Professional Documents

Culture Documents

WaboCrete SiliconeSeal 0321 DataSheet-2.2023

Uploaded by

marketing.avaneeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WaboCrete SiliconeSeal 0321 DataSheet-2.2023

Uploaded by

marketing.avaneeshCopyright:

Available Formats

®

WaboCrete® SiliconeSeal

High Performance Silicone and Elastomeric Concrete Expansion Joint System

(Licensed for use under US Patent No. 5.190.395)

Features Benefits

System combines a flexible

header and rapid curing

• Repair

+100% / -50% movement

solution

sealant for maintenance and

overlay applications

Provides a watertight system

• Unique

while absorbing impact traffic

design

loads

No priming of the joint

• Primerless interface is required for the RECOMMENDED FOR:

Wabo®SiliconeSeal • Horizontal expansion joint applications on

Cold applied, ambient cure bridges, highways, parking decks, and

• Rapid stadiums.

system allows quick and easy

installation

installation • New construction or repair and maintenance of

existing expansion joints. Structures where

DESCRIPTION: minimum construction closure time is a factor.

WaboCrete® SiliconeSeal system is a high • Expansion joint applications with a maximum

performance expansion joint utilizing a dynamic movement range of +100% / -50% of the joint

two-part sealant between impact absorbing gap.

elastomeric concrete headers. The flexible

header of WaboCrete® Parking Series coupled PACKAGING/COVERAGE:

with Wabo®SiliconeSeal make it an ideal

expansion joint system for the new construction • WaboCrete® II:

or repair of existing joints. With an extensive o PTA – ½ gal container

history, WaboCrete® Parking Series elastomeric o PTB – 1 gal container

concrete is most widely used in header o PTC – 60 lbs aggregate

applications for bridges and parking structures. o Yield = 1030 in3 = 0.6 ft3

The polyurethane based header material was • Wabo®SiliconeSeal is a 1:1 mix and available

developed to minimize edge spalling associated in:

with high impact loads while achieving superior o Standard 50.72 oz dual cartridge kit

bonding capabilities to a variety of substrates. (PTA - 25.36 oz; PTB – 25.36 oz)

Product packaging is designed to minimize waste o 10 gal unit (PTA - 5 gal; PTB – 5 gal)

and maximize installation workforce output. o Yield will vary depending on joint

design, tooling, backer rod placement,

waste, and experience. See below for

typical yield values

Watson Bowman Acme

95 Pineview Drive

Amherst, NY 14228

phone: 716-691-7566

fax: 716-691-9239

watsonbowmanacme.com

®

YIELD/UNIT

JOINT YIELD/KIT

(50.72 oz

WIDTH (10 Gal Unit) Cartridge)

1" (25mm) 317 LF (96.6m) 12.6 LF (3.8m)

1.5" (38mm) 194 LF (59.1m) 7.8 LF (2.4m)

2" (50mm) 135 LF (41.1m) 5.3 LF (1.6m)

2.5" (64mm) 100 LF (30.5m) 3.9 LF (1.2m)

3" (76mm) 78 LF (23.8m) 3.0 LF (0.9m)

TECHNICAL DATA:

Design Information

Wabo®SiliconeSeal is a two-part, self-leveling, low modulus sealant, which can be used for joint openings of

3.25” or less. The maximum movement must not exceed 100% of the joint opening at the time of installation. The

minimum movement must not be less than 50% of the joint opening at the time of installation.

Wabo®SiliconeSeal should be applied to a minimum thickness of 1/2”, not to exceed 5/8”. The system should be

installed with a 1/2” recess below the riding surface.

PHYSICAL PROPERTIES (Wabo®SiliconeSeal):

PHYSICAL ASTM TEST

PROPERTIES METHOD PART A PART B

Color White Gray

Viscosity 88,000 cps 34,000 cps

Leveling C 639 self levels self levels

Extrusion rate ml/min. C 1183 200-600 200-600

PHYSICAL ASTM TEST

REQUIREMENTS

PROPERTIES METHOD

Leveling C 639 self levels

Tack free time C 679 60 minute max.

Joint elongation D 5329 (1) (2) 600% min.

Joint Modulus, 100% D 5329 (1) (2) 15 psi (.10MPa) max

Cure evaluation D 5893 Pass @ 4 hrs, max

Ultimate Elongation D 412 Die C (1) 1000% min.

Stress @ 150% D 412 Die C (1) 25 psi max. (.17 Mpa)

Shore Hardness, 00 C 661 (1) 40 - 80

Specific Gravity D 792 (1) 1.20 - 1.40

(1) Specimens cured at 77 +/-3 F and 50 +/-5% R.H. For 7 days

(2) Specimens size is 1/2"wide x 1/2" deep x 2" long.

Watson Bowman Acme

95 Pineview Drive

Amherst, NY 14228

phone: 716-691-7566

fax: 716-691-9239

watsonbowmanacme.com

®

APPLICATION:

INSTALLATION SUMMARY:

• Concrete substrates must be abrasive • Slowly add the aggregate component to

blasted to remove all latencies and the mixed liquids and mix until all

contaminants which may cause bonding aggregate is coated (approximately 1

problems. Steel substrates must be minute). This mix can be poured into the

abrasive blasted to near white metal. properly prepared blockout, in which the

• Apply Wabo®Bonding Agent (primer) to primer is still wet. The material will flow

surface of the properly prepared concrete and self-level. Use a margin trowel to work

prior to installation of WaboCrete® Parking material and finish surface.

Series. Do NOT apply Wabo®Bonding • For sloped conditions, add Wabo®Non-

Agent to steel substrates. There must be Flow Additive to the liquid-aggregate

no visible moisture prior to the application mixture.

of the primer. Primer can be brush applied.

Do NOT allow primer to dry prior to • A non-gassing closed-cell expanded

placement of WaboCrete® Parking Series. polyethylene foam rod, approximately 25%

larger in diameter than the joint gap is

• Thoroughly pre-mix (approximately 20 positioned in the joint opening such that

seconds) Part B separately before pouring the top of the rod is 1” (25mm) below the

entire contents of Part B into clean 5 gallon riding surface.

container. Add Part A and mix both

components for approximately 30 seconds,

or until well blended.

Watson Bowman Acme

95 Pineview Drive

Amherst, NY 14228

phone: 716-691-7566

fax: 716-691-9239

watsonbowmanacme.com

®

• The Wabo®SiliconeSeal system shall be • WaboCrete® II components have a shelf

applied in one direction only to a thickness life of 18 months and Wabo®SiliconeSeal

of 1/2” (12mm) minimum, while not components have a shelf life of 1 year.

exceeding 5/8” (16mm) and maintaining a

• Periodically inspect the applied material

1/2” (12mm) recess from the riding surface.

and repair localized areas as needed.

• Clean all excess material from the edges of Consult a Watson Bowman Acme

the joint opening as soon as possible. DO representative for additional information.

NOT allow the silicone to cure before

• Make certain the most current version

removing it.

of the product data sheet is being used.

• Allow the Wabo®SiliconeSeal system to set Please consult the website

approximately 30 minutes (at 77˚F) before (www.watsonbowmanacme.com) or

traffic is allowed onto the joint. Longer cure contact a customer service representative.

times are required during cooler

temperatures. RELATED DOCUMENTS:

• Material Safety Data Sheets

FOR BEST RESULTS:

• WaboCrete®SiliconeSeal Specification

• Install when concrete substrate is clean,

sound, dry, and cured (14 day minimum). • WaboCrete®SiliconeSeal Sales Drawings

• Do not install if the joint’s anticipated • WaboCrete® SiliconeSeal Installation

movement will exceed the system’s Procedure

movement range.

• WaboCrete® II Data Sheet

• Protect the work area with appropriate

plastic sheeting.

OPTIONS/EQUIPMENT:

• Do not allow any of the components to

freeze prior to installation. Store all • Use a 3/4” slow speed, high torque, drill

components out of direct sunlight in a clean, with a egg-beater (or mud beater) style

dry location between 50˚F (10˚C) and 90˚F mixing paddle to mix WaboCrete® Parking

(32˚C). Do NOT install when surface Series.

temperature is less than 40˚F (4˚C). • For Wabo®SiliconeSeal use a dual

component application gun suitable to

packaging. Contact WBA for

recommendations.

LIMITED WARRANTY:

Watson Bowman Acme Corp. warrants that this product conforms to its current applicable specifications. WATSON BOWMAN ACME CORP. MAKES NO OTHER WARRANTY, EXPRESS OR

IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. The sole and exclusive remedy of Purchaser for any claim

concerning this product, including, but not limited to, claims alleging breach of warranty, negligence, strict liability or otherwise, is the replacement of product or refund of the purchase price, at the

sole option of Watson Bowman Acme Corp. Any claims concerning this product shall be submitted in writing within one year of the delivery date of this product to Purchaser and any claims not

presented within that period are waived by Purchaser. IN NO EVENT SHALL WATSON BOWMAN ACME CORP. BE LIABLE FOR ANY SPECIAL, INCIDENTAL, CONSEQUENTIAL (INCLUDES

LOSS OF PROFITS) OR PUNITIVE DAMAGES. Other warranties may be available when the product is installed by a factory trained installer. Contact your local Watson Bowman Acme

representative for details. The data expressed herein is true and accurate to the best of our knowledge at the time published; it is, however, subject to change without notice.

WaboCrete_SiliconeSeal_0321

Watson Bowman Acme

95 Pineview Drive

Amherst, NY 14228

phone: 716-691-7566

fax: 716-691-9239

watsonbowmanacme.com

You might also like

- OK - Brochure VAM® 21 PDFDocument6 pagesOK - Brochure VAM® 21 PDFsubodhasinghNo ratings yet

- Dos Iii - Unit Iv Masonry WallDocument26 pagesDos Iii - Unit Iv Masonry WallMohamed ArzathNo ratings yet

- Concrete Masonry - Site Practice and Workmanship GuideDocument28 pagesConcrete Masonry - Site Practice and Workmanship GuideRey Eduard Q. UmelNo ratings yet

- Flowserve Pump Gas SealsDocument37 pagesFlowserve Pump Gas SealslubangjarumNo ratings yet

- Asme BPVC IxDocument7 pagesAsme BPVC IxNVTVNNo ratings yet

- VAM SFC 0511 SPDocument8 pagesVAM SFC 0511 SP11tkt11No ratings yet

- Factors Affecting Hot Dip Galvanized CoatingsDocument9 pagesFactors Affecting Hot Dip Galvanized CoatingsSreedhar Patnaik.M100% (1)

- SAUDI ARAMCO TOTAL REFINING CIVIL DESIGN CRITERIADocument39 pagesSAUDI ARAMCO TOTAL REFINING CIVIL DESIGN CRITERIAntrkulja@hotmail.comNo ratings yet

- Catalog PACKINGDocument24 pagesCatalog PACKINGAnton FransiscusNo ratings yet

- Raychem Shrink SleevesDocument12 pagesRaychem Shrink SleevesislamakthamNo ratings yet

- Memcor UF Product Data Sheet CPII MemRackDocument2 pagesMemcor UF Product Data Sheet CPII MemRackDio MiNo ratings yet

- Ficha Tecnica Cinta de Juntas 930 35 50 PDFDocument3 pagesFicha Tecnica Cinta de Juntas 930 35 50 PDFfernando100% (1)

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Chapter 9 Design of Composite ConstructionsDocument18 pagesChapter 9 Design of Composite Constructionsapi-2661168786% (7)

- Astm f1545 Plastic Lined PipeDocument8 pagesAstm f1545 Plastic Lined PipesivagulfNo ratings yet

- Structural Engineering Thesis TopicsDocument1 pageStructural Engineering Thesis Topicsaleena489% (9)

- 2.6 List of Testing Equipments PDFDocument4 pages2.6 List of Testing Equipments PDFAmir BorhanipourNo ratings yet

- WaboCreteStripSealPark 1216 DataSheetDocument5 pagesWaboCreteStripSealPark 1216 DataSheetSean BrownNo ratings yet

- WaboCrete Membrane 1206Document4 pagesWaboCrete Membrane 1206MARCO ANTONIO AYALA MARTINEZNo ratings yet

- WaboElastoFlex Park 0408Document4 pagesWaboElastoFlex Park 0408Cristhian Alfonso Mandujano PérezNo ratings yet

- PS 14 Anchor Bolt TolerancesDocument4 pagesPS 14 Anchor Bolt TolerancesjebrijaNo ratings yet

- SKF Grease Test Rig EmcorDocument4 pagesSKF Grease Test Rig EmcorCarlosNo ratings yet

- DPF 390 FlexDocument3 pagesDPF 390 FlexCESAR GUERRERONo ratings yet

- Clock Spring Diamond Wrap BrochureDocument2 pagesClock Spring Diamond Wrap BrochuremuhammadxpNo ratings yet

- Web ProductSheet DiamondWrap 2018 PDFDocument2 pagesWeb ProductSheet DiamondWrap 2018 PDFRiankwnNo ratings yet

- SKF Grease Test Rig EMCORDocument4 pagesSKF Grease Test Rig EMCORJOSUE TAFOYA REYESNo ratings yet

- GYP1113 Red Book Plus-Optimised Oct 2015w PDFDocument40 pagesGYP1113 Red Book Plus-Optimised Oct 2015w PDFCYnthia chuaNo ratings yet

- 62 017 Dowsil 890 SL Si Joint SealantDocument4 pages62 017 Dowsil 890 SL Si Joint SealantScott HendersonNo ratings yet

- Tyfo UC StripsDocument2 pagesTyfo UC Stripsyusak santosoNo ratings yet

- Description Features and CharacteristicsDocument2 pagesDescription Features and CharacteristicsPranpath NarupantawartNo ratings yet

- pds-cpd-SikaWrap Hex100G-us PDFDocument2 pagespds-cpd-SikaWrap Hex100G-us PDFjohanes b mudaNo ratings yet

- Recommended Performance Guideline For Chip Seal: NoticeDocument9 pagesRecommended Performance Guideline For Chip Seal: NoticeAnna KLNo ratings yet

- Sikawrap® Hex-230 C: Product Data SheetDocument4 pagesSikawrap® Hex-230 C: Product Data SheetArindam SarkarNo ratings yet

- Envirolube XE Extreme TDS 190828 203810Document1 pageEnvirolube XE Extreme TDS 190828 203810Don HowardNo ratings yet

- Protective & Marine Coatings: Sher-Clear™Document4 pagesProtective & Marine Coatings: Sher-Clear™Ana CabreraNo ratings yet

- Canusa Flanş Izolasyonu Için Isı Ile Büzüşen Levha Çözümü PDS - NA - HSDocument2 pagesCanusa Flanş Izolasyonu Için Isı Ile Büzüşen Levha Çözümü PDS - NA - HSozcanNo ratings yet

- Viledon MVPGTE10-LDocument2 pagesViledon MVPGTE10-LmsafwanizzudinNo ratings yet

- GPCDOC Local TDS Switzerland Shell Spirax S6 GXME 75W-80 (en-CH) TDSDocument2 pagesGPCDOC Local TDS Switzerland Shell Spirax S6 GXME 75W-80 (en-CH) TDSgrs030391No ratings yet

- Five Star Rapid Epoxy GroutDocument2 pagesFive Star Rapid Epoxy GroutJohnprasannaNo ratings yet

- Sikatack Panel: Panel Adhesive For Ventilated FaçadesDocument2 pagesSikatack Panel: Panel Adhesive For Ventilated FaçadeselpibematadorNo ratings yet

- The Birth of An Innovative Solution For Oil PumpingDocument2 pagesThe Birth of An Innovative Solution For Oil PumpingMateo PorrasNo ratings yet

- High Density CycloneDocument2 pagesHigh Density CycloneEdson CastelliNo ratings yet

- Basf Masterseal m200 TdsDocument2 pagesBasf Masterseal m200 Tdsangelito bernalNo ratings yet

- Sikaflex®-2c SL: Two-Component, Self-Levelling, Polyurethane Elastomeric SealantDocument3 pagesSikaflex®-2c SL: Two-Component, Self-Levelling, Polyurethane Elastomeric SealantRay GongNo ratings yet

- Us-Cam-Ps-Aa 0416 WebDocument4 pagesUs-Cam-Ps-Aa 0416 WebPatrickNo ratings yet

- Brochure - Century SmallDocument8 pagesBrochure - Century SmallBalqis BaslemanNo ratings yet

- TDS Shell Spirax s6 Gxme 75w-80Document2 pagesTDS Shell Spirax s6 Gxme 75w-80rstec pyNo ratings yet

- ABB Instrumentation: From The Leader in Remote Seal TransmittersDocument26 pagesABB Instrumentation: From The Leader in Remote Seal TransmittersMorteza alizadehNo ratings yet

- Sikaflex 252 TDSDocument3 pagesSikaflex 252 TDSxingobuilderNo ratings yet

- Sika Carbodur SDocument4 pagesSika Carbodur SMohamed alhaj EmadNo ratings yet

- CC - GCCM Data SheetDocument2 pagesCC - GCCM Data SheetLarizza TesicoNo ratings yet

- EN350490 - 1810 2810 BrochureDocument8 pagesEN350490 - 1810 2810 Brochuresf wNo ratings yet

- SGXT Civil Datasheet (CB - 09.01.10)Document2 pagesSGXT Civil Datasheet (CB - 09.01.10)Masood KhanNo ratings yet

- Spirapak 4033 HFM 183 VPP Uf DatasheetDocument2 pagesSpirapak 4033 HFM 183 VPP Uf DatasheetJohnNo ratings yet

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningDocument2 pagesSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezNo ratings yet

- Type 656 Diaphragm ActuatorDocument4 pagesType 656 Diaphragm Actuatorapi-37549310% (1)

- KB Fr4 61606160a6160c Raw Material Technical Information Data SheetDocument2 pagesKB Fr4 61606160a6160c Raw Material Technical Information Data Sheettrupzup7No ratings yet

- Shell Advance 4T AX7 10W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Advance 4T AX7 10W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsEarl Jenn AbellaNo ratings yet

- WaboCrete II 0718 DataSheetDocument4 pagesWaboCrete II 0718 DataSheetMARCO ANTONIO AYALA MARTINEZNo ratings yet

- FC81081Document2 pagesFC81081Khalid ZaeemNo ratings yet

- Envirolube Xe Extreme: Technical Data SheetDocument1 pageEnvirolube Xe Extreme: Technical Data SheetDon HowardNo ratings yet

- Shell Advance Fuel Save 10w 30Document2 pagesShell Advance Fuel Save 10w 30Muhammad Salman SaeedNo ratings yet

- Sika® Carbodur® S: Product Data SheetDocument4 pagesSika® Carbodur® S: Product Data Sheetrikki nijigenNo ratings yet

- WaboWeatherSeal - II - 0321 - DataSheet - (Juntas para Muros 1)Document3 pagesWaboWeatherSeal - II - 0321 - DataSheet - (Juntas para Muros 1)Karlas Carolina GutierreNo ratings yet

- Leak Free Stuffing BoxesDocument2 pagesLeak Free Stuffing BoxesjorgeNo ratings yet

- Prod CatalianDocument87 pagesProd Cataliananon_591741392No ratings yet

- 29 - Application of Adhesives and Bonded Joint Design in Improving Vehicle Structure PerformanceDocument18 pages29 - Application of Adhesives and Bonded Joint Design in Improving Vehicle Structure Performancemohamed mourad Lafifi100% (1)

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Sheet Piles: There Are 3 Main Types of Sheet Pile WallsDocument7 pagesSheet Piles: There Are 3 Main Types of Sheet Pile WallsniyatiNo ratings yet

- TR-CA-MS-003 - B Concrete FoundationDocument31 pagesTR-CA-MS-003 - B Concrete Foundationsamer8saifNo ratings yet

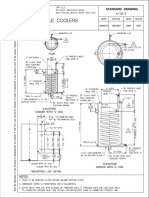

- Sample CoolersDocument1 pageSample CoolersMohcen ZRIRAKNo ratings yet

- Details of Measurement (Preliminaries)Document30 pagesDetails of Measurement (Preliminaries)Engr SwapanNo ratings yet

- SubmittalDocument45 pagesSubmittalsydneyaus2005No ratings yet

- Bill of Quantity Items Print Preview: Current Tender DetailsDocument2 pagesBill of Quantity Items Print Preview: Current Tender DetailsAbu MariamNo ratings yet

- Natural Rubber V Butyl RubberDocument4 pagesNatural Rubber V Butyl Rubbersamdelacruz1030No ratings yet

- MS-35 Precast Conc ManholesDocument2 pagesMS-35 Precast Conc ManholesMahaboob PashaNo ratings yet

- Appendix A: Abbreviations, Symbols, and Unit ConversionsDocument28 pagesAppendix A: Abbreviations, Symbols, and Unit ConversionsNajeeb A.MNo ratings yet

- Choudhary Et Al 2021Document15 pagesChoudhary Et Al 2021Patrick MinusculliNo ratings yet

- CMC Seamless Pipes enDocument16 pagesCMC Seamless Pipes enNehme Gedeon100% (1)

- Guideline For Quality Management For Concrete BridgesDocument105 pagesGuideline For Quality Management For Concrete BridgesEr Sanjay MahatoNo ratings yet

- 0751 VICTAULIC in Mechanical PipingDocument17 pages0751 VICTAULIC in Mechanical PipingsyafiqNo ratings yet

- Buildings 11 00443Document25 pagesBuildings 11 00443karthicfinconNo ratings yet

- Carbozinc 608 HB-ProductFlyer - 112817Document2 pagesCarbozinc 608 HB-ProductFlyer - 112817Muhammad Prima JayaNo ratings yet

- Detalied Estimate For MacadamDocument1 pageDetalied Estimate For Macadamhakim imtiyazNo ratings yet

- Pariej Final Specification.Document121 pagesPariej Final Specification.Douglas RobinsonNo ratings yet

- Cawangan Pakar Dan Kejuruteraan Awam Jabatan Kerja Raya Malaysia, Kuala LumpurDocument2 pagesCawangan Pakar Dan Kejuruteraan Awam Jabatan Kerja Raya Malaysia, Kuala LumpurHidayah A.RahmanNo ratings yet

- SMAW Demo Teaching 2019Document44 pagesSMAW Demo Teaching 2019WilmerNo ratings yet

- Thyssen Krup Stainlesssteel - BrochurenewDocument23 pagesThyssen Krup Stainlesssteel - BrochurenewthomasNo ratings yet

- HEROSEDocument9 pagesHEROSEpt tabNo ratings yet