Professional Documents

Culture Documents

34-SAMSS-514 - Dec. 26. 2013

Uploaded by

LainhatanhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

34-SAMSS-514 - Dec. 26. 2013

Uploaded by

LainhatanhCopyright:

Available Formats

Materials System Specification

34-SAMSS-514

Combustible Gas and Hydrogen Sulfide Monitors

26 December 2013

Document Responsibility: Instrumentation Standards Committee

Saudi Aramco DeskTop Standards

Table of Contents

Previous Issue: 26 January 2009

Scope............................................................. 2

Conflicts and Deviations................................. 2

References..................................................... 2

General Requirements................................... 3

Technical Requirements................................. 5

Performance Tests......................................... 8

Other Miscellaneous Requirements............... 9

Next Planned Update: 26 December 2018

Page 1 of 10

Primary contact: Abeediah, Saeed Mohammad on +966-13-8801338

CopyrightSaudi Aramco 2013. All rights reserved.

Document Responsibility: Instrumentation

Issue Date: 26 December 2013

Next Planned Update: 26 December 2018

34-SAMSS-514

Combustible Gas and Hydrogen Sulfide Monitors

Scope

This specification defines the minimum mandatory requirements for stationary

combustible gas and hydrogen sulfide detection and monitoring systems, the purpose of

which is to detect and warn of the presence of combustible gas and hydrogen sulfide gas

in ambient air.

Conflicts and Deviations

2.1

Any conflicts between this specification and other applicable Saudi Aramco

Materials System Specifications (SAMSSs), Engineering Standards (SAESs),

Standard Drawings (SASDs), or industry standards, codes, and forms shall be

resolved in writing by the Company or Buyer Representative through the

Manager, Process & Control Systems Department of Saudi Aramco, Dhahran.

2.2

Direct all requests to deviate from this specification in writing to the Company or

Buyer Representative, who shall follow internal company procedure SAEP-302

and forward such requests to the Manager, Process & Control Systems

Department of Saudi Aramco, Dhahran.

References

Material or equipment supplied to this specification shall comply with the latest edition

of the references listed below, unless otherwise noted.

3.1

Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302

Instructions for Obtaining a Waiver of a Mandatory

Saudi Aramco Engineering Requirement

Saudi Aramco Inspection Requirements

Form 175-344900

Combustible Gas and Hydrogen Sulfide Monitors

Saudi Aramco Forms and Data Sheets

Form 8020-514-ENG

Instrument Specification Sheet - Combustible Gas

and Hydrogen Sulfide Monitors

Form NMR-7930

Nonmaterial Requirements

Page 2 of 10

Document Responsibility: Instrumentation

Issue Date: 26 December 2013

Next Planned Update: 26 December 2018

3.2

34-SAMSS-514

Combustible Gas and Hydrogen Sulfide Monitors

Industry Codes and Standards

International Society for Measurement and Control (Formerly Instrument

Society of America)

ANSI/ISA-60079-29-1 (12.13.01)-2013 Explosive Atmospheres - Part 29-1:

Gas Detectors - Performance Requirements of

Detectors for Flammable Gases

ANSI/ISA-92.00.01-2010 Performance Requirements for Toxic Gas

Detectors

ANSI/ISA-12.13.04-2007 Performance Requirements for Open Path

Combustible Gas Detectors

General Requirements

4.1

Engineering Units

All dimensions and measurements shall be in the International System of

Units (SI), and may be followed by the equivalent value in English

(conventional) units between brackets. When not critical, the equivalent

dimensions may be rounded off to their nearest practical value.

4.2

Environmental Conditions

4.2.1

Temperature

Instruments and control systems shall operate continuously under the

following ambient air temperatures without any degradation of the

manufacturer's guaranteed performance:

Maximum

Minimum

Indoor Air

(2)

Conditioned

35C

(95F)

10C

(50F)

Outdoor

(1)(2)(3)

Sheltered

55C

(131F)

0C

(32F)

Outdoor

(2)(3)

Unsheltered

65C

(149F)

0C

(32F)

Notes:

1)

"Sheltered" refers to permanent, ventilated enclosures or buildings, or permanently

fixed sunshades with a top and three sides.

2)

For instruments which dissipate internal heat and are installed in custom engineered

enclosures (e.g., enclosures not included in the original manufacturer's temperature

certification), an additional 15C shall be added to the above maximum temperatures.

An example, for "indoor air conditioned" installation, the equipment must perform at

35 + 15 = 50C. Similarly, for the "outdoor unsheltered" case, the equipment shall be

designed for a maximum operating temperature of 65 + 15 = 80C.

Page 3 of 10

Document Responsibility: Instrumentation

Issue Date: 26 December 2013

Next Planned Update: 26 December 2018

3)

4.2.2

34-SAMSS-514

Combustible Gas and Hydrogen Sulfide Monitors

For the outdoor installations only, the designer can take credit for forced or passive

cooling to eliminate or reduce the 15C heat rise. For example, if vortex coolers are

used, the heat removal capacity of the coolers may be subtracted from the generated

heat. No more than 15C reduction in temperature will be given as credit. The

designer shall substantiate his claim by providing the support data and calculations.

Contaminants

The equipment manufacturer shall ensure that the equipment is designed

to withstand the following air quality requirements:

4.2.2.1

Dust Concentration

Usual airborne dust concentration is 1 mg/m. During

sandstorms, dust concentrations may reach 500 mg/m.

Particle sizes are as follows:

95% of all particles are less than 20 micrometers

50% of all particles are less than 1.5 micrometers

Elements present in dust include compounds of calcium, silicon,

magnesium, aluminum, potassium, chlorides and sodium.

When wetted (high humidity conditions) these compounds

function as electrolytes and can result in severe corrosion.

Other pollutants present in the atmosphere under the extreme

conditions are:

H2S

Hydrocarbon

4.2.2.2

20 ppm (vol/vol)

150 ppm (vol/vol)

SO2

10 ppm (vol/vol)

CO

100 ppm (vol/vol)

NOx

5 ppm (vol/vol)

O3

1 ppm (vol/vol)

Wind-borne Sea Water Spray

Equipment which is not enclosed or hermetically sealed, but is

situated offshore or near shore (i.e., within 1 km from

shoreline), shall be protected against corrosion and operational

failure due to wind-borne sea water spray and the accumulation

of wetted salt (NaCl).

Page 4 of 10

Document Responsibility: Instrumentation

Issue Date: 26 December 2013

Next Planned Update: 26 December 2018

4.2.3

34-SAMSS-514

Combustible Gas and Hydrogen Sulfide Monitors

Humidity

Indoor humidity design basis shall be 20% to 80% relative humidity.

Outdoor design basis shall be 5% to 95% relative humidity (noncondensing).

Technical Requirements

Technical requirements, shown below, together with the Standards cited in the

References and with specific information entered on the Instrument Specification Sheet

Form 8020-514-ENG, shall be followed by the Vendor in formulating a quotation or

supplying instruments.

5.1

Sensor

5.1.1

5.1.2

General Requirements

5.1.1.1

Sensors shall be certified for use in Class I, Div. 1, Groups C

and D or Class I, Zone 1, Group IIA & IIB hazardous locations

by UL, FM, CSA, or any of the agencies in the Approved IECEx

Certification Bodies (ExCBs) under the IECEx Certified

Equipment Scheme, , and shall be marked accordingly.

Certification to ATEX directives alone is not acceptable.

5.1.1.2

The vendor shall provide a list of gases and substances which

would desensitize or otherwise adversely affect the sensor.

Any effects on the sensor due to oxygen enriched or oxygen

deficient atmospheres, or high concentrations of the detected

gas, shall also be addressed.

5.1.1.3

Sensors shall be constructed of materials resistant to corrosive

effects of any gases or vapors specified on Form

8020-514-ENG.

5.1.1.4

The vendor shall advise the Company or Buyer Representative

of adverse effects, if any, on sensors as a result of continuous

operation at the environmental extremes listed in Paragraph

4.2.2.

Catalytic Bead Combustible Gas Sensor

5.1.2.1

Sensors for combustible gas detection shall be catalytic beadtype diffusion detectors unless specified otherwise on Form

8020-514-ENG.

Page 5 of 10

Document Responsibility: Instrumentation

Issue Date: 26 December 2013

Next Planned Update: 26 December 2018

5.1.2.2

5.1.3

5.1.4

5.2

34-SAMSS-514

Combustible Gas and Hydrogen Sulfide Monitors

Sensors shall have an operating range of 0-100% LEL of the

specified gas.

Infrared Combustible Gas Sensor

5.1.3.1

When specified on Form 8020-514-ENG, infrared point and/or

open path sensors shall be provided.

5.1.3.2

Sensors shall automatically check for and alarm fouled optics

or blocked beam conditions. Fouled optics or beam blockage

shall not cause a high gas concentration indication or alarm.

5.1.3.3

Sensors shall be immune from interference due to adverse

weather conditions.

5.1.3.4

Point sensors shall have an operating range of 0-100% LEL of

the specified gas.

5.1.3.5

Open path sensors shall determine gas concentration over the

entire path length. Gas concentration shall be expressed as

LEL-meter (percent LEL of the gas cloud multiplied by the

portion of the beam occupied by the gas cloud in meters).

5.1.3.6

Infrared beam alignment tools, if required, shall be provided.

Hydrogen Sulfide Sensor

5.1.4.1

Hydrogen sulfide detection systems shall employ stationary

sensors of the solid state, diffusion adsorption-type as indicated

on Form 8020-514-ENG.

5.1.4.2

Sensors shall have an operating range of 0-100 ppm hydrogen

sulfide in air.

5.1.4.3

For sensors or sensor components which have a finite shelf life,

the vendor shall provide storage and turnover

recommendations to the Company or Buyer Representative.

Transmitter

5.2.1

The transmitter shall be housed with the sensor in a common housing.

5.2.2

Transmitters and housings shall be certified for use in Class I, Div. 1,

Groups C and D or Class I, Zone 1, Group IIA & IIB hazardous locations

by UL, FM, CSA, or any of the agencies in the Approved IECEx

Certification Bodies (ExCBs) under the IECEx Certified Equipment

Page 6 of 10

Document Responsibility: Instrumentation

Issue Date: 26 December 2013

Next Planned Update: 26 December 2018

34-SAMSS-514

Combustible Gas and Hydrogen Sulfide Monitors

Scheme, and shall be marked accordingly. Certification to ATEX

directives alone is not acceptable.

5.2.3

Loop voltage shall be 24 VDC nominal. Power shall be supplied by the

control unit or logic solver to which the transmitter is connected.

5.2.4

Transmitters shall incorporate calibration and fault diagnostic features,

and provide a linear output of 0-22 mA, minimum range. The following

information shall be represented by the signal range:

Detector trouble/open loop

(<4 mA)

Calibration mode/bypass

(<4 mA)

Analog output signal

(4-20 mA)

Signal over-range

(>20 mA)

5.2.5

The 4-20 mA output shall correspond to 0-100% LEL combustible gas,

or 0-100 ppm hydrogen sulfide, in air.

5.2.6

Transmitters for all sensor types shall incorporate an integral, linear

analog or digital indicator for calibration, and for display of actual gas

concentrations.

5.2.7

Indication of operational status, including calibration mode and fault

conditions, shall be provided at the transmitter.

5.2.8

Calibration shall be nonintrusive, i.e., may be performed without

opening the sensor/transmitter housing or declassifying the hazardous

area. Calibration shall require only one person.

5.2.9

Calibration shall require a key or tool in order to prevent accidental,

unintentional, or random adjustments.

5.2.10 Zero and span adjustments shall be non-interactive.

5.2.11 The vendor shall specify transmitter wiring requirements, including

cable type, size, maximum length, and shielding.

5.3

Control Unit

5.3.1

The control unit, when specified, shall be a rack- or cabinet-mounted

system of single-channel control modules.

5.3.2

Twenty percent spare rack capacity (slots), in addition to the required

number of channels specified on Form 8020-514-ENG shall be provided.

Blank faceplates shall cover these spare slots.

Page 7 of 10

Document Responsibility: Instrumentation

Issue Date: 26 December 2013

Next Planned Update: 26 December 2018

34-SAMSS-514

Combustible Gas and Hydrogen Sulfide Monitors

5.3.3

Power for the control unit chassis shall be 120/230 VAC, 60 Hz.

Power supply to the detector shall be 24 VDC.

5.3.4

Control units incorporating integral power supply modules for logic and

loop power shall have redundant modules, such that failure of a single

module does not disable the detection system.

5.3.5

Each control module shall have two single-pole, double-throw (SPDT)

relays to provide critical and warning alarm outputs, and one SPDT fault

relay.

5.3.5.1

Minimum relay contact rating shall be 0.5 A at 120/230 VAC,

non-inductive.

5.3.5.2

The critical (high-high) alarm shall de-energize to alarm and be

latching. A manual reset pushbutton shall be provided on the

module to reset the alarm after the gas concentration falls

below setpoint. The setpoint shall be adjustable. The vendor

shall set the critical alarm setpoint to the value specified on

Form 8020-514-ENG.

5.3.5.3

The warning (high) alarm shall de-energize to alarm and shall be

latching or non-latching as specified on Form 8020-514-ENG.

A latching alarm shall be reset by the same pushbutton described

in Paragraph 5.3.5.2. The setpoint shall be adjustable.

The vendor shall set the warning alarm setpoint to the value

specified on Form 8020-514-ENG.

5.3.5.4

The fault alarm shall be normally energized and shall

deenergize to alarm. This alarm shall indicate sensor,

transmitter, control unit, or wiring faults or power failure.

5.3.6

An analog or digital indication of concentration, in percent LEL for

combustible gas, or in parts-per-million (ppm) for hydrogen sulfide, shall

be provided on each module.

5.3.7

Indicating lamps, preferably LEDs, shall be provided on the front of each

control module for power, high-high alarm, high alarm and fault indication.

Performance Tests

6.1

Accuracy

6.1.1

The minimum accuracy for combustible gas monitors shall be 3% of

full-scale gas concentration or 10% of the applied test gas

Page 8 of 10

Document Responsibility: Instrumentation

Issue Date: 26 December 2013

Next Planned Update: 26 December 2018

34-SAMSS-514

Combustible Gas and Hydrogen Sulfide Monitors

concentration, whichever is greater.

6.1.2

6.2

The minimum accuracy for hydrogen sulfide monitors shall be 2 ppm

concentration or 10% of the applied test gas concentration, whichever

is greater.

Type Testing

6.2.1

The vendor shall provide a third party (UL, FM, or CSA or other Saudi

Aramco approved agencies) certificate of full compliance to ANSI/ISA60079-29-1 (12.13.01)-2013 for all combustible gas monitor specified on

Form 8020-514-ENG. This requirement is applicable to both catalytic

bead and point IR.

6.2.2

The vendor shall provide a third party (UL, FM, or CSA or other Saudi

Aramco approved agencies) certificate of full compliance to

ANSI/ISA-92.00.01-2010 for all hydrogen sulfide monitor specified on

Form 8020-514-ENG.

6.2.3

The vendor shall provide a third party (UL, FM, or CSA or other Saudi

Aramco approved agencies) certificate of full compliance to ANSI/ISA12.13.04 for all infrared open path combustible gas monitor specified on

Form 8020-514-ENG.

Other Miscellaneous Requirements

7.1

7.2

Marking

7.1.1

Combustible gas monitoring instruments shall be marked by the vendor

in accordance with ANSI/ISA-60079-29-1 (12.13.01)-2013, Section 4.3,

Labeling and Marking.

7.1.2

Hydrogen sulfide monitoring instruments shall be marked by the vendor

in accordance with ANSI/ISA-92.00.01-2010, Section 4.12, Labeling

and Marking.

7.1.3

Open path combustible gas monitors shall be marked by the vendor in

accordance with ANSI/ISA-12.13.04-2007, Section 3.2, Markings.

Installation, Operation and Maintenance

7.2.1

The vendor shall provide the applicable instructions and data listed in

ANSI/ISA-60079-29-1 (12.13.01)-2013, Section 4.4, Instruction

Manual, for combustible gas monitoring instruments.

Page 9 of 10

Document Responsibility: Instrumentation

Issue Date: 26 December 2013

Next Planned Update: 26 December 2018

7.3

34-SAMSS-514

Combustible Gas and Hydrogen Sulfide Monitors

7.2.2

The vendor shall provide the applicable instructions and data listed in

ANSI/ISA-92.00.01-2010, Section 4.13, Instruction Manual, for

hydrogen sulfide monitoring instruments.

7.2.3

The vendor shall provide the applicable installation and operation manual

listed in ANSI/ISA-12.13.04-2007, Section 3.3, Manufacturers

Installation and Operation Manual for open path combustible gas

monitors.

Inspection

Items manufactured to this specification for combustible gas and hydrogen

sulfide monitors are subject to the minimum Inspection requirements as

specified in Saudi Aramco Inspection Requirements Form 175-344900.

7.4

Nonmaterial Requirements

The supplier shall provide nonmaterial items as shown on Form NMR-7930.

26 December 2013

Revision Summary

Major revision updating the next revision date and clarification to some references based

on recent ISA updates.

Page 10 of 10

You might also like

- ARAMCO DrawingDocument1 pageARAMCO DrawingLainhatanhNo ratings yet

- IP-19 Fire Precautions at Petroleum Refineries and Buk Storage InstallationsDocument166 pagesIP-19 Fire Precautions at Petroleum Refineries and Buk Storage InstallationsPetrNo ratings yet

- Elizabeth Frazer - The Problems of Communitarian Politics - Unity and Conflict (2000)Document292 pagesElizabeth Frazer - The Problems of Communitarian Politics - Unity and Conflict (2000)kitopensabemNo ratings yet

- Section 34 - Sight GlassDocument27 pagesSection 34 - Sight GlasshammamiNo ratings yet

- 11 Mindfuck Tactics Used by Abusers and Cult LeadersDocument3 pages11 Mindfuck Tactics Used by Abusers and Cult LeadersIgnotum Umbra100% (1)

- Microsoft pre-training skills assessment checklistDocument1 pageMicrosoft pre-training skills assessment checklistRichard DiotelesNo ratings yet

- 34 Samss 716Document12 pages34 Samss 716naruto256No ratings yet

- 052KP 01 New 24" Gas Transmission Pipeline To Alkhalij Power Generation Station Control /ESD and Operating Philosophy 052KP 01 PHL IN 001, Rev.01Document26 pages052KP 01 New 24" Gas Transmission Pipeline To Alkhalij Power Generation Station Control /ESD and Operating Philosophy 052KP 01 PHL IN 001, Rev.01Jabel Oil Services Technical DPTNo ratings yet

- Test Your Knowledge On Pumps - Online Quiz - Chemical Engineering SiteDocument10 pagesTest Your Knowledge On Pumps - Online Quiz - Chemical Engineering Sitemyself_riteshNo ratings yet

- BS en 61331-1-2014Document30 pagesBS en 61331-1-2014Ebi Rahmani100% (2)

- Matter 1B Forms, Properties and ChangesDocument26 pagesMatter 1B Forms, Properties and ChangesQuerubin SalesNo ratings yet

- SAES-A-401 - Nov. 3, 2013 PDFDocument41 pagesSAES-A-401 - Nov. 3, 2013 PDFLainhatanhNo ratings yet

- Flow - IPSDocument64 pagesFlow - IPSAn VaNo ratings yet

- Monitor Transformer Temperatures with PC-414R IndicatorDocument4 pagesMonitor Transformer Temperatures with PC-414R IndicatorMKNo ratings yet

- TO-HQ-02-001 - 01 Interface DocumentDocument26 pagesTO-HQ-02-001 - 01 Interface DocumentKthiri WaelNo ratings yet

- 105M6369 Cda 000Document65 pages105M6369 Cda 000Rabah AmidiNo ratings yet

- MSS SP-126 2007 Steel in Line Spring Assisted Center Guided Check Valves PDFDocument18 pagesMSS SP-126 2007 Steel in Line Spring Assisted Center Guided Check Valves PDFLainhatanhNo ratings yet

- Control Narratives GDC-121-8Document89 pagesControl Narratives GDC-121-8Romner CórdovaNo ratings yet

- Fakhr-9 (A3)Document11 pagesFakhr-9 (A3)Qayyum KhanNo ratings yet

- OFFSHORE FUNCTIONAL SPECDocument35 pagesOFFSHORE FUNCTIONAL SPECjtaylor2k1No ratings yet

- PR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionDocument38 pagesPR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionagumsyahNo ratings yet

- Siemens Mammomat 300 Installation and Startup InstructionsDocument93 pagesSiemens Mammomat 300 Installation and Startup Instructionsousama100% (1)

- 34 Samss 514Document10 pages34 Samss 514naruto256100% (1)

- INDUSTRY UPDATE: SAFETY INSTRUMENTED FIRE & GAS SYSTEMS (SI-FGSDocument13 pagesINDUSTRY UPDATE: SAFETY INSTRUMENTED FIRE & GAS SYSTEMS (SI-FGSjulsaezNo ratings yet

- Offshore Facilities Life-Saving Appliance Requirements (Amendments/Supplements To Solas and Associated Lsa)Document17 pagesOffshore Facilities Life-Saving Appliance Requirements (Amendments/Supplements To Solas and Associated Lsa)Gilang AdhityaNo ratings yet

- SAES-Y-101 Custody Metering of Hydrocarbon GasesDocument38 pagesSAES-Y-101 Custody Metering of Hydrocarbon GasesZubair RaoofNo ratings yet

- Specification For Biodiversity: Petroleum Development Oman L.L.C. Health Safety Environment & Sustainable DevelopmentDocument11 pagesSpecification For Biodiversity: Petroleum Development Oman L.L.C. Health Safety Environment & Sustainable DevelopmentHari Prakash GrandheyNo ratings yet

- H2S Impact EvaluationDocument38 pagesH2S Impact EvaluationharyonodanielNo ratings yet

- Well data analysisDocument20 pagesWell data analysisAhmedNo ratings yet

- Papua LNG Upstream Project: Instrumentation Control and Safeguarding Systems Design BasisDocument46 pagesPapua LNG Upstream Project: Instrumentation Control and Safeguarding Systems Design BasisSangaranNo ratings yet

- Gassi Touil Feed Gas Custody Transfer SystemDocument19 pagesGassi Touil Feed Gas Custody Transfer SystemKhaled RemchiNo ratings yet

- F&G Cause and Effect Matrix for Salalah Methanol ProjectDocument6 pagesF&G Cause and Effect Matrix for Salalah Methanol ProjectpavanNo ratings yet

- 5313 Red Eye 2G Water-Cut Meter PDFDocument8 pages5313 Red Eye 2G Water-Cut Meter PDFTruecaller CallerNo ratings yet

- Saep 50Document40 pagesSaep 50syed jeelani ahmed100% (1)

- 34 Samss 515Document13 pages34 Samss 515naruto256No ratings yet

- MSS SP-88-2010 Diaphragm Valves PDFDocument16 pagesMSS SP-88-2010 Diaphragm Valves PDFLainhatanh100% (1)

- SS SamplingValveBrochureDocument12 pagesSS SamplingValveBrochureJOBRAN SofienNo ratings yet

- Modern CV Template StyleDocument2 pagesModern CV Template StyleRedi Joel Córdova ArbietoNo ratings yet

- Petrobras: Reactor Furnace Burner Q-114-F-001Document9 pagesPetrobras: Reactor Furnace Burner Q-114-F-001Raphael SuzartNo ratings yet

- 2016 - LPG-Basics of Proving LPG MetersDocument151 pages2016 - LPG-Basics of Proving LPG MetersPustinjak SaharicNo ratings yet

- Fundamentals of Orifice Metering PDFDocument3 pagesFundamentals of Orifice Metering PDFshiryNo ratings yet

- Coriolis Part 1Document18 pagesCoriolis Part 1yao nestorNo ratings yet

- Hserm D Off SHR PDF CompleteDocument29 pagesHserm D Off SHR PDF Completecrni rokoNo ratings yet

- Saes J 002Document25 pagesSaes J 002Dinesh BoopalanNo ratings yet

- BP SP 50 001 A4 General Instrument SpecificationDocument41 pagesBP SP 50 001 A4 General Instrument SpecificationTeguh YuliantoNo ratings yet

- GP 31-01 - 1-26-2015Document25 pagesGP 31-01 - 1-26-2015pushloop1243100% (1)

- FPM-DU-1501-C.1 - Fire - and Gas - Analysis - and - PlacementDocument40 pagesFPM-DU-1501-C.1 - Fire - and Gas - Analysis - and - PlacementShivani DubeyNo ratings yet

- (SB0A001) Measurement Products and Systems For The Oil and Gas IndustryDocument62 pages(SB0A001) Measurement Products and Systems For The Oil and Gas IndustryRoberto Carlos Teixeira100% (1)

- Tender Doc - TAS at Bhatinda PDFDocument237 pagesTender Doc - TAS at Bhatinda PDFMEHDINo ratings yet

- IBL-I-DS-001 - 017 - C - Instrument Datasheet Signed AGa 20201230 - CompressedDocument49 pagesIBL-I-DS-001 - 017 - C - Instrument Datasheet Signed AGa 20201230 - Compresseddandi zlk100% (1)

- Operating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355Document138 pagesOperating Instructions Flowsic600 Ultrasonic Gas Flow Meter en Im0011355farhan100% (1)

- Gas Detection For Offshore ApplicationDocument11 pagesGas Detection For Offshore ApplicationBryant Bruce Picon YangNo ratings yet

- Safety - System ESD PSDDocument9 pagesSafety - System ESD PSDMakiber100% (1)

- PVC - Explosion Caused by Flashing Liquid in A Process VesselDocument8 pagesPVC - Explosion Caused by Flashing Liquid in A Process Vesselwiboonwi100% (1)

- High Integrity Pressure Protection System SIL VerificationDocument22 pagesHigh Integrity Pressure Protection System SIL Verificationjose vasquezNo ratings yet

- American Hospital Supply Corporation Case Study-Surojit SahaDocument6 pagesAmerican Hospital Supply Corporation Case Study-Surojit Sahasurojitsaha15094No ratings yet

- C5 SCH A - FinalDocument13 pagesC5 SCH A - FinalNadim JilaniNo ratings yet

- ESD vs PSD - Understanding the Difference between Emergency Shutdown and Process ShutdownDocument2 pagesESD vs PSD - Understanding the Difference between Emergency Shutdown and Process ShutdownKyrie AbayaNo ratings yet

- Safety Case Guideline: Engineers Australia Practice NoteDocument24 pagesSafety Case Guideline: Engineers Australia Practice NoteHtoo Htoo KyawNo ratings yet

- Appendix-2 SRS 03112016Document15 pagesAppendix-2 SRS 03112016Qayyum KhanNo ratings yet

- IBU-SMO-DC D002 Barrier Guidelines - Revision 3.1 (2020)Document51 pagesIBU-SMO-DC D002 Barrier Guidelines - Revision 3.1 (2020)Boedi Syafiq100% (1)

- Daily HSE Summary Report 16-02-2018Document3 pagesDaily HSE Summary Report 16-02-2018Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Flow MeasurementDocument62 pagesFlow MeasurementnwabukingzNo ratings yet

- GEO 17-07-003 R002 V1R1 33000 Series Butterfly Valve IEC 61508 Assessment ReportDocument16 pagesGEO 17-07-003 R002 V1R1 33000 Series Butterfly Valve IEC 61508 Assessment Reportarmin heidariNo ratings yet

- Simops V3 I3 03 PDFDocument5 pagesSimops V3 I3 03 PDFravikrssNo ratings yet

- Technical Recommendations For Choke Valve SpecificationsDocument7 pagesTechnical Recommendations For Choke Valve SpecificationsajaysapruNo ratings yet

- Gas Book - HoneywellDocument43 pagesGas Book - HoneywellGuillermo LeanzaNo ratings yet

- Safety & Life SavingDocument15 pagesSafety & Life SavingNurul JannatiNo ratings yet

- Denver Fire Alarm Test Prep: Initiating Devices and Notification AppliancesDocument39 pagesDenver Fire Alarm Test Prep: Initiating Devices and Notification AppliancesawadalmekawyNo ratings yet

- 34 Samss 118 PDFDocument9 pages34 Samss 118 PDFCherukunnon JubuNo ratings yet

- SIL Methodology: A Methodology For SIL Verification in Accordance With IEC 61508 and IEC 61511 RequirementsDocument24 pagesSIL Methodology: A Methodology For SIL Verification in Accordance With IEC 61508 and IEC 61511 Requirementsmdfaheem786No ratings yet

- AVK Pneumatic Gate Valves BrochureDocument2 pagesAVK Pneumatic Gate Valves BrochureCuong Nguyen ChiNo ratings yet

- Calibrate Fire & Gas Detection SystemsDocument5 pagesCalibrate Fire & Gas Detection Systemskirandevi1981No ratings yet

- Major Equipment List of Each FacilityDocument24 pagesMajor Equipment List of Each FacilityLainhatanhNo ratings yet

- Tổng hợp đề thi IELTS Reading Test Practice with answersDocument71 pagesTổng hợp đề thi IELTS Reading Test Practice with answersLainhatanhNo ratings yet

- AssignmentTechSpecInstructionReport, HRSGDocument3 pagesAssignmentTechSpecInstructionReport, HRSGLainhatanhNo ratings yet

- Shop Surveillance Plan & Progress Status - FormDocument1 pageShop Surveillance Plan & Progress Status - FormLainhatanhNo ratings yet

- Document To Be Submitted by VendorsDocument3 pagesDocument To Be Submitted by VendorsLainhatanhNo ratings yet

- Contractor SurveillanceDocument2 pagesContractor SurveillanceLainhatanhNo ratings yet

- Gay FileDocument1 pageGay FileLainhatanhNo ratings yet

- Nonconformity Report: Customer Data Order DataDocument1 pageNonconformity Report: Customer Data Order DataLainhatanhNo ratings yet

- Document To Be Submitted by VendorsDocument3 pagesDocument To Be Submitted by VendorsLainhatanhNo ratings yet

- CRS - Construction Strategy Plan - 24th August 2022Document9 pagesCRS - Construction Strategy Plan - 24th August 2022LainhatanhNo ratings yet

- De Cuong On Thi Hoc Ky 2 Mon Tieng Anh Lop 6 Nam Hoc 2015 2016Document9 pagesDe Cuong On Thi Hoc Ky 2 Mon Tieng Anh Lop 6 Nam Hoc 2015 2016LainhatanhNo ratings yet

- Technical Document Submission GuideDocument3 pagesTechnical Document Submission GuideLainhatanhNo ratings yet

- Motorcycle Safety Guide & ManualDocument193 pagesMotorcycle Safety Guide & ManualLainhatanhNo ratings yet

- BàI TậP Về Câu Điều Kiện Loại 1Document3 pagesBàI TậP Về Câu Điều Kiện Loại 1LainhatanhNo ratings yet

- De Thi Lop 6 Cuoi Ki 2 Mon Tieng Anh de 1Document6 pagesDe Thi Lop 6 Cuoi Ki 2 Mon Tieng Anh de 1LainhatanhNo ratings yet

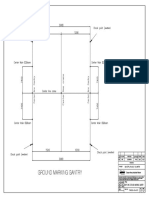

- Groud Marking Gantry PDFDocument4 pagesGroud Marking Gantry PDFLainhatanhNo ratings yet

- De 950086 019 PDFDocument1 pageDe 950086 019 PDFLainhatanhNo ratings yet

- De Thi Lop 6 Cuoi Ki 2 Mon Tieng Anh de 3Document6 pagesDe Thi Lop 6 Cuoi Ki 2 Mon Tieng Anh de 3LainhatanhNo ratings yet

- Gas 1627Document7 pagesGas 1627LainhatanhNo ratings yet

- High Tension BoltDocument5 pagesHigh Tension BoltLainhatanhNo ratings yet

- 5.2 TOFD With Omniscan ProcedureDocument9 pages5.2 TOFD With Omniscan ProcedureLainhatanhNo ratings yet

- De 950086 014 PDFDocument1 pageDe 950086 014 PDFLainhatanhNo ratings yet

- Appendix III - Psai Terminals Technical Specifications & General ScopeDocument14 pagesAppendix III - Psai Terminals Technical Specifications & General ScopeLainhatanhNo ratings yet

- Gantrex Technical Bulletin Summarizes European Crane Rail StandardsDocument3 pagesGantrex Technical Bulletin Summarizes European Crane Rail StandardsLainhatanhNo ratings yet

- MSS SP-85 2002 GRAY IRON GLOBE & - ANGLE VALVES FLANGED AND THREADED ENDS PDFDocument12 pagesMSS SP-85 2002 GRAY IRON GLOBE & - ANGLE VALVES FLANGED AND THREADED ENDS PDFLainhatanhNo ratings yet

- Management Science Chapter 11Document42 pagesManagement Science Chapter 11Myuran SivarajahNo ratings yet

- Peru 120W Solar All in One V2.0Document6 pagesPeru 120W Solar All in One V2.0luciano añorgaNo ratings yet

- 03 Preliminary PagesDocument12 pages03 Preliminary PagesBillie Jan Louie JardinNo ratings yet

- Daya Dan Gerakan: Force and MotionDocument21 pagesDaya Dan Gerakan: Force and MotionzinziemeewahNo ratings yet

- Linux Unit 4Document34 pagesLinux Unit 4Adeefa AnsariNo ratings yet

- Needle Tip Deformation After PDL and Intraseptal Dental Local AnesthesiaDocument5 pagesNeedle Tip Deformation After PDL and Intraseptal Dental Local AnesthesiaMohammad AkheelNo ratings yet

- 3x Anglais Ecran-4Document4 pages3x Anglais Ecran-4EMRE KAAN USTANo ratings yet

- Analisis Unsur-Unsur Intrinsik Cerpen "Senyum Karyamin" Karya Ahmad TohariDocument8 pagesAnalisis Unsur-Unsur Intrinsik Cerpen "Senyum Karyamin" Karya Ahmad TohariP4T GamingNo ratings yet

- Joanne Mitchell 2223rtkl0155 Email Orig - RedactedDocument29 pagesJoanne Mitchell 2223rtkl0155 Email Orig - RedactedmegankshannonNo ratings yet

- فايبر L.3Document13 pagesفايبر L.3Alaa AdeebNo ratings yet

- Science Expo 2023-24Document2 pagesScience Expo 2023-24zuhair burneyNo ratings yet

- GLA University - Student's No Dues DetailsDocument2 pagesGLA University - Student's No Dues DetailsRishi JakarNo ratings yet

- Business Aptitude Test: BAT™ Module I - Academic AptitudeDocument18 pagesBusiness Aptitude Test: BAT™ Module I - Academic AptitudePriyam SaraogiNo ratings yet

- Fiber Optic Temperature Laser RadarDocument7 pagesFiber Optic Temperature Laser RadarLesther RivasNo ratings yet

- 12 Gold 4 - C3 EdexcelDocument13 pages12 Gold 4 - C3 EdexcelShwan HasanNo ratings yet

- Cowin E7 Manual PDFDocument10 pagesCowin E7 Manual PDFPaylish100% (1)

- RESUMEDocument3 pagesRESUMEravi 1234No ratings yet

- Sist Elec. D6KDocument2 pagesSist Elec. D6KJose Luis Aguero PomachaguaNo ratings yet

- "Enhancement of A Heat Exchanger by Conical Inserts": A Project Report OnDocument32 pages"Enhancement of A Heat Exchanger by Conical Inserts": A Project Report OnDevashish RaturiNo ratings yet

- Faren Buildcon Plasto ReadyDocument1 pageFaren Buildcon Plasto ReadyFaren TradersNo ratings yet