Professional Documents

Culture Documents

GS0303 Stage 1 Audit Report-Sigma

Uploaded by

Elias JarjouraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GS0303 Stage 1 Audit Report-Sigma

Uploaded by

Elias JarjouraCopyright:

Available Formats

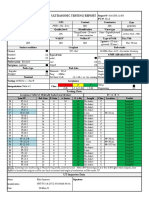

Management System Certification

Stage 1 Audit Report

Organization: Sigma cylinders

Address: Address 1 :Lebanon, Ein El Tineh, Celine 2 Building, 1st floor

Address 2 : Ivory Coast, Yopougib, PK 24 – Zone Industrielle

Standard(s): ISO9001:2015, Accreditation Body(s): SAS

ISO14001:2015,ISO45001:2018

Representative: Mr.Mohmad shams

Site(s) audited: Same as above Date(s) of audit(s): 26/5/2021

EAC Code: 17 NACE Code: 27.1 Technical QM17.1

Area code: EM 19

OH 8

Effective No.of 10 ( Lebanon ) No. of Shifts: 1

Personnel: 8 ( Abidjian )

Lead auditor: Nazih Mawlawy Additional team Tony Abisafi

member(s):

Additional

Attendees and

Roles:

This report is confidential and distribution is limited to the audit team, audit attendees, client representative, the SGS

office and may be subject to Accreditation Body, Certification Scheme owners or any other Regulatory Body sampling in

line with our online Privacy Statement which can be accessed here

1. Audit objectives

Specific Objectives of Stage 1 audit are:

- to review the client’s management system documented information;

- evaluate the client’s site-specific conditions and to undertake discussions with the client’s

personnel to determine the preparedness for stage 2;

- review the client’s status and understanding regarding requirements of the standard, in particular

with respect to the identification of key performance or significant aspects, processes, objectives

and operation of the management system;

- obtain necessary information regarding the scope of the management system, including: the

client’s site(s); processes and equipment used; levels of controls established (particularly in case of

multisite clients); applicable statutory and regulatory requirements;

- review the allocation of resources for stage 2 and agree the details of stage 2 with the client;

Job n°: Report date: 26/5/2021 Visit Type: S1 Visit n°: 1

CONFIDENTIAL Document: GS0303 Issue n°: Issue 18 Page n°: 1 of 7

- provide a focus for planning stage 2 by gaining a sufficient understanding of the client’s

management system and site operations in the context of the management system standard or

other normative document;

- evaluate if the internal audits and management reviews are being planned and performed, and that

the level of implementation of the management system substantiates that the client is ready for

stage 2.

▪ Note: A management system certification audit is not a legal compliance audit

2. Audit scope

Design , maunufacturitng and sates of various types of LPG Cylinders

For multi-site audits an Appendix listing all relevant sites and/or remote N/A Yes No

locations has been established (attached) and agreed with the client

For integrated audits, confirm the current level of the client’s IMS integration: N/A Basic High

3. Critical audit findings

The following findings, if not appropriately addressed before commencement of the stage 2 audit are likely

to result in major nonconformities being identified or an inability to complete the Stage 2 audit.

Non

4. Non critical audit findings

The following findings, if not appropriately addressed, may lead to nonconformities being identified at the

Stage 2 audit.

4.Context of the organization: clause 4.1,4.2,4.3,4.4

Internal and external issues :

Job n°: Report date: 26/5/2021 Visit Type: S1 Visit n°: 1

CONFIDENTIAL Document: GS0303 Issue n°: Issue 18 Page n°: 2 of 7

- Social and cultural , political ,legal regulatory , technoligilcal

- Key drives and trends having impact on sigma objectives

- Specific internal : governance ,structures and roles

- Capabilities , resources and knowledge ,competences

- standards and guidelines adopted to sigma

- contractural relationship

- key interface between processes

Interested parties :

Customers . bank insurer, stakholders , regulator ,government , top management

Suppliers

Employees

Neighbours , technical competitors

Scope : Design , maunufacturitng and sales of various types of LPG Cylinders

( documented information ) .

Process map :

Sales and customer services , design , purchasing , production , shipping

5 leadership: clause 5.1,5.2,5.3,5.4

QHSE / policy : statement

Organization chart : for Lebanon factory & head office

Site Abidjian : supply chain is limited to Head office

( interconnected ) .QHSE officer

Supply chain &logistics manager

Loading officer

Operation manager : job description : authorities

Consultation and participation

Procedure + enviroemtnatl apsects impat list / operation health ans safety riks and unacceptable hazards

6.planning: clause 6.1,6.2,6.3

QHSE risk assessment / processes and mitigation including risks of legal requirments

Criteria / procedure of evlatuation and monitoring .

Covering : factory in Lebanon and abidijian ( operational and non operational process )

QHSE objectives : for 2021

By process and action plan

Operation :

Sales and customer service / design and production /quality control and delivery

Job n°: Report date: 26/5/2021 Visit Type: S1 Visit n°: 1

CONFIDENTIAL Document: GS0303 Issue n°: Issue 18 Page n°: 3 of 7

Change management process :

Change management plan /document changes

7.support : clause 7.1,7.2,7.3,7.4,7.5

Process of awarness and internal /external communication

Organization chart for all sites last updated 3/2021

Preventive maintenace program for building and equipments

List of machine activities : preventive and frequency

Ex: assembly mold / shearing machine

Calibration : digital balance , pressure gauge ( IRI calibration ) /calibration certificates (available )

Welding machines calibration / only black steel product no stainless steel

Welding calibaration records

Internal and external communication procedure

Awareness: session HSE

Training plan :QHSE

Frill drill / first safety / fire fighting / awarness + technical trainings ( organizational knowledge )

Emergency preparedness and response process

Documented information : procedure

Documnent distribution list : diffusion matrix

Creating , coding , modification

Document control procedure / including back ups

8.operation: clause 8.1,8.2,8.4,8.5,8.6,8.7

Operation processes :

Supply chain and logistics

Sales and customer support : psot sales process / tender participation

Procurement :theory shall be finalized , supplier selction and evaluation , po, reception of purchased product

Design and calculation : general procedure &guidelines for design of steel cylinders with water capacity of

up to 150 literes

Warehousing : warehouse in -out , location , material idenitification

Delivery : transport and shipment

Production and quality control : hydrostatic testing

Testing form m including installed valves :

Apply works procedure specification :WPS as per welding process /sampling

Non IRI ( Welding / dimension and paint)

Weld ,map traceability sheet .

Emergency preparedness and response : fire drill / reports and training of evacuation

First aid kits /first aider by sites ( training and appointing )

Operational controls : admin signs / engineering controls

Safety signs / exit route fire extinguishers and fire alarms

Ethanol /tinner tanks ; operational controls valves and restrict acess /cut off

Safety and environmetnal signs including hazardous material and wastes

Job n°: Report date: 26/5/2021 Visit Type: S1 Visit n°: 1

CONFIDENTIAL Document: GS0303 Issue n°: Issue 18 Page n°: 4 of 7

Spil kits / shall be available next to chemical tanks /containers along with a second containments

PPE’s By acticities and areas

Ground marking for circulation

Fresh air ventilation / exraction fans / exhaust

Lifting / storing / circulation /welding /separation between acetelaine and oxegen

Post weld heat treatment

Butane tanks equipded by safety valves /cut off

9.performance evaluation : clause 9.1,9.2,9.3

Verified : customer support process

Customer satisfaction surveys

Performance evaluaton tools

Internal audit program /checklist and report for IMS ( 2021 )

Management review meeting agenda and attendees 2/2021

HSE performance evaluation

10.improvement: clause 10.1,10.2,10.3

NCR / IAF process and templates

Data collection and analysis reports For IMS

Opportunities for improvement by supply chain processes

Accident / incident reports (YTD ) 4/2021 investigation and action plans

Environmental reports on consumption and waste management and relevant improvement ( 3/2021 )

5. Audit Conclusions

The Stage 1 audit was successful in meeting the stated objectives: Yes No

The stage 1 audit was limited in time and scope to the stated objectives and it is possible that additional

weaknesses will be identified during future audit activities. With consideration to the findings identified in section

3 and 4 of this report, the overall conclusions of the audit are as follows:

The management system has been planned to conform with all the requirements of the Yes No

audit standard:

The management system is designed to achieve the organization’s policy objectives: Yes No

Based on the information provided, the system is designed to identify and manage Yes No

compliance with statutory, regulatory and contractual requirements:

The internal audit and management review planning assure appropriate coverage Yes No

prior to the Stage 2 Audit:

Job n°: Report date: 26/5/2021 Visit Type: S1 Visit n°: 1

CONFIDENTIAL Document: GS0303 Issue n°: Issue 18 Page n°: 5 of 7

Any scope exclusions are appropriate and justified: N/A Yes No

The Stage 2 audit should proceed as presently planned: Yes No

Comments or details of necessary changes to the stage 2 audit plan:

1- Internal and external issues : shall cover issues from all sites including evironemtnal and health and

safety .clasue 4.1

2- Interested parites shall also be specified with their requirements including HSE for all sites. clause 4.2

3- External documents can be added to the interested parties table specifically defined and referred

.clasue 4.4

4- Process man : better to develop a main process flow path and a supporting process one .clause 4.4

5- Main processes : wareshoue process shall be added , production : sub process : cutting , welding ,

paiting ,quality control , shall be set stating the outsourcing process also .clause 4.4

6- HSE process shall clearly added to the process map and then detailed in organization chart as

postions and relatively at JD’s as factory HSE officer , supervisor , manager .. .clause 4.4 ,5.3

7- QHSE Policy : needs to be revised to include clearer commitment to meet customers requirements ,

pollution preventon , accident ,illness , injuries and work related health and safety issues .clause 5.1

8- Organization chart : supply chain processes postions shall be elaborated .clause 5.3

9- Risks assesement QHSE / process risks . associated environmental and health and safety hazards

shall be considered , mitigation ,and evaluation criteria .clause 6.1

10- Change management : shall use the change management program in full details , topic ,plans action

maintaining the intergrity of IMS .clause 6.3

11- All IMS documents shall be coded as per relevant procedure of documented information menttioniing

the code ,issue and edition number ,date , review /preparation and approval .clause 7.5

12- Sales process :tender participation sub processes shall be added (not only post sales process )

covering B2B ,B2C, B2G in all sites .clause 8.2

13- Procurement : supplier selection and evaluation , purchase order , reception of purchased product shall

be established including the use ot suncontractors and outsourcing .clasue 8.4

14- Evacuation plan . safety and environmental signs , shall be posted at factory including fire escape

routes , PPE’S , exit signs , fire extinguishers and hazardous materials , fire alarm and fire pump firsdt

aids kits and clinic ( where applicable ) ,at offices escape route signs : exist signs , fire extighushers

,first aid and evacuation plans .clause 8.1

15- Evacuation drill for factories ,and offices shall be performed as well ad first aid trainings and safety fire

fighting training , it can be performed fron red cross and civil defense , a certificate shall be issued and

renewed on yearly bases. Clause 8.2

16- Design process : shall focus design review and verification against customer requirements prior to send

order to production ,clause 8.3

Job n°: Report date: 26/5/2021 Visit Type: S1 Visit n°: 1

CONFIDENTIAL Document: GS0303 Issue n°: Issue 18 Page n°: 6 of 7

17- More details in required on quality control process and product release by customer order a proper

documentation /records shall be considered prior to release products to customer .clause 8.6

18- Internal audit report shall cover all site and processes , emphasising on opportunity for improvements

and extent of IMS conformity .clause 9.2

19- Management review minutes of meeting shall cover all topics mentioned In clause 9.3.2

20- Customer feedbacks shall be collected ( as via surveys or other method ) and analysed , where it

positive or negiative , taking into consideration the need to open an IAF .Clause 9.1

21- Data shall be collected and analysed in addition to customer feed backs , on supplier performance ,

customer orders , quotation and bids, process conformity, supply chain efficiency ,end product re-work

and first time right , Non conforming product percentage , waste type segregation , collection and

recycling imclcuding natural rescources consumption as water , diesel , electricity , raw materilas ,

waste management shall cover ( liquid , solid and gas) , incidents/ accidents and near misses shall be

reported and analysed . clause 9.1, 10.2

6. Opening and Closing Meeting Attendance Record

Name Position Opening Closing

Mohmas Shamas GM x x

Elias Jarjoura Consultant /MR X X

Jowa Nachar HR Manager X X

Job n°: Report date: 26/5/2021 Visit Type: S1 Visit n°: 1

CONFIDENTIAL Document: GS0303 Issue n°: Issue 18 Page n°: 7 of 7

You might also like

- Audit checklist templates for quality, EMS and OH&S management systemsDocument4 pagesAudit checklist templates for quality, EMS and OH&S management systemssrsureshrajanNo ratings yet

- Quality Management Systems ExamplesDocument9 pagesQuality Management Systems Examplesselinasimpson351No ratings yet

- NCR (Ims Procrument Dept)Document1 pageNCR (Ims Procrument Dept)Mohammed BadruddinNo ratings yet

- Chapter 16: Spills Report FormDocument2 pagesChapter 16: Spills Report FormNoor Muddassir Khan100% (1)

- ISO 14001 Internal Audit ChecklistDocument7 pagesISO 14001 Internal Audit Checklisthamidin_syarifNo ratings yet

- Safety Audit PDFDocument11 pagesSafety Audit PDFaqibNo ratings yet

- EIA Registration FormDocument2 pagesEIA Registration FormOluwaseun Babs LawalNo ratings yet

- Audit Cover Summary PageDocument12 pagesAudit Cover Summary PageJoe EleanNo ratings yet

- Toolbox Meeting Attendance RecordDocument1 pageToolbox Meeting Attendance RecordChaudhary Wasim MurtazaNo ratings yet

- ISO 45001 Homework Audit TipsDocument5 pagesISO 45001 Homework Audit TipsimNo ratings yet

- Top10 Hse Interviewquestions With AnswersDocument21 pagesTop10 Hse Interviewquestions With AnswersramodNo ratings yet

- Safety, Health & Environment Policy: Purpose ExpectationsDocument1 pageSafety, Health & Environment Policy: Purpose ExpectationsWibowo ArieNo ratings yet

- ISO 45001 - Risks and Opportunities To The OH&S MSDocument5 pagesISO 45001 - Risks and Opportunities To The OH&S MShhahungdaoNo ratings yet

- Consultant - Water & Waste EngineeringDocument10 pagesConsultant - Water & Waste EngineeringBanerjee SuvranilNo ratings yet

- Electronic Open Assessment FAQsDocument2 pagesElectronic Open Assessment FAQsshiyas M.MNo ratings yet

- EPA Region 4 Procedure for Controlling Nonconforming WorkDocument6 pagesEPA Region 4 Procedure for Controlling Nonconforming WorkMassimiliano PorcelliNo ratings yet

- BSP Contractor HSSE QuestionnaireDocument3 pagesBSP Contractor HSSE QuestionnaireMohamad HafizNo ratings yet

- HSE MS Training Feb 2019Document17 pagesHSE MS Training Feb 2019Musalim Shaikh100% (1)

- The Minitemaid Company Occupational Health and Safety Management SystemDocument9 pagesThe Minitemaid Company Occupational Health and Safety Management SystemPrakash PatelNo ratings yet

- IMS Internal Audit ScheduleDocument1 pageIMS Internal Audit ScheduleAkd DeshmukhNo ratings yet

- IMS - Internal Audit ChecklistDocument11 pagesIMS - Internal Audit ChecklistAli TavakoliNo ratings yet

- 1a. CV Hareesh 2024 Updtd-NDocument5 pages1a. CV Hareesh 2024 Updtd-NsoftwaresolutionsinstantNo ratings yet

- QEHS ManualDocument100 pagesQEHS ManualRob WillestoneNo ratings yet

- IRCA Application FormDocument7 pagesIRCA Application Formpatung patungNo ratings yet

- EHS LEGAL COMPLIANCEDocument4 pagesEHS LEGAL COMPLIANCEanoushia alviNo ratings yet

- RISK Mba 17Document22 pagesRISK Mba 17Cecily Sandra100% (1)

- SHEMDocument6 pagesSHEMAjith Kumar AjithNo ratings yet

- ISO 14001 Aspect - Impact AnalysisDocument13 pagesISO 14001 Aspect - Impact Analysiskalan1983100% (1)

- QA/QC Welding Inspector ResumeDocument24 pagesQA/QC Welding Inspector ResumeMq SharozNo ratings yet

- GP3101 ISO 14001 - 2004 ChecklistDocument5 pagesGP3101 ISO 14001 - 2004 ChecklistMagalyNo ratings yet

- Orient Paper Mills, Amlai (Prop. Orient Paper & Industries Limited)Document1 pageOrient Paper Mills, Amlai (Prop. Orient Paper & Industries Limited)Ravi Shankar ChakravortyNo ratings yet

- Talaat A.Kader: QEHSS DirectorDocument6 pagesTalaat A.Kader: QEHSS DirectormohammedNo ratings yet

- Engine Oil MSDSDocument7 pagesEngine Oil MSDSSantos RexNo ratings yet

- Checklist for Tractor Loader Backhoe InspectionDocument1 pageChecklist for Tractor Loader Backhoe InspectionHSE Heryginting100% (1)

- NQA 10 Steps To IMS Guide 7 10 2016 - 1Document1 pageNQA 10 Steps To IMS Guide 7 10 2016 - 1Norman AinomugishaNo ratings yet

- TQM Unit 5 - IsO 14000 SystemDocument62 pagesTQM Unit 5 - IsO 14000 SystemBabin DhasNo ratings yet

- Amendment No. 3 February 2021 TO Is 10500: 2012 Drinking Water - SpecificationDocument3 pagesAmendment No. 3 February 2021 TO Is 10500: 2012 Drinking Water - SpecificationSharad JoshiNo ratings yet

- IMS Audit - Version 1Document11 pagesIMS Audit - Version 1arobNo ratings yet

- SRP-Waste Management Plan-G225IEX-SRP-R-PLN-003Document10 pagesSRP-Waste Management Plan-G225IEX-SRP-R-PLN-003Ows AnishNo ratings yet

- Manual: Procedure Titel: HSE-ManualDocument11 pagesManual: Procedure Titel: HSE-ManualGeetha_jagadish30No ratings yet

- EMS Awareness PosterDocument2 pagesEMS Awareness PosterShahfiee AbdullahNo ratings yet

- BBQ - Behaviour Based Quality CardDocument2 pagesBBQ - Behaviour Based Quality Cardittiphon31No ratings yet

- Lead Exposure Control PlanDocument3 pagesLead Exposure Control PlanShahzeb HassanNo ratings yet

- Mudon Ahlia Real Estate Co.W.L.L. Annual Training Plan 2014: Prepared byDocument2 pagesMudon Ahlia Real Estate Co.W.L.L. Annual Training Plan 2014: Prepared byHebatallah FahmyNo ratings yet

- Ensure sufficient natural and artificial lightingDocument3 pagesEnsure sufficient natural and artificial lightingMohamed MounerNo ratings yet

- Ini Dia Dokumen ISO14001Document9 pagesIni Dia Dokumen ISO14001karjayaNo ratings yet

- SLCP Verification ProtocolDocument62 pagesSLCP Verification ProtocolWILFREDO SSOCONSULTORESNo ratings yet

- 9001, 14001, 45001 - Mandatory Documents and Records Required MatrixDocument3 pages9001, 14001, 45001 - Mandatory Documents and Records Required Matrixشیخ صادقNo ratings yet

- 3 HardeningDocument14 pages3 HardeningyuvarajchiNo ratings yet

- Guided Self Regulation (March 2020) PDFDocument4 pagesGuided Self Regulation (March 2020) PDFHasnulNo ratings yet

- API 570 CertificateDocument1 pageAPI 570 CertificateEhab AhmedNo ratings yet

- Performance Management System Ip PDFDocument11 pagesPerformance Management System Ip PDFsahib singhNo ratings yet

- ISCC EU RED II-GAP Audit Procedure Point-Of-Origin v1.0Document4 pagesISCC EU RED II-GAP Audit Procedure Point-Of-Origin v1.0asantosoNo ratings yet

- Lifecycle Assessment of Paint PDFDocument8 pagesLifecycle Assessment of Paint PDFRiz Jomaica Arenas100% (1)

- HSE PRO 02 F01b Contractor Pre-Qual Questionnaire - 2016-08Document4 pagesHSE PRO 02 F01b Contractor Pre-Qual Questionnaire - 2016-08DKY EDPAPNo ratings yet

- Guide for Managing Solid Waste at Chemical PlantDocument3 pagesGuide for Managing Solid Waste at Chemical PlantAkimBiNo ratings yet

- Dikenson Enterprises training procedureDocument5 pagesDikenson Enterprises training procedureShannon MooreNo ratings yet

- Chui AutoDocument4 pagesChui AutoKLONE DONNo ratings yet

- 5259-C3-V1-S2R-9001 Audit Summary ReportDocument5 pages5259-C3-V1-S2R-9001 Audit Summary ReportHanhan Jaya MahendraNo ratings yet

- 1.4 Evidance ISO 9001-2015 On ProcessDocument6 pages1.4 Evidance ISO 9001-2015 On ProcessRaharjo YakinNo ratings yet

- 17_OilProcess_RepoDocument1 page17_OilProcess_RepoElias JarjouraNo ratings yet

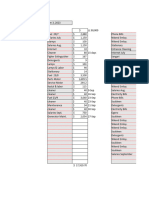

- 2- Preventive Maintenance Calendar- M-F-PMC-001-PE- Rev(0)Document3 pages2- Preventive Maintenance Calendar- M-F-PMC-001-PE- Rev(0)Elias JarjouraNo ratings yet

- Expenses term 3 (1)Document2 pagesExpenses term 3 (1)Elias JarjouraNo ratings yet

- Fuel Dispensing Safety ChecklistDocument1 pageFuel Dispensing Safety ChecklistToygar SavkinerNo ratings yet

- 00.1 App 1 List of Internal Documents Integrated Preview ENDocument1 page00.1 App 1 List of Internal Documents Integrated Preview ENblitzkrigNo ratings yet

- Iso 9712 2012 PDFDocument19 pagesIso 9712 2012 PDFBala KrishnanNo ratings yet

- Jarjoura's Site VisitDocument15 pagesJarjoura's Site VisitElias JarjouraNo ratings yet

- 3 RFP Documents ICLM DB 588Document8 pages3 RFP Documents ICLM DB 588Elias JarjouraNo ratings yet

- Safety Data Sheet (SDS) Liquefied Petroleum Gas (LPG) : 1. Product and Company DetailsDocument5 pagesSafety Data Sheet (SDS) Liquefied Petroleum Gas (LPG) : 1. Product and Company DetailsFARDANo ratings yet

- Quality Manual: Free Preview VersionDocument5 pagesQuality Manual: Free Preview VersionAmit Kumar UkeNo ratings yet

- EHQMS Process Audit ReportDocument2 pagesEHQMS Process Audit ReportManuela SavuNo ratings yet

- API-650 Code Annex-U Requirements for Ultrasonic Examination in lieu of RadiographyDocument11 pagesAPI-650 Code Annex-U Requirements for Ultrasonic Examination in lieu of RadiographyElias JarjouraNo ratings yet

- Chania. Greece, 1997Document5 pagesChania. Greece, 1997Elias JarjouraNo ratings yet

- 5ffcacac1fcf866bc8f2ea63 - Fulcrum Checklist - Gas Station Inspection ChecklistDocument4 pages5ffcacac1fcf866bc8f2ea63 - Fulcrum Checklist - Gas Station Inspection ChecklistElias JarjouraNo ratings yet

- Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3Document1 pageWelding Procedure Specification (WPS) : Asme Ix & Asme B31.3Elias JarjouraNo ratings yet

- Ultrasonic Testing Report: Famsco - LebanonDocument1 pageUltrasonic Testing Report: Famsco - LebanonElias JarjouraNo ratings yet

- Ielts Usa Practice Listening TestDocument10 pagesIelts Usa Practice Listening TestsfsfNo ratings yet

- Aisc 207-16 Audit Guide All Fabricator, Manufacturer and Erector Programs and EndorsementsDocument31 pagesAisc 207-16 Audit Guide All Fabricator, Manufacturer and Erector Programs and EndorsementsJorge perezNo ratings yet

- Organizational Chart for Jad Jaber CompanyDocument1 pageOrganizational Chart for Jad Jaber CompanyElias JarjouraNo ratings yet

- Operation ManualDocument71 pagesOperation ManualElias JarjouraNo ratings yet

- Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3Document1 pageWelding Procedure Specification (WPS) : Asme Ix & Asme B31.3Elias JarjouraNo ratings yet

- API-650 Code Annex-U Requirements for Ultrasonic Examination in lieu of RadiographyDocument11 pagesAPI-650 Code Annex-U Requirements for Ultrasonic Examination in lieu of RadiographyElias JarjouraNo ratings yet

- Method 201aDocument44 pagesMethod 201aamrusyahidNo ratings yet

- PA UTR 2021 053 (Final)Document1 pagePA UTR 2021 053 (Final)Elias JarjouraNo ratings yet

- Appendix 6 BU Handover ChecklistDocument4 pagesAppendix 6 BU Handover ChecklistK Muhammed AneesNo ratings yet

- Fuel Dispensing Safety ChecklistDocument1 pageFuel Dispensing Safety ChecklistToygar SavkinerNo ratings yet

- Quality Management System Diffusion Matrix - RemarksDocument6 pagesQuality Management System Diffusion Matrix - RemarksElias JarjouraNo ratings yet

- Fuel Dispensing Safety ChecklistDocument1 pageFuel Dispensing Safety ChecklistToygar SavkinerNo ratings yet

- Iso 22991 2004 en PDFDocument11 pagesIso 22991 2004 en PDFElias JarjouraNo ratings yet

- Aqualisa Quartz Simply A Better Shower SpreadsheetDocument6 pagesAqualisa Quartz Simply A Better Shower SpreadsheetZimam Khasin ArsyadNo ratings yet

- Supply Chain Q&A: Managing Processes Across CompaniesDocument7 pagesSupply Chain Q&A: Managing Processes Across Companiesdr jaimanNo ratings yet

- Human Resources Audit Provides Valuable Insights for Strategic PlanningDocument22 pagesHuman Resources Audit Provides Valuable Insights for Strategic PlanningRevathi RevathiNo ratings yet

- Employee Development & Talent ManagementDocument10 pagesEmployee Development & Talent ManagementsnehabasuNo ratings yet

- JaguarDocument7 pagesJaguarPurab MohapatraNo ratings yet

- Pe Module 4Document24 pagesPe Module 4rain MCNo ratings yet

- Audit Planning Chapter 7Document7 pagesAudit Planning Chapter 7Angela RamosNo ratings yet

- CIO Awards 2015 winners achieving higher business goalsDocument11 pagesCIO Awards 2015 winners achieving higher business goalsRonaldoNo ratings yet

- EAM For ManufacturingDocument9 pagesEAM For Manufacturingmikcarh58No ratings yet

- Financial Statement Audit QuizDocument3 pagesFinancial Statement Audit Quiz시나50% (2)

- WB2005 Labor PoliciesDocument66 pagesWB2005 Labor PoliciesMircea IlasNo ratings yet

- What Is Auditor IndependenceDocument6 pagesWhat Is Auditor IndependenceNeriza PonceNo ratings yet

- Nebosh: Management of Health and Safety Unit Ig1Document5 pagesNebosh: Management of Health and Safety Unit Ig1Mohamed Abdullah0% (1)

- Ms - MuffDocument17 pagesMs - MuffDayuman LagasiNo ratings yet

- IRB Board approves Q2 results, preferential issues to Cintra and GICDocument43 pagesIRB Board approves Q2 results, preferential issues to Cintra and GICslohariNo ratings yet

- Hong Leong Bank Strategic AnalysisDocument22 pagesHong Leong Bank Strategic AnalysisYeong Dee0% (1)

- Financial Accounting, 8/e, Chapter 13 ANSWERS TO QUESTIONSDocument36 pagesFinancial Accounting, 8/e, Chapter 13 ANSWERS TO QUESTIONSLazaros KarapouNo ratings yet

- Champikage WikramayaDocument4 pagesChampikage WikramayaNethaliAmarasiri75% (4)

- Agriculture Warehousing in IndiaDocument10 pagesAgriculture Warehousing in IndiaAmrit SharmaNo ratings yet

- Mangalore Chemicals & Fertilizers LTD & Paradeep Phosphate LTD MergerDocument6 pagesMangalore Chemicals & Fertilizers LTD & Paradeep Phosphate LTD Mergeraditiyab-pgdm-2022-24No ratings yet

- 2018 Annual Total Compensation Paid To JobsOhio EmployeesDocument4 pages2018 Annual Total Compensation Paid To JobsOhio EmployeesJo InglesNo ratings yet

- Three Stage Growth ModelDocument12 pagesThree Stage Growth ModelNavleen KaurNo ratings yet

- How To Procure DPINDocument2 pagesHow To Procure DPINCorproNo ratings yet

- SNDM Sem2 - Session 5Document8 pagesSNDM Sem2 - Session 5Kunal SainiNo ratings yet

- Sedafiat SDN BHD Goes Live On Ramco ERP (Company Update)Document3 pagesSedafiat SDN BHD Goes Live On Ramco ERP (Company Update)Shyam SunderNo ratings yet

- Irm PDFDocument27 pagesIrm PDFerraticNo ratings yet

- Tuten and Solomon - Chapter 2Document38 pagesTuten and Solomon - Chapter 2dheerajnimNo ratings yet

- Paper 1 - JKKPDocument26 pagesPaper 1 - JKKPalexcus1539No ratings yet

- EDP Audit MCQsDocument3 pagesEDP Audit MCQsSaria Waqas0% (1)

- EW Ch3 Case Audit Planning MemoDocument7 pagesEW Ch3 Case Audit Planning MemoNursalihah Binti Md NorNo ratings yet