Professional Documents

Culture Documents

Geh-1702a Type LC, U High Voltage Bushings

Geh-1702a Type LC, U High Voltage Bushings

Uploaded by

Bruno Samos0 ratings0% found this document useful (0 votes)

26 views24 pagesOriginal Title

GEH-1702A TYPE LC, U HIGH VOLTAGE BUSHINGS

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views24 pagesGeh-1702a Type LC, U High Voltage Bushings

Geh-1702a Type LC, U High Voltage Bushings

Uploaded by

Bruno SamosCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 24

FIce

INSTRUCTIONS GEH-1702A

HIGH VOLTAGE BUSHINGS

TYPE K

AND

TYPE U

GENERAL @@ ELECTRIC

CONTENTS

GENERAL INSTRUCTIONS. . «

INTRODUCTION. ........

SHIPPING AND UNPACKING... esse eeeeeeeeeeeree

STORAGE. eee esses eeeeeeeee

INSTALLATION. ....- acne

ELECTRICAL CONNECTIONS (Intemal). .

ELECTRICAL CONNECTIONS (External)... +-..--0+

INSTRUCTIONS FOR SPECIFIC TYPES OF BUSHINGS. .......

TYPE LC BUSHINGS. ...+. 4+

SHIPPING-STORING. «++. +++

TYPE U BUSHINGS. ......++45

SHIPPING.

HANDLING

EXAMINATION, ess eeseeeeeeeeees

STORAGE. ....

INSTALLATION.

SERVICE. . «

@ HIGH VOLTAGE BUSHINGS

TYPE LC AND TYPE U

GENERAL INSTRUCTIONS

e INTRODUCTION

Years of experience in the design and .

manufacture of thousands of sealed bushings

have been incorporated in the Type LC bush«

ing for circuits up to and including 69 kv,

and in the Type U bushing for circuits 69 kv

and above.

The Type LC bushing illustrated in Figs. ‘

Land 2 is a modification of the Type L bush- RaHcsL gt

ing and is designed to incorporate simplified

construction and reduced physical dimen

sions for this voltage range. These bushings

8 are interchangeable with the flange-clamped

Fig. 2. Circuit breaker bushing Type LC rated

25 kv, 1200 amperes

Type L bushing and retain all of their proved

e operating characteristics. Elimination of the

cemented on clamping rings permits a reduc-

tion in the over-all height of the bushing

above the apparatus cover, Because of this

height reduction, the replacement of a flange-

clamped Type 'L bushing with a center-

clamped Type LC bushing may in some cases,

require shortening of the detachable cable

conductor on 400 ampere transformer bush-

ings, and likewise lengthening of the line

lead connections.

3 The Type U bushing illustrated in Figs. 3

Fig. 1. Transformer bushing Type LC rated 25kv, and 4 is a hermetically sealed bushing the

400 amperes design of which permits appreciable reduc-

GEH-1702A High-Voltage Bushings Type LC and U

Fig. 3. Transfomer bushing Type U rated 115 ky,

{800 amperes!

tions in physical dimensions and weight over

the Type F bushing while retaining all of

the superior features and operating charac

teristics of the latter.

SHIPPING AND UNPACKING

General Electric bushings, after being care-

fully tested, inspected and packed are

shipped ready for installation. Bushing crates

or boxes should always be opened carefully

to avoid damage to the bushings.

Immediately upon receipt, the bushing or

bushings should be examined for any damage

sustained in transit. If injury or rough han-

dling is evident, a damage claim should be

filed with the carrier and the nearest General

Electric Apparatus Sales Office notified.

STORAGE

In general, all bushings should be stored

in a clean dry place and preferably in an up-

right position. Type U bushings shipped ver-

tically in crates may be stored outdoors as

received. All Type LC bushings as well

4

188

YW

Figs 4s Gircuit-breaker bushing Type U rated 115 kv

as Type U bushings which were shipped

horizontally, should be prepared for installa-

tion or storage immediately upon receipt as

explained later in this publication under the

heading of the specific type of bushing

involved.

INSTALLATION

All bushings, as soon as unpacked and in

spected for damage, should be wiped clean

Fig. 5+ Details of top end of 400-ampere Type LC

= transformer bushing

High-Voltage Bushings Type LC and Type U GEH-1702A

®.

Fig. 6 Details of top end of 800-ampere Type U

‘transformer bushing

and dry. Instructions regarding the installa-

tion of the Type 1.C and Type U bushings

appear later in this publication under the

heading of the specific type of bushing

involved.

ELECTRICAL CONNECTIONS

(INTERNAL)

Internal connections between a bushing

and the apparatus on which it is mounted are

made in one of two ways as follows:

1. By means of a detachable cable con-

ductor placed inside the central tube of the

bushing with one end connected to a terminal

stud at the top of the bushing, This construc

tion is illustrated in Fig. 5 for Type LC

bushings and in Fig. 6 for Type U bushings.

This detachable flexible cable conductor

with terminal stad attached is usually in-

cluded as an integral part of the parent ap-

paratus with which the bushing is to be used.

To assemble the bushing to the parent ap-

paratus, remove the terminal cap (TI), steel

pin (16) and spare (shipping) stud (T5). Pass

a wire ot cord down through the bushing tube

and attach it to the hole in the top end of

the terminal stud on the apparatus cable.

Lower the bushing into opening of the ap-

paratus cover and at the same time draw the

cable up through the tube by means of the

wire or cord. Secure the cable terminal stud

Fig. 7. Details of top end of 1200-ampere Type LC

circuit-hreaker bushing

to the top cap by feplacing the steel pin

(16), After the terminal cap gasket (T2) has

been coated with a thin film of light oil and

placed in position, screw the terminal cap

onto the cable terminal stud and tighten until

the outside rim of the terminal cap makes a

metal-to-metal seat on the bushing cap. Ex-

cessive tightening should be avoided as this

only tends to bead the steel pin.

2. By connection to a fixed conductor.

Bushings having a fixed conductor (where

the central tube or rod is utilized as @ con-

ductor) as illustrated in Fig. 7 for Type LC

bushing and Fig. 8 for Type U bushing, are

mounted on the parent apparatus cover and

Figs 8. Details of 1200-ampere Type U circuit

breaker bushing

4

GEH-1702A High-Voltage Bushings Type LC and Type U

internal connection made to the bottom ter

minal of the bushing.

ELECTRICAL CONNECTIONS

( EXTERNAL)

Connections from the line to the top ter-

minal of the bushing should be tight and

INSTRUCTIONS FOR SPEC

TYPE LC BUSHINGS

SHIPPING AND STORING

‘Type LC bushings of which Figs. 1 and 2

are typical, are shipped in a vertical posi«

tion in suitably designed shipping containers

to assure ample protection against normal

transportation hazards. These bushings

should be kept in a clean dry place whether

in storage or while awaiting installation. If

during transportation, the Herkolite* exten-

sion below the ground sleeve has been ex:

posed to rain ot snow, it should be imme-

diately wiped dry. In such cases surface dry-

ing only is required. For convenience in

handling and to afford maximum protection

against damage Type LC bushings may be

stored in the shipping containers in which

they are received.

TYPE U BUSHINGS

SHIPPING

Individual bushings are usually shipped

horizontally in excelsior lined crates. Bush-

ings shipped in groups of three to six inclu-

sive are carefully packed in crates and are

shipped vertically. Figs. 3 and 4 illustrate

vypical Type U bushings.

HANDLING

Bushings Rated 69 or 73 KV

Only bushings rated 69 kv or 73 kv may be

lifted from the horizontal position or removed

from a vertical crate by use of a rope sling

placed under the top petticoat of the top

porcelain.

‘Registered trade-mark of O-B Compeny

made so that they will not loosen in service

and will not produce stresses which would

tend to cause damage to the bushing. There

should be sufficient flexibility in the line

connections to prevent mechanical stresses

from expansion or contraction, or from wind

sway. Long spans of unsupported conductor,

especially if outdoors, should be avoided.

IFIC TYPES OF BUSHINGS

Bushings Rated 92 KV and up

Bushings rated above 73 kv are provided

with integrally cast lifting eyes in the sup-

port flange. Considerations of weight and

general physical dimensions require that

when lifting Type U bushings of these rat-

ings from the horizontal position or removing

from vertical crates, the main lifting tackle

should always be attached to the lifting eyes

in the support flange. An auxiliary tackle

between the main lifting medium, and a rope

“collar” around the top of the porcelain and

under the top petticoat, enables the handler

Fig. 9. Method of lifting bushings equipped with

lifting eyes

to raise the bushing to a vertical position

without damage. The auziliary tackle serves

only to guide the bushing or hold it to a ver

tical position, or to any desired angle from

the vertical. See Fig. 9.

EXAMINATION

Upon receipt, and with the bushing in a

vertical position, the level of the insulating

liquid as indicated by the oil-level gage

should be noted. With the bushing tempera-

ture in the range of 20-25 C, the indicating

pointer should indicate approximately normal

ail level. The surfaces of the porcelain

should be observed for indications of broken

porcelain, which would cause leakage but

would be too small to affect the oil-level

gage.

STORAGE

Type U bushings shipped vertically may

be stored out of doors as received. Place

Type U bushings, which are shipped hori-

zontally in boxes, in a vertical position as

soon as possible and store with top end up

as shown in Fig, 10. In handling the larger

bushings it may be advisable to remove them

from their crates before storing in a vertical

position.

Bushings in storage should be located in

a place where there is no danger of breakage:

Fig. 10, Method of storing boxed bushing

Fig. 11. Bushing with capacitance tap

INSTALLATION

When mounting Type U bushings in the

parent apparatus, either in a vertical posi-

tion or at an angle with the vertical, the

same manner of handling should be used as

described above for the respective ratings.

All Type U bushings, when mounted at an

angle with the vertical, should be assembled

with the oil-level gage at the lowest point to

insure proper oil-level indication.

Bushings should be wiped clean and dry

when being installed.

When assémbling a bushing onto the ap-

paratus cover, the attaching bolts should be

tightened a fraction of a turn at a time, pro-

gressively, in one direction until the bolts

are uniformly tight.

If it becomes necessary to energize a

Type U bushing which has been in a hori-

zontal position within 48 hours, the bushing

should be gently rocked to release any en-

trapped gas or air which may have lodged in

the insulating structure,

Capacitance Tap

Standard Type U bushings have a capaci~

tance-tap outlet inside of a small chamber

just above the mounting flange. See Figs. 3,

4 and 11. The capacitance-tap chamber on

‘Type U bushings for application on circuit

breakers are filled with No. 219 compound at

the factory.

When the bushing is to be connected to a

potential device, first open the capacitance-

7

GEH-1702A High-Voltage Bushings Type LC and Type U

tap chamber by unscrewing the plug-like

cap, using 2 suitable container to catch the

small amount of No. 219 compound in the

chamber, Assemble the potential-device cable

tighdy in place. Remove the small filling-

hole plug and double-jacketed asbestos

McKim gasket and refill the chamber with

No. 219 compound to a level which willleave

an air space of approximately 1/8 in. over

the liquid. The sealing plug and gasket

should then be replaced, and securely tight-

ened to prevent the entrance of moisture.

The capacitance-tap chamber on Type U

bushings for application on transformers is

not filled since in such applications the

capacitance tap is used principally for power-

factor testing, and this outlet therefore

needs no further attention.

SERVICE

Type U bushings require little or.ao main-

tenance other than a periodic checking of

the oil-level gage and cleaning of the porce-

lain. In locations where abnormal conditions

prevail such as salt deposits, cement dust,

ete., it should be recognized that a special

hazard exists and the bushings should be

cleaned regularly to avoid accumulations on

the extemal surfaces which might cause

flashover.

TRANSFORMER AND ALLIED PRODUCTS DIVISION

GENERAL @@ ELECTRIC

PITTSFIELD, MASSACHUSETTS

53200

‘Siperseden CEH-1702 ancl OM-ASG64

it ia UAL

INSTRUCTIONS GEH-1702B

HIGH VOLTAGE BUSHINGS

TYPE u

AND

TYPE U

GENERAL @@ ELECTRIC

CONTENTS e@

Page

HANDLING... .

EXAMINATION, ... 555

STORAGE. ....

INSTALLATION. .. «

SERVICE. e+e eseeeeeuee

GENERAL INSTRUCTIONS. «02.0 eee v eee e erence eee eee eae eeees 3

INTRODUCTION Ess istttteesuiei velco ea ieintoranisttrieadeit elaine

SHIPPING AND UNPACKING. . . - Pare ete eee

STORAGE. itty eee re ante eit eetae 4

INSTALLATIONS estes aisttceidtn rca ristredsiite 4

ELECTRICAL CONNECTIONS (Internal)... 04.0 eee ee 5

ELECTRICAL CONNECTIONS (External). eee alte 6

INSTRUCTIONS FOR SPECIFIC TYPES OF BUSHINGS. .... +++ 6

SEEPE UG BUSHINGS cit fiero circ nntrerstant eerie 6

SHIPPING-STORING. ees eee cence teeter ener ee 6

TYPE U BUSHINGS. .........04. ifeceeepee este 6

SHIPPING. ... ea eet ‘6

6

7

7

7

8

ett re or ol dl ro espn epi eu lg cl ih in pen

e HIGH VOLTAGE BUSHINGS

TYPE LC AND TYPE U

GENERAL INSTRUCTIONS

INTRODUCTION

Years of experience in the design and

manufacture of thousands of sealed bushings

have been incorporated in the Type LC bush-

ing for circuits up to and including 69 kv,

and in the Type U bushing for circuits 69 kv

and above,

The Type LC bushing illustrated in Figs.

Land 2 is a modification of the Type L bush- =

ing and is designed to incorporate simplified

canstruction and reduced physical dimen-

sions for this voltage range. These bushings

8 are interchangeable with the flange-clamped 4

i

;

Fig. 2. Circuit breaker bushing Type LC rated

25 kv, 1200 amperes

‘Type L bushing and retain all of their proved

operating characteristics. Elimination of the

cemented on clamping tings permits a reduc

tion in the over-all height of the bushing

above the apparatus cover. Because of this

height reduction, the replacement of a flange-

clamped Type L bushing with a center

clamped Type LC bushing may in some cases,

require shortening of the detachable cable

conductor on 400 ampere transformer bush

ings, and likewise lengthening of the line

, lead connections.

The Type U bushing illustrated in Figs. 3

Fig. L. ‘Transformer bushing Type LC rated 25 kv, ad 4 is a hermetically sealed bushing the

400 amperes design of which permits appreciable reduce

GEH-1702B High-Voltage Bushings Type LC and Type U

Fig. 3+ Transformer bu

ing Type U rated 115 ky,

{00 amperes

tions in physical dimensions and weight over

the Type F bushing while retaining all of

the superior features and operating charac-

teristics of the latter.

SHIPPING AND UNPACKING

General Electric bushings, after being care-

fully tested, inspected and packed are

shipped ready for installation. Bushing crates

or boxes should always be opened carefully

to avoid damage to the bushings.

Immediately upon receipt, the bushing or

bushings should be examined for any damage

sustained in transit. If injury or rough han-

dling is evident, a damage claim should be

filed with the carrier and the nearest General

Electric Apparatus Sales Office not

STORAGE

In general, all bushings should be stored

in a clean dry place and preferably in an up-

right position. Type U bushings shipped ver

tically in crates may be stored outdoors as

received. All Type LC bushings as well

4

Fig. dy Cireuit-breaker bushing Type U rated 115 kv

as Type U bushings which were shipped

horizontally, should be prepared for installa-

tion or storage immediately upon receipt as

explained later in this publication under the

heading of the specific type of bushing

involved.

INSTALLATION

AI] bushings, as soon as unpacked and in-

spected for damage, should be wiped clean

Fig, 5. Details of top end of 400-ampere Type LC

transformer bushing

High-Voltage Bushings Type LC and Type U_GEH-17028

y

Fig. 6. Details of top ond of 800-ampere Type U

“ Teanafomer bushing

and dry. Instructions regarding the installa-

tion of the Type LC and Type U bushings

appear later in this publication under the

heading of the specific type of bushing

involved.

ELECTRICAL CONNECTIONS

(INTERNAL)

Internal connections between a bushing

and the apparatus on which it is mounted are

made in one of two ways as follows:

1. By means of a detachable cable con-

ductor placed inside the central tube of the

bushing with one end connected to a terminal

stud at the top of the bushing. This construc-

tion is illustrated in Fig. 5 for Type LC

bushings and in Fig. 6 for Type U bushings.

This detachable flexible cable conductor

with terminal stud attached is usually in-

cluded as an integeal part of the parent ap-

paratus with which the bushing is co be used.

To assemble the bushing to the parent ap-

paratus, remove the terminal cap (Tl), steel

pin (T6) and spare (shipping) stud (T5). Pass

a wire or cord down through the bushing tube

and attach it to the hole in the top end of

the terminal stud on the apparatus cable.

Lower the bushing into opening of the ap-

paratus cover and at the same time draw the

cable up through the tube by means of the

wire or cord. Secure the cable terminal stud

Fig. 7. Details of tp end of 1200-anpere Type LG

e circuit breaker bushing,

to the top cap by replacing the steel pin

(16). After the terminal cap gasket (T2) has

been coated with a thin film of light oil and

placed in position, screw the terminal cap

onto the cable terminal stud and tighten until

the outside rim of the terminal cap makes a

metal-to-metal seat on the bushing cap. Ex-

cessive tightening should be avoided as this

only tends to bend the steel pin.

2. By connection to a fixed conductor.

Bushings having a fixed conductor (where

the central tube or rod is utilized as a cone

ductor) as illustrated in Fig. 7 for Type LC

bushing and Fig. 8 for Type U bushing, are

mounted on the parent apparatus cover and

1——_4

Ny

72

CEES

i<

As

Figs 8 Details of 1200-ampere Type U circuite

breaker bushing,

GEH-1702B High-Voltage Bushings Type LC ond Type U

internal connection made to the bottom ter

minal of the bushing.

ELECTRICAL CONNECTIONS

( EXTERNAL}

Connections from the line to the top ter

minal of the bushing should be tight and

made so that they will not loosen in service

and will not produce stresses which would

tend to cause damage to the bushing. There

should be sufficient flexibilicy in the line

connections to prevent mechanical stresses

from expansion or contraction, or from wind

sway. Long spans of unsupported conductor,

especially if outdoors, should be avoided.

INSTRUCTIONS FOR SPECIFIC TYPES OF BUSHINGS

TYPE LC BUSHINGS

SHIPPING AND STORING

‘Type LC bushings of which Figs. 1 and 2

are typical, are shipped in a vertical posi

tion ia suitably designed shipping containers

to assure ample protection against normal

transportation hazards. These bushings

should be kept in a clean dty place whether

in storage or while awaiting installation. If

during transportation, the Herkolite* exten-

sion below the ground sleeve has been ex-

posed to rain or snow, it should be imme-

diately wiped dry. In such cases surface dry-

ing only is required. For convenience in

handling and to afford maximum protection

against damage Type LC bushings may be

stored in the shipping containers in which

they are received.

TYPE U BUSHINGS

SHIPPING

Individual bushings are usually shipped

horizontally in excelsior lined crates. Bush-

ings shipped in groups of three to six inclu-

sive are carefully packed in crates and are

shipped vertically. Figs. 3 and 4 illustrate

typical Type U bushings.

HANDLING

Bushings Rated 69 or 73 KV

Only bushings rated 69 kv or 73 kv may be

lifted from the horizontal position or removed

from a vertical crate by use of a rope sling

placed under the top petticoat of the top

porcelain.

‘Registered trade-nark of G- Company

‘6

Bushings Rated 92 KV ond op

Bushings rated above 73 kv are provided

with integrally cast lifting eyes in the sup-

port flange. Considerations of weight and

general physical dimensions require that

when lifting Type U bushings of these rate

ings from the horizontal position or removing

from vertical crates, the main lifting tackle

should always be attached to the lifting eyes

in the support flange. An auxiliary tackle

between the main lifting medium, and a rope

“collar”? around the top of the porcelain and

under the top petticoat, enables the handler

Fig. 9, Method of lifting bushings equipped with

lifting eyes

High-Voltage Bushings Type LC and Type U_GEH-17028

to raise the bushing to a vertical position

without damage. The auxiliary tackle serves

only to guide, the bushing or hold it to a ver

tical position, or to any desired angle from

the vertical. See Fig. 9.

EXAMINATION

Upon receipt, and with the bushing in a

vertical position, the level of the insulating

liquid as indicated by the oil-level gage

should be noted. With the bushing tempera

tuse in the range of 20-25 C, the indicating

pointer should indicate approximately normal

cil level. The surfaces of the porcelain

should be observed for indications of broken

porcelain, which would cause leakage but

would be too small to affect the oil-level

gage.

STORAGE

Type U bushings shipped vertically may

be Stored out of doors as received. Place

Type U bushings, which are shipped hori

zontally in boxes, in a vertical position as

soon as possible and store with top end up

as shown in Fig. 10. In handling the larger

bushings it may be advisable to remove them

from their crates before storing in a vertical

position.

Bushings in storage should be located in

a place where there is no danger of breakage.

» 10. Method of storing boxed bushing

Pig. 11. Bushing with capacitance tap

INSTALLATION

When mounting Type U bushings in the

parent apparatus, either in a vertical posi-

tion or at an angle with the vertical, the

same manner of handling should be used as

described above for the respective ratings.

All Type U bushings, when mounted at an

angle with the vertical, should be assembled

with the oil-level gage at the lowest point to

insure proper oil-level indication.

Bushings should be wiped clean and dry

when being installed.

When assembling a bushing onto the ap-

paratus cover, the attaching bolts should be

tightened a fraction of a turn at a time, pro-

gressively, in one direction until the boles

are uniformly tight.

lf it becomes necessary to energize a

Type U bushing which has been in a hori-

zontal position within 48 hours, the bushing

should be gently rocked to release any en=

trapped gas or ait which may have lodged in

the insulating structure.

Capacitance Top

Standard Type U bushings have @ capaci=

tance-tap outlet inside of a small chamber

just above the mounting flange. See Figs. 3,

4 and 11, The capacitance-tap chamber on

Type U bushings for application on circuit

breakers are filled with No. 219 compound at

the factory.

When the bushing is to be connected to a

potential device, first open the capacitances

q

GEH-1702B High-Voltage Bushings Type LC and Type U

tap chamber by unscrewing the plug-like

cap, using a suitable container to catch the

small amount of No. 219 compound in the

chamber. Assemble the potential device

cable tightly in place. Remove the Lok-Thred

filling plug* and fill the chamber with No.

219 compound to a level which will leave an

air space of approximately 1/8 in. over the

liquid. Replace and securely tighten the fill-

ing plug to prevent the entrance of moisture.

On bushings previously equipped with fill-

ing plug and double-jacketed McKim gaskets,

use anew McKim gasket when replacing the

plug.

The capacitance-tap chamber on Type U

* Product of National Screw & Mg. Co.

bushings for application on transformers is

not filled since in such applications the

capacitance tap is used principally for power

factor testing, and this outler therefore

needs no further attention.

SERVICE

Type U bushings require little or no maine

tenance other than a periodic checking of

the oil-level gage and cleaning of the porce-

lain, In locations where abnormal conditions

prevail such as salt deposits, cement dust,

ete., it should be recognized that a special

hazard exists and the bushings should be

cleaned regularly to avoid accumulations on

the external surfaces which might cause

flashover.

POWER TRANSFORMER DEPARTMENT

GENERAL @@ ELECTRIC

PITTSFIELD,

83 4500)

MASS.

‘Supersedes GEH-IT02A and GELIS664

tho to USA.

GEH-1702

INSTRUCTIONS

HIGH-VOLTAGE

BUSHINGS

Type U

GENERAL @@ ELECTRIC

FOREWORD

IN ADDITION to the instructions contained herein on unpack

ing, handling, installation and storage of Type U bushings for

operation on oil-filled apparatus, the following publications,

covering other Types of General Electric bushings are avail-

able, and will be supplied upon request to the nearest sales

office of the General Electric Company.

Instructions for Type F bushings for operation on oil-filled

apparatus are contained in GEH-1329.

Instructions for Type F bushings for operation with both

ends in air are contained in GEI-32331.

Application information (such as interchangeability of new

and old bushings and of bushings on different classes of ap-

paratus) on Type L and Type OF bushings is contained in ap-

plication Bulletins GET-906 and GET-907.

Operating information on inspection, testing and maintenance

of Types A,B,L, and OF bushings will be found in GET-908.

Dimensions and a description of the construction of standard

Type L bushings will be found in GEA+2513,

Dimensions and a description of the construction of standard

‘Type OF bushings will be found in GEA-2514.

Ordering information on bushings, accessories, and parts for

all types of bushings, see Publication GEA-3949.

alan operate of

‘ese tnotructine do not purport t cover all dates o« var

“Shicnuate, sould ther moron be dgstes or shows porticalar Br

‘re not covered sufticlenly forthe parciaect’s purposes, Ihe atier should be We

(Goneeat Eletic Company.

HIGH-VOLTAGE BUSHINGS

TYPE U

INTRODUCTION

Years of experience in the design and

manufacture of thousands of sealed bushings

has been incorporated in the Type U pres

sure-tight bushing. Successful operation, and

longer and more economical service will be

obtained by adhering closely to the rec-

ommended methods of unpacking, handling,

installing, and storing of these bushings as

outlined herein.

SHIPPING AND UNPACKING

HANDLING

General Electric bushings, after being

carefully tested, inspected, and packed, are

shipped ready for installation. Bushing crates

or boxes should always be opened carefully

to avoid damage, particularly to the porce-

lain of the bushings. See Fig. 1.

Individual bushings are usually shipped

horizontally in excelsior lined crates, Bush-

ings shipped in groups of three to six in-

clusive are carefully packed in crates and

are shipped vertically.

Bushings Rated 69 or 73 KV

Only bushings rated 69 kv or 73 kv may be

lifted from the horizontal position or re~

moved from a vertical crate by use of a rope

sling placed under the top petticoat of the

top porcelain.

Bushings Rated 92 KV and up

Bushings tated above 73 kv are provided

with integrally cast lifting eyes in the sup-

port flange. Considerations of weight and

general physical dimensions require that

when lifting Type U bushings of these rat=

ings from the horizontal position or removing

from vertical crates, the main lifting tackle

should always be attached to the lifting

eyes in the support flange. An auxiliary

tackle between the main lifting medium, and

a rope ‘collar’ around the top of the porce-

lain and under the top petticoat, enables the

handler to raise the bushing to a vertical

position without damage. The auxiliary tackle

Fig 1

serves only to guide the bushing or hold it

to a vertical position, or to any desired

angle from the vertical. See Fig. 2.

EXAMINATION

Upon receipt, and with the bushing in a

vertical position, the level of the insulating

liquid as indicated by the oil-level gage

should be noted. With the bushing tempera~

ture in the range of 20-25 C, the indicating

pointer should indicate approximately normal

oil level. The surfaces of the porcelain

should be observed for indications of broken

porcelain, which would cause leakage but

would be too small to affect the oil-level

gage.

STORAGE

Type U bushings shipped vertically may

be stored out of doors as received. It is ree~

ommended that, where size permits, bushings

shipped horizontally in boxes be placed in a

vertical position as soon as possible as

shown in Fig. 3. In handling the larger bush-

ings it may be advisable to remove them from

their crates before storing in a vertical

position.

Bushings in storage should be located in

a place where there is no danger of

breakage.

INSTALLATION

When mounting Type U bushings in the

parent apparatus, either in a vertical posi-

Type U High-Voltage Bushings GEH-1702

Fig 2

tion or at an angle with the vertical, the

same manner of handling should be used as

described above for the respective ratings.

All Type U bushings, when mounted at an

angle with the vertical, should be assembled

with the oil-level gage at the lowest point to

insure proper oil-level indication.

Bushings should be wiped clean and dry

when being installed.

When assembling a bushing onto the ap

paratus cover, the attaching bolts should be

tightened a fraction of a turn at a time, pro-

gressively, in one direction until the bolts

are uniformly tight.

If it becomes necessary to place Type U

bushings into service which have been

shipped or stored horizontally or to apply

high potential test thereto, and where the

bushing is to be energized within 48 hours,

the bushing should be gently rocked to re~

lease any entrapped gas or air which may

have lodged in the insulating structure dur-

ing such shipping or storage,

ELECTRICAL CONNECTIONS

INTERNAL

Connections between a bushing and the

apparatus on which it is mounted are made

in one of two ways,

4

1. By means of a detachable cable con-

ductor passing up through the central tube of

the bushing and connected inside of the top

end of the bushing as illustrated in Fig. 4.

2. When the tube or rod of the bushing is

used as the conductor, the connection is

made directly to a tetminal at the bottom of

the bushing. In this type of connection, the

top of the bushing is in accordance with

Fig. 5.

When installing a bushing of this type,

first bolt the bushing to the apparatus cover,

and then make the connection to the terminal

of the bushing. Care should be taken to

avoid mechanical stresses being imposed on

the bushing during assembly of connections.

Connections must be made in such a manner

that no constant strain will be applied after

assembly.

ja

peo

Fig 3

JN.

Fig. 4

EXTERNAL

Detachable Conductor Bushings

The detachable cable with cable terminal

studs attached is usually included as an in~

tegral part of the apparatus on which the

bushing is to be installed.,

When making connections on a detachable

conductor bushing, top end of which is shown

in Fig. 4, remove terminal cap TI, steel pin

T6, and spare stud TS from the bushing.

Then pass a wire or cord down through the

bushing tube, and attach it to the hole in

the top of the cable terminal stud, which is

attached to the apparatus cable. The bush-

ing should then be lowered into the opening

in the apparatus cover. At the same time

draw the cable up through the tube by means

of the wire or cord. The cable terminal stud

should then be secured to the top cap by re-

placing the steel pin T6.

After the terminal cap gasket T2 has been

coated with a thin film of oil and placed in

position, the terminal cap T1 should be

screwed on the cable terminal stud and

tightened in place, until the outside rim of

the cap makes a fim metal-to-metal seat on

the bushing cap. Tightening beyond this

point only tends to bend che steel pin and is

unnecessary.

Type U High-Voltage Bushings GEH.1702

Fig. 5

Fixed Conductor Bushings

Bushings with conductors which are in-

tegral parts of the bushings have a terminal

cap as shown in Fig. 5, and need not be

removed.

EXTERNAL LINE CONNECTION

When connecting the bushings to the line

or extemal circuit, care should be taken to

assure that the connections from the line to

the top bushing terminal are tight. The line

connection must not impose any strain on

the terminals which will cause the contact

joints to become loose, Sufficient flexibility

and short spans in the connecting leads

should be provided to avoid mechanical

strain due to expansion or contraction of the

line or from wind sway, which might damage

the bushing.

CAPACITANCE-TAP BUSHINGS

Type U bushings have a capacitance-tap

outlet inside of a small chamber just above

the mounting flange. See Fig. 6. The bush-

ing is the same as shown on the cover page.

If the bushing is co be operated without con-

nection to a potential device, this outlet

needs no further attention.

When the bushing is to be connected to a

potential device, first open the capacitance-

tap chamber by unscrewing the plug-like cap

5

GEH-1702 Type U High-Voltage Bushings

and assemble the potential-device cable

tightly in place. Remove the small filling

hole plug and double-jacketed asbestos

McKim gasket and fill the chamber with No.

219 compound to a level which will leave an

air space of approximately 4 in. over the

liquid, The sealing plug and gasket should

then be replaced, and securely tightened to

prevent the entrance of moisture.

SERVICE

Type U bushings require little or no main

tenance other than a periodic checking of

the oil-level gage and cleaning of the por

celain. In locations where abnormal condi:

tions prevail such as salt deposits, cement

dust, etc. it should be recognized that a

special hazard exists and the bushings

should be cleaned regularly to avoid accu-

mulations on the external surfaces which

might cause flashover.

IF YOU REQUIRE SERVICE

IF AT ANY TIME you fied it necessary to repair, recondition, or rebuild your G-E apparctus, there are 30 GE service shops

‘whose faclties are available day and wight for work in the shops oF On Your premises, Factory methods and genuine G-E

renewal ports are vied to mainlain the original performance of your G-E apparatus. W youneed parts oly, immediate

shipment of many items can be made from warehowse stock

The services of our factories, engineering divisions, and sales offices ore clio avcilable to assist you with engineering

problems. For ful information obout thase services, cantoct the nearest service shop of soles office ated below:

APPARATUS SERVICE SHOPS

sueio 11.6, 318 Wen

(hereon 28, W.Va.36 Macca amy

Grerone "00 thet food

Sheage #0. 5695 into Se

Encnet 2, Ob “a We Sh

Eivelond 4 Ohs,. 4968 Wondlond Aen

‘lens 15, 213 conn St

Dall 9, Tomas 3202 Novos Wey

Denver coo, 3959 toner Sh

Devt 2; ch 3580 hed Ave

Howon 20 Taras 3554 Haey Winen Orie

Jian, aeons

aes Ory sive om se

er Angelos eth, 60 Stentor Ww

Mibwaukee 9 Whe.” 940W 6 Fas va

‘Maveapotn 12, ina 2025 40 Ave A

Now vore iat ais W. 138 3

inde, Pe... aa 1 Savonth Sh

Png 6, Ps “59 Bean hon

Partacd 18; rosea Son Franco 2, Cel... 1OR8Hanibon Sh Tole 4, Ob 1 So. 8. dak

Remand 24, V0 Sai Late Chy & Uoh 301 ,Seronm West Sons Par .N orrion St

‘St os 10, Me Stoie work ‘REED Fw re, 8. Younghown 5, Ohio. 272 Indra Ae.

APPARATUS SALES OFFICES

sion 8, Ob 395 5 Moles ey $k argh 22, Po.

‘ison 7.9 93 Sate Se we Fenton 3, ware

‘oquerate Nex hs i &

‘ttown 1084 Honiton Tau rn

Jaren. {Joo Fok 330 yates

Ieptetn Wine” "S81 W Coleg tou Sik. Sah

bes, a! 1 Spring Ses (restora Ave Edy, — Rcbmand Wf; Vacs 2700 rnin

posutas s, he iam SG0.N Seard $end, Ca

‘Ao sys 8, Rosnoke 6, Vo

i312 the Oat St Recrmters NY, Se he.

N10 Nritnos St Recfrd Lie en

85 Caer ae ABO Wostigen Ave Rand 30M Canter St

19 chenengo i 2D3 Wen captel Sacramental. 86 Fores Bang

‘sod Seyest ve, Jecaom 2 300 € Union St Scginne eh 317 bearnger tag

Sapestonn Yo. Bor 48,2 Second Sh 113 Na owt

Joon ty, Teme 3217329 W, Wein 8 0 8 man 3

tatoo. ‘io 3 st hry 8

amos Cy 6 ian 108 W, ‘so Hac Sig

‘San hance 6 oli,” 233 Montgomery Se

: Yos'W Aieger St Son Jone, Cle "40? Ban of sca

Sovomah Ge ae yon

ie bach rk, 103 w. Copia ave Suan, Won, Fie ecard he

Ghoonscge' Yeon 632 Georgio ave Lecivile ky: fss's Founh st; Stuur Cy i owe “soy sa 8

Geeoge Oo PS BOL B64 849% Cnat se anon 4 Wie Teneowel st. Sus Fale! S° Dati Subp tee

‘Ecol 7, Gro ‘SW. ed St 17S" St; Soh end Vind. 2 We Jefe te

Spakone 8 Perret

Hams

Seaneld 3 Man

Stoaion cate

i2's'Sam: —Syrocoa 2M

Dolor 2, Tons.

Davenport owe. 348 Je

8. o

x 1208 North &

Bayon 2, One at Tee

Bemer Cot. 74s area 8 ‘0 Madon vo

Bev halses 9 lowe iy hc

Dolan, tl Taw Soper 8 570 Lexinghon va,

Fina, to tain ort Weaelawn aver 253 socond Waning 3, DE.

Een Tosan 109 Oregon 3 229 Webote Waterbury 8%, Conn ne IIT We

fae To's Swelen Sea aera eter or zoe Wit

Esgent, Ove 2p'wetlevenm St Ohlone Gay 2, Gua. IVR Robinson SL Waenang Va ad'tounesnm 3

Ergne 18 fed ss ss12S NW four St Omane'® Nebr <-46? S Sereteces St Waste 2 Rape 20. 0 200 Eh 8

Ferme Var ‘si ease fata ky 331 fourm 3 : ‘cy Mai

21 Wi. ion Sh ‘id Wont

Forges Fal in 369 etaron Bs 307 Ne

aie lia hr

Cencan Goneral Herre Company, Li, Yronte

Hewat W. A. Ramsey, Ltd, Wonciol

‘TRANSFORMER AND ALLIED PRODUCTS DIVISION, GENERAL ELECTRIC COMPANY, PITTSFIELD, MASS.

ast (ato ithe in U.S.A,

e?

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- IEEE STD C62.92.3-2012Document36 pagesIEEE STD C62.92.3-2012Bruno Samos100% (1)

- Panasonic Sa-Ht40p ht40pc SMDocument73 pagesPanasonic Sa-Ht40p ht40pc SMBruno SamosNo ratings yet

- How To Convert Old Substation To A Digital SubstationDocument16 pagesHow To Convert Old Substation To A Digital SubstationBruno Samos0% (1)

- A Case Study of Fault Level Calculations For A MVLV Network Using Direct MethodDocument18 pagesA Case Study of Fault Level Calculations For A MVLV Network Using Direct MethodBruno Samos100% (1)

- My Experience in Drafting The Layout of An LV Switchgear Equipment Inside InstallationsDocument21 pagesMy Experience in Drafting The Layout of An LV Switchgear Equipment Inside InstallationsBruno SamosNo ratings yet

- Generation Plan Map 2Document1 pageGeneration Plan Map 2Bruno SamosNo ratings yet

- Invoice #588323: Date: 01/09/2023Document1 pageInvoice #588323: Date: 01/09/2023Bruno SamosNo ratings yet

- IEEE Recommended Settings For Generator ProtectionDocument7 pagesIEEE Recommended Settings For Generator ProtectionBruno SamosNo ratings yet

- MV 105 5kV8kV Copper v1 7 26 17Document1 pageMV 105 5kV8kV Copper v1 7 26 17Bruno SamosNo ratings yet

- Ag2017-10 20170413Document9 pagesAg2017-10 20170413Bruno SamosNo ratings yet

- CH M80ka23 Spec enDocument1 pageCH M80ka23 Spec enBruno SamosNo ratings yet

- IRP Transmission and Distribution ProjectsDocument24 pagesIRP Transmission and Distribution ProjectsBruno SamosNo ratings yet

- A9R1BBCDocument62 pagesA9R1BBCBruno SamosNo ratings yet

- IEEE Recommended Settings For Generator Protection Ver Nov 09Document3 pagesIEEE Recommended Settings For Generator Protection Ver Nov 09Bruno SamosNo ratings yet

- Ag2015-21 20150512Document20 pagesAg2015-21 20150512Bruno SamosNo ratings yet

- Full Development of Annex A Exercise-J CardenasDocument17 pagesFull Development of Annex A Exercise-J CardenasBruno SamosNo ratings yet

- Simulation Software ComparativesDocument60 pagesSimulation Software ComparativesBruno SamosNo ratings yet

- CCVT and CC - Instruction ManualDocument24 pagesCCVT and CC - Instruction ManualBruno SamosNo ratings yet

- EnergyDocument5 pagesEnergyBruno SamosNo ratings yet

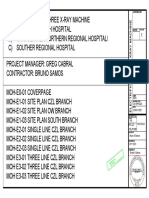

- Moh-Xray MachineDocument13 pagesMoh-Xray MachineBruno SamosNo ratings yet

- ToR - Electrical EngineerDocument4 pagesToR - Electrical EngineerBruno SamosNo ratings yet

- Manualof ProceduresDocument28 pagesManualof ProceduresBruno SamosNo ratings yet

- English Scholarships STR OEA 2021Document10 pagesEnglish Scholarships STR OEA 2021Bruno SamosNo ratings yet

- Advanced Programming and Design For Your Small Machine: Hands-On LabDocument23 pagesAdvanced Programming and Design For Your Small Machine: Hands-On LabBruno SamosNo ratings yet

- Eletrical Power Supply B.M.C.Document7 pagesEletrical Power Supply B.M.C.Bruno SamosNo ratings yet

- Lot For Mr. & Mrs. Jerome Palma: FessionaDocument6 pagesLot For Mr. & Mrs. Jerome Palma: FessionaBruno SamosNo ratings yet