0% found this document useful (0 votes)

141 views14 pagesAPI 650/653 Shell Stress Analysis

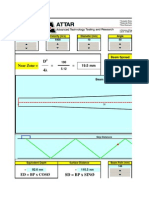

The document provides information on maximum allowable shell stresses according to API 650/653 standards. It lists the nominal plate thickness and corresponding maximum allowable stress based on plate grade and courseness. It also provides the maximum allowable stress in pounds per square inch. The document then evaluates the thicknesses of shell plates for a specific tank against the required minimum thicknesses calculated using parameters like tank diameter, height, and stress allowances. It identifies any strakes where the existing thickness is below the minimum required.

Uploaded by

tranhuy3110Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

141 views14 pagesAPI 650/653 Shell Stress Analysis

The document provides information on maximum allowable shell stresses according to API 650/653 standards. It lists the nominal plate thickness and corresponding maximum allowable stress based on plate grade and courseness. It also provides the maximum allowable stress in pounds per square inch. The document then evaluates the thicknesses of shell plates for a specific tank against the required minimum thicknesses calculated using parameters like tank diameter, height, and stress allowances. It identifies any strakes where the existing thickness is below the minimum required.

Uploaded by

tranhuy3110Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 14