Professional Documents

Culture Documents

Metraloop OIM

Metraloop OIM

Uploaded by

SaidFerdjallahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metraloop OIM

Metraloop OIM

Uploaded by

SaidFerdjallahCopyright:

Available Formats

METRALOOP™ EXPANSION JOINT

THERMAL APPLICATION

OPERATION, INSTALLATION AND MAINTENANCE INSTRUCTIONS

General: The MetraLoop™ consists of two parallel sections of corrugated hose and braid with connecting fittings as specified for

project requirements. The Metraloop can accommodate axial and lateral movement.

Application / Notes:

1. The Metraloop is used in a wide range of services from cryogenic to steam and applications such as compensation for

thermal expansion and contraction, seismic movement, and building settlement.

2. Metraloops will be shipped with a tag that specifies it’s rated movement. Confirm that the system movements are within

the rating of the Metraloop.

3. Verify that the system pressures do not exceed the published at ratings of the Metraloop found on www.metraflex.com

4. Metraloops can be installed at any point of the pipe run between anchors.

5. The general Metraflex recommendation is that a guide be used on each side of the Metraloop if any of the hanger rods

deflect 4° or more due to the pipe movement.

Installation:

1. Inspect joint for shipping damage, insure that the shipping bar is intact.

2. During installation, make sure that the sections of flexible hose and braid are protected from damage and overextension.

Weld splatter must be kept away from the flexible legs.

3. Nesting Clearance. Often several Metraloops are nested inside of each other, when this is the case the installer should

verify that there is enough clearance between the Metraloops after insulation to allow for the full expected movement.

Refer to the submittal for the nest.

4. When required, Metraloops should be insulated with flexible unicellular, mineral wool or fiberglass insulation. Ridged

insulations should be avoided on the hose element to avoid point loading the hose. Insulation should be selected and

installed to avoid moisture entrapment.

5. For Copper sweat applications, cold strap the fitting that is being soldered or brazed. Thoroughly flush flux from the

inside of the system, clean off any flux from the outside of the hose.

6. Metraloops are shipped with shipping bars to maintain the Loops neutral position. Shipping bars must be removed after

installation

7. The 180 return fitting must be supported in a way that allows lateral movement. Nested loops may have two hanger

brackets on the 180° return. 2.5” Diameter and smaller stock loops +-4” Movement are self-supporting and do not need

any additional support.

CUSTOMER

PROJECT

ENGINEER DESCRIPTION:

ARCHITECT METRALOOP EXPANSION JOINT

THERMAL APPLICATION

PRO. OR P.O. NO.

Operation, Installation and Maintenance Instructions

DRAWING BY: DATE: DRAWING NO.

JC 01-05-16 LOOP-OIM 1 of 3

METRALOOP™ EXPANSION JOINT

THERMAL APPLICATION

OPERATION, INSTALLATION AND MAINTENANCE INSTRUCTIONS

Installation Continued:

Provided a hanger for loops 3” diameter and

larger. The hanger rod must allow the 180˚

return fitting to move horizontally.

Horizontal is the recommended installation for

STEAM applications. Consult factory for steam

applications.

For horizontal pipe runs with the Metraloop

hanging down, no additional support for the

180˚ return fitting is required.

Provided a hanger for loops 3” diameter and

larger.

The hanger rod or support must be spring

loaded to allow the 180˚ to move up and

down.

CUSTOMER

PROJECT

ENGINEER DESCRIPTION:

ARCHITECT METRALOOP EXPANSION JOINT

THERMAL APPLICATION

PRO. OR P.O. NO.

Operation, Installation and Maintenance Instructions

DRAWING BY: DATE: DRAWING NO.

JC 01-05-16 LOOP-OIM 2 of 3

METRALOOP™ EXPANSION JOINT

THERMAL APPLICATION

OPERATION, INSTALLATION AND MAINTENANCE INSTRUCTIONS

Installation Continued:

Provided a hanger for loops 3” diameter and

larger.

The hanger rod or support must be spring

loaded to allow the 180˚ to move up and

down.

Testing:

1. See Metraflex’s published data for allowable test pressure.

2. Metraflex recommends hydrostatic test only. If an air test is performed, appropriate safety precautions must be made.

Steam Precautions:

1. For steam applications Metraflex recommends the use of double braiding for the hose.

2. Metraflex recommends that flexible hose products be only installed in well trapped systems.

Maintenance:

The Metraloop is maintenance free and has no serviceable parts. Periodic visual inspections should be done. Inspections should

be made after any seismic event.

Contact Metraflex or your local Metraflex Representative with ANY questions.

CUSTOMER

PROJECT

ENGINEER DESCRIPTION:

ARCHITECT METRALOOP EXPANSION JOINT

THERMAL APPLICATION

PRO. OR P.O. NO.

Operation, Installation and Maintenance Instructions

DRAWING BY: DATE: DRAWING NO.

JC 01-05-16 LOOP-OIM 3 of 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Dokumen - Tips Inspection Checklist Distillation ColumnDocument5 pagesDokumen - Tips Inspection Checklist Distillation ColumnSaidFerdjallah100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Techetch ComDocument2 pagesTechetch ComSaidFerdjallahNo ratings yet

- Distillation Column - Tray Hydraulics-1Document10 pagesDistillation Column - Tray Hydraulics-1SaidFerdjallahNo ratings yet

- TEG Transfer PumpDocument22 pagesTEG Transfer PumpSaidFerdjallahNo ratings yet

- Whatispiping ComDocument2 pagesWhatispiping ComSaidFerdjallahNo ratings yet

- Entree Gaz Humid - Sortie Gaz 337871 Entree Condensat Froid - Sortie Condensat Chaud 86557Document1 pageEntree Gaz Humid - Sortie Gaz 337871 Entree Condensat Froid - Sortie Condensat Chaud 86557SaidFerdjallahNo ratings yet

- What Is Modal Analysis and Why Is It Necessary Caesar II Piping Modal Analysis Steps With PDFDocument8 pagesWhat Is Modal Analysis and Why Is It Necessary Caesar II Piping Modal Analysis Steps With PDFSaidFerdjallah100% (1)

- Expansion Loop FotDocument7 pagesExpansion Loop FotSaidFerdjallahNo ratings yet

- WhatsnewPF V1403Document2 pagesWhatsnewPF V1403SaidFerdjallahNo ratings yet

- Carotek Filtration Strainers Selection Guide 06042020Document3 pagesCarotek Filtration Strainers Selection Guide 06042020SaidFerdjallahNo ratings yet

- BB 1Document1 pageBB 1SaidFerdjallahNo ratings yet

- Simulations of The Kettle Reboiler Shell Side Thermal-Hydraulics With Different Two-Phase Flow ModelsDocument14 pagesSimulations of The Kettle Reboiler Shell Side Thermal-Hydraulics With Different Two-Phase Flow ModelsSaidFerdjallahNo ratings yet

- Thin and Thick-Walled Stress Analysis of Pressure VesselDocument31 pagesThin and Thick-Walled Stress Analysis of Pressure VesselSaidFerdjallahNo ratings yet

- JT Assembly English Letter ADocument2 pagesJT Assembly English Letter ASaidFerdjallahNo ratings yet

- Deux Ou Trois DeshydrateurDocument10 pagesDeux Ou Trois DeshydrateurSaidFerdjallahNo ratings yet

- Turbo Expander CompressorDocument8 pagesTurbo Expander CompressorSaidFerdjallahNo ratings yet

- 05 StimulatingDocument11 pages05 StimulatingSaidFerdjallahNo ratings yet

- Improvement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventDocument7 pagesImprovement of TEG Regeneration in Natural Gas Dehydration Using A Hydrocarbon SolventSaidFerdjallahNo ratings yet

- 15 Gate ValvesDocument2 pages15 Gate ValvesSaidFerdjallahNo ratings yet

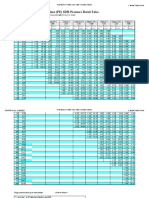

- Polyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsDocument24 pagesPolyethylene (PE) SDR-Pressure Rated Tube: Friction Loss CharacteristicsSaidFerdjallahNo ratings yet

- Samson: Improved Control Valve Sizing For Multiphase FL OwDocument8 pagesSamson: Improved Control Valve Sizing For Multiphase FL OwSaidFerdjallahNo ratings yet

- Asme CodesDocument14 pagesAsme CodesSaidFerdjallahNo ratings yet

- What Is Winterization? Requirements For The Basic Design of Winterization SystemsDocument7 pagesWhat Is Winterization? Requirements For The Basic Design of Winterization SystemsSaidFerdjallahNo ratings yet

- M389 Process Pumps, Valves, & Pipe Spreadsheet AnalysisDocument52 pagesM389 Process Pumps, Valves, & Pipe Spreadsheet AnalysisSaidFerdjallahNo ratings yet

- A Guide of Refinery ProcessDocument32 pagesA Guide of Refinery ProcessSaidFerdjallahNo ratings yet