+Maintenance) + (Edited) Alm Abc+edit+docx+ (SGD)Document5 pages0 +RFQ+ (ACU+Maintenance) + (Edited) Alm Abc+edit+docx+ (SGD)ŔingoStarr Echavez OrilloNo ratings yet

- Sop 45 PDFDocument4 pagesSop 45 PDFmanil_50% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet