Professional Documents

Culture Documents

tAD1640/1641/1642ge-B: 16.12 Liter, In-Line 6 Cylinder

Uploaded by

Adolfito PBOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

tAD1640/1641/1642ge-B: 16.12 Liter, In-Line 6 Cylinder

Uploaded by

Adolfito PBCopyright:

Available Formats

tAD1640/1641/1642ge-B

16.12 liter, in-line 6 cylinder

TAD1640GE-B, TAD1641GE-B and TAD1642GE-B are The TAD1640GE-B, TAD1641GE-B and TAD1642GE-B complies

powerful, reliable and economical Generating Set Diesel with EU Stage 2 exhaust emission regulations.

Engines built on the dependable in-line six design.

Easy service and maintenance

Durability and low noise Easily accessible service and maintenance points contribute to the

Designed for easiest, fastest and most economical installation. ease of service of the engine.

Well-balanced to produce smooth and vibration-free operation

with low noise level.

• Fully electronic with Volvo Penta EMS 2.4

To maintain a controlled working temperature in cylinders and

• Dual frequency switch (between 1500 rpm and 1800 rpm)

combustion chambers, the engine is equipped with piston cooling.

The engine is also fitted with replaceable cylinder liners and valve • RoHS2 compliant

seats/guides to ensure maximum durability and service life of the • High power density

engine.

• Emission compliant

Low exhaust emission

The state of the art, high-tech injection and charging system with • Low noise levels

low internal losses contributes to excellent combustion and low

• Gen Pac configuration

fuel consumption.

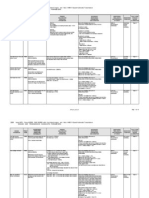

50 Hz / 1500 rpm 60 Hz / 1800 rpm

Continuous Prime Standby Continuous Prime Standby

power power power power power power

kWm kWe kVA kWm kWe kVA kWm kWe kVA kWm kWe kVA kWm kWe kVA kWm kWe kVA

TAD1640GE-B 294 276 345 392 368 461 431 405 506 323 303 379 430 405 506 479 450 563

TAD1641GE-B 323 303 379 432 406 508 475 446 558 364 342 428 489 460 575 550 517 646

TAD1642GE-B 377 355 443 505 475 593 556 523 653 399 375 469 536 504 630 589 554 692

Generator efficiency (typical): 94%

kWm = kiloWatt mechanical, net with fan*; kWe = kiloWatt electrical = kWm x Generator eff.; kVA = kiloVoltAmpere calculations based on a 0.8 power factor = kWe / 0.8

1 kW = 1 hp x 1.36; 1 hp = 1 kW x 0.7355

*) According to technical data

tAD1640/1641/1642ge-B

16.12 liter, in-line 6 cylinder

Technical Data Technical description

Configuration and no. of cylinders............................................................. in-line 6 Engine and block

Method of operation.................................................................................. 4-stroke – Optimized cast iron cylinder block with optimum distribution of forces

Bore, mm (in.).......................................................................................... 144 (5.67) without the block being unnecessary heavy.

Stroke, mm (in.).......................................................................................165 (6.50) – Wet, replaceable cylinder liners

Displacement, l (in³)........................................................................... 16.12 (983.7) – Piston cooling for low thermal load on pistons and reduced ring tem-

Compression ratio...........................................................................................16.5:1 perature

Dry weight, kg (lb)...............................................................................1480 (3263) – Tapered connecting rods to reduce risk of piston cracking

Dry weight with Gen Pac, kg (lb)......................................................... 1910 (4211) – Crankshaft induction hardened bearing surfaces and fillets with seven

Wet weight, kg (lb)............................................................................... 1550 (3417) main bearings for moderate load on main and big-end bearings

Wet weight with Gen Pac, kg (lb)..................................................... 2020 (4453) – Nitrocarburized transmission gears for heavy duty operation

Performance – Keystone top compression rings for long service life

TAD1640GE-B TAD1641GE-B TAD1642GE-B

– Viscous type crankshaft vibration damper

rpm 1500 1800 1500 1800 1500 1800 – Replaceable valve guides and valve seats

Prime 392 430 432 489 505 536 – Over head camshaft and four valves per cylinder equipped with cam-

Power, kW (hp) (533) (585) (588) (665) (687) (729)

shaft damper to reduce noise and vibrations.

Standby 431 479 475 550 556 589

Power, kW (hp) (586) (651) (646) (748) (756) (801) Lubrication system

– Full flow oil cooler

Fuel consumption – Full flow disposable spin-on oil filters, for extra high filtration

Prime Power, g/kWh (lb/hph) – The lubricating oil level can be measured during operation (Standard

TAD1640GE-B TAD1641GE-B TAD1642GE-B

dipstick only)

– Gear type lubricating oil pump, gear driven by the transmission

1500 rpm 1800 rpm 1500 rpm 1800 rpm 1500 rpm 1800 rpm

25% 233 233 233 249 219 234 Fuel system

(0.378) (0.378) (0.378) (0.403) (0.356) (0.380) – Self de-aerating system. When replacing filters all fuel stays in the en-

50% 205 205 205 210 198 203 gine.

(0.332) (0.332) (0.332) (0.341) (0.321) (0.329) – Non-return fuel valve

75% 201 201 201 205 196 202 – Electronic unit injectors

(0.326) (0.326) (0.326) (0.332) (0.318) (0.327)

– Fuel prefilter with water separator and water-in-fuel indicator / alarm

100% 200 209 200 207 193 204 – Gear driven low-pressure fuel pump

(0.325) (0.325) (0.325) (0.335) (0.313) (0.330)

– Fine fuel filter with manual feed pump and fuel pressure switch

Standby Power, g/kWh (lb/hph) – Fuel shut-off valve, electrically operated

TAD1640GE-B TAD1641GE-B TAD1642GE-B

Cooling system

1500 rpm 1800 rpm 1500 rpm 1800 rpm 1500 rpm 1800 rpm

– Efficient cooling with accurate coolant control through a water distribu-

25% 250 259 227 232 215 296 tion duct in the cylinder block. Reliable sleeve thermostat with mini-

(0.405) (0.419) (0.368) (0.376) (0.348) (0.480)

mum pressure drop

50% 212 215 203 202 197 202 – Belt driven, maintenance-free coolant pump with high degree of effi-

(0.343) (0.349) (0.328) (0.327) (0.320) (0.327)

ciency

75% 205 206 200 203 198 205 Turbo charger

(0.332) (0.333) (0.324) (0.329) (0.322) (0.332)

– Efficient and reliable turbo charger

100% 207 208 197 204 196 206 – Extra oil filter for the turbo charger

(0.336) (0.337) (0.319) (0.331) (0.317) (0.334)

Electrical system

Dimensions – Engine Management System 2 (EMS 2.4), an electronically controlled

Not for installation. Dimensions in mm. processing system which optimizes engine performance. It also in-

cludes advanced facilities for diagnostics and fault tracing

– The instruments and controls connect to the engine via the CAN SAE

J1939 interface, either through the Control Interface Module (CIM) or

the Digital Control Unit (DCU). The CIM converts the digital CAN bus

signal to an anolog signal, making it possible to connect a variety of

instruments. The DCU2 is a control panel with display, engine control,

1881

monitoring, alarm, parameter setting and diagnostic functions. The

DCU2 also presents error codes in clear text.

– Sensors for oil pressure, oil temp, boost pressure, boost temp, coolant-

temp, fuel temp, water in fuel, fuel pressure and two speed sensors.

Crank case pressure, piston cooling pressure, oil level and air filter

pressure drop sensors.

1160

2386 (DURING TRANSPORT) MAX LENGTH 3090}

– Alternator 24V / 80A

Rating guidelines Power standards

CONTINUOUS POWER is defined as being the The engine performance corresponds to ISO

maximum power which the generating set is capable 3046, BS 5514 and DIN 6271. The technical data

of delivering continuously while supplying a con- applies to an engine without cooling fan and op-

stant electrical load when operated for an unlimited

English 04-2021 © 2021 AB Volvo Penta.

erating on a fuel with calorific value of 42.7 MJ /

number of hours per year under the agreed operat- kg (18360 BTU/lb) and a density of 0.84 kg/liter

ing conditions with the maintenance intervals and

(7.01 lb/US gal), also where this involves a devia-

procedures being carried out as prescribed by the

tion from the standards. Power output guaranteed

manufacturer.

within 0 to +2% att rated ambient conditions at

PRIME POWER rating corresponds to ISO Standard delivery. Ratings are based on ISO 8528. Engine

Power for continuous operation. It is applicable for speed governing in accordance with ISO 8528-5

supplying electrical power at variable load for an un- G3.

limited number of hours instead of commercially pur-

chased power. A10 % overload capability for govering

Please contact your local Volvo Penta dealer for further information.

purpose is available for this rating. Please note that products illustrated may differ from production

STAND-BY POWER rating corresponds to ISO Stan- models. Not all models and accessories are available in all markets,

and standard equipment may vary between different markets. Every

dard Fuel Stop Power. It is applicable for

supplying stand-by electrical power at variable load AB Volvo Penta effort has been made to ensure that facts and figures are correct at

the time of publication. However, Volvo Penta reserves the right to

in areas with well established electrical networks in SE-405 08 Göteborg, Sweden make changes without prior notice at any time.

the event of normal utility power failure. No overload www.volvopenta.com

capability is available for this rating.

You might also like

- Volvo 47709013 - ENDocument2 pagesVolvo 47709013 - ENNolberto RiosNo ratings yet

- Tad1651Ge: 16.12 Liter, In-Line 6 CylinderDocument2 pagesTad1651Ge: 16.12 Liter, In-Line 6 CylinderSze TimNo ratings yet

- tAD1341/1342/1343ge-B: 308/343/366 KW (419/466/498 HP) at 1500 RPM, 335/395/406 KW (456/537/552 HP) at 1800 RPMDocument2 pagestAD1341/1342/1343ge-B: 308/343/366 KW (419/466/498 HP) at 1500 RPM, 335/395/406 KW (456/537/552 HP) at 1800 RPMMOAMMEDNo ratings yet

- Tad1351Ge: 12.78 Liter, In-Line 6 CylinderDocument2 pagesTad1351Ge: 12.78 Liter, In-Line 6 CylinderJoséNo ratings yet

- Tad1351Ge: 12.78 Liter, In-Line 6 CylinderDocument2 pagesTad1351Ge: 12.78 Liter, In-Line 6 Cylinderjulio cesar navaNo ratings yet

- TAD1641GE: Volvo Penta Genset EngineDocument2 pagesTAD1641GE: Volvo Penta Genset EnginesIMPEX sHARMANo ratings yet

- TAD1641GE: Volvo Penta Genset EngineDocument2 pagesTAD1641GE: Volvo Penta Genset EngineHenry PabloNo ratings yet

- TAD1631GE: Volvo Penta Genset EngineDocument2 pagesTAD1631GE: Volvo Penta Genset EngineEko SulistyoNo ratings yet

- Maximum 1950 KW (2615 HP) at 1950 RPM (Intermediate Duty) : Standard EquipmentDocument2 pagesMaximum 1950 KW (2615 HP) at 1950 RPM (Intermediate Duty) : Standard EquipmentQuant ExalmarNo ratings yet

- Tad1242ge Tad1242geDocument2 pagesTad1242ge Tad1242gesabujNo ratings yet

- Tad1641ge PDFDocument2 pagesTad1641ge PDFjuanNo ratings yet

- NTA855G4Document3 pagesNTA855G4Shahid Shaikh100% (1)

- TAD941GEDocument2 pagesTAD941GEjesus silvaNo ratings yet

- Volvo EngineDocument63 pagesVolvo EngineFCDSGN100% (1)

- Tad530Ge: 50 Hz/1500 RPM 60 Hz/1800 RPMDocument2 pagesTad530Ge: 50 Hz/1500 RPM 60 Hz/1800 RPMpoorNo ratings yet

- Perkins 650P PDFDocument5 pagesPerkins 650P PDFFranklin FernandezNo ratings yet

- Petroleum Oil Well Service Engine: 1996 EPA and Carb Non-Road Emissions CertifiedDocument2 pagesPetroleum Oil Well Service Engine: 1996 EPA and Carb Non-Road Emissions Certifiedyamil ramirezNo ratings yet

- Tad 1240 GeDocument2 pagesTad 1240 GeFedor GrigorievNo ratings yet

- 4000 Series: Diesel Engine - Electro Unit 948 KWM at 1800 RPM Net Standby PowerDocument5 pages4000 Series: Diesel Engine - Electro Unit 948 KWM at 1800 RPM Net Standby Power謝玉順No ratings yet

- QST30-G4: Fuel OptimizedDocument3 pagesQST30-G4: Fuel OptimizedJavier DominguezNo ratings yet

- VTA28-G5: Fuel OptimizedDocument3 pagesVTA28-G5: Fuel OptimizedIslam HemdanNo ratings yet

- QSL9-G4: Emissions Compliance: EU Stage IIIA at 50Hz and 60Hz EPA Tier 3 at 50Hz and 60HzDocument2 pagesQSL9-G4: Emissions Compliance: EU Stage IIIA at 50Hz and 60Hz EPA Tier 3 at 50Hz and 60HzH 8C100% (1)

- 4000 Series: Diesel Engine - Electropak 2083 KWM at 1500 RPM Net Standby PowerDocument5 pages4000 Series: Diesel Engine - Electropak 2083 KWM at 1500 RPM Net Standby PowerNoman MasoodNo ratings yet

- 1506a-E88tag5 Hci444d PDFDocument13 pages1506a-E88tag5 Hci444d PDFPanna YasminNo ratings yet

- @perkins: 2300 Series 2306C-E14TAG2Document2 pages@perkins: 2300 Series 2306C-E14TAG2Khaled KamelNo ratings yet

- 4000 Series: Diesel Engine - Electropak 2083 KWM at 1500 RPMDocument5 pages4000 Series: Diesel Engine - Electropak 2083 KWM at 1500 RPMOrkhan AhadzadeNo ratings yet

- L36GSI DgsDocument2 pagesL36GSI DgsSyafiq MuhammadNo ratings yet

- Datashhet 4012-46tag2aDocument5 pagesDatashhet 4012-46tag2aacrotech100% (1)

- NT855 G6 PDFDocument2 pagesNT855 G6 PDFnaveed100% (1)

- Tad733Ge: 50 Hz/1500 RPM 60 Hz/1800 RPMDocument2 pagesTad733Ge: 50 Hz/1500 RPM 60 Hz/1800 RPMamir amirNo ratings yet

- @perkins: 1000 Series 1004TG1Document2 pages@perkins: 1000 Series 1004TG1Anas BasarahNo ratings yet

- @perkins: 1000 Series 1004TG1Document2 pages@perkins: 1000 Series 1004TG1OG100% (1)

- C Series Marine 480 HP (343kW) : Engine SpecificationsDocument2 pagesC Series Marine 480 HP (343kW) : Engine SpecificationsFred WestlingNo ratings yet

- TAMD163PDocument2 pagesTAMD163PdimasanggararobertsonNo ratings yet

- Kta 38 G7Document3 pagesKta 38 G7ophar100% (1)

- 1100 SeriesDocument5 pages1100 SeriesRafatNo ratings yet

- 47712910Document2 pages47712910jamesNo ratings yet

- 1006TAG2 ElectropaK PN1793 PDFDocument2 pages1006TAG2 ElectropaK PN1793 PDFAnas BasarahNo ratings yet

- TAD941GE: Volvo Penta Industrial DieselDocument2 pagesTAD941GE: Volvo Penta Industrial DieselGiangDoNo ratings yet

- Perkins 450KVADocument5 pagesPerkins 450KVAGabriel Andres ValenciaNo ratings yet

- Tad 1641 GeDocument2 pagesTad 1641 GeGiangDoNo ratings yet

- Kta 38 G3Document3 pagesKta 38 G3opharNo ratings yet

- QSX15-G9: EPA NSPS CertifiedDocument3 pagesQSX15-G9: EPA NSPS CertifiedMarcos Batista Dos SantosNo ratings yet

- DB S60 1DS GB 3231171 112010 PDFDocument2 pagesDB S60 1DS GB 3231171 112010 PDFjhonmarcNo ratings yet

- Perkins EngineDocument5 pagesPerkins EnginesahilNo ratings yet

- QSX15 G9Document3 pagesQSX15 G9Gestión del Talento Humano GEMRANo ratings yet

- 4016TAG2A 1500 RPM Electro Unit PN2181Document5 pages4016TAG2A 1500 RPM Electro Unit PN2181Md ShNo ratings yet

- 4000 Series: 4012-46TAG2ADocument5 pages4000 Series: 4012-46TAG2Aherry tristantoNo ratings yet

- Perkins 500P PDFDocument5 pagesPerkins 500P PDFsaleemNo ratings yet

- 1506a E88tag4Document5 pages1506a E88tag4franklinNo ratings yet

- 1206a-E70ttag3 PN3184 - 4Document4 pages1206a-E70ttag3 PN3184 - 4MohamedJaberKutkutMjkNo ratings yet

- QSX15-G9 XpiDocument3 pagesQSX15-G9 XpiMd ShNo ratings yet

- Dvigatel Cummins Nta855 g4Document2 pagesDvigatel Cummins Nta855 g4HanNo ratings yet

- 2206A-E13TAG2 EngineDocument4 pages2206A-E13TAG2 EngineAnamta KhanNo ratings yet

- KTA38-G5: Fuel OptimizedDocument3 pagesKTA38-G5: Fuel OptimizedRenato Matičević0% (1)

- 2800 Series: 2806A-E18TTAG5Document4 pages2800 Series: 2806A-E18TTAG5ali ahmedNo ratings yet

- QSX15 G8 Cummins Engine PDFDocument3 pagesQSX15 G8 Cummins Engine PDFCahuapaza Gilmer100% (2)

- QSX15 G8 1 PDFDocument11 pagesQSX15 G8 1 PDFMd MkNo ratings yet

- Calculating engine cycle parameters and performanceDocument8 pagesCalculating engine cycle parameters and performanceleno voiNo ratings yet

- Yamaha Wr125 Service ManualDocument372 pagesYamaha Wr125 Service Manualzeltragh83% (6)

- Part Book Cat 777G PDFDocument831 pagesPart Book Cat 777G PDFdewa100% (1)

- Engine and Emission Control: Group 17Document24 pagesEngine and Emission Control: Group 17Davit OmegaNo ratings yet

- Ajuste IAC and TPSDocument17 pagesAjuste IAC and TPSLuis Ignacio SilvaNo ratings yet

- Parts List of Engine Assy of Bobcat 590 - Job No - 6817 LS-00617Document3 pagesParts List of Engine Assy of Bobcat 590 - Job No - 6817 LS-00617CwsNo ratings yet

- 2006 Trans Eng12Document19 pages2006 Trans Eng12eurospeed2No ratings yet

- A Project On Pneumatic ViceDocument13 pagesA Project On Pneumatic ViceKumar Gk50% (2)

- Ad BLUEDocument61 pagesAd BLUEFrancisco Santiago Gallardo100% (3)

- TPD1285E2SSSSSDocument44 pagesTPD1285E2SSSSSHebert GahujfaNo ratings yet

- Code: 1120000 NS 39: Technical DataDocument3 pagesCode: 1120000 NS 39: Technical DataAlina CostinNo ratings yet

- Illustration 29 07 2017 PDFDocument1 pageIllustration 29 07 2017 PDFGlenn D. KleinNo ratings yet

- Pulsar 220 Ug - BS - Ib - SPCDocument74 pagesPulsar 220 Ug - BS - Ib - SPCMichaell KingsNo ratings yet

- TurboDocument9 pagesTurboPedro Alejandro Campos CatrianNo ratings yet

- MOD 15 en EditavelDocument704 pagesMOD 15 en EditavelJoao Santos100% (10)

- Conectores-de-Borna TRAFODocument4 pagesConectores-de-Borna TRAFOJunior MartinezNo ratings yet

- Reduce Main Bearing CorrosionDocument4 pagesReduce Main Bearing Corrosionkaarthik saaiNo ratings yet

- Motores BG Gas - 4103877Document6 pagesMotores BG Gas - 4103877Elio Custodio HuachacaNo ratings yet

- 08 ValveOperatingGearDocument64 pages08 ValveOperatingGearFrimpong Justice AlexNo ratings yet

- 2 Conventional Efi DieselDocument16 pages2 Conventional Efi DieselSharan SuryaNo ratings yet

- AOT303 - Ktu Qbank PDFDocument8 pagesAOT303 - Ktu Qbank PDFUmarul MushtaqNo ratings yet

- Motive Engine Parts Catalogue 2012 v6Document204 pagesMotive Engine Parts Catalogue 2012 v6ararsiva50% (2)

- Lps and MpsDocument14 pagesLps and MpsAkash Singh TomarNo ratings yet

- Kawasaki Fe290-400 Engine ServiceDocument101 pagesKawasaki Fe290-400 Engine ServicePaul Jett100% (2)

- IGSO-540 Parts CatalogDocument134 pagesIGSO-540 Parts Catalogprivateaerospace100% (1)

- WaukeshaBrochure1079 NUEVODocument18 pagesWaukeshaBrochure1079 NUEVOMatthew BrownNo ratings yet

- TccsDocument94 pagesTccsaditianasukadarusmanNo ratings yet

- Cat 1010-1 CAT PUMP DE 110Document2 pagesCat 1010-1 CAT PUMP DE 110carlos cortezNo ratings yet

- Sumitomo Forklift Parts Catalogue For S/N C812 B871 Part2Document162 pagesSumitomo Forklift Parts Catalogue For S/N C812 B871 Part2Петр100% (4)

- LF6430(X60) Parts Catalog (Ver:201205-1) Parts GuideDocument242 pagesLF6430(X60) Parts Catalog (Ver:201205-1) Parts GuideFlávio SoaresNo ratings yet