Professional Documents

Culture Documents

N107 - Selection of Hold Service Insulation

N107 - Selection of Hold Service Insulation

Uploaded by

Nob Odyk Nows0 ratings0% found this document useful (0 votes)

3 views9 pagesOriginal Title

N107_-_Selection_of_Hold_Service_Insulation

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views9 pagesN107 - Selection of Hold Service Insulation

N107 - Selection of Hold Service Insulation

Uploaded by

Nob Odyk NowsCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 9

Doc. No.: N107

SPECIFICATION

Rev. No: 0A.

SELECTION OF HOT SERVICE INSULATION

PT. TRANS-PACIFIC PETROCHEMICAL INDOTAMA

SPECIFICATION

FOR

SELECTION OF HOT SERVICE INSULATION

REVISION 0A

Issued For

REV-DESC. | contract Document

[PREPARERD WAUO

[DATE 13/07/02

[LEAD ENG/ 2D "Fo?

DATE 7

[PROJECT

IENG/ DATE

Doc. No.: NIO7

SPECIFICATION

FOR Rev. No.: 0A,

SELECTION OF HOT SERVICE INSULATION

Page 2 of 9

TABLE OF CONTENT

1 SCOPE

2 INSULATION CODE DESIGNATIONS

3. INSULATION CRITERIA

GENERAL

3.2 STEAM TRACED AND STEAM JACEKTED (ST, SJ) 5

3.3. ELECTRIC HEAT TRACED (ET) —~ 5

3.4 HEAT CONSERVATION (HC) — 3

3.5 PROCESS STABILIZATION (PS) 4

3.6 PERSONNEL PROTECTION (PP) — 4

3.7 FIRE PROTECTION (FR)— 4

3.8 SOUND CONTROL (AH) — 7]

3.9 HOTOIL(HO) — a

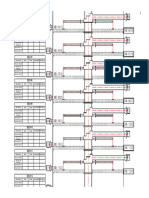

TABLE:

PIPE AND EQUIPMENT INSULATION THICKNESSES (MM) FOR ABOVE AMBIENT

EMPERATURE (HOT INSULATION AND PERSONNEL PROTECTION).

Doc. No.: Ni07

SPECIFICATION

FOR

SELECTION OF HOT SERVICE INSULATION

Rev. No: 0A

Page 3 of 9

SCOPE

il This specification covers the general requirements for insulation applied to the exterior

surfaces of hot service (above ambient) equipment and piping, to limit the amount of heat

loss and to provide personnel protection. For Hot Service insulation materials and details,

see specification N 108.

12 This specification also defines insulation code designations to be used to identify

insulation requirements on the line designation table and P&IDs.

13 The schedule of insulated, painted, and fireproofed equipment shall designate the

requirements for equipment, and the line designation table shall designate the insulation

and painting requirements for piping.

14 Insulation thickness for Pipe and Equipment Hot Insulation and Personne! Protection are

shown in Tables A. -

13 Equipment means pumps, compressors, motors, vessels, heat exchangers, tanks, etc.

2 INSULATION CODE DESIGNATIONS

2.1 ‘The index of the Insulation Code Designations are as follows :

INSULATION CODE DESCRIPTION

+ HEAT TRACED AND JACKETED INSULATION

STAND SJ ‘Steam heat Protection

ET Electric Heat Traced

* HOT INSULATION

HC Heat Conservation

PS Process Stabilization

PP Personnel Protection

FR, Fire Protection

AH ‘Sound Control

HO Hot Oil

+ COLD INSULATION (See specification N105)

Page 4 of 9

SPECIFICATION

FOR

SELECTION OF HOT SERVICE INSULATION

INSULATION CRITERIA

General

The normal operating temperature of the contents of equipment and piping shall be used in

the determination of the need for, and the thickness of, insulation on equipment and piping

with the exception of the following :

a¢ When piping and equipment are furnished with means for protective heating, the

operating temperature of the process fluid shall be used.

(6. When the temperature is not given for equipment in steam service, the saturated steam.

temperature corresponding to the steam pressure shall be used.

Cc. The operating temperature of a fluid for vertical vessels may vary over the vessel

length, the insulation thickness may be changed as required over this length.

f- When piping and equipment is subject to regeneration condition, the regeneration

temperatures shall be used.

3.1.2 Steam traps and unions in all insulated lines shall not be insulated.

3.1.3. Vessels which are to be post weld heat treated may have an insulation thickness suitable

for the heat jreating operation when itis desirable to install permanent insulation before the

heat treatifig operation is performed.

3.1.4 The following equipment and parts of equipment shall not normally be insulated :

a. Equipment and piping where heat loss to the atmosphere is a design requirement or

desirable

Blowers and compressors

Water side of coolers and condensers unless for personnel protection

Bellows expansion joints and similar types of mechanical equipment.

Cooling water lines

Seal pots, vent chambers, and drip pots should be insulated only if steam traced.

Bearing housings of pumps

Mixers, expansion joints, flow glasses, hoses, nameplates

Pipe and equipment supports

Piping and equipment intermittently heated shall not be insulated such as :

Relief valves and relief system located in line sloped to drain

Vents and drains

Flare systems

Drain systems

re me pes

SPECIFICATION

FOR

SELECTION OF HOT SERVICE INSULATION

‘Doc. No.: NI07

Page 5 of 9

STEAM TRACED AND STEAM JACEKTED (ST, SJ)

3.2.1 Steam tracing of piping is covered in the design and installation of Steam heat Tracing

Project Specification C103. —

3.2.2 Insulation shall be applied to traced or jacketed piping, flanges, fittings, valves and

equipment to reduce heat loss.

3.2.3 The temperature required to be maintained shall be used to determine the thickness of

insulation for steam traced lines or equipment. Insulation requirements are the same as for

ee Process stabilization (PS)

"B3 ELECTRIC HEAT TRACED (ET)

3.3.1 Electric heat tracing is covered in the design and installation of Electric Heat Tracing

Specification. He

3.3.2 Insulation shall be applied to traced piping, flanges, fittings, valves and equipment to

reduce heat loss. tare

3.3.3 The temperature required to be maintained shall be used to determine the thickness of

insulation for electric traced lines or equipment. Insulation requirements are the same as

for process stabilization (PS). Minimum thickness shall be 2" (5mm)

3.4 HEAT CONSERVATION (HC)

3.4.1 Insulation shall be applied to equipment, piping, flanges, fittings, valves and equipment

with an operating temperature above 145°F (63°C) where heat loss is critical and heat

conservation is desirable. The following criteria shall be followed:

PIPING

1. Insulate piping to limit heat loss.

2. Valves, valve bonnets, and flanges are not insulated, including those in steam lines

leading to heat transfer equipment and unit heaters

3. External insulation should not be used on internally insulated piping.

4, Valves, valves bonnets and flanges shall be insulated in steam lines to drivers and

process equipment, except heat transfer equipment.

EQUIPMENT

5. Equipment flanges and manholes shall not be insulated

6. Exchanger channel section (unless in steam service) and body flanges are not insulated,

unless required for personnel protection

Doc. No.: N107

SPECIFICATION

FOR Rev. No.: 0A

SELECTION OF HOT SERVICE INSULATION

Page 6 0f9

3.6

3.6.1

3.7

B71

Pumps under 400°F (204°C) are not insulated, however personnel protection may be

required when the fluid temperature is 145°F (63°C) to 400°F (204°C)

8. Fans, compressors, and blowers are not to be insulated, except for sound control.

9. External insulation shall not be used on internally insulated equipment

10. Expansion, rotation joints and similar types of mechanical equipment are not insulated,

PROCESS STABILIZATION (PS)

Insulation shall be applied to equipment, piping, flanges, fittings, valves and equipment

with an operating temperature above 81°F where heat loss is critical. The following criteria

shall be followed :

PIPING

1. Insulate process lines in which heat loss is critical to the system.

2. Valves, valve bonnets, and flanges are insulated.

ae

External insulation should not be used on incgmally insulated piping,

EQUIPMENT

4, Equipment flanges and manholes are insulated

5. Exchanger channel section and body flanges are insulated.

6. Pumps under 40°F (204°C) are not insulated unless heat loss is critical to the system.

Personnel protection may be required when the fluid temperature is 145°F (63°C) to

400°F (204°C)

7. Fans, compressors, and blowers are not insulated, unless heat loss is critical or for

sound control.

8. Extemal insulation shall not be used on internally insulated equipment

9. Insulate expansion, rotation joints and similar types of mechanical equipment, only

‘when heat loss is critical to the system. _~

PERSONNEL PROTECTION (PP)

Insulation or shields shall be provided as determined by the Purchaser on surfaces with a

temperature above 145°F (63°C) for protection of personnel. Personnel protection when

required should extend 7 feet (2.13 meters) above grade of operating or maintenance

platform and 24 inches (610 mm) horizontally beyond areas accessible to personneld uring

operations.

FIRE PROTECTION (FR)

When fire protection insulation is a requirement stainless stee! jacketing shall be used.

7

SPECIFICATION

FOR

SELECTION OF HOT SERVICE INSULATION

Page 7 of 9

SOUND CONTROL (AH)

Insulation is provided to reduce sound levels when required for piping and equipment. The

following guidelines shall be used :

a. System I — 10 DB and Lower-Frequency 2000 Hz and up (150°F to 1200°F) (66°C to

649°C).

Apply two inch (50 mm) layers of 8 Ib/eu.fi. (128 kg/cu. Meter) single-foil faced

‘mineral wool board with facing inside or pipe covering. Outer covering over the

mineral wool insulation shall be 0.056 inch aluminum jacketing with factory applied

moisture barrier.

b. System 2 — 10 DB and Lower-Frequency 2000 Hz and up (150°F to 450°F) (66°C to

232°C).

Insulated pipe or valves with a maximum temperature limit of 450°F (232°C). Apply

two 2” layers of 6 Ib/ewft. (96 kg/cu. Meter) single-foil faced fiberglass material with

facing inside. Outer covering over the fiberglass material shall be 0.056 inch aluminum

jacketing with factory applied moisture barrier. For temperatures above 450°F (232°C)

use system 1.

©. System 3 - 10 DB and Lower-Frequency 2000 Hz and up (150°F to 450°F) (66°C to

232°C).

Ceaser pipe or valves with a maximum temperature limit of 450°F (232°C). Apply

two 2” layers of 6 Ib/cu.ft. (96 ke/cu. Meter) single-foil faced fiberglass material with

facing inside. Outer covering over the fiberglass material shall be a 1 Lb/sq.ft (4.88

kkg/sq. meter) of lead, lead-coated vinyl or other non-lead product approved by the

Purchaser. Outer covering over fiberglass and lead material shall be 0.056 inch

aluminum jacketing with factory applied moisture barrier.

d. System 4-10 DB and Lower-Frequency 2000 Hz and up (150°F to 1200°F) (66°C to

649°C).

Insulated pipe or valves with a maximum temperature limit of 1200°F (649°C) with

two 2” layer of 8 lb/cu.ft. (238 kb/cu. Meter) single-foil faced mineral wool material

with facing inside or pipe covering. Outer covering over the mineral wool material

shall be a ILb/sq.ft (4.88 ke/sq. meter) of lead, lead coated vinyl or other non-lead

product as approved by the Purchaser. Outer covering over the mineral wool and lead

material shall be 0,056 inch aluminum jacketing with factory applied moisture barrier.

pe

Doc. No.: N107

SPECIFICATION

FOR Rev. No.: 0A

SELECTION OF HOT SERVICE INSULATION

Page 8 of 9

¢. System 5 ~ 10 DB and Lower-All Frequency ~ Cold Service (149°F and below) (65° C

and below) See specification N105.

HOT OIL (HO)

Item contains heat transfer type oil (i.e. Dowtherm). Insulation requirements are the same

as process stabilization (PS) except only cellular glass insulation shall be used.

“0v'0 JO.

TONVLLINT NV HUAN ONLLIAOVE ONIIOOURITHL VAM ONY GNIM (yur 8) HIN $ “LENIGWY (9.97) 4008 NV

LIAL (069) loSbI JO TUNLVATAWEL TOVERINS V ONINIVLNIVIN CNV SOINONOOE NO GESVE SUV SSENNOIHL 7

ANTINdINDT UO SANIT GAQVUL LVIH ORILIATA NO GaSN 3a TIVHS Ww OS JO WNININ YL

NOILVINSNI 100M TVUANIW HHL OWd (0.665) Jo0011 NVHL SS dO TUNLVAIdWAL TOVIUALNI

NV TAVH OL SSUNAOIWL LNAIOMINSIO SSANAOINL NOLLVINSNI AAG OWWVAFO AG OL YIAVT LSUd +

:SaN0N,

WaAVTUIAN > WAV TTIONIS

uaaidinbg

oa! sol a oct su oor 06 St so os put 82 2400

081 $91 0 ia si 001 06 SL 9 os 8

om 0st 0 oft 001 06 SL 9 os 9.

on 0st 0 oct 004, 06, SL $9 os ve

ol ost 0 oct 00 001 06 Si 9 os, 0

$91 ost a oct oor 06 SL 9 9 os

$91 orl ofl suv 01 06 SL 9 0s os oF

$91 oft Et su oor 06 St 59 os oF or

ost a oer sul oot 06 St. 9 os oF oF

ost oc! su

Of si 01 06 06 St st so os ov oF 9

oe su ‘01 06 se SL 9 os, oF ov St s

si oot 001 06 SL 9 9 os oy ov St *

g 001 06 St st 9 os os oF oF St €

oor 06 SL SL 9. 59 os 0s or or St o

001 06 SL st 9 9 os os OF or St z

OF 96 su 9 9 os os os OF. oF St wiredn

sig | so | sose | oso $66 sts on sty ous ste 09%. (an)

Do TUNLVUAdIWIL ONILVAIdO WAWIXV BZIS Idld

(i B.LON) (NOMOSLOUd TANNOSUId GNY NOILYINSNI LOH) SAUNLVUSINAL LNSISWY

AOSV YOd (WH) SYSSINAOIHL NOLLYINSNI LNAWINDS GNV adid

Vilevl

20p woweynst] 29i0s95 19H JO UoH99195 VOU LOIN

630.6980

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 001 2Document1 page001 2Nob Odyk NowsNo ratings yet

- Bottom Head: Description Start Finish Completed RemainingDocument1 pageBottom Head: Description Start Finish Completed RemainingNob Odyk NowsNo ratings yet

- Class Schedule: Monday Tuesday Wednesday Thursday FridayDocument2 pagesClass Schedule: Monday Tuesday Wednesday Thursday FridayNob Odyk NowsNo ratings yet

- Astm A381Document5 pagesAstm A381Nob Odyk NowsNo ratings yet

- Dimyati Makin Curriculum Vitae 2021Document7 pagesDimyati Makin Curriculum Vitae 2021Nob Odyk NowsNo ratings yet

- Ashar Aji - Mechanical Construction EngineerDocument14 pagesAshar Aji - Mechanical Construction EngineerNob Odyk NowsNo ratings yet

- Draft Change Instruction Letter IDocument8 pagesDraft Change Instruction Letter INob Odyk NowsNo ratings yet

- RL20.1880-D-GEN-1021-00 - Route Simulation - 5Document1 pageRL20.1880-D-GEN-1021-00 - Route Simulation - 5Nob Odyk NowsNo ratings yet

- RL20.1880-D-GEN-1021-00 - Route Simulation - 6Document1 pageRL20.1880-D-GEN-1021-00 - Route Simulation - 6Nob Odyk NowsNo ratings yet

- RL20.1880-D-TRA-0821-00 - Transportation ArrangementDocument1 pageRL20.1880-D-TRA-0821-00 - Transportation ArrangementNob Odyk NowsNo ratings yet

- RL20.1880-D-GEN-1021-00 - Route Simulation - 2Document1 pageRL20.1880-D-GEN-1021-00 - Route Simulation - 2Nob Odyk NowsNo ratings yet

- Combustion TechnologyDocument51 pagesCombustion TechnologyNob Odyk NowsNo ratings yet

- CRS - Requisition For Scaffolding Work - Rev0 - KS LEEDocument2 pagesCRS - Requisition For Scaffolding Work - Rev0 - KS LEENob Odyk NowsNo ratings yet

- RL20.1880-D-GEN-1021-00 - Route Simulation - 3Document1 pageRL20.1880-D-GEN-1021-00 - Route Simulation - 3Nob Odyk NowsNo ratings yet

- Epc Revitalization Project of RCC Ru Vi Balongan: Rev - No. 0 NO. 6 of 88Document1 pageEpc Revitalization Project of RCC Ru Vi Balongan: Rev - No. 0 NO. 6 of 88Nob Odyk NowsNo ratings yet

- CRS Rev.0ADocument1 pageCRS Rev.0ANob Odyk NowsNo ratings yet

- MO No. Plant Planner Equipment Work Center Items Material No. Material Description UOM Reqmnt - Qty Unrest - QtyDocument4 pagesMO No. Plant Planner Equipment Work Center Items Material No. Material Description UOM Reqmnt - Qty Unrest - QtyNob Odyk NowsNo ratings yet

- LR13000 Brochure en v2011Document12 pagesLR13000 Brochure en v2011Nob Odyk NowsNo ratings yet