Professional Documents

Culture Documents

Single Component Shrink-Free Structural Grout: Features

Uploaded by

mathewsujith310 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

B 30

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesSingle Component Shrink-Free Structural Grout: Features

Uploaded by

mathewsujith31Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

B 30

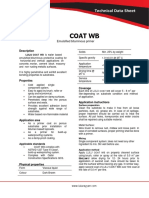

Single Component Shrink-free Structural Grout

Features

Shrink-free

Strong

Simply add required quantity of water

Can be used at flowable or pourable consistency

Chloride free

Non-staining

Can be applied by pump

High compressive strength

Excellent performance

ARDEX ENDURA (INDIA) PRIVATE LIMITED

Corporate Office & Regd. Office: 73/1B,

Byregowda Indl. Estate, Srigandhanagar,

Hegganahalli, Peenya 2nd Stage,

Bangalore - 560 091, Karnataka, INDIA.

Tel: +91-80-2836 1672 / 2836 1673

Fax: +91-80-2836 2078

E-mail: customercare@ardexendura.com

B 30

Single Component Shrink-free Structural Grout

DESCRIPTION CLEANING STORAGE AND SHELF LIFE

B 30 is an advanced, virtually tension free B 30 can be removed from tools and B 30 has a shelf life of 6 months if kept in a

cementitious structural grout. It is a grey equipment by washing in clean water dry, store between 5ºC and 30ºC in the original

cement based powder with suitable size of immediately after use. Any hardened material unopened containers. The product should be

aggregates and powder additives. The flowable will need to be removed mechanically. protected from frost, away from direct sunlight

consistency can be achieved by adding and sources of heat.

required amount of clear water to B 30. This PROPERTIES

flowable grout can be applied for gap thickness The following results were obtained at flowable PRECAUTIONS

10 - 75 mm. consistency (4.75 litres of water per 25kg bag) B 30 considered non-hazardous in normal

and at a temperature of 27 ± 1ºC. usage. The presence of cement in the product

USES gives an alkaline mortar which may cause

B 30 is used in grouting heavy machinery base PHYSICAL PROPERTIES some local irritation if prolonged contact with

plates, void gap filling of thickness 10 - 75 mm. B 30 @ 27 ± 1ºC the skin takes place. Care should be taken to

It can be used for column base plate and avoid inhalation or ingestion of dust and

Test method for Typical result

anchor rods. prevent contact with the eyes.

Flow Properties

SUBSTRATE PREPARATION DISPOSAL/SPILLAGE

Flow 190 - 220 mm

The surface must be hard, sound and free Spillage of any of the component products

of dust, dirt and other barrier materials such should be absorbed onto sand or other inert

Time for expansion —

as grease, paint, lime coatings, plaster and materials and transferred to a suitable

Start: 15 minutes

excessive adhesive residues, etc. disposable vessel. Disposal of such spillage

Finish: 2 hours

Use a suitable Degreaser to remove polish, or empty packaging should be in accordance

wax, grease, oil and similar contaminating with local waste disposal authority regulations.

Fresh wet density Approximately

substances. Latiance should be removed

2350kg/m³

from concrete surfaces. For further information please refer to the

depending on actual

Pre wet the substrate prior to grouting. Product Safety Data Sheet.

consistency used

MIXING CONDITIONS OF SALE

To the required amount of water in a clean Expansion An expansion of Sold subject to the Company's conditions

mixing container add the powder and stir characteristics 2 - 4% overcomes of sale which are available on request.

thoroughly for 5 minutes until a lump-free plastic settlement in

mortar is produced. A 25kg bag requires the unset material NOTE

4.75 litres of water. The information supplied in this datasheet

Compressive strength

The use of an mixing paddle with a 10 mm is based upon extensive experience and is

BS 1881, Part 116: 1983 given in good faith in order to help you.

chuck slow speed (600 - 1,000 r.p.m.) electric

drill makes light work of mixing. 1 day 25.0 N/mm² Our Company policy is one of continuous

Mixed B 30 should be applied within 3 days 47.0 N/mm² Research and Development; we therefore

15 minutes at 27 ± 1ºC . This time is extended 7 days 58.0 N/mm² reserve the right to update this information

at lower and reduced at higher temperatures. 28 days 66.0N/mm² at any time without prior notice. We also

guarantee the consistent high quality of our

APPLICATION Flexural strength products; however as we have no control

Pour the mixed B 30 onto the prepared floor. BS 4551 : 1998 over site conditions or the execution of the

The mixed mortar will flow up to 15 minutes. 1 day 3.0 N/mm² work, we accept no liability for any loss or

Use a suitable spreader to obtain the required 3 days 6.0 N/mm² damage which may arise as a result thereof.

thickness. 7 days 7.0 N/mm²

A long handled gauging tool with height 28 days 10.0 N/mm²

adjustment for thickness will simplify this

operation. A long handled trowel can be used Tensile strength

for finishing off. A steel finishing float can be 28 days 3.7 N/mm²

used for feather edging and touch up work.

Apply at temperatures above 5ºC. Pull out bond strength

IS 2770, Part 1: 1967

CURING 7 days 4.72 N/mm²

On completion of the grouting operation 28 days 5.46 N/mm²

exposed areas should be thoroughly cured with

curing membrane or continuous application of Modulus of Elasticity BRANCHES

water spray or wet hessian. Young's modulus 30.0 N/mm² AHMEDABAD 079 26425310 LUCKNOW 0522 4043251

ASTM-D 469:94 AURANGABAD 9881249293 LUDHIANA 0161 2532170

BANGALORE 080 22230138 MANGALORE 0824 2442176

SPECIFIC APPLICATIONS BHUBANESHWAR 9937091799 MUMBAI 022 65133299

Where large floors require grouting with B 30 it PACK SIZE CALICUT 0495 2333065 PUNE 020 64781879

25kg CHENNAI 044 24748673 RAIPUR 0771 6539055

may be advantageous to use a pump to mix DELHI 011 32092369 RAILA 9509764756

and place the B 30. ERNAKULAM 0484 2341044 RAJKOT 9328286287

YIELD GOA 0832 2750992 SALEM 0427 2211454

The approximate yield per 25kg bag is HUBLI 0836 2236919 TRICHY 0431 6454649

HYDERABAD 040 27550293 TRIVANDRUM 0471 2558648

Consistency Flowable or Pourable INDORE 0731 4021148 VIJAYAWADA 0866 3254587

Yield Approximately 11 litres JAIPUR 0141 2392993 VISAKAPATNAM 0891 6469499

06/12

KOLKATA 033 23452581

You might also like

- Dura Grout: A.B.E. Construction ChemicalsDocument3 pagesDura Grout: A.B.E. Construction ChemicalsVirah Sammy ChandraNo ratings yet

- High Strength, Cementitious, Non-Shrink Precision GroutDocument2 pagesHigh Strength, Cementitious, Non-Shrink Precision GroutYASHICA VAITTIANATHANNo ratings yet

- Boscoflex: Flexible Cementitious Waterprofing MembraneDocument2 pagesBoscoflex: Flexible Cementitious Waterprofing MembraneCLENTH FLORentinoNo ratings yet

- Ep 300Document2 pagesEp 300mathewsujith31No ratings yet

- Sikadur®-53: Product Data SheetDocument3 pagesSikadur®-53: Product Data Sheetjet toledoNo ratings yet

- Masterseal 540 - Map v1-0716Document3 pagesMasterseal 540 - Map v1-0716Mcr KumaraNo ratings yet

- Barralastic Method StatementDocument2 pagesBarralastic Method StatementrajragavanNo ratings yet

- Ultrapower MP Non-Toxic Epoxy CoatingDocument2 pagesUltrapower MP Non-Toxic Epoxy CoatingAdhigana QSNo ratings yet

- Bostik Boscolastic Rev1Document2 pagesBostik Boscolastic Rev1decenabuilders2016No ratings yet

- Dura. Grout: Non-Shrink Cementitious GroutDocument2 pagesDura. Grout: Non-Shrink Cementitious GroutANILNo ratings yet

- High Early & Ultimate Strength, Cementitious, Structural Precision GroutDocument2 pagesHigh Early & Ultimate Strength, Cementitious, Structural Precision GroutYASHICA VAITTIANATHANNo ratings yet

- Sika Nigeria - Sika Grout 212 - V2Document3 pagesSika Nigeria - Sika Grout 212 - V2willy iremNo ratings yet

- PDS Sika 101h en IN 09 2023 2 1Document3 pagesPDS Sika 101h en IN 09 2023 2 1cp7582463No ratings yet

- Solvent Free, Low Viscosity, Epoxy Primer: Mixing DescriptionDocument2 pagesSolvent Free, Low Viscosity, Epoxy Primer: Mixing DescriptionSameehu TVNo ratings yet

- Shrinkage Compensated Cementitious GroutDocument3 pagesShrinkage Compensated Cementitious GroutPramod SinghNo ratings yet

- Expangrout GP: General Purpose Non-Shrink Cementitious Grout UsesDocument4 pagesExpangrout GP: General Purpose Non-Shrink Cementitious Grout UsesZaid AhmedNo ratings yet

- Sikagrout - 200 PT: Product Data SheetDocument3 pagesSikagrout - 200 PT: Product Data SheetFrancis Hiro LedunaNo ratings yet

- Cement-Based Mortar for Laying Concrete BlocksDocument1 pageCement-Based Mortar for Laying Concrete BlocksSebastianAnNo ratings yet

- Boscoflex: Flexible Cementitious Waterprofing MembraneDocument2 pagesBoscoflex: Flexible Cementitious Waterprofing MembranenizarazuNo ratings yet

- Boscolastic TDSDocument2 pagesBoscolastic TDSSasi KumarNo ratings yet

- BoscoflexDocument2 pagesBoscoflexGeloNo ratings yet

- BC Bitumen CoatingDocument3 pagesBC Bitumen CoatingSyerifaizal Hj. MustaphaNo ratings yet

- Non-shrink underwater groutDocument4 pagesNon-shrink underwater grouttin aungtunNo ratings yet

- Sikagrout® GP: Product Data SheetDocument4 pagesSikagrout® GP: Product Data SheetCatherine Fatima Mae LeynoNo ratings yet

- TDS MasterSeal-540Document2 pagesTDS MasterSeal-540Taposh PaulNo ratings yet

- Techflow Grout GP: General-Purpose Class C, Non Shrink, Dual Expansion Cementitious GroutDocument3 pagesTechflow Grout GP: General-Purpose Class C, Non Shrink, Dual Expansion Cementitious GroutBala KathirveluNo ratings yet

- Masterseal 540: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 540: Flexible, Polymer Cement Waterproofing SlurryRicky Reung100% (1)

- Sikagrout - 228Document3 pagesSikagrout - 228Anonymous T7zEN6iLHNo ratings yet

- Masonry Grout Filler Technical Data SheetDocument2 pagesMasonry Grout Filler Technical Data SheetMaha MuflehNo ratings yet

- Aquaarm Multicrete Aquaarm Multicrete Aquaarm MulticreteDocument2 pagesAquaarm Multicrete Aquaarm Multicrete Aquaarm MulticreteShabbir LokhandwalaNo ratings yet

- BASF Masterseal 540 PDFDocument2 pagesBASF Masterseal 540 PDFJM Subion100% (1)

- WPM 300 TDSDocument2 pagesWPM 300 TDSPetrus PaulusNo ratings yet

- Masterseal 540 TdsDocument2 pagesMasterseal 540 TdsRhinzy CajuraoNo ratings yet

- Sikagrout - 220Document3 pagesSikagrout - 220Rukmana's FamilyNo ratings yet

- PDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKDocument2 pagesPDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKRoemaric AguasNo ratings yet

- Sikagrout 215: General Purpose Non-Shrink Cementitious GroutDocument3 pagesSikagrout 215: General Purpose Non-Shrink Cementitious GroutDani LerviNo ratings yet

- CIKO FloGroutDocument3 pagesCIKO FloGroutAbdul YaskarNo ratings yet

- Technical Data Sheet for Emulsified Bituminous PrimerDocument2 pagesTechnical Data Sheet for Emulsified Bituminous Primerhandhammer qatarNo ratings yet

- Sikadur®-42 (Au) : Product Data SheetDocument3 pagesSikadur®-42 (Au) : Product Data SheetPramuditha SuraweeraNo ratings yet

- TDS - Conbextra BB72 IN - IndiaDocument2 pagesTDS - Conbextra BB72 IN - IndiaVikas Singh ChandelNo ratings yet

- Sikagrout - 220Document3 pagesSikagrout - 220wan arifNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds enadriansyahNo ratings yet

- H.V. NC SANDING SEALER PRODUCT OVERVIEWDocument1 pageH.V. NC SANDING SEALER PRODUCT OVERVIEWمحمد عزتNo ratings yet

- TDS Weberad 220 SBRDocument2 pagesTDS Weberad 220 SBRMahmoudFarhatNo ratings yet

- Sika Raintite: Liquid Membrane Waterproofing SystemDocument2 pagesSika Raintite: Liquid Membrane Waterproofing SystemMoatz HamedNo ratings yet

- Egrout S50Document2 pagesEgrout S50m.elsanee.cubicNo ratings yet

- BrushcreteDocument2 pagesBrushcreteSunilNo ratings yet

- Masterseal 555S: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 555S: Flexible, Polymer Cement Waterproofing SlurryshashiNo ratings yet

- H. V. NC: Matt ClearDocument1 pageH. V. NC: Matt Clearمحمد عزتNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPm.elsanee.cubicNo ratings yet

- Brushbond FlexDocument2 pagesBrushbond FlexDio Adam MahendraNo ratings yet

- Conbextra GPDocument4 pagesConbextra GPMuhammad ShoaibNo ratings yet

- Brushbond FlexDocument2 pagesBrushbond FlexbibahNo ratings yet

- Bostik Screed WP Prepacked Drymix Waterproof Floor ScreedDocument2 pagesBostik Screed WP Prepacked Drymix Waterproof Floor Screedraviteja036No ratings yet

- Alccobond (GP)Document2 pagesAlccobond (GP)Siddhesh Kamat MhamaiNo ratings yet

- Abe Construction Chemicals Duraflex DatasheetDocument2 pagesAbe Construction Chemicals Duraflex DatasheetEthanNo ratings yet

- Polygrout NS: Non-Shrink Free Flow Cementitious GroutDocument2 pagesPolygrout NS: Non-Shrink Free Flow Cementitious GroutGavriel NgNo ratings yet

- Ficha Inscripcion SSDocument2 pagesFicha Inscripcion SSalexNo ratings yet

- Sikafloor Level-50 High Performance Self-Leveling UnderlaymentDocument3 pagesSikafloor Level-50 High Performance Self-Leveling UnderlaymentRialno TambunanNo ratings yet

- EC Tech Report High Performance Polyurethanes: PDFFrom EverandEC Tech Report High Performance Polyurethanes: PDFVincentz Network GmbH & Co. KGNo ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Request For Information - SWML CrusherDocument3 pagesRequest For Information - SWML Crushermathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- L&C BrochureDocument6 pagesL&C Brochuremathewsujith31No ratings yet

- Accreditation Trakhees Ae Regulations Green Mobile Index HTMDocument1 pageAccreditation Trakhees Ae Regulations Green Mobile Index HTMmathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- 2014 05 16 Project Manual IncompleteDocument376 pages2014 05 16 Project Manual Incompletenap_carinoNo ratings yet

- 17-0112 Sample AgreementDocument7 pages17-0112 Sample Agreementmathewsujith31No ratings yet

- 2014 05 16 Project Manual IncompleteDocument376 pages2014 05 16 Project Manual Incompletenap_carinoNo ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Contract Building and RepairDocument3 pagesContract Building and Repairmathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- Create PDFs in Apps with Pdfcrowd HTML to PDF APIDocument1 pageCreate PDFs in Apps with Pdfcrowd HTML to PDF APImathewsujith31No ratings yet

- Create PDF in Your Applications With The Pdfcrowd: HTML To PDF ApiDocument1 pageCreate PDF in Your Applications With The Pdfcrowd: HTML To PDF Apimathewsujith31No ratings yet

- AggrementDocument7 pagesAggrementPalanisamy MNo ratings yet

- SNNPRG South Omo Zone Construction DepartementDocument23 pagesSNNPRG South Omo Zone Construction DepartementIbrahim DawudNo ratings yet

- Acoustical Properties of Building Materials ExplainedDocument10 pagesAcoustical Properties of Building Materials ExplainedSATURN KYLE FLORESNo ratings yet

- TDS - Es-221Document2 pagesTDS - Es-221scribd8341No ratings yet

- Sussex Art Studios - Summer School Courses 2011Document2 pagesSussex Art Studios - Summer School Courses 2011h_m_b_talbotNo ratings yet

- IMA-Europe - Recycling Sheets - 2018Document24 pagesIMA-Europe - Recycling Sheets - 2018Nazanin SabetNo ratings yet

- Acron MC Microwavable Flask: GC Lab Technologies IncDocument1 pageAcron MC Microwavable Flask: GC Lab Technologies IncNaveen S YadavNo ratings yet

- Rendercon ChemDocument4 pagesRendercon ChemHarshvardhan PathakNo ratings yet

- Metal Framing and Finishing CatalogDocument228 pagesMetal Framing and Finishing CatalogAlbie Santos50% (2)

- Building SOR 01.12.2020 Volume 2Document469 pagesBuilding SOR 01.12.2020 Volume 2Shiv Shankar Shukla50% (2)

- Stucco Italiano - Venetian PlastersDocument37 pagesStucco Italiano - Venetian PlastersClara PolistenaNo ratings yet

- Department of Archaeology Item Rates: Ministry of Culture, Tourism & Civil AviationDocument7 pagesDepartment of Archaeology Item Rates: Ministry of Culture, Tourism & Civil AviationKrijan Mali100% (1)

- Adx 999 SM PDFDocument10 pagesAdx 999 SM PDFSusana KhoNo ratings yet

- 01 CONCRETE - Part 1Document37 pages01 CONCRETE - Part 1angelicaNo ratings yet

- Woodland Scenics CatalogDocument180 pagesWoodland Scenics Catalogbcase23100% (1)

- Silres BS 4004: Silane EmulsionsDocument3 pagesSilres BS 4004: Silane EmulsionsVaittianathan MahavapillaiNo ratings yet

- Product Information: MouldingDocument3 pagesProduct Information: MouldingFlorentin VorniceluNo ratings yet

- Architects-STP SpecificationsDocument88 pagesArchitects-STP Specificationsrakesh patiNo ratings yet

- General Specification (Building) 30-01-21Document586 pagesGeneral Specification (Building) 30-01-21rupesh417No ratings yet

- Block Plastering and Tile Scope Sheet FinalDocument12 pagesBlock Plastering and Tile Scope Sheet FinalMOHAMED MOINUDDIN KHANNo ratings yet

- Checklist For Control Room DesignDocument4 pagesChecklist For Control Room DesignRupesh KhandekarNo ratings yet

- Sathyaprakash - FC and Demolition QuoteDocument4 pagesSathyaprakash - FC and Demolition QuoteSad JokerNo ratings yet

- Reviewer in Art AppDocument10 pagesReviewer in Art Appkiamarie matienzoNo ratings yet

- Pool Plaster and Concrete Product GuideDocument42 pagesPool Plaster and Concrete Product GuideMuhammad Farhan PutraNo ratings yet

- Khaadi Fabric Store at - Boq (r2) - Id Works - 24-12-2018Document48 pagesKhaadi Fabric Store at - Boq (r2) - Id Works - 24-12-2018Kashan ShoukatNo ratings yet

- TDS Renderoc CF India2Document2 pagesTDS Renderoc CF India2AL RawaqNo ratings yet

- Building Rate AnalysisDocument6 pagesBuilding Rate AnalysisSanjay Babu RaghubanshiNo ratings yet

- Bus Stand Design EstimateDocument109 pagesBus Stand Design EstimateANKESH SHRIVASTAVANo ratings yet

- IAF (EAC) Codes and Descriptions ListDocument25 pagesIAF (EAC) Codes and Descriptions ListUmar IkramNo ratings yet

- Project Data: Twenty-Nine Million Five Hundred Thirty-One Thousand One Hundred Forty-Three and 21/100Document28 pagesProject Data: Twenty-Nine Million Five Hundred Thirty-One Thousand One Hundred Forty-Three and 21/100Coleen IrisNo ratings yet