Professional Documents

Culture Documents

07 1964 CH-Engine Tune-Up

07 1964 CH-Engine Tune-Up

Uploaded by

Jose LaproviteraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07 1964 CH-Engine Tune-Up

07 1964 CH-Engine Tune-Up

Uploaded by

Jose LaproviteraCopyright:

Available Formats

SECTION 7

ENGINE TUNE-UP

This section outlines the 1964 engine tune-up pro

cedures that differ from procedures outlined in the

1961 Shop Manual.

All engines are equipped with positive crankcase

ventilation systems and Delcotron AC charging systems.

CARBURETOR ADJUSTMENTS

Carburetor adjustments for new remote choke car

buretors and the low silhouette 4GC are outlined in

Section 10 of this manual, as are their specifications.

FAN BELT ADJUSTMENT

Fan belt adjustment should be measured using a

strand tension gauge tool J-7316 midway between

pulleys fig. 1. Adjust the belt to obtain a gauge read

ing of 75±5 lbs.

DELCOTRON GENERATOR AND

REGULATOR CHECK Fig. 2-Positive Ventilation 1-6

An instrument test of delcotron output and regu

lator setting should not be made as a regular tune-up battery hydrometer and light load test outlined in

Section 9 should be made, followed by any indicated

test; THE CONDITION OF THE BATTERY INDI-

electrical circuit tests.

CATES THAT THESE TESTS BE MADE. Over-

charging is indicated by excessive use of water and

undercharging by slow cranking speeds, low hydrom- POSITIVE CRANKCASE VENTILATION SYSTEM

eter reading etc. At each tune-up period therefore a refer to figures 2, 3 and 4

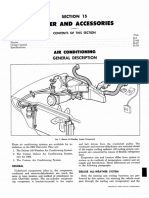

All 1964 Chevrolet engines have either "positive" or

"closed" positive ventilation systems utilizing mani

fold vacuum to draw fumes and contaminating

vapors into the combustion chamber where they are

burned. The crankcase ventilation system has an

important function and should be understood and

serviced properly.

In both positive and closed crankcase ventilation,

air is drawn through the engine, through a regulating

valve and into the manifold, drawing crankcase vapors

and fumes with it to be burned. Positive ventilation

uses a vented oil filler cap for clean air intake to the

engine, while the closed positive ventilation system

draws the clean air from the carburetor air cleaner

and has a non-vented oil filler cap.

Crankcase ventilation is closed positive through a

fixed metered orifice at the carburetor base and air is

routed from the clean air side of the air cleaner, to the

rear of the block, through the push-rod cavity under

the intake manifold, to the oil filler tube and then

through a hose to the orifice at carburetor flange.

The oil filler cap is non-vented.

The orifice should be cleaned at each tune-up period

and can be tested in the same manner as the valve was

Fig. 1 -Fan Belt Adjustment in 1963 if desired.

CHEVROLET SHOP MANUAL SUPPLEMENT

ENGINE TUNE-UP 7-2

Positive ventilation valves are designed specifically installing a new valve and retesting to be sure the

for each engine to control the amount of flow from valve was at fault rather than engine seals. A green

the crankcase to the manifold. VALVES SHOULD reading with new valve indicates first valve was

NEVER BE CHANGED FROM ONE SIZE ENGINE bad-a duplication of first reading, with new

TO ANOTHER. valve, indicates other engine trouble, the original

The crankcase ventilation valve and the vented oil valve was good.

filler cap will eventually plug and become ineffective,

therefore, the valve should be tested and the vented

283

oil filler cap should be washed in solvent, blown dry ENGINE 230 321

with compressed air and be re-oiled at regular 6 Cyl. V-8

intervals. See section 0. Production 5649998 5649996

Part

Two methods for testing the ventilation valve are No. Service Pkg. 6418440 5649689

as follows:

Valve Type No. CV 607 CV 590

LABEL White Print Red Print

ENGINE RPM DROP METHOD: Color Code on on

Red White

1. Connect tachometer and vacuum gauge as for CT-i Tester Setting 4 2

idle speed and mixture adjustment.

2. Set parking brake and start engine.

3. a. 4 and 6 cylinder engines-Remove valve from

rocker arm cover with hose still connected,

plug the open end of the valve and read engine

rpm change.

b. 8 cylinder engine-Disconnect ventilation hose

at valve or orifice on carburetor base, block

vacuum opening and read engine rpm change.

4. A change of less than 50 rpm indicates a plugged

ventilation metering hole-replace the valve or

clean fixed orifice and adjust idle speed and mix

ture.

CRANKCASE VENTILATION TESTER METHOD:

A.C. TYPE CT-i TESTER

1. Remove oil filler cap and install tester adapter

with tube connector.

2. Remove oil gauge dipstick and seal the opening

with a plug or tape.

3. Closed Positive Ventilation System-Disconnect

air cleaner to oil filler tube or rocker cover hose

at air cleaner and plug the end of hose with tape

or a plug.

4. Connect rubber hose to tester base and to filler

cap adapter, then adjust the selector knob on

base of tester for valve being tested. see chart

below

5. Start engine and allow to run at normal idle.

6. Hold tester upright and make sure there are no

kinks in the hose. Look directly into viewing

windows and observe indicator color.

7. A reading of green indicates a proper functioning

valve. Any other reading should be verified by Figs. 3 and 4-Crankcase Ventilation

CHEVROLET SHOP MANUAL SUPPLEMENT

ENGINE TUNE-UP 7-3

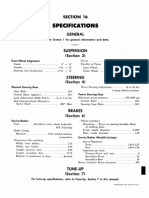

1964 PASSENGER CAR ENGINE TUNE-UP SPECIFICATIONS

ENGINE 230 283 327 327 409 409 409

H.P. 140 - 195 250 300 340 400 425

WCFB

Carburetors BC 2GC or AFB 4GC AFB ]Dual

4GC AFB

Compression PSI 130 150 160 160 150 150 150

Note 1

Make and Colder AC-44N AC-44 AC-43 AC-C42N

SPARK Number STD. AC-46N AC-45 - AC-44 AC-43N

PLUGS Hotter - AC-45 AC-44N

Gap .035"

Point

Ignition Dwell 31°-34° 28°-32°

Distrib

utor Point .019" New- .016" Used

Gap

Point Arm

Spring Preset at 19-23 oz.

Tension

Condenser .18-.25 Microfarad

Fan Belt 75 ± 5 Lbs. Using Strand Tension Gauge

Polyure- Polyure- Paper

Air Cleaner thane thane Replace

Note 2 wash and Paper Element Wash and

Reoil Reoil

TAPPET Inlet Hydraulic-One Turn to Center Plunger Mech.-.012 .018®

CLEAR

ANCE Exhaust Hydraulic-One Turn to Center Plunger Mech.-.020 .030®

8° BTDC

Ignition Timing 4° BTDC Nominal Nominal 6° BTDC

Note No. 4 Range 4°-8° Range Nominal 12 BTDC Nominal

6°-12°

Engine Idle

Syn.

Auto.

500 750 I 750

RPM In Drive 500 - -

FUEL Press. 332 T. 53 to 63/2 PSI 73, to 83/2 PSI

PUMP 43/2 PSI

Vol. One Pint in 30 to 45 Seconds

Cooling System

15 PSI on Air Conditioned Vehicles

Pressure

Te AC-CV-590® Fixed Metered Orifice

Note 1-All plugs removed and throttle wide open.

Note 2-Paper element-check at 1st 12,000 and each 6,000 miles thereafter. Polyurethane each 12,000 miles.

®Note 3-Sustained high speed.

Note 4-Spark advance line disconnected and vacuum opening plug.

®Note 5-Optional metered orifice.

CHEVROLET SHOP MANUAI SUPPLEMENT

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mosa Welder 2 Stroke Gas ManualDocument54 pagesMosa Welder 2 Stroke Gas ManualJose LaproviteraNo ratings yet

- A1700 Torques y OtrosDocument6 pagesA1700 Torques y OtrosJose LaproviteraNo ratings yet

- 02 1963 CH-LubricationDocument2 pages02 1963 CH-LubricationJose LaproviteraNo ratings yet

- 10 1963 CH-Fuel & ExhaustDocument28 pages10 1963 CH-Fuel & ExhaustJose LaproviteraNo ratings yet

- 14 1963 CH-BodyDocument97 pages14 1963 CH-BodyJose LaproviteraNo ratings yet

- 16 1963 CH-SpecificationsDocument8 pages16 1963 CH-SpecificationsJose LaproviteraNo ratings yet

- 12 1964 CH-Man TransDocument18 pages12 1964 CH-Man TransJose LaproviteraNo ratings yet

- 13 1964 CH-Auto TransDocument32 pages13 1964 CH-Auto TransJose LaproviteraNo ratings yet

- 04 1964 CH-SteeringDocument24 pages04 1964 CH-SteeringJose LaproviteraNo ratings yet

- 02 1964 CH-LubricationDocument2 pages02 1964 CH-LubricationJose LaproviteraNo ratings yet

- 10 1964 CH-Fuel & ExhaustDocument51 pages10 1964 CH-Fuel & ExhaustJose LaproviteraNo ratings yet

- 15 1964 CH-Heater & AccDocument59 pages15 1964 CH-Heater & AccJose LaproviteraNo ratings yet

- 09 1964 CH-Electrical SystemsDocument52 pages09 1964 CH-Electrical SystemsJose LaproviteraNo ratings yet

- 03 1964 CH-Frame & SuspDocument4 pages03 1964 CH-Frame & SuspJose LaproviteraNo ratings yet

- Kubota D1105 V1505 Operators ManualDocument108 pagesKubota D1105 V1505 Operators ManualJose LaproviteraNo ratings yet

- Deutz Parts Catalogue - BAM Parts TurkeyDocument140 pagesDeutz Parts Catalogue - BAM Parts TurkeyJose LaproviteraNo ratings yet

- Ada Motor MWM ArosDocument1 pageAda Motor MWM ArosJose LaproviteraNo ratings yet