0% found this document useful (0 votes)

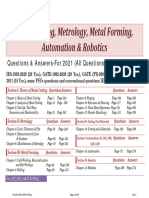

166 views3 pagesMetal Cutting Process Classification Guide

Metal cutting processes can be classified into four main categories: mechanical cutting, thermal cutting, chemical cutting, and abrasive cutting. Mechanical cutting relies on a sharp tool to physically remove material and includes processes like turning, milling, and drilling. Thermal cutting uses heat from processes like oxy-fuel cutting and plasma cutting to melt or burn away material. Chemical cutting utilizes chemical reactions through processes such as electrochemical machining to remove metal. Abrasive cutting involves abrasive particles removing metal through abrasive water jet cutting or abrasive wire cutting. The choice of metal cutting method depends on the material, part geometry, and desired surface finish.

Uploaded by

fatmafarahCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

166 views3 pagesMetal Cutting Process Classification Guide

Metal cutting processes can be classified into four main categories: mechanical cutting, thermal cutting, chemical cutting, and abrasive cutting. Mechanical cutting relies on a sharp tool to physically remove material and includes processes like turning, milling, and drilling. Thermal cutting uses heat from processes like oxy-fuel cutting and plasma cutting to melt or burn away material. Chemical cutting utilizes chemical reactions through processes such as electrochemical machining to remove metal. Abrasive cutting involves abrasive particles removing metal through abrasive water jet cutting or abrasive wire cutting. The choice of metal cutting method depends on the material, part geometry, and desired surface finish.

Uploaded by

fatmafarahCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd