Professional Documents

Culture Documents

Katalog Split Duct York

Katalog Split Duct York

Uploaded by

Musholla BaiturrahimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Katalog Split Duct York

Katalog Split Duct York

Uploaded by

Musholla BaiturrahimCopyright:

Available Formats

R

S PL IT DUCT

MAL - YVL SERIES

MAC - YVC SERIES

R407 - R410A

INSTALL CONFIDENCE WWW.SAM POERNAERKON PRATAMA .CO M

SPLIT DUCT

MAL - YVL SERIES

R-407

Indoor Unit

MAL 75 - 100 MAL 125 - 150

MAL 75 - 100 MAL 125 - 150

Standard Horizontal Air Discharge Vertical Horizontal Air Discharge

Adjustable 3 Fan Speed (Direct Drive) Belt Driven *IE3 Motor (Optional)

Designed ESP 100 Pa Designed ESP 150 Pa

Build in Filter Rack Build in Filter Rack

Outdoor Unit Remote Control

YVL 75 - 150

OPTIONAL

YVL 75 - 100 REMOTE CONTROL

Accumulator Small Wired Controller

High Efficiency Scroll Compressor Cooling Operation Mode

High & Low Pressure Protection (auto/cool/dry/fan)

Phase Reversal Protection Sleep Mode & Independent On-Off Timer

Vertical Air Discharge LCD Display Clock

Horizontal Air Discharge (Optional) Self Diagnostic Function

Aluminium Fin Room Temperature Setting

Coating

www. sa mp oe r n a e r kon p ra ta m a .com 1

SPLIT DUCT

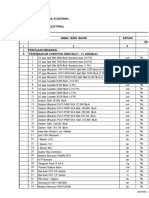

SPECIFICATIONS

Specifica�ons : MAL 75 - 150 / YVL 75 - 150 (50 Hz)

Duct Split (C/L) - 50 Hz

Indoor MAL

Unit 75 100 125 150

Models

Outdoor YVL

Unit 75 100 125 150

Btu/h 75000 10000 125000 150000

Cooling kW 21,98 29,3 36,63 43,95

kcal/h 18901 25202 31502 37802

Nominal Capacities

Btu/h

Heating kW

V/Ph/Hz 380-415/3/50

Power Supply

Ph 3 3 3 3

Power Consumption kW 8,89 11,8 12,64 16,78

Running Current A 16,9 20,7 24,9 27,17

Type N-2

Nitrogen

Precharge psi 100

V/Ph/Hz 380-415/3/50

Power Supply

Ph 1 1 3 3

Forward Curve Centrifugal Forward Curve Centrifugal

Fan Type

Direct Drive Belt Drive

Airflow m3/h 4200 5600 7000 8420

Blower diameter-qty Inch-Ea 9x7-2 10x8-2 15x15-1 15x15-1

Motor quantity Ea 2 2 1 1

Fan

Speed (H/M/L) rpm 1250/1150/980 1250/1150/1050 1400 1400

Input Power W 882x2 982x2 1442 1908

Output Power W 450x2 550x2 1500 1500

Running Current A 6,33 8,8 2,8 3,7

Motor Pulley Type - - B1x3.5" B1x3.5"

Blower Pulley Type - - B1x6.5" B1x6.5"

Material Copper Tube

Indoor unit

Pipe

Diameter mm 9,5

Coil Tube

Material Bluefin Aluminium

Fin Row 4 4 3 4

Fin per Inch 14 14 14 14

Face Area ft2 4,74 6,14 10,23 10,23

Material Electro Galvanized Steel

Casing Finishing Epoxy Polyester Powder Paint

Insulation PE

Height mm 482 550 871 871

Dimension Width mm 1550 1550 1550 1550

Depth mm 762 762 982 982

Gross Weight Kg 126 134 198 206

Air Filter Frame Size (Qty) T'14xH:624xW:340(2Pcs) T'14xH:624xW:442(2Pcs) T'14xH:620xW:762(2Pcs) T'14xH:620xW:762(2Pcs)

Liquid Inch 5/8" 5/8" 5/8" 5/8"

Piping Pipe Size Suction Inch 1-1/8" 1-1/8" 1-3/8" 1-3/8"

Drain Inch 1 1 1 1

Connection Type Brazed

V/Ph/Hz 380-415/3/50

Power Supply

Ph 3 3 3 3

Qty 1 1 1 1

Compressor Type Scroll

Compressor

Capacitor μF

Max. Starting Current A 95 125 125 175

Nominal Current A 16,4 19,2 22,1 24,17

Input Power W 6880 9130 10200 13620

Vibration Insulator Rubber

Protection Device Internal Over Load Protector + Phase Protector

Qty 1 1 1 1

Fan Type/Drive Axial/Direct Drive

Fan Speed rpm 930 930 930 920

Blade Material Aluminium

Fan

Diameter Inch 25 25 25 28

Rated Running Current A 1,6 1,6 1,6 1,9

Outdoor unit

Rated Output W 600 600 600 675

Rated Input W 800 800 800 900

Material Copper Tube

Pipe

Diameter mm 9,5

Coil Tube

Material Goldfin Aluminium

Fin Row 2 2 2 2

Fin per Inch 14 14 14 14

Surface Area ft2 18,95 18,95 18,95 27

Material Electro Galvanized Steel

Casing

Finishing Epoxy Polyester Power Paint

Height mm 944 944 944 1098

Dimension Width mm 900 900 900 1065

Depth mm 970 970 970 1107

Weight (Included Packing) Kg 145 158 166 220

Suction Accumulator Ea 1 1 1 1

Control System High-Low Pressure Auto

Liquid Inch 5/8" 5/8" 5/8" 5/8"

Pipe Size

Piping Suction Inch 1-1/8" 1-1/8" 1-3/8" 1-3/8"

Connection Type Brazed

Refrigerant R407C

Ra�ng Condi�ons Cooling Hea�ng Remarks: The above and specifia�ons are subject to change without prior no�ce for product improvement.

Indoor Temperature 27�C DB/19�C WB 20�C DB/15�C WB

Outdoor Temperature 35�C DB/24�C WB 7�C DB/6�C WB

www. sa mp oe r n a e r kon p ra ta m a .com 2

MAL - YVL

SPLIT DUCT (200-600) SERIES

R-407

Indoor Unit

MAL

MAL

Standard Horizontal Air Discharge

Single Speed Motor & Belt Drive Blower

IE3 Motor (Optional)

Designed ESP

- MAL 200 = 150 Pa

- MAL 250 - 450 = 200 Pa

- MAL 500 = 250 Pa

- MAL 600 = 300 Pa

Multi Condensing Unit Drive

Build in Filter Rack

Convertible Air Discharge at Site

for MAL 125 - 600

Outdoor Unit Remote Control

YVL

YVL 75 - 100 SEQUENTIAL REMOTE CONTROL

Accumulator Wallpad with 7.5m Interconnecting Cable

High Efficiency Scroll Compressor 7 Days Weekly Timer & Day Display

High & Low Pressure Protection TiO2 On-Off & Status Indication

Phase Reversal Protection Error Code Display

Vertical Air Discharge

Alumunium Fin

Coating

www. sa mp oe r n a e r kon p ra ta m a .com 3

SPLIT DUCT

SPECIFICATIONS

Specifica�ons : Ducted Type (MAL 200-600) R-407 50Hz Rev 2

Indoor MAL

Unit 200 250 300 350 400 450 500 600

Models

Outdoor YVL

Unit 100x2 125x2 150x2 125x2+100 100x4 150x3 125x4 150x4

Btu/h 200000 250000 300000 350000 400000 450000 500000 600000

Nominal Capacities Cooling kW 58,62 73,27 87,93 102,58 117,23 131,89 146,54 175,85

kcal/h 50400 63000 75600 88200 100800 113400 126000 151200

V/Ph/Hz 380-415/3/50

Power Supply

Ph 3 3 3 3 3 3 3 3

Power Consumption kW 21,89 25,13 31,97 35,95 42,94 49,45 52,23 66,91

Running Current A 44,92 50,26 56,4 74,5 87,9 86,91 109,3 117,58

Refrigerant Type R407C

V/Ph/Hz 380-415/3/50

Power Supply

Ph 3 3 3 3 3 3 3 3

Capacity Step % 100-50-0 100-50-0 100-50-0 100-71-64-36-29-0 100-75-50-25-0 100-67-33-0 100-75-50-25-0 100-75-50-25-0

Material Electro Galvanized Steel

Casing Finishing Epoxy Polyester Powder Coating

Insulation PE

Blower Material Zinc Coated Steel

Type/Drive Centrifugal/Belt Driven

Blower Size 15-15 18-18 18-18 18-18 500 500 500 560

Blower Pulley Inch 6,5 10 8 12 12 11 13 14

Motor Pulley Inch 4 5,5 4,5 7 5,5 5,5 7 7

Airflow CFM 6400 8000 9000 10500 12000 13500 15000 18000

Fan

ESP Pa 150 200 200 200 200 200 250 300

Motor Type Squirrel Cage Induction

Rated Running Current A 6,52 8,06 8,06 11,1 11,1 14,4 20,9 20,9

Rated Output W 3000 4000 4000 5500 5500 7500 11000 11000

Rated Input W 3628 4728 4728 6418 6418 8591 12429 12429

Motor Poles 4 4 4 4 4 4 4 4

Motor Blower Center mm 320 667 667 856 370 370 340 353

Vertical

V-Belt-Size Inch 41 76 72 97 56 55 58 60

Belt

Motor Blower Center mm 287 618 615 815 298 268 287 382

Indoor unit

Horizontal

V-Belt-Size Inch 39 73 68 94 47 47 54 63

Material Copper Tube

Tube

Diameter mm 9,5

Material Bluefin Aluminium

Thickness 0,11

Coil

Fin Circuit 2 2 2 3 4 3 4 4

Row 4 4 5 4 4 4 5 6

Fin Per Inch 12 14 12 14 14 14 12 12

Face Area ft2 12,06 16,04 17,76 24,65 27,88 27,88 27,88 36,49

Face Velocity m/s 2,69 2,54 2,58 2,17 2,19 2,46 2,73 2,51

Height mm 883 1280 1280 1485 1536 1536 1536 1926

Width mm 1894 1866 1866 2122 2274 2274 2274 2274

Dimension

Depth mm 936 1130 1130 1130 1448 1448 1448 1873

Wooden Casing mm 1025x2050x1080 1445x2016x1355 1445x2016x1355 1650x2277x1355 1715x2404x1630 1715x2404x1630 1715x2404x1630 2115x2450x2030

Control Thermostatic Expansion Valve

Gross Weight Kg 244 368 378 438 556 570 610 920

Noise level dB 68,5 69 71 68 68,5 74 76,5 69

Air Filter Qty Ea 3 6 6 6 8 8 8 12

Air Filter Frame Size (L x H x D) mm 500x722x22 540x527x22 540x527x22 615x627x22 500x655x22 500x655x22 500x655x22 500x572x22

Liquid Inch 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8"

Pipe Size Suction Inch 1-1/8" 1-3/8" 1-3/8" 1-1/8"-1-3/8" 1-1/8" 1-3/8" 1-3/8" 1-3/8"

Drain Inch 1 1 1 1 1 1 1 1

Factory Setting Vertical

Air Discharge Arrangement

Field Setting Vertical/Horizontal

V/Ph/Hz 380-415/3/50

Power Supply

Ph 3 3 3 3 3 3 3 3

Qty 1 1 1 1 1 1 1 1

Compressor Type Scroll

Compressor

Capacitor μF

Max. Starting Current A 125x2 125x2 175x2 125x3 125x4 175x3 125x4 175x4

Nominal Current A 19.2x2 22.1x2 24.17x2 22.1x2 + 19.2 19.2x4 24.17x3 22.1x4 24.17x4

Input Power W 9130x2 10200x2 13620x2 10200x2 + 9130 9130x4 13620x3 10200x4 13620x4

Vibration Insulator Rubber

Protection Device Internal Over Load Protector + Phase Protector

Qty 1 1 1 1 1 1 1 1

Fan Type/Drive Axial/Direct Drive

Fan Speed rpm 930 930 920 930 930 920 930 920

Blade Material Aluminium

Fan

Diameter Inch 25 25 28 25 25 28 25 28

Rated Running Current

Outdoor unit

A 1.6x2 1.6x2 1.9x2 1.6x3 1.6x4 1.9x3 1.6x4 1.9x4

Rated Output W 600x2 600x2 675x2 600x3 600x4 675x3 600x4 675x4

Rated Input W 800x2 800x2 900x2 800x3 800x4 900x3 800x4 900x4

Material Copper Tube

Pipe

Diameter mm 9,5

Coil Tube

Material Goldfin Aluminium

Fin Row 2 2 2 2 2 2 2 2

Fin per Inch 14 14 14 14 14 14 14 14

Surface Area ft2 18,95 18,95 27 18,95 18,95 27 18,95 27

Material Electro Galvanized Steel

Casing

Finishing Epoxy Polyester Power Paint

Height mm 944 944 1098 944 944 1098 944 1098

Dimension Width mm 900 900 1065 900 900 1065 900 1065

Depth mm 970 970 1107 970 970 1107 970 1107

Weight (Included Packing) Kg 158 166 220 158-166 158 220 166 220

Suction Accumulator Ea 1 1 1 1 1 1 1 1

Control System High-Low Pressure Auto

Liquid Inch 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8" 5/8"

Pipe Size

Piping Suction Inch 1-1/8" 1-3/8" 1-3/8" 1-1/8"-1-3/8" 1-1/8" 1-3/8" 1-3/8" 1-3/8"

Connection Type Brazed

Ra�ng Condi�ons Cooling Hea�ng Remarks: The above and specifia�ons are subject to change without prior no�ce for product improvement.

Indoor Temperature 27�C DB/19�C WB 20�C DB/15�C WB

Outdoor Temperature 35�C DB/24�C WB 7�C DB/6�C WB

www. sa mp oe r n a e r kon p ra ta m a .com 4

SPLIT DUCT

MAC - YVC SERIES

R-410A

Indoor Unit

MAC 75 - 100 MAC 125 - 150

MAC 75 - 100 MAC 125 - 150

Standard Horizontal Air Discharge Vertical Horizontal Air Discharge

Adjustable 3 Fan Speed (Direct Drive) Belt Driven *IE3 Motor (Optional)

Designed ESP 100 Pa Designed ESP 150 Pa for MAC 125-200

Build in Filter Rack Designed ESP 200 Pa for MAC 250

Build in Filter Rack

Outdoor Unit Remote Control

YVC 75 - 150

OPTIONAL

REMOTE CONTROL MAC 75 - 100

Small Wired Controller

Cooling Operation Mode

(auto/cool/dry/fan)

Sleep Mode & Independent On-Off Timer

LCD Display Clock

Self Diagnostic Function

Room Temperature Setting

YVC 75 - 100

High Efficiency Scroll Compressor

with Accumulator

High & Low Pressure Protection

Phase Reversal Protection

Vertical Air Discharge SEQUENTIAL REMOTE CONTROL

MAC 200 -250

Horizontal Air Discharge (Optional) Wallpad with 7.5m Interconnecting Cable

Aluminium Fin 7 Days Weekly Timer & Day Display

TiO2 On-Off & Status Indication

Coating Error Code Display

www. sa mp oe r n a e r kon p ra ta m a .com 5

SPLIT DUCT

SPECIFICATIONS

Specifica�ons : MAC 75 - 250 / YVC 75 - 150 R410A 50Hz

www. sa mp oe r n a e r kon p ra ta m a .com 6

MAC - YVC

SPLIT DUCT (300-600) SERIES

R-410A

Indoor Unit

MAC

MAC

Single Speed Motor & Belt Drive Blower

IE3 Motor (Optional)

Designed ESP

- MAC 300 = 200 Pa

- MAC 500 = 250 Pa

- MAC 600 = 300 Pa

Multi Condensing Unit Drive

Build in Filter Rack

Convertible Air Discharge at Site

for MAC 125 - 500

Outdoor Unit Remote Control

YVC

YVC SEQUENTIAL REMOTE CONTROL

High Efficiency Scroll Compressor Wallpad with 7.5m Interconnecting Cable

with Accumulator 7 Days Weekly Timer & Day Display

High & Low Pressure Protection TiO2 On-Off & Status Indication

Phase Reversal Protection Error Code Display

Vertical Air Discharge

Horizontal Air Discharge (Optional)

Aluminium Fin

Coating

www. sa mp oe r n a e r kon p ra ta m a .com 7

SPLIT DUCT

SPECIFICATIONS

Specifica�ons : MAC 300 - 600 R410A 50Hz

www. sa mp oe r n a e r kon p ra ta m a .com 8

KEUNGGULAN YORK

Menggunakan 2 motor dan 2 blower,

sehingga apabila salah 1 motor off atau rusak masih bisa running 1 sistem

Motor dilengkapi dengan 3 kecepatan high, medium dan low.

Fungsi TXV dan distributor (kapiler) untuk mengatur laju aliran refrigerant

distributor mengatur laju refrigerant dengan cara mememcah aliran refrigerant

menjadi beberapa bagian TXV mengatur refrigeran dengan cara menutup dan membuka

aliran refrigerant, dengan sensor bulb

Kelebihan menggunakan TXV karena menggunakan sensor, laju aliran dapat

terkontrol sesuai suhu dikeluaran evap. jadi apabila suhu lingkungan berubah - rubah

aliran refrigrant akan bergerak sesuai kebutuhan. berbeda dengan distributor yang fungsinya hanya

memecah aliran refrigerant saja. jadi apabila suhu lingkungan berubah - rubah aliran refrigerant

akan tetap sama.

Kekurangan distributor �dak dapat menyesuaikan aliran refrigerant

sehingga apabila suhu lingkungan dingin bisa mengakibatkan frezz

Kelebihan Powder Coa�ng :

1. Hasil Warna Lebih Tajam dan Tebal

Teknik Cat Oven Powder Coa�ng akan menghasilkan tampilan warna yang lebih tajam

dan lebih tebal dibandingkan dengan teknik cat lainnya.ketebalan cat yang dihasilkan

oleh teknik lain sekitar 60-80 micron

2. Permukaan Keras

Pada teknik Cat Oven Powder Coa�ng permukaan yang dihasilkan lebih keras,

Hal ini menjadikan perlindungan yang lebih kuat terhadap paparan sinar matahari dan air hujan.

3. Sifat Adhesif Sangat Kuat

Sifat Adhesif adalah kemampuan sebuah molekul tarik menarik dengan dengan molekul yang berbeda jenis.

Nah, hal ini membuat sebuah zat menempel satu sama lain karena molekulnya saling tarik menarik atau merekat.

Kuatnya Sifat Adhesif menyebabkan serbuk powder lebih menyatu dengan permukaan besi.

4. Menutup Pori-Pori Permukaan plat

Proses Cat Oven Powder Coa�ng menghasilkan warna yang tajam dan tebal, hal ini akan membuat pori-pori permukaan

plat tertutup lebih sempurna. Berbeda dengan cat minyak, yang pada jangka waktu tertentu akan terdapat retakan yang

bisa menjadi jalan masuknya air, uap maupun embun. Sehingga elemen tersebut bisa masuk ke pori-pori yang lama kelamaan

akan memicu karat.

www. sa mp oe r n a e r kon p ra ta m a .com 9

KEUNGGULAN YORK

Evaporator pelapis bluefin berfungsi sebagai an� korosidan an� jamur,

sehingga �dak menimbulkan bau pada evaporator. Lapisan bluefin dapat mempermudah mengalirkan

air sisa pendinginan ke drainpan, sehingga pertukaran panas pada

evaporator �dak terganggu.

Fungsi Accumulator:

Mencegah masuknya refrigeran cair masuk ke kompresor dimana jika ikut terkompresi bisa merusak komponen kompresor

Sehingga kompresor lebih terjaga dari masuknya refrigerant cair, karena apabila adanya refrigerant cair yang

masuk ke kompresor akan menyebabkan liquid back.

Condenser pelapis goldfin dapat mencegah karat, korosi,dan menumpuknya kotoran. Sehingga bisa diaplikasikan ditepi pantai

Proses pembersihan yang mudah karena debu dan kotoran dapat mudah terbawa air, sehingga kinerja AC lebih op�mal

Fan terserififikasi AMCA

www. sa mp oe r n a e r kon p ra ta m a .com 1 0

R

AUTHORIZED DISTRIBUTOR

CONTACT US

Jl. Kompleks Rukan Taman Meruya Blok M No. 1-2

Meruya Utara, Kembangan, Jakarta Barat 11620

Phone: +62 21 585 6035

contact@sampoernaerkonpratama.com

www.sampoernaerkonpratama.com

SAMPOERNA

ERKON PRATAMA

You might also like

- Harga ATSDocument3 pagesHarga ATSTama KusumahNo ratings yet

- Precommissioning Check List For Fan Coil UnitsDocument2 pagesPrecommissioning Check List For Fan Coil UnitsSyed ShahbazNo ratings yet

- Rab MDPDocument4 pagesRab MDPkikputririzNo ratings yet

- Desain Cathlab Aster 1, 2017 RDocument16 pagesDesain Cathlab Aster 1, 2017 RHendramawat Aski Safarizki100% (1)

- Grounding Test FormDocument1 pageGrounding Test FormTommy JamesNo ratings yet

- BQ MAXX COFFEE Penawaran MalangDocument2 pagesBQ MAXX COFFEE Penawaran MalangAjie PurnamaNo ratings yet

- Kabel Metal Nyy, Nym, Nya, NyfgbyDocument14 pagesKabel Metal Nyy, Nym, Nya, NyfgbyMitha Wahyu PangestiNo ratings yet

- SLD Plts Hybrid System 3 KW PDFDocument1 pageSLD Plts Hybrid System 3 KW PDFKeanuNo ratings yet

- Insuflex CatalogDocument15 pagesInsuflex Catalogmarceilinus devaluanto100% (1)

- Standarisasi KabelDocument44 pagesStandarisasi Kabeladzan isaacNo ratings yet

- Schneider EZC MCCB PDFDocument13 pagesSchneider EZC MCCB PDFSebastian WenasNo ratings yet

- Acc Bu KokoDocument57 pagesAcc Bu KokoAditya Krisna JayaNo ratings yet

- Cheap Pricelist AC Daikin OK PDFDocument2 pagesCheap Pricelist AC Daikin OK PDFAby ManyuNo ratings yet

- Rencana Anggaran Biaya Dock To Dock: Pekerjaan Pemasangan Central & Instalasi Gas LPGDocument1 pageRencana Anggaran Biaya Dock To Dock: Pekerjaan Pemasangan Central & Instalasi Gas LPGShasa Harihandini100% (1)

- Yahagi Siren S-283Document1 pageYahagi Siren S-283WidyaNo ratings yet

- Price List TOSO 15 April 2016 R-3Document2 pagesPrice List TOSO 15 April 2016 R-3Wachid SetiaBifazter FansthegunnersNo ratings yet

- System Features: Floor StandingDocument1 pageSystem Features: Floor StandingKevin Lau100% (1)

- KDK 2018 Fan CatalogeDocument32 pagesKDK 2018 Fan CatalogeOnn LajerNo ratings yet

- Standard Non-Inverter CS/CU-YN18WKJ: Air Conditioners Single SplitDocument1 pageStandard Non-Inverter CS/CU-YN18WKJ: Air Conditioners Single SplitBoy KailimangNo ratings yet

- MizuDocument1 pageMizuPrima Fitra SaputraNo ratings yet

- FE Brosur PDFDocument2 pagesFE Brosur PDFsudiNo ratings yet

- TPG HybridDocument9 pagesTPG HybridRoza Firdaus-kunNo ratings yet

- Vas Series: Fixed Blades Axial Flow FansDocument4 pagesVas Series: Fixed Blades Axial Flow FansTedi A MaulanaNo ratings yet

- VPDM NewDocument3 pagesVPDM NewBudi SugiantoroNo ratings yet

- Price Fitting Besi 2Document8 pagesPrice Fitting Besi 2opik97No ratings yet

- BoQ SampleDocument158 pagesBoQ Samplevix Yams setNo ratings yet

- Tiang PJU Octagonal 9mDocument1 pageTiang PJU Octagonal 9mRiyuRazeNo ratings yet

- Vit Series: Inlinecentrifugal Duct FanDocument3 pagesVit Series: Inlinecentrifugal Duct FanTedi A MaulanaNo ratings yet

- Harga Tray TimsDocument2 pagesHarga Tray Timsaji sasongkoNo ratings yet

- CATALOG-TATEYAMA Low PDFDocument8 pagesCATALOG-TATEYAMA Low PDFtri hantoroNo ratings yet

- (Revisi 16 November 2020) : CNP (Southern Pump) Price ListDocument99 pages(Revisi 16 November 2020) : CNP (Southern Pump) Price Listkalimosodo 010% (1)

- Cu PVCDocument2 pagesCu PVCFani Dwi Putra57% (7)

- PT NGI Price List Kitz Gate Valve 2019Document1 pagePT NGI Price List Kitz Gate Valve 2019Kiki WidyaNo ratings yet

- WTP Tag Agustus PercepatanDocument114 pagesWTP Tag Agustus Percepatankrisyanto krisyanto100% (1)

- Manual Book UV AQUAFIDESDocument48 pagesManual Book UV AQUAFIDESMartha WidjayaNo ratings yet

- Grundfos JPD - PT-22-24 PDFDocument3 pagesGrundfos JPD - PT-22-24 PDFmandahandriNo ratings yet

- Primacon Bata RinganDocument2 pagesPrimacon Bata RinganBoy GalihNo ratings yet

- 1014 Graha Paramita II Bintaro, Tangerang (r.12) Jaga - Citra - Inti Fans Mar21 250321Document3 pages1014 Graha Paramita II Bintaro, Tangerang (r.12) Jaga - Citra - Inti Fans Mar21 250321imam wardhanaNo ratings yet

- Brosur KDK Fan PDFDocument39 pagesBrosur KDK Fan PDFanon_795575819No ratings yet

- Handy FlexDocument3 pagesHandy FlexwinNo ratings yet

- Basic Price SingkawangDocument160 pagesBasic Price Singkawangm.azhar irwansyahNo ratings yet

- Argapura, PT - Rvs.05ENG - 044 - 1509Document4 pagesArgapura, PT - Rvs.05ENG - 044 - 1509TristanNo ratings yet

- University Training Center-UNJDocument9 pagesUniversity Training Center-UNJAlie RakasiwaNo ratings yet

- AC Cassette DAIKIN Non InverterDocument1 pageAC Cassette DAIKIN Non InverterYusup Supri YadieNo ratings yet

- Daftar Harga Pipa Besi Merk SPS: Pt. Golden Piping IndonesiaDocument1 pageDaftar Harga Pipa Besi Merk SPS: Pt. Golden Piping IndonesiailhamNo ratings yet

- Extract Pages From Tower Triangle 20 M - Revisi 1Document2 pagesExtract Pages From Tower Triangle 20 M - Revisi 1Sholahuddin DiinNo ratings yet

- Rab Gudang Pt. Emas Mineral MurniDocument78 pagesRab Gudang Pt. Emas Mineral MurniFin AryNo ratings yet

- Brosur+Len+200+Wp 24V+MonocrystallineDocument2 pagesBrosur+Len+200+Wp 24V+Monocrystallineeric_agustianNo ratings yet

- REGELTEX Electrovolt Gloves TDS1Document2 pagesREGELTEX Electrovolt Gloves TDS1Georgina TiNo ratings yet

- Light Commercial (Non-Inverter) Catalogue PDFDocument10 pagesLight Commercial (Non-Inverter) Catalogue PDFZaw Moe KhineNo ratings yet

- Metode Pelaksanaan (Metode Kerja) DM AllDocument69 pagesMetode Pelaksanaan (Metode Kerja) DM AllEko Indra Saputra100% (1)

- Laplace MPNC Basic 20 KVADocument2 pagesLaplace MPNC Basic 20 KVARayhand adjiNo ratings yet

- Daftar Harga Satuan Bahan Dan Upah: NO Uraian Satuan Harga Dasar (RP) A TenagaDocument15 pagesDaftar Harga Satuan Bahan Dan Upah: NO Uraian Satuan Harga Dasar (RP) A TenagadaniNo ratings yet

- Technical Drawing PDFDocument170 pagesTechnical Drawing PDFLazzarus Az GunawanNo ratings yet

- T2700 Tower Specifications PDFDocument8 pagesT2700 Tower Specifications PDFmdalt9180No ratings yet

- Isolasi Pipa Insulflex FMDocument4 pagesIsolasi Pipa Insulflex FMsasongkoediNo ratings yet

- Monitoring Shop DrawingDocument1 pageMonitoring Shop DrawingSholikhinIbnuRamadhanNo ratings yet

- Jakarta Central Asia Steel Certificate QMS43581 20220714Document1 pageJakarta Central Asia Steel Certificate QMS43581 20220714Slamet Tri Usadha100% (1)

- Lapisan Penutup Atap BajaDocument1 pageLapisan Penutup Atap BajaDevi SaputraNo ratings yet

- Approval Drawing Control Valve For Fire Line - KORVAL DATA SHEETDocument5 pagesApproval Drawing Control Valve For Fire Line - KORVAL DATA SHEETMusholla BaiturrahimNo ratings yet

- Westlock Position MonitorDocument1 pageWestlock Position MonitorMusholla BaiturrahimNo ratings yet

- Fisher DVC Product Selection - DVC6200 Series OnlyDocument4 pagesFisher DVC Product Selection - DVC6200 Series OnlyMusholla BaiturrahimNo ratings yet

- Icom IC M510 BrochureDocument4 pagesIcom IC M510 BrochureMusholla BaiturrahimNo ratings yet

- Restricted SamplerDocument2 pagesRestricted SamplerMusholla BaiturrahimNo ratings yet

- Cleaning Chemical WallchartDocument1 pageCleaning Chemical WallchartMusholla BaiturrahimNo ratings yet