Professional Documents

Culture Documents

Q400.SRM (20) .SRM51-20-10-00-01 Finish Codes

Uploaded by

Tinh nguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Q400.SRM (20) .SRM51-20-10-00-01 Finish Codes

Uploaded by

Tinh nguyenCopyright:

Available Formats

D STRUCTURAL REPAIR MANUAL

**ON A/C ALL

Finish Codes

1. General

A. The finish code identifies the surface treatment and coatings, with the sequence in which they

apply to each part or assembly on the Dash 8, Series 400 aircraft.

2. Finish Codes

Protective Treatment Coating System Table

PROTECTIVE TREATMENT MATERIAL

TREATMENTS SPECIFICATION

CODE METHOD

A1 Anodize − Chromic acid MIL−A−8625 Type I

A2 Anodize − Hard sulphuric acid MIL−A−8625 Type 3,

Class 1

Anodize − Colorless sulphuric acid MIL−A−8625 Type 2,

Class 1, colorless

A3 ANODIZING

Anodize − Color sulphuric acid MIL−A−8625 Type 2,

Class 2, color

A6 Anodizing − Hard sulphuric acid MIL−A−63576 Type I

(PTFE Impregnated)

A7 Anodize, thin film sulphuric acid MIL−A−8625 Type IIB

Chemical conversion coating − Dip MIL−C−5541 Class 1A

application (Alodine)

C1

Chemical conversion coating − MIL−C−5541 Class 1A

Manual application (Alodine)

C2 Manganese phosphate −

CHEMICAL

SURFACE Dry film lubricant − Oven cure, wear

TREATMENT resistant

C3 −

Molykote 106, Kal−Gard KG 200

(high temperature)

C4 Dichromate treatment − For −

magnesium alloys

C5 Zinc phosphate −

Dry film lubricant − Air dry, wear and

C7 fluid resistant −

Molykote D−321R

C8 CHEMICAL Dry film lubricant − Air dry, wear and MIL−L−23398, SAE AS

SURFACE corrosion resistant 1701 Class II

TREATMENT

C9 Surface treatment of CRES Steel −

Low electrical resistance chemical MIL−DTL−5541, Class

C10 conversion coating − Dip and Manual 3

application (Alodine)

PSM 1−84−3 − MASTER

EFFECTIVITY: Struct. Ident−01

See first effectivity on page 1 of 51−20−10 Struct.

Ident−01 51−20−10 Page 1

Feb 05/2020

Print Date: 2020-09-18

D STRUCTURAL REPAIR MANUAL

Protective Treatment Coating System Table

PROTECTIVE TREATMENT MATERIAL

TREATMENTS SPECIFICATION

CODE METHOD

E1 PLATING Cadmium Plating QQ−P−416E, Class I,

Type I

E2 PLATING Chromium Plating −

E3 PLATING Nickel Plating − Electrodeposited −

Nickel Plating − Electroless Class 1:

As plated, no heat treatment.Class 2:

Heat treated by type as shown below

E4 after plating.Type A: Heat treated for −

relief of hydrogen embrittlement.Type

B: Heat treated to increase plating

PLATING hardness.

E5 Chromium plating − Decorative, dull −

satin finish

E6 Chromium plating − Decorative, −

bright satin finish

Copper plating − When used for

stopping off areas of steel parts for

carburizing, nitriding or heat

E7 treatment −

Copper flash − When used as an

PLATING undercoating for chrome plating

Cadmium−Titanium plating − For low

E8 alloy steels heat treated up to 280− −

305 ksi

E9 Chrome plating − For steels heat MIL−STD−1501

treated to 220−240 ksi and above

Primer − Alkyd, zinc chromate, for

F1 countersink only, Type I (bulk), color TT−P−1757

T. (34151 green to Federal standard)

F2 Lacquer − Cellulose nitrate, flat, A−A−3164

ORGANIC pigmented

COATING AND

F2 FINISHES Lacquer − Cellulose nitrate, gloss, A−A−3165

pigmented

F4 Lacquer − Cellulose nitrate, clear A−A−3165

F5 Enamel − Alkyd, baking DHMS C4.07

PSM 1−84−3 − MASTER

EFFECTIVITY: Struct. Ident−01

See first effectivity on page 1 of 51−20−10 Struct.

Ident−01 51−20−10 Page 2

Feb 05/2020

Print Date: 2020-09-18

D STRUCTURAL REPAIR MANUAL

Protective Treatment Coating System Table

PROTECTIVE TREATMENT MATERIAL

TREATMENTS SPECIFICATION

CODE METHOD

Compound − Corrosion preventive, MIL−PRF−16173 Grade

Grade 1, Hard film 1

Compound − Corrosion preventive, MIL−PRF−16173 Grade

Grade 2, soft film 2

Compound − Corrosion preventive,

Grade 3, soft film, water displacing

ORGANIC DHMS C4.12

F13 COATING AND Type I: Colourless transparent

FINISHES Type II: Coloured transparent

Compound − Corrosion preventive,

Grade 4, soft, medium, heavy duty

compound BMS 10−83 and DHMS

Type I: Colourless transparent C4.12

Type II: Coloured transparent

F14 Primer − Urethane for polycarbonate BMS 10−83 Type I or

DHMS C4.22 Type I

F16 Compound − Jointing, corrosion −

ORGANIC preventive, DSC 489

COATING AND Primer − polyester for magnesium

F17 FINISHES alloys −

Primer − Epoxy polyamide Type II: MIL−P−23377, DHMS

F19 Strontium chromate, green. Type III: C4.01

Zinc phosphate, white.

F20 Enamel − Polyurethane protective DHMS C4.05

coating

Primer − Integral fuel tank.

F21 MIL−C−27725, DHMS

ORGANIC Type I, Grade A and Grade B: C4.06

COATING AND Polyurethane

FINISHES Primer − Integral fuel tank.

F21 MIL−C−27725, BMS

Type II, Class A: Epoxy 10−20

F22 Enamel − Epoxy, gloss, semi−gloss DHMS C4.11

or lusterless

Enamel − Epoxy, urethane

compatible, corrosion resistant, DHMS C4.18 Type I

ORGANIC intermediate, Type 1: Reserved

F23 COATING AND Type II: Reserved DHMS C4.18 Type II

FINISHES

Type III: Less than 1% aromatic DHMS C4.18 TYPE 3

amine in mixed components

PSM 1−84−3 − MASTER

EFFECTIVITY: Struct. Ident−01

See first effectivity on page 1 of 51−20−10 Struct.

Ident−01 51−20−10 Page 3

Feb 05/2020

Print Date: 2020-09-18

D STRUCTURAL REPAIR MANUAL

Protective Treatment Coating System Table

PROTECTIVE TREATMENT MATERIAL

TREATMENTS SPECIFICATION

CODE METHOD

Enamel − Polyurethane, pigmented

and clear, gloss, semi−gloss or

ORGANIC lusterless. Type 4 −Highly flexible

F24 COATING AND and impact resistant for aircraft DHMS C4.04

FINISHES exterior. Type 6 − Highly flexible and

rain erosion resistant for aircraft

exterior

Enamel powder coatings, Type I:

Electrostatic spray application. Type

F28 II: Fluidized bed application. Class1: DHMS C4.10

High gloss. Class2: Semi−gloss.

Class 3: Low gloss.

ORGANIC

F29 COATING AND Enamel − Polyurethane, teflon filled, DHMS C4.08

FINISHES abrasion resistant

F31 Enamel − Polyurethane, anti−static DHMS C4.13 TYPE 1

(High resistance type), black

F32 Sealant − Polyurethane (Tempo DHMS C4.11

1900)

F33 Compound − Surface finishing (for DSC 206−1, −2, −3 and

glass or fabric laminates) −4

F34 Enamel − Polyurethane, anti−static DHMS C4.13 TYPE 2

(low resistance type), black

F35 ORGANIC Coating − Epoxy, high build clear, DHMS C4.20

COATING AND fuel vapor barrier

FINISHES Coating − Polyurethane, erosion MIL−C−83231, Type II,

F36 resistant, unpaved runway protection Class A

Enamel − Polyurethane, pigmented

F37 and clear, standard flexibility, high DHMS C4.04 TYPE 2,

resistance to hydraulic fluid for Class A

aircraft exterior

F38 Coatings − Fireproof, intumescent −

Coatings − Mar resistant, decorative.

Type I: General purpose dip coat

compound. Type II: General purpose

F39 spray coat compound. Type III: MIL−P−20689C

ORGANIC General Purpose roller coat

COATING AND compoundClass 1: General Use.

FINISHES Class 2: Fungus resistant.

F40 Coating − Polyurethane, anti−static, MIL−C−83231, Type II,

erosion resistant Class A

F41 Coating − Anti−static, conductive BMS 10−21 Type III

epoxy

PSM 1−84−3 − MASTER

EFFECTIVITY: Struct. Ident−01

See first effectivity on page 1 of 51−20−10 Struct.

Ident−01 51−20−10 Page 4

Feb 05/2020

Print Date: 2020-09-18

D STRUCTURAL REPAIR MANUAL

Protective Treatment Coating System Table

PROTECTIVE TREATMENT MATERIAL

TREATMENTS SPECIFICATION

CODE METHOD

F42 Enamel − Urethane, interior BMS 10−83 TYPE 2 or

decorative DHMS C4.22 TYPE 6

F45 ORGANIC Primer − High temperature resistant DHMS C4.21

COATING AND Liquid Adhesive Primer, modified

F46 FINISHES epoxy phenolic, thermosetting DHMS A6.03−1

F47 Primer − Epoxy/Polyurethane base DHMS C4.30

coat/Polyurethane clear coat

M1 METALIZING Coatings − Aluminum wire spray −

Coatings − Ion Vapor Deposit

aluminum. Class 1: 0.001−0.002 inch

M2 METALIZING thick.Class 2: 0.0005−0.0009 inch MIL−C−83488

thick. Class 3: 0.0003−0.0005 inch

thick. Type I: As coated. Type II: With

supplementary chromate treatment.

M3 METALIZING Coating, Tungsten Carbide plus DHMS C4.19, Type I

Cobalt, thermal spray

SF11 Buffed finish − Mirror bright −

SF21 Satin finish − Bright −

SF22 BUFFING & Satin finish − Semi−bright −

POLISHING

SF24 Satin finish − Coarse −

SF32 Brush finish − Medium −

PSM 1−84−3 − MASTER

EFFECTIVITY: Struct. Ident−01

See first effectivity on page 1 of 51−20−10 Struct.

Ident−01 51−20−10 Page 5

Feb 05/2020

Print Date: 2020-09-18

THIS PAGE INTENTIONALLY LEFT BLANK

Print Date: 2020-09-18

You might also like

- 4637 EnuDocument2 pages4637 Enuluis trigosNo ratings yet

- Ep Grease MolyDocument1 pageEp Grease MolyFilipposNo ratings yet

- ZINCALUME® G300 Steel With Activate™ Technology: Structural - S Metallic Coated - MCDocument3 pagesZINCALUME® G300 Steel With Activate™ Technology: Structural - S Metallic Coated - MCEwo50 NewNo ratings yet

- Spec Cross Reference PassivateDocument1 pageSpec Cross Reference PassivateSivaramSubramanianNo ratings yet

- PLATINGDocument1 pagePLATINGdineshNo ratings yet

- Brochure - Rev 15 PDFDocument9 pagesBrochure - Rev 15 PDFCicero Gomes de SouzaNo ratings yet

- ZINCALUME® Steel G250 Datasheet May 2023Document3 pagesZINCALUME® Steel G250 Datasheet May 2023a0931474125No ratings yet

- 1191 EnuDocument2 pages1191 EnuhartadiNo ratings yet

- Military Plating Spec-1Document11 pagesMilitary Plating Spec-1Durbha RaviNo ratings yet

- Technologically Advanced Lubricants from Japan High Performance Metal Stamping OilDocument2 pagesTechnologically Advanced Lubricants from Japan High Performance Metal Stamping OilHarry IpNo ratings yet

- Jet-Lube #202 Moly-Lith - TDS - EnglishDocument1 pageJet-Lube #202 Moly-Lith - TDS - EnglishDon HowardNo ratings yet

- Cepsa Arga LitioDocument1 pageCepsa Arga LitioRamonNo ratings yet

- Eni Rotra MP 85W-140 gear oil protects under heavy loadsDocument2 pagesEni Rotra MP 85W-140 gear oil protects under heavy loadsDesta 77No ratings yet

- 1275 EnuDocument2 pages1275 EnuJan HendriksNo ratings yet

- Eni i-Base Professional 10W-40 Engine Oil PerformanceDocument2 pagesEni i-Base Professional 10W-40 Engine Oil PerformancehartadiNo ratings yet

- Mobilgrease MPDocument2 pagesMobilgrease MPjerrypoaNo ratings yet

- Adeco Lithium Grease 2: Technical Data SheetDocument1 pageAdeco Lithium Grease 2: Technical Data SheetVelibor KaranovicNo ratings yet

- Cepsa Arga Complex Litio 2Document1 pageCepsa Arga Complex Litio 2RamonNo ratings yet

- Eni I Sigma TOP MS 15W40Document2 pagesEni I Sigma TOP MS 15W40ranjanguptNo ratings yet

- Molyguard CF - Robot - M0826 - ENDocument1 pageMolyguard CF - Robot - M0826 - ENJeferson DantasNo ratings yet

- MPG Eplf Series: BenefitsDocument1 pageMPG Eplf Series: BenefitsvarunNo ratings yet

- Shielding Gases for Welding & CuttingDocument12 pagesShielding Gases for Welding & CuttingJuan Carlos100% (3)

- Plating and MetPLATING & METAL FINISHING SPECIFICATIONS ISO 9001:2008, Nadcap, ITAR, Federal Fire Arms Licenseal Finishing SPECDocument1 pagePlating and MetPLATING & METAL FINISHING SPECIFICATIONS ISO 9001:2008, Nadcap, ITAR, Federal Fire Arms Licenseal Finishing SPECStas Zabarsky0% (1)

- Aluminum AnodizingDocument7 pagesAluminum Anodizingkarthik venkatachalamNo ratings yet

- Eni Lamium 11C Is A Highly RefinedDocument2 pagesEni Lamium 11C Is A Highly RefinedSou MadaNo ratings yet

- Eni I-Sigma Performance E7 15W-40Document2 pagesEni I-Sigma Performance E7 15W-40Luis VillalbaNo ratings yet

- KAJO-BIO-Longlife Grease LZR 2: Product InformationDocument2 pagesKAJO-BIO-Longlife Grease LZR 2: Product InformationMassimiliano VolaNo ratings yet

- Zincalume G550 Steel: Metallic Coated - MC Structural - SDocument1 pageZincalume G550 Steel: Metallic Coated - MC Structural - SEwo50 New0% (1)

- Eni Blasia 220: Eni Blasia 220 Is A Gear Oil With EP Characteristics For Enclosed Industrial Gears Lubricated WithDocument2 pagesEni Blasia 220: Eni Blasia 220 Is A Gear Oil With EP Characteristics For Enclosed Industrial Gears Lubricated WithMartín BaezaNo ratings yet

- Applications: Eni Spa Refining&Marketing Viale Giorgio Ribotta, 51 - 00144 Roma +39 06 5988.1 Date 25/01/2019 Code 1035 1Document2 pagesApplications: Eni Spa Refining&Marketing Viale Giorgio Ribotta, 51 - 00144 Roma +39 06 5988.1 Date 25/01/2019 Code 1035 1haripuscasNo ratings yet

- Properties of Cover Grades (As Per IS: 1891)Document2 pagesProperties of Cover Grades (As Per IS: 1891)Raja NarenderNo ratings yet

- ISO TITLEDocument4 pagesISO TITLEOswaldo Manuel Ramirez Marin100% (2)

- Eni Rotra LSX 75W-90 synthetic gear oilDocument2 pagesEni Rotra LSX 75W-90 synthetic gear oilmitarjocNo ratings yet

- 1482402756balmerol Licom 2 PremiumDocument2 pages1482402756balmerol Licom 2 PremiumSabari SreekumarNo ratings yet

- Mobilgrease XHP 222 PdsDocument2 pagesMobilgrease XHP 222 PdsmuhammadNo ratings yet

- AGIP-Universal DL Sae 15w-40Document2 pagesAGIP-Universal DL Sae 15w-40Muhammad RipandiNo ratings yet

- Eni Blasia 320Document2 pagesEni Blasia 320behruzNo ratings yet

- Agip Blasia FMPDocument2 pagesAgip Blasia FMPRanjan GuptaNo ratings yet

- Characteristics (Typical Figures) Agip Dicrea 32 46 68 100 150 220 320Document2 pagesCharacteristics (Typical Figures) Agip Dicrea 32 46 68 100 150 220 320anon_925307644No ratings yet

- Grease NO. 0, 1, 2, 3 & MP: DescriptionDocument1 pageGrease NO. 0, 1, 2, 3 & MP: DescriptionKian GonzagaNo ratings yet

- Eni Top 2000Document2 pagesEni Top 2000Iftikhar AmjadNo ratings yet

- QPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDocument4 pagesQPS-C5 Industrial & Costal Painting Procedure-OP - PP - WI - 006 - C5 PDFDeepak UpadhyayNo ratings yet

- 1035 EnuDocument2 pages1035 EnuhartadiNo ratings yet

- High load industrial gear lubricants - Tauro REPSOL 220 & 320Document1 pageHigh load industrial gear lubricants - Tauro REPSOL 220 & 320randiNo ratings yet

- Alumina Carbide Grades: CVD Coated Grades SteelDocument3 pagesAlumina Carbide Grades: CVD Coated Grades SteelVasoya ManojNo ratings yet

- PDF - 16012777053 SABIT PRIMER D-41Document1 pagePDF - 16012777053 SABIT PRIMER D-41MohamedNo ratings yet

- Servofilm 32 mineral oil for steel mills & rubber processingDocument1 pageServofilm 32 mineral oil for steel mills & rubber processingSurya IntlNo ratings yet

- Marine-MP TDS EnglishDocument1 pageMarine-MP TDS EnglishjaymuscatNo ratings yet

- Ina Lis 1 2 and 3 111344Document1 pageIna Lis 1 2 and 3 111344Pero Plemeniti SimicNo ratings yet

- RND259Document1 pageRND259LAB PPCVNo ratings yet

- Lubricating Greases: Application GuideDocument12 pagesLubricating Greases: Application GuidefabioNo ratings yet

- Litica Ep Tcm14-54592Document2 pagesLitica Ep Tcm14-54592Nolbys EspinosaNo ratings yet

- Eni I-Ride Racing 10W-50 Is A "Top Synthetic" Lubricant Formulated With High Quality Base StocksDocument2 pagesEni I-Ride Racing 10W-50 Is A "Top Synthetic" Lubricant Formulated With High Quality Base StocksAlexey KolmakovNo ratings yet

- Pds CA Variocut G 101Document2 pagesPds CA Variocut G 101tribolasNo ratings yet

- Ultrapaste Cu 12 SF - 2017 (E)Document1 pageUltrapaste Cu 12 SF - 2017 (E)HANIF AKBARNo ratings yet

- Eni OSO 32: Eni OSO 32 Is A High Performance Antiwear Hydraulic Oil, Specifically Designed To Meet The MostDocument2 pagesEni OSO 32: Eni OSO 32 Is A High Performance Antiwear Hydraulic Oil, Specifically Designed To Meet The MostCelineKevinNo ratings yet

- Spheerol LMMDocument2 pagesSpheerol LMMSabari SreekumarNo ratings yet

- AGIP-Top MS 15w-40Document2 pagesAGIP-Top MS 15w-40Muhammad RipandiNo ratings yet

- Graisse N 31315Document1 pageGraisse N 31315kirandhivya1821No ratings yet

- Astm 2438Document10 pagesAstm 2438Tinh nguyenNo ratings yet

- Mil I 8846DDocument12 pagesMil I 8846DTinh nguyenNo ratings yet

- 27.12.2022 - Curing Condition of Sealant - PPG Aerospace PS 870 B-1.2 - MIL-PRF-81733D - NHThongDocument3 pages27.12.2022 - Curing Condition of Sealant - PPG Aerospace PS 870 B-1.2 - MIL-PRF-81733D - NHThongTinh nguyenNo ratings yet

- Mil PRF 16173e (Document34 pagesMil PRF 16173e (Tinh nguyenNo ratings yet

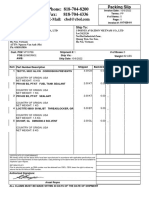

- Packing Slip Details for 3 Points AviationDocument1 pagePacking Slip Details for 3 Points AviationTinh nguyenNo ratings yet

- Product Information: Tectyl™ 502-CDocument2 pagesProduct Information: Tectyl™ 502-CnicusebpNo ratings yet

- CDS1 - SMCDocument37 pagesCDS1 - SMCMartin EkoNo ratings yet

- Alkosign Product CatalogeDocument20 pagesAlkosign Product CatalogeShree AgrawalNo ratings yet

- Conversion To Loop Cooler RLB-90Document16 pagesConversion To Loop Cooler RLB-90rafaelNo ratings yet

- Die CutDocument6 pagesDie CutHBracing1100% (1)

- Bonneville T100 accessories guideDocument7 pagesBonneville T100 accessories guide이세형No ratings yet

- Analysis of Hard Chromium Coating Defects and Its Prevention MethodsDocument6 pagesAnalysis of Hard Chromium Coating Defects and Its Prevention MethodsMULYADINo ratings yet

- 79 Chromium Plated Brass Angle ValveDocument2 pages79 Chromium Plated Brass Angle ValveArun UdayabhanuNo ratings yet

- 2012 PacBay CatalogDocument88 pages2012 PacBay CatalogDušan IvanovNo ratings yet

- Heat Treatment of Gauge MaterialsDocument16 pagesHeat Treatment of Gauge MaterialsshdblikhnNo ratings yet

- Anilox RollDocument37 pagesAnilox RollSudhakar Joshi100% (4)

- Contact and Career Details for Chemical EngineerDocument3 pagesContact and Career Details for Chemical Engineerpankaj chaudharyNo ratings yet

- Ventilação Local Exaustora EM GalvanoplastiaDocument66 pagesVentilação Local Exaustora EM GalvanoplastiaJoaoDuarteNo ratings yet

- Chromium Plating ProcessDocument7 pagesChromium Plating ProcessAdelNo ratings yet

- Nickel Chrome PlatingDocument8 pagesNickel Chrome PlatingRITWIKNo ratings yet

- MAN B&W Diesel A/S Service Letter on Nimonic Exhaust ValvesDocument14 pagesMAN B&W Diesel A/S Service Letter on Nimonic Exhaust ValvesKamlakarPatwariNo ratings yet

- Front Mount HF TechdataDocument14 pagesFront Mount HF TechdataAlexandru NicuNo ratings yet

- PComP BrochureDocument2 pagesPComP BrochureanupamghildyalNo ratings yet

- Construction Materials Used in Marine Diesel EnginesDocument4 pagesConstruction Materials Used in Marine Diesel Enginesshihab100% (1)

- Chem 1 PDFDocument33 pagesChem 1 PDFJelena ZdravkovicNo ratings yet

- BOMcheck REACH Candidate List Screening For Supplied Articles - June 2023Document80 pagesBOMcheck REACH Candidate List Screening For Supplied Articles - June 2023ansu.ggmNo ratings yet

- Engine Parts MaterialsDocument4 pagesEngine Parts Materialsmy generalNo ratings yet

- Gask o Seal PDFDocument24 pagesGask o Seal PDFThang CaoNo ratings yet

- H SprinklerAccessories 0Document10 pagesH SprinklerAccessories 0BagusBudiNo ratings yet

- Buffoli Booklet - USA PhoscoatingDocument138 pagesBuffoli Booklet - USA PhoscoatingMark GarrettNo ratings yet

- Trimark: Service & Replacement PartsDocument60 pagesTrimark: Service & Replacement PartsMary Joyce Herjas AlvarezNo ratings yet

- Hard Chrome ReplacementDocument7 pagesHard Chrome ReplacementPhu, Le HuuNo ratings yet

- DRAGFLOW TECH INFO ON CHROME WEAR PARTS AND SEAL ARRANGEMENTDocument2 pagesDRAGFLOW TECH INFO ON CHROME WEAR PARTS AND SEAL ARRANGEMENTAlditho PomatayNo ratings yet

- Fittings For Glass 2012Document532 pagesFittings For Glass 2012transinovNo ratings yet

- Casewell Plating2001 PDFDocument50 pagesCasewell Plating2001 PDFHarindra Kusumpriya100% (1)

- The Fortessa Collection 2010Document36 pagesThe Fortessa Collection 2010monu6006No ratings yet