Professional Documents

Culture Documents

963E Benchtop Air Ionizer User Guide

Uploaded by

Pragadeeshwaran SubramanianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

963E Benchtop Air Ionizer User Guide

Uploaded by

Pragadeeshwaran SubramanianCopyright:

Available Formats

USER GUIDE TB-9007

963E Benchtop Air Ionizer

Installation, Operation and Maintenance

The 963E Benchtop Air Ionizer and its accessories are

available as the following item numbers:

Item Description

963E Benchtop Air Ionizer, North America

963E-NO Benchtop Air Ionizer, without Power Cord

770047 Boom Arm

963E-X Power Adapter, 100-240VAC Input, 24VDC

1.5A Output, No Power Cord

770000 Power Cord, North America Plug

770001 Power Cord, UK Plug

770002 Power Cord, Europe Plug

770003 Power Cord, China Plug

Packaging

1 Benchtop Air Ionizer

1 Power Adapter with IEC C14 Inlet, 24 VDC

1 Power Cord with North America Plug (item 963E only)

Figure 1. SCS 963E Benchtop Air Ionizer

Installation

Description The Benchtop Air Ionizer mounts easily in a variety of

positions using the provided tilting bracket/stand. Place

The SCS 963E Benchtop Air Ionizer is a self-contained the unit on the work surface and point it at the area or

ionizing air blower designed to remove static charges object to be neutralized. Alternatively, the mounting

from non-conductive objects. The proprietary circuitry bracket may be attached directly to or above the

contained in the blower generates balanced levels of workstation, or on another supporting structure. Note

positive and negative ions. The ionizer is equipped with that placement of the Ionizer is important in determining

a two speed fan which allows the user to select the its effectiveness. The distance from the target object,

amount of ionized air to be delivered to the target object. and fan speed affect the ionizer’s performance. As

The Benchtop Air Ionizer meets the required limits of distance increases or fan speed is reduced, the

ANSI/ESD S20.20 tested per ANSI/ESD STM3.1 or discharge time will increase.

ESD TR53.

Connect the switching power supply to the Ionizer using

The Benchtop Air Ionizer reduces a static charge the Mini DIN connector. Then, using the appropriate

of ± 1000V to ± 100V in less than two seconds (the electrical power cord, connect the switching power

discharge time) at a distance of one foot (30 cm) using supply to an electrical outlet.

the high fan speed. Testing is performed in accordance

with the ionization standard ANSI/ESD STM3.1.

Operation

The Benchtop Air Ionizer requires 24VDC power, which

is supplied through a Mini DIN connector on the back of The three position rocker switch on the front of the

the unit. The Ionizer is packaged with a switching power unit is the POWER switch. The center switch position

supply, capable of converting 100V–240VAC, 50/60 Hz (marked O) is the OFF position. The upper and lower

into 24VDC. The switching power supply uses a 6 ft. switch positions (marked II and I) turn the unit on to

(1.8 m) cord to connect to the ionizer, and has an IEC HIGH and LOW fan speeds. Use this switch to turn the

320 input socket for incoming power. It comes with a unit on and to select the desired fan speed. A green

North American-style three-prong plug or Continental monitor light is also illuminated respectively on the front

Europe (EURO) plug. Two versions are available of the unit, which indicates that the power switch is in

depending on the power cord plug (European or North one of the ON positions, and that the ionizer is now in

American). The Ionizer should only be used with the use.

included power supply.

SCS - 926 JR Industrial Drive, Sanford, NC 27332

East: (919) 718-0000 | West: (909) 627-9634 • Website: StaticControl.com

TB-9007 Page 1 of 4 January 2023 © 2023 DESCO INDUSTRIES INC

Employee Owned

Calibration

The SCS Benchtop Air Ionizer is factory adjusted to

provide optimum performance. Further adjustment in the

field is not possible. However, the following instructions

can be followed to determine whether the Ionizer is

performing to specifications. The testing follows the

procedure outlined in the standard for Ionization, ANSI/

ESD STM3.1. Please refer to this standard for more

complete information.

Frequency of recalibration should be based on the

critical nature of those ESD sensitive items handled and

the risk of failure for the ESD protective equipment and

materials. In general, SCS recommends that calibration

be performed annually.

Periodically measure the balance and neutralization

times of the Bencthop Air Ionizer to verify that it is

Figure 2. Using the 963E Benchtop Air Ionizer performing within specifications. These measurements

should be taken using a charged plate monitor such as

the SCS items 711, 770004 and 770005.

Maintenance

Occasional cleaning of the case and of the ionizing Calibration should be performed in accordance with

electrodes are the only routine maintenance procedures the ESD Association ionization standard ANSI/ESD

required. STM3.1. With the fan speed set to high and a distance

of 12 inches (30 cm), the neutralization (discharge) time

CLEANING THE CASE of ±1000V to ±100V should be less than 2 seconds, and

Wipe the case with a soft cloth moistened with water. the balance should be ±15V or better.

If a stronger cleaning solution is required, mild soap

with water may be used. The use of any other cleaning

solutions is not recommended.

CLEANING THE EMITTER POINTS

NOTE: Disconnect the power to the ionizer whenever

cleaning the emitter points.

When the emitter pionts become dirty, the internal

circuitry of the ionizer will be automatically adjusted to

emit an equal amount of positive and negative ions.

Particulates on the emitter point may, however, inhibit

ionization to a limited degree. The emitter points are

located between the fan blades and the rear grill. A jet

of clean, compressed air can be used to remove dirt

on emitter points. If a more rigorous cleaning method is

needed to remove particulate, clean the points with a

cotton swab dampened with isopropyl alcohol. Access to

the points is available through the rear grill. Be careful

not to damage the points during cleaning.

SCS - 926 JR Industrial Drive, Sanford, NC 27332

East: (919) 718-0000 | West: (909) 627-9634 • Website: StaticControl.com

TB-9007 Page 2 of 4 © 2023 DESCO INDUSTRIES INC

Employee Owned

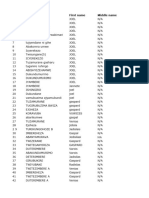

Neutralization (Discharge) Times

All data was taken with the fan speed set to high. All time measurements are in seconds.

NOTE: Discharge times in seconds are representative only and are not a guarantee. Discharge times are actual

measurements recorded in a factory ambient environment.

Per ANSI/ESD S20.20, the test method for Product Qualification test is ANSI/ESD STM3.1, and for Compliance

Verification is ESD TR53 which advises “Measurements should be made at the location where ESD sensitive items

are to be ionized.” A larger area may require additional ionizers. Per S20.20 the required limit for ionizer discharge

time is user defined. Use Table to determine the number of ionizers to achieve ionization of area to be neutralized

to meet your company’s ESD control plan specified discharge times.

The comparative efficiency of bench top ionizers is determined by a standard test published by the ESD

Association: ANSI/ESD STM3.1. Typical positive and negative decay times (±1000V to ±100V) measured using this

standard are shown in Figure 3. The performance of the ionizer was measured with the unit positioned as shown,

with the fan speed on high and without a filter.

12" 12" 12" 12"

TP1 +174.9 TP4 +34.7 TP7 +24.2 TP10 +30.5

Charged Plate -159.6 -34.3 -22.9 -35.7

12"

Air Flow

TP2 +1.1 TP5 +3.2 TP8 +6.6 TP11 +10.6

-1.2 -3.5 -7.5 -11.1

963E Benchtop 12"

Air Ionizer

TP3 +53.2 TP6 +8.5 TP9 +7.4 TP12 +11.0

-55.3 -10.0 -9.4 -12.7

Figure 3. Neutralization (Discharge) Times

SCS - 926 JR Industrial Drive, Sanford, NC 27332

East: (919) 718-0000 | West: (909) 627-9634 • Website: StaticControl.com

TB-9007 Page 3 of 4 © 2023 DESCO INDUSTRIES INC

Employee Owned

Specifications Regulatory Information

Input Voltage and AC Power Adapter FCC

Frequency This device complies with Part 15 of the FCC Rules.

Power Input: Operation is subject to the following two conditions: (1)

100-240VAC, 50/60 Hz this device may not cause harmful interference, and

Power Output: (2) this device must accept any interference received,

24VDC, 1.0-1.5A including interference that may cause undesired

operation.

Power Consumption 10 W

Dimensions 9" H x 8.5" W x 4.5" D NOTE: This equipment has been tested and found

(including stand) (23 cm x 22 cm x 11 cm) to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are

Weight 2.5 lbs (1.1 kg) designed to provide a reasonable protection against

Balance (Offset ±15V harmful interference when the equipment is operated in

Voltage) at 12" a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not

Neutralization < 2 seconds installed and used in accordance with the instruction

(Discharge) Time at 12" manual, may cause harmful interference to radio

Maximum Airflow 112 CFM communications. Operation of this equipment in a

Emitter Points Tungsten residential area is likely to cause harmful interference

in which case the user will be required to correct the

Ozone <0.005 ppm interference at their own expense.

Certifications cULus, CE NOTE: Modifications to this device shall not be made

Country of Origin China without the written consent of SCS. Unauthorized

modifications may void the authority granted under

Federal Communication Rules and Industry Canada

Rules permitting the operation of this device.

ICES Statement

This Class A digital apparatus meets all requirements

of the Canadian Interference-Causing Equipment

Regulations. Cet appareil numérique de la classe A

respecte toutes les exigences du Règlement sur le

matériel brouilleur du Canada.

WEEE Statement

The following information is only for EU-member States:

The mark shown to the right is in compliance with Waste

Electrical and Electronic Equipment Directive 2002/96/

EC (WEEE). The mark indicates the requirement NOT

to dispose the equipment as unsorted municipal waste,

but use the return and collection systems according to

local law.

CE Statement

Meets EU safety, health and environmental protection

requirements.

UL Statement

Meets UL requirements.

Limited Warranty, Warranty Exclusions, Limit

of Liability and RMA Request Instructions

See the SCS Warranty -

StaticControl.com/Limited-Warranty.aspx

SCS - 926 JR Industrial Drive, Sanford, NC 27332

East: (919) 718-0000 | West: (909) 627-9634 • Website: StaticControl.com

TB-9007 Page 4 of 4 © 2023 DESCO INDUSTRIES INC

Employee Owned

You might also like

- JVC MXG 71 R Service ManualDocument86 pagesJVC MXG 71 R Service ManualZoran BunčićNo ratings yet

- BLDC SPEC - 0021 - 2005 (Rev.2) PDFDocument18 pagesBLDC SPEC - 0021 - 2005 (Rev.2) PDFdivisional electrical enggNo ratings yet

- PI144K 311 TD EN - Rev - ADocument10 pagesPI144K 311 TD EN - Rev - AMohamed AbdElhamedNo ratings yet

- ABB Brake Chopper ManualDocument32 pagesABB Brake Chopper Manualjuna erfanNo ratings yet

- Installation and Operation Manual: MODEL AK-950-F - SeriesDocument10 pagesInstallation and Operation Manual: MODEL AK-950-F - SeriesAdrian TodeaNo ratings yet

- Pi044f-311-Td-En 3PDocument10 pagesPi044f-311-Td-En 3PthaiNo ratings yet

- Plasma Air PA600 Series: Installation, Operation & Maintenance ManualDocument4 pagesPlasma Air PA600 Series: Installation, Operation & Maintenance ManualDesiana PermataNo ratings yet

- Plasma AIR MODEL 660: Installation, Operation & Maintenance ManualDocument4 pagesPlasma AIR MODEL 660: Installation, Operation & Maintenance ManualWawan NuryanaNo ratings yet

- PI044GDocument10 pagesPI044GracsoNo ratings yet

- PI144J - Winding 311: Technical Data SheetDocument10 pagesPI144J - Winding 311: Technical Data SheetMarvin GoetzNo ratings yet

- MAJAX-2 axial fans specification guideDocument7 pagesMAJAX-2 axial fans specification guidedokundotNo ratings yet

- WON0502-B: Installation Instructions FOR Electric FurnacesDocument15 pagesWON0502-B: Installation Instructions FOR Electric FurnacesRobNo ratings yet

- PI144K-06-TD-EN_Rev_ADocument9 pagesPI144K-06-TD-EN_Rev_AKevin Eduardo Palpa MedranoNo ratings yet

- PI144H-311-TD-En Alternator Standard PI144H - 3 Ph-Winding 311Document10 pagesPI144H-311-TD-En Alternator Standard PI144H - 3 Ph-Winding 311mnezamiNo ratings yet

- Data Sheet Stamford UCI274E1-Wending 311-3 PhaseDocument9 pagesData Sheet Stamford UCI274E1-Wending 311-3 PhaseCimmangNo ratings yet

- MX GT90Document51 pagesMX GT90Gaby FigueroaNo ratings yet

- High Power Digital Arc Lamp Power Supply - ManualDocument23 pagesHigh Power Digital Arc Lamp Power Supply - Manualluciano_gularteNo ratings yet

- Sunon: Specification For ApprovalDocument14 pagesSunon: Specification For ApprovalMarcio NovoNo ratings yet

- Stamford PMG Pi14f AscotDocument10 pagesStamford PMG Pi14f AscotJan AhmedNo ratings yet

- Time of Flight: Jordan Tof Products, IncDocument24 pagesTime of Flight: Jordan Tof Products, Inczf dengNo ratings yet

- ECOSTAND 081-1 - 2019 - Fans - MEPS - English - ReviewedDocument12 pagesECOSTAND 081-1 - 2019 - Fans - MEPS - English - ReviewedIBRAHIMA NDIAYENo ratings yet

- Abb PVS800Document4 pagesAbb PVS800bluedepthNo ratings yet

- Pi044g 06 TD en Rev ADocument9 pagesPi044g 06 TD en Rev AVladimirGuerreroNo ratings yet

- TV Service Manual Provides Repair GuidanceDocument42 pagesTV Service Manual Provides Repair GuidanceFredy FigueroaNo ratings yet

- Electric Fire PumpDocument8 pagesElectric Fire Pumprkpatel40No ratings yet

- Stamford-Uci 27 4FDocument9 pagesStamford-Uci 27 4FKevin GuoNo ratings yet

- VSX-609 709 RRV2274Document64 pagesVSX-609 709 RRV2274sollersNo ratings yet

- GenII Main Rotor Sikorsky S76 Pushrod 1.00Document23 pagesGenII Main Rotor Sikorsky S76 Pushrod 1.00agripinaluzmilaaNo ratings yet

- PI044H - Technical Data Sheet Winding 05Document7 pagesPI044H - Technical Data Sheet Winding 05juan echeverryNo ratings yet

- GDM 5403Document59 pagesGDM 5403Flaviano SaccàNo ratings yet

- Description: Dimmer Signal CircuitDocument3 pagesDescription: Dimmer Signal CircuitJack CardiagNo ratings yet

- Pioneer Vsx-409rds SMDocument53 pagesPioneer Vsx-409rds SMHector Antonio Oviedo AlvarezNo ratings yet

- PI044F - Winding 05: Technical Data SheetDocument9 pagesPI044F - Winding 05: Technical Data SheetmunhNo ratings yet

- Service Manual: Simple-2Document30 pagesService Manual: Simple-2AlexNo ratings yet

- BOQ - Ductless Basement Ventilation System With Axial Jet FanDocument10 pagesBOQ - Ductless Basement Ventilation System With Axial Jet FanRamakrishnanNo ratings yet

- Pioneer PDP 5071 5070pu Arp 3354Document219 pagesPioneer PDP 5071 5070pu Arp 3354Dan Prewitt100% (1)

- Epson Emp820asmeDocument87 pagesEpson Emp820asmeafranio batistaNo ratings yet

- Service Manual: Compact Component SystemDocument93 pagesService Manual: Compact Component Systemsaputra ekaNo ratings yet

- JVC Av-N29304 Av-N29430 Chassis Fe2Document57 pagesJVC Av-N29304 Av-N29430 Chassis Fe2Milo65No ratings yet

- Pioneer VSX-108Document39 pagesPioneer VSX-108Eduardo RossettoNo ratings yet

- LT PN - BDDocument27 pagesLT PN - BDDarshit VyasNo ratings yet

- Christmas Projector ManualDocument3 pagesChristmas Projector ManualLuis AcostaNo ratings yet

- 963/963E Benchtop Air Ionizer Instructions: Downloaded From Manuals Search EngineDocument11 pages963/963E Benchtop Air Ionizer Instructions: Downloaded From Manuals Search EngineJP anonymousNo ratings yet

- NetController II Install (30-3001-994 - D1 PDFDocument10 pagesNetController II Install (30-3001-994 - D1 PDFwendy vegaNo ratings yet

- NetController II Install (30-3001-994 - D1 PDFDocument10 pagesNetController II Install (30-3001-994 - D1 PDFwendy vegaNo ratings yet

- Kd-Sd80bte Sd80bten Sd80btey (Sm-Ma530 Rev.001)Document51 pagesKd-Sd80bte Sd80bten Sd80btey (Sm-Ma530 Rev.001)Roberd MihailovNo ratings yet

- JVC 45Document33 pagesJVC 45Pravin Mevada100% (1)

- User Manual for APA600/1000/1400 Power AmplifiersDocument38 pagesUser Manual for APA600/1000/1400 Power AmplifiersAlex SantiagoNo ratings yet

- E360 Series Manual de ServicioDocument128 pagesE360 Series Manual de ServicioJuan Felipe RodriguezNo ratings yet

- UCI274GDocument9 pagesUCI274GChristian Rivera FloverNo ratings yet

- Videocon Nano1-Cst Vcn14mbf-CnaDocument24 pagesVideocon Nano1-Cst Vcn14mbf-CnaRamesh Singh100% (1)

- JVC HX-Z9 Manual de ServicioDocument66 pagesJVC HX-Z9 Manual de ServicioJosé BenavidesNo ratings yet

- Air Conditioner NissanDocument34 pagesAir Conditioner NissanFrederikusNo ratings yet

- UCDI274K 311 1P TD EN - Rev - ADocument10 pagesUCDI274K 311 1P TD EN - Rev - AMuntasir MunirNo ratings yet

- Nicotra Axial Fans PDFDocument48 pagesNicotra Axial Fans PDFosama alabsi100% (1)

- 02.power Transformer-160 &63mvaDocument138 pages02.power Transformer-160 &63mvaraj_stuff006100% (1)

- 50a60 SMDocument50 pages50a60 SMmazdog69No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Natural Law's Rise and FallDocument17 pagesNatural Law's Rise and FallNoel James100% (2)

- Chapter 01Document33 pagesChapter 01Michael BANo ratings yet

- A Brazilian Furniture Industry Case StudyDocument17 pagesA Brazilian Furniture Industry Case StudyEnrique MabanoNo ratings yet

- Inter CavablarDocument86 pagesInter CavablarcavidannuriyevNo ratings yet

- Freebie The Great Composerslapbookseries ChopinDocument24 pagesFreebie The Great Composerslapbookseries ChopinAnonymous EzNMLt0K4C100% (1)

- Insurance Dispute Over Mortgaged PropertyDocument2 pagesInsurance Dispute Over Mortgaged PropertyBetson CajayonNo ratings yet

- Data Compilation TemplateDocument257 pagesData Compilation TemplateemelyseuwaseNo ratings yet

- Senguntha KshatriyaDocument34 pagesSenguntha Kshatriyabogar marabuNo ratings yet

- OS Fundamentals: Memory, Processes, KernelsDocument36 pagesOS Fundamentals: Memory, Processes, KernelsSparkerz S Vijay100% (1)

- 19C.Revolution and Counter Rev. in Ancient India PARTIII PDFDocument94 pages19C.Revolution and Counter Rev. in Ancient India PARTIII PDFVeeramani ManiNo ratings yet

- The Next Form of DemocracyDocument313 pagesThe Next Form of DemocracyVanderbilt University Press100% (2)

- The Small Trees High Productivity Initiative: Principles and Practice in High Density Orchard DesignDocument1 pageThe Small Trees High Productivity Initiative: Principles and Practice in High Density Orchard DesignPutchong SaraNo ratings yet

- Chapter 22 Managing Personal Communications - Direct and Database Marketing and Personal SellingDocument17 pagesChapter 22 Managing Personal Communications - Direct and Database Marketing and Personal SellingBrian Duela100% (1)

- Vasitars PVT Limited - Pipeline RepairsDocument12 pagesVasitars PVT Limited - Pipeline RepairsPavan_yoyo100% (1)

- Unit 10 Working DrawingsDocument17 pagesUnit 10 Working Drawingsomoak2015No ratings yet

- Osamu Dazai: Genius, But No Saint - The Japan TimesDocument3 pagesOsamu Dazai: Genius, But No Saint - The Japan TimesBenito TenebrosusNo ratings yet

- Bhrighu Saral Paddathi - 33: by Saptarishis AstrologyDocument8 pagesBhrighu Saral Paddathi - 33: by Saptarishis AstrologyAnonymous y3hYf50mTNo ratings yet

- E Thesis Uas DharwadDocument5 pagesE Thesis Uas DharwadLori Head100% (1)

- Korean Lesson PlanDocument4 pagesKorean Lesson Planapi-272316247No ratings yet

- Study PlanDocument2 pagesStudy PlanAbu FatihNo ratings yet

- SAP EWM TM IntegrationDocument28 pagesSAP EWM TM IntegrationAruna DasNo ratings yet

- Exam StructuralDocument1 pageExam StructuralJoyce DueroNo ratings yet

- Saint Aquinas and Mercantilism School of ThoughtsDocument11 pagesSaint Aquinas and Mercantilism School of ThoughtsKatunga MwiyaNo ratings yet

- ĐỀ THI GIỮA KÌ 2 - E9 (TẤN)Document4 pagesĐỀ THI GIỮA KÌ 2 - E9 (TẤN)xyencoconutNo ratings yet

- (ART.) VEKEMANS, Charlotte SEGERS, Yves (2020) Settler Farming, Agricultural Colonisation and Development in Katanga (Belgian Congo), 1910-1920Document32 pages(ART.) VEKEMANS, Charlotte SEGERS, Yves (2020) Settler Farming, Agricultural Colonisation and Development in Katanga (Belgian Congo), 1910-1920Vitor RodriguesNo ratings yet

- 7 Introduction To Life SkillsDocument2 pages7 Introduction To Life SkillsMailat SoranaNo ratings yet

- Puromines Vs CA DigestDocument2 pagesPuromines Vs CA DigestBea Alonzo100% (1)

- LU4 OverheadsDocument38 pagesLU4 OverheadsVj TjizooNo ratings yet

- Yukot, LeeYDocument5 pagesYukot, LeeYDevansh GoelNo ratings yet

- UPSA - Ethics of Project Management-3Document42 pagesUPSA - Ethics of Project Management-3JSN1790% (1)