75% found this document useful (4 votes)

1K views21 pagesEXAMPLE Audit Report

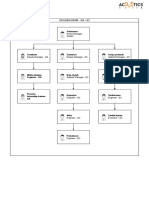

The document is an audit report for Shanghai Feiting Pipe Manufacturing Ltd conducted on behalf of Boustead International Heaters Limited. It summarizes the audit conducted on December 25-26, 2020, which evaluated Feiting's production systems, quality management system, welding/material controls, health and safety, and management structure. The audit verified that Feiting's facilities, equipment, and procedures were acceptable to the client.

Uploaded by

LainhatanhCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

75% found this document useful (4 votes)

1K views21 pagesEXAMPLE Audit Report

The document is an audit report for Shanghai Feiting Pipe Manufacturing Ltd conducted on behalf of Boustead International Heaters Limited. It summarizes the audit conducted on December 25-26, 2020, which evaluated Feiting's production systems, quality management system, welding/material controls, health and safety, and management structure. The audit verified that Feiting's facilities, equipment, and procedures were acceptable to the client.

Uploaded by

LainhatanhCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd