Professional Documents

Culture Documents

SM1007 Thin Cylinder Datasheet

Uploaded by

mmoojjttaabbaa1112Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SM1007 Thin Cylinder Datasheet

Uploaded by

mmoojjttaabbaa1112Copyright:

Available Formats

Materials Testing and Properties

T h in Cyl in der

SM1007

Benchtop machine to allow students to perform stress and strain tests on a thin walled cylinder.

Introducing Mohr’s circle and Poisson’s ratio.

screenshot of the

optional VDAS® software

K ey F e at u res

• Ideal for student use and classroom demonstrations

• For comprehensive analysis of the stresses and strains in a thin-walled cylinder, under internal pressure

• Introduces stress and strain, and how to measure and analyse them

• Includes experiments to find Young’s modulus and Poisson’s ratio

• Closed-end and open-end conditions to allow circumferential or biaxial stress tests

• High-quality electrical-resistance precision strain gauges measure cylinder strains

• Includes built-in microprocessor-controlled display of strain measurements

• Mounted on a sturdy base, to form a compact product ideal for use on a workbench

• Self-contained, hand-operated hydraulic pressurising system for accurate pressure control

• Completely self-contained, needs no other parts

TecQuipment Ltd, Bonsall Street, long eaton, Nottingham NG10 2AN, UK

tecqu ipment. c o m +4 4 115 972 2611 sales@tecquipment.com

AD/DB 0422 Page 1 of 3

T h in Cyl in der

SM1007

Description Learning Outcomes

TecQuipment’s Thin Cylinder apparatus allows students Investigations into stresses and strains in a thin cylinder, to

to perform experiments that examine stress and strain give students an understanding of:

in a thin-walled cylinder. It clearly shows the principles,

• Longitudinal stress, hoop (or circumferential) stress,

theories and analytical techniques, and provides effective,

radial stress and biaxial stress

practical support to studies.

• The behaviour of the cylinder under both open and

A sturdy base contains all parts of the Thin Cylinder

closed-end conditions

apparatus. This forms a compact product, ideal for use on

a workbench. • The use of strain gauges

A thin-walled, oil-filled aluminium cylinder held in a robust • The stress strain relationship and value of Young’s

frame so that the cylinder is free to move along its axis. modulus for the cylinder material

The cylinder is stressed using a hydraulic handpump to

• Indirect strain and stress

pressurise the oil. Strain gauges on the cylinder surface

measure strain, and a gauge and electronic sensor • The value of Poisson’s ratio for the cylinder material

measure hydraulic pressure.

• The use of Mohr’s circle to calculate the shear strain at

Students can measure strains with the cylinder in two ‘end any position in the cylinder

conditions’:

• The use of the ‘superposition method’ to find the

• Open end: the cylinder has no axial load, so there is no principal strains

direct axial stress.

• The effect of the biaxial stress system

or

• Sources of error in their experiments

• Closed end: the cylinder has axial loads, so there is

direct axial stress. R ec o mmend ed Anc illar ies

Students use a hand-wheel on the frame to set these end • Bench-mounted version of the Versatile Data

conditions. Acquisition System (VDAS-B)

To perform experiments, students choose either closed or

open-end conditions. They set the gauges to zero and use

Essential Services

the pump to pressurise the cylinder. They take readings Electrical supply:

at several stages while they increase the pressure. The Single phase, 90 - 250 VAC, 50 / 60 Hz, 1A

results can be taken by hand using the in-built display and

pressure gauge, and results plotted by hand. Alternatively, B ench space needed: 1 m x 0.5 m

students can use TecQuipment’s optional Versatile Data

Acquisition System (VDAS®) to capture the data and plot

O per ating C o nd itio ns

the relevant graphs and export data. They then compare O perat ing enviro nment:

their results with calculations made using stress and strain Laboratory

theory.

Storage temperature range:

A user guide is supplied with the Thin Cylinder apparatus. –25°C to +55°C (when packed for transport)

The guide includes full details of the equipment, detailed

experiment procedures, theory and results. O perat ing t emperat u re ra nge:

+5°C to +40°C

For quick and reliable tests, TecQuipment can supply

VDAS® which gives accurate real-time data capture, O perat ing relat ive hu midit y ra nge:

monitoring and display, calculation and charting of 80% at temperatures < 31°C decreasing linearly to 50% at

all important readings on a computer (computer not 40°C

included).

Sound Levels

Standard Features

The measured sound pressure level of this apparatus is

• Supplied with comprehensive user guide less than 70 dB(A).

• Five-year warranty

• Manufactured in accordance with the latest European

Union directives

• ISO9001 certified manufacturer

TecQuipment Ltd, Bonsall Street, long eaton, Nottingham NG10 2AN, UK

tecqu ipment. c o m +4 4 115 972 2611 sales@tecquipment.com

AD/DB 0422 Page 2 of 3

T h in Cyl in der

SM1007

Specifications

TecQuipment is committed to a programme of continuous

improvement; hence we reserve the right to alter the

design and product specifcation without prior notice.

Nett dimens io ns and w e i gh t:

715 mm x 370 mm x 380 mm and 30 kg

Ap proximat e pac ked di m e n s i on s a n d w e i gh t:

0.25 m3 and 41 kg

O il:

Shell Tellus S2 M32 or equivalent (supplied with 500 mL

spare)

Cylinder and reservoir capacity:

Approximately 2 litres

Cylin d er mat er ial :

Aluminium alloy

Pr ess u r e:

Displayed by Bourdon gauge, with output for VDAS®

Strain:

Measured by electrical resistance gauges and displayed

digitally, with output for VDAS®

TecQuipment Ltd, Bonsall Street, long eaton, Nottingham NG10 2AN, UK

tecqu ipment. c o m +4 4 115 972 2611 sales@tecquipment.com

AD/DB 0422 Page 3 of 3

You might also like

- High Impulse Voltage and Current Measurement Techniques: Fundamentals – Measuring Instruments – Measuring MethodsFrom EverandHigh Impulse Voltage and Current Measurement Techniques: Fundamentals – Measuring Instruments – Measuring MethodsNo ratings yet

- SM1011 Thick Cylinder DatasheetDocument3 pagesSM1011 Thick Cylinder Datasheethansdavid.aquino2004No ratings yet

- TM25 Journal Bearing DatasheetDocument2 pagesTM25 Journal Bearing Datasheet3059 SUNARAM HANSDAHNo ratings yet

- STS17 Redundant Truss DatasheetDocument3 pagesSTS17 Redundant Truss DatasheetLeandro Silva SantosNo ratings yet

- STS5 Bending Stress in A Beam DatasheetDocument3 pagesSTS5 Bending Stress in A Beam DatasheetLeandro Silva SantosNo ratings yet

- TE38 Solar Collector DatasheetDocument2 pagesTE38 Solar Collector Datasheetניסן בורוכובNo ratings yet

- STS12 Euler Buckling of Struts DatasheetDocument3 pagesSTS12 Euler Buckling of Struts DatasheetLeandro Silva SantosNo ratings yet

- H52 Series and Parallel Pump Test SetDocument2 pagesH52 Series and Parallel Pump Test SetOğuzcan KaynakNo ratings yet

- SM1005 Euler Buckling Datasheet PDFDocument3 pagesSM1005 Euler Buckling Datasheet PDFSuranga DilshanNo ratings yet

- Continuous and Indeterminate Beam ExperimentsDocument2 pagesContinuous and Indeterminate Beam ExperimentsBright KnightNo ratings yet

- AF27 Laval Nozzle Pressue Apparatus DatasheetDocument3 pagesAF27 Laval Nozzle Pressue Apparatus DatasheetUzair BukhariNo ratings yet

- STS12 Euler Buckling of Struts DatasheetDocument3 pagesSTS12 Euler Buckling of Struts DatasheetOmar KetfiNo ratings yet

- STS12 Euler Buckling of Struts DatasheetDocument3 pagesSTS12 Euler Buckling of Struts DatasheetOmar KetfiNo ratings yet

- Boudary LayetDocument2 pagesBoudary LayetTaha BaigNo ratings yet

- PSA30 Distance Protection DatasheetDocument2 pagesPSA30 Distance Protection DatasheetSAYYAMNo ratings yet

- H215 Osborne Reynolds Apparatus DatasheetDocument2 pagesH215 Osborne Reynolds Apparatus DatasheetSebastian GomezNo ratings yet

- SM1001 Torsion Testing DatasheetDocument3 pagesSM1001 Torsion Testing DatasheetChriv SokundavannNo ratings yet

- TD1000 Boyles Law DatasheetDocument2 pagesTD1000 Boyles Law DatasheetRorisang MolotsiNo ratings yet

- STS16 Plastic Bending of Portals DatasheetDocument3 pagesSTS16 Plastic Bending of Portals DatasheetLeandro Silva SantosNo ratings yet

- EC1500 Refrigeration Trainer Datasheet 0719Document2 pagesEC1500 Refrigeration Trainer Datasheet 0719Zunuran NasrullahNo ratings yet

- Centrifugal Pump Test Set: Screenshot of The Optional VDAS® SoftwareDocument3 pagesCentrifugal Pump Test Set: Screenshot of The Optional VDAS® SoftwareSyafiq Sabran HasnanNo ratings yet

- Standard Operating Procedure: Name of The Lab./facility Electronics LabDocument10 pagesStandard Operating Procedure: Name of The Lab./facility Electronics LabShashikant VermaNo ratings yet

- Theory of Machines: Centre of PercussionDocument2 pagesTheory of Machines: Centre of PercussionC. ZaragozaNo ratings yet

- Euler Buckling ExperimentDocument3 pagesEuler Buckling ExperimentOmar KetfiNo ratings yet

- Barkatullah University Tensile Test PresentationDocument20 pagesBarkatullah University Tensile Test PresentationSalman KhanNo ratings yet

- H11 Centre of Pressure DatasheetDocument2 pagesH11 Centre of Pressure DatasheetgezhoubapichanakiNo ratings yet

- STS2 Bending Moments in A Beam DatasheetDocument3 pagesSTS2 Bending Moments in A Beam DatasheetAsef ShahriarNo ratings yet

- 160 LW Bending Tester v2.0Document4 pages160 LW Bending Tester v2.0Sá StrapassonNo ratings yet

- Stress and StrainDocument15 pagesStress and StrainDiego Leonardo GonzálezNo ratings yet

- H405 Pipe Surge DatasheetDocument5 pagesH405 Pipe Surge DatasheetAdakole ObekaNo ratings yet

- Celda de CargaDocument18 pagesCelda de CargaronainteNo ratings yet

- H47 Centrifugal Pump DatasheetDocument3 pagesH47 Centrifugal Pump Datasheetcamilo.gonzalez.pozoNo ratings yet

- How to Use an Analogue MultimeterDocument36 pagesHow to Use an Analogue MultimeterErick Jose Salas HidalgoNo ratings yet

- Mechanical Testing SOP for Spiral PC WireDocument3 pagesMechanical Testing SOP for Spiral PC WireNirmal WiresNo ratings yet

- Calculating a compound centre of percussionDocument2 pagesCalculating a compound centre of percussionABHISHEKNo ratings yet

- Presentasi Raytech wr50Document31 pagesPresentasi Raytech wr50yori arifNo ratings yet

- Schneider Automatic Circuit Recloser SWP: 1. Purpose and ScopeDocument7 pagesSchneider Automatic Circuit Recloser SWP: 1. Purpose and ScopeJairo WilchesNo ratings yet

- TD1002 Heat Transfer Datasheet PDFDocument2 pagesTD1002 Heat Transfer Datasheet PDFlecala 205No ratings yet

- Civil Engineering Department Lab ManualDocument47 pagesCivil Engineering Department Lab Manualubaid quaziNo ratings yet

- 70 120 160 DCTS DS en V16Document4 pages70 120 160 DCTS DS en V16Mohamed AshrafNo ratings yet

- ST 9122 Experimental Techniques and InstrumentationDocument18 pagesST 9122 Experimental Techniques and InstrumentationananthaaNo ratings yet

- Experimental Techniques and InstrumentationDocument18 pagesExperimental Techniques and InstrumentationMaharajan McsNo ratings yet

- Doble Test ProceduresDocument21 pagesDoble Test ProceduresRamKumarNo ratings yet

- Doble Test ProceduresDocument21 pagesDoble Test Proceduresdsfas100% (1)

- 1SNC169001C0210Document24 pages1SNC169001C0210Gianc87No ratings yet

- Modular Airflow BenchDocument2 pagesModular Airflow BenchTaha BaigNo ratings yet

- Triaxial Compression TestDocument6 pagesTriaxial Compression TestMarionne AlmedaNo ratings yet

- 1.Strength-of-Materials V+Document36 pages1.Strength-of-Materials V+sriramNo ratings yet

- Essential Electrical and Electronics Lab ExperimentsDocument89 pagesEssential Electrical and Electronics Lab ExperimentsYaswanth KanugantiNo ratings yet

- Material Science and Testing LabDocument26 pagesMaterial Science and Testing LabJitendra JangidNo ratings yet

- TD1005 Free and Forced Convection Datasheet 0518 PDFDocument3 pagesTD1005 Free and Forced Convection Datasheet 0518 PDFAmier AziziNo ratings yet

- Bellows Pressure SensorsDocument13 pagesBellows Pressure Sensorspritesh deshmukhNo ratings yet

- Stress and Strain LabDocument14 pagesStress and Strain LabDiego Leonardo GonzálezNo ratings yet

- Tensile Test PresentationDocument36 pagesTensile Test Presentationssdivi100% (2)

- CE117 Process Trainer DatasheetDocument3 pagesCE117 Process Trainer DatasheetCRISTOBAL ANDRES SUSARTE RODRIGUEZNo ratings yet

- AF10 Air Flow DatasheetDocument2 pagesAF10 Air Flow DatasheetaminemohamedjobNo ratings yet

- Universal Testing MachineDocument28 pagesUniversal Testing MachineMarc Anthony de VillaNo ratings yet

- High Voltage Measurement Techniques: Fundamentals, Measuring Instruments, and Measuring MethodsFrom EverandHigh Voltage Measurement Techniques: Fundamentals, Measuring Instruments, and Measuring MethodsNo ratings yet

- Atomic Structure DPP 2 PDFDocument2 pagesAtomic Structure DPP 2 PDFtan jig0% (1)

- 04Document15 pages04Aravindan KrishnamoorthyNo ratings yet

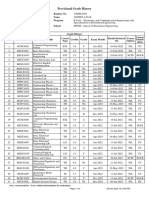

- StudentGradeHistory 21BML0190Document3 pagesStudentGradeHistory 21BML0190brotin2002No ratings yet

- Chinox 168: AntioxidantDocument2 pagesChinox 168: AntioxidantDanilo CunhaNo ratings yet

- Lecture - Electron DiffractionDocument12 pagesLecture - Electron DiffractionOlivia WahyudiNo ratings yet

- UFO Files From The UK Government DEFE 24/1999Document321 pagesUFO Files From The UK Government DEFE 24/1999Exit ExitNo ratings yet

- Cleaning-In-Place in The Dairy IndustryDocument11 pagesCleaning-In-Place in The Dairy IndustryihllhmNo ratings yet

- PT Fuchs Lubricants (Arrow Asia-Aldaco Citrajaya) - Nissan-Samp PDFDocument1 pagePT Fuchs Lubricants (Arrow Asia-Aldaco Citrajaya) - Nissan-Samp PDFpinot san92No ratings yet

- 4ph1 2pr Que 20230121Document24 pages4ph1 2pr Que 20230121Nang Seng Tawng HparawNo ratings yet

- Lab. 2 Three Component SystemsDocument4 pagesLab. 2 Three Component Systemssultan100% (1)

- CO2 Adsorption Using Octa(aminophenyl)silsesquioxane Grafted Mesoporous SBA-15Document9 pagesCO2 Adsorption Using Octa(aminophenyl)silsesquioxane Grafted Mesoporous SBA-15cansuNo ratings yet

- Science Class X Sample Paper Test 02 For Board Exam 2024 AnswersDocument14 pagesScience Class X Sample Paper Test 02 For Board Exam 2024 Answerssingh2008adityaNo ratings yet

- Photonic Crystal FiberDocument6 pagesPhotonic Crystal FiberHugoAlmNo ratings yet

- SteamDocument40 pagesSteamRupesh AnandNo ratings yet

- Earth Science: Quarter 2 - Module 1 Weathering of RocksDocument15 pagesEarth Science: Quarter 2 - Module 1 Weathering of RocksRonian DuruinNo ratings yet

- ElectrolysisDocument17 pagesElectrolysisAdil Yaqub - 74665/TCHR/CNTBNo ratings yet

- Statistical Thermodynamics of Ideal GasesDocument29 pagesStatistical Thermodynamics of Ideal GasesSwapnanil MandalNo ratings yet

- Registration Certificate for Talon 0.005 BB RodenticideDocument17 pagesRegistration Certificate for Talon 0.005 BB RodenticidepurwadiNo ratings yet

- Evaporation FullDocument57 pagesEvaporation FullMonty KushwahaNo ratings yet

- Myp 2 Term 1 SciencesDocument6 pagesMyp 2 Term 1 Sciencesishaq.yakubuNo ratings yet

- Shuaiba Transition Zone Fields: From Laboratory Scal Experiments To Field Development ChallengesDocument12 pagesShuaiba Transition Zone Fields: From Laboratory Scal Experiments To Field Development Challengesari_siNo ratings yet

- Biomolecules Key Notes 2020Document14 pagesBiomolecules Key Notes 2020Pon Adityan JeyamuruganNo ratings yet

- Article1430240348 - Isehunwa Et AlDocument7 pagesArticle1430240348 - Isehunwa Et AlAbhishek DubeyNo ratings yet

- Biofiltration of Volatile Organic Compounds Using Fungi and Its Conceptual and Mathematical Modeling2018biotechnology Advances 11 15Document5 pagesBiofiltration of Volatile Organic Compounds Using Fungi and Its Conceptual and Mathematical Modeling2018biotechnology Advances 11 15manuelNo ratings yet

- Some Aspects of Petroleum Refinery Simulation: A: The Nature of Crude OilDocument22 pagesSome Aspects of Petroleum Refinery Simulation: A: The Nature of Crude OilmarraezNo ratings yet

- Solar Radiation Transfer Through Building Envelopes: Principles of Heating 9562-09Document52 pagesSolar Radiation Transfer Through Building Envelopes: Principles of Heating 9562-09Omar ArdilaNo ratings yet

- Rip-Current Type, Spacing and Persistence, Narrabeen Beach, AustraliaDocument25 pagesRip-Current Type, Spacing and Persistence, Narrabeen Beach, AustraliaShmigglerNo ratings yet

- Creatin in ADocument2 pagesCreatin in AErick AlvarezNo ratings yet

- A Study On Anasysis and Fabrication of An Ice Plant ModelDocument13 pagesA Study On Anasysis and Fabrication of An Ice Plant ModelLeyzer MalumayNo ratings yet

- Prelim Exam-Organic Chem No KeyDocument6 pagesPrelim Exam-Organic Chem No KeyRAMIL BAUTISTANo ratings yet