Professional Documents

Culture Documents

Quality Management System Diffusion Matrix - Remarks

Uploaded by

Elias JarjouraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Management System Diffusion Matrix - Remarks

Uploaded by

Elias JarjouraCopyright:

Available Formats

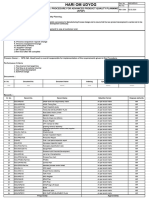

QUALITY MANAGEMENT SYSTEM

DIFFUSION MATRIX

Date of Remarks

Document of record title Code Latest Implemen- Include all your remarks:

edit" tation 1- Filled document location

2- Who is filling the report

3- Frequency of filling

4- Any other remark you might notice

once you do the handover with

Charbel

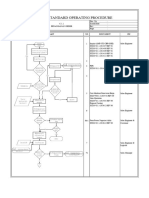

Process Map QM-F0 1 01/04/2018

Policy QM-F1 1 01/07/2009

Control of Documents M1P1 1 01/07/2009

Diffusion Matrix M1P1-F1 1 01/07/2009

Change-review-cancel M1P1-F2 1 01/07/2009

documents

Change-review-cancel M1P1-F3 1 01/07/2009

documents LIST

Documents transfer M1P1-F4 1 01/07/2009

evidence

Control of records M1P2 1 01/07/2009

List of external M1P2-F1 1 01/07/2009

documents

1 01/07/2009

Managing Internal M1P4 1 01/07/2009

Quality audit

List of Internal Quality M1P4-F1 1 01/07/2009

Auditors

Internal Audit Plan M1P4-F2 1 01/07/2009

Internal Audit M1P4-F3 1 01/07/2009

questionnaire

NC description Form M1P4-F4 1 01/07/2009

Internal Audit report M1P4-F5 1 01/07/2009

Managing of corrective M1P5 1 01/07/2009

& preventive actions

Improvement action form M1P5-F1 3 01/07/2018

IAF log M1P5-F2 1 01/07/2009

Management Review M1P6 1 01/07/2009

Management review M1P6-F1 1 01/07/2009

invitation

Management review M1P6-F2 1 01/07/2009

minutes

Management review M1P6-F3 1 01/07/2009

decisions follow up

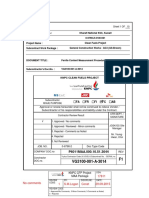

Ref.: M1P1-F1 Rev.:1 Date:01/07/2009

QUALITY MANAGEMENT SYSTEM

DIFFUSION MATRIX

Date of Remarks

Document of record title Code Latest Implemen-

edit" tation

Customer Satisfaction M1P7 1 01/07/2009

Evaluation

Guide satisfaction M1P7-G1 1 01/07/2009

information analysis

Complaint and request M1P7-F1 1 01/07/2009

data form

Complaint and request M1P7-F2 1 01/07/2009

log

Complaint request M1P7-F3 1 01/07/2009

answer

Customer satisfaction M1P7-F4 1 01/07/2009

evaluation questionnaire

Quality Control System M1P8 1/1 08/01/2010

Product Quality plan M1P8-F1 1/1 08/01/2010

Quality Control register M1P8-F2a 2 03/01/2018

form_raw material

Quality control register M1P8- 1 01/07/2009

form_preparing circle F2b

Quality control register M1P8-F2c 1 01/07/2009

form_company info

Quality control register M1P8- 1 01/07/2009

form_half cylinder F2d

Quality control register M1P8-F2e 1 01/07/2009

form_base welding

Quality control register M1P8-F2f 1 01/07/2009

form_ventre cylinder

Quality control register M1P8- 1 01/07/2009

form_fire cylinder F2g

Quality control register M1P8- 1 01/07/2009

form_water pressure F2h

cylinder

Quality control register M1P8-F2i 1 01/07/2009

form_painting cylinder

Quality control register M1P8-F2j 1 01/07/2009

form_air pressure

cylinder

Quality control register M1P8- 1 01/07/2009

form_weight batch F2k

cylinder

Quality control register M1P8- 1 01/07/2009

form_calibration sheet F2L

Quality control register M1P8- 1 01/07/2009

form_Burst test F2m

Ref.: M1P1-F1 Rev.:1 Date:01/07/2009

QUALITY MANAGEMENT SYSTEM

DIFFUSION MATRIX

Date of Remarks

Document of record title Code Latest Implemen-

edit" tation

Quality control register M1P8- 1 01/07/2009

form_Tensile test F2n

Quality control register M1P8- 1 01/07/2009

form_Bend Test F2o

Quality control Paint M1P8- 1 01/07/2018

Test F2P

Test report form_Final M1P8-F3 1 01/07/2009

product

List of Quality M1P8-F4 01/07/2009

controllers

System quality plan M1P8-F5 01/07/2009

Processes Quality & M1P8-F6 1 01/07/2009

Efficiency Performance

Status

Risk Assessment M1P9 0 01/04/2018

Risk Assesment LOG M1P9-F1 1 01/04/2018

Product design and P1P1 1 01/04/2018

production planning

Product design form P1P1-F1 1 01/07/2009

Product design register P1P1-F2 1 01/07/2009

Weekly production plan P1P1-F4 2 01/01/2018

Production report form P1P1- 2 01/04/2018

F7A-E

Sales & Delivery P2P1 1 01/07/2009

Sales request form P2P1-F1 1 01/07/2009

Sales request log form P2P1-F2 1 01/07/2009

Stock availability request P2P1-F3 1 01/07/2009

answer form

Manufacturing Procedure P3P1 1 01/07/2009

and guidelines

Recruitment & Perform S1P1 1/1 21/09/2010

evaluation

Guide company jobs S1P1-G1 1 01/07/2009

description

Date of

Document of record title Code Latest Implemen-

edit" tation

Organizational Chart S1P1-F0 3 01/04/2018

Form

Request for personnel S1P1-F1 1 01/07/2009

recruitment

Ref.: M1P1-F1 Rev.:1 Date:01/07/2009

QUALITY MANAGEMENT SYSTEM

DIFFUSION MATRIX

Job description form S1P1-F2 1 01/07/2009

Recruitment status log S1P1-F3 1 01/07/2009

Memo Personnel S1P1-F4 1 01/07/2009

Recruitment publication

Employee Evaluation S1P1-F5 2 01/01/2018

Form

Attendance S1P1-F6a- 1 01/01/2018

b

Employee Rotation Sheet S1P1-F7 0 01/02/2018

Table of Deputies S1P1-F8 0 01/02/2018

Employee Satisfaction S1P1-F9 0 01/02/2018

Survey And Auto-

Evaluation

Employees Training S1P2 1 01/07/2009

Identification of training S1P2-F1 1 01/07/2009

needs

Employees Training Plan S1P2-F2 1 01/07/2009

Employee training S1P2-F3 1 01/07/2009

Course nomination

Training course S1P2-F4 1 01/07/2009

employee evaluation

Training course S`P2-F5 1 01/07/2009

employee benefit

Purchasing & supplier S2P1 2 01/01/2018

evaluation

Supplier register S2P1-F1 1 01/07/2009

Suppliers approved list S2P1-F2 1 01/07/2009

Supplier evaluation sheet S2P1-F3 2 01/04/2018

Maintenance S3P1 1/1 13/10/2010

Equipment status S3P1-F1 1 01/07/2009

Machine Data Card S3P1-F2 1 01/07/2009

Machine maintenance S3P1-F3 1 01/07/2009

record

Annual Maintenance S3P1-F4 1 01/07/2009

Program

Machine Maintenance 3P1-F5 1 01/07/2009

Request

Values and Context MG-VC 0 01/04/2018

Control of changes 0 01/04/2018

request MG-VC-

F1

Ref.: M1P1-F1 Rev.:1 Date:01/07/2009

QUALITY MANAGEMENT SYSTEM

DIFFUSION MATRIX

Date of Remarks

Document of record title Code Latest Implemen-

edit" tation

Storing S3P2 1/1 17/09/2010

Equipment Request S3P2-F1 1 01/07/2009

Receipt

Material request form S3P2-F2 1 01/07/2009

Loss of material or S3P2-F3 1 01/07/2009

equipment minutes

Weekly stock (steel) S3P2-F4a 1 17/09/2010

Weekly stock (Raw Material) S3P2-F4b 1 17/09/2010

Weekly stock (LPG Cylinders) S3P2-F4c 1 17/09/2010

Monthly stock (steel) S3P2-F5a 1 17/09/2010

Monthly stock (Raw Material) S3P2-F5b 1 17/09/2010

Monthly stock (LPG Cylinders) S3P2-F5c 1 17/09/2010

Annually stock (steel) S3P2-F6a 1 17/09/2010

Annually stock (Raw Material) S3P2-F6b 1 17/09/2010

Annually stock (LPG S3P2-F6c 1 17/09/2010

Cylinders)

Tensile testing procedure QC1P1 1 01/01/2016

Tensile testing Report QC1P1-F1 1

Guided Bend Testing Procedure QC1P2 1 01/01/2016

Guided Bend Testing Report QC1P2-F1 1

Macro-etching Procedure QC1P3 1 01/01/2016

Job Description for weld 1

QC1P3-F1

personnel

Procedure for Batch Sampling 1

and Dimensional Inspection

QC1P4 01/01/2016

Dimensional Inspection Report QC1P4-F1 1

Visual Inspection Procedure QC1P5 1 01/01/2016

Weld map-Traceability sheet - 1

QC1P5-F1

Visual Welding Inspection

Radiographic testing procedure QC1P6 1 01/01/2016

Liquid penetrant Procedure QC1P7 1 01/01/2016

Magnetic Particle Procedure QC1P8 1 01/01/2016

Pressure Testing Procedure QC1P9 1 01/01/2016

Mig Welding Machine 1

Calibration Procedure

QC1P10 01/01/2016

Post weld Heat treatment 1

(PWHT)

QC1P11 01/01/2016

* Definitions and Abbreviations

O= Owner P = Participant I = Informed

BOD = DG = Director General VDG= Vice Director

Board of Dirctors General

TQM = PM = Production Manager HRM = Human

Ref.: M1P1-F1 Rev.:1 Date:01/07/2009

QUALITY MANAGEMENT SYSTEM

DIFFUSION MATRIX

Technical and Resources Sales

Quality Manage Purchasing Manager

MM = Maintenance SM = Storing Manager SEM = Section

Manager Manager

SPM = Sales and

Purchasing Manager

Ref.: M1P1-F1 Rev.:1 Date:01/07/2009

You might also like

- TMS Castings Quality Manual 2009Document3 pagesTMS Castings Quality Manual 2009shifaNo ratings yet

- National & International Standards Master ListDocument2 pagesNational & International Standards Master ListBhakti MahbubaniNo ratings yet

- BFS_R2-1 Criteria 1 of 2Document456 pagesBFS_R2-1 Criteria 1 of 2katerina.shulevska21No ratings yet

- MOTIVA Lab Master Document ListDocument2 pagesMOTIVA Lab Master Document ListahkiaenaaaaNo ratings yet

- Format Issue RecordDocument4 pagesFormat Issue RecordBharatNo ratings yet

- Element ListDocument1 pageElement Listrgrao85No ratings yet

- Control Engineering DrawingsDocument5 pagesControl Engineering DrawingslokelooksNo ratings yet

- Practicas de Ingenieria QuimicaDocument84 pagesPracticas de Ingenieria Quimicadistribuidoraggs2012No ratings yet

- Standards ManagementDocument3 pagesStandards ManagementGourav SainiNo ratings yet

- Managing Change at Daejung Mo PartsDocument4 pagesManaging Change at Daejung Mo PartsubraghuNo ratings yet

- Iso ProceduresDocument57 pagesIso ProceduresShin Mey100% (4)

- Point 1 - B) Procedure For Managemet of ChangeDocument3 pagesPoint 1 - B) Procedure For Managemet of Changemahesh KhatalNo ratings yet

- Guideline Safety, Health and Environmental Protection - Safety N-G-HE 260Document3 pagesGuideline Safety, Health and Environmental Protection - Safety N-G-HE 260MEGAN ASBROCKNo ratings yet

- NeralaccessmarineDocument52 pagesNeralaccessmarineDevin HardyNo ratings yet

- Embraer Training ManualDocument270 pagesEmbraer Training ManualKent100% (1)

- Process Engg Practices To Be Used in The Refinery IndustryDocument86 pagesProcess Engg Practices To Be Used in The Refinery IndustryuddinNo ratings yet

- 4M Change ProcedureDocument2 pages4M Change ProcedureKRISHAN KUMARNo ratings yet

- Quality Audit Report SummaryDocument27 pagesQuality Audit Report Summarypuri16No ratings yet

- Notification - BHA LostDocument2 pagesNotification - BHA LostGhinet Teodor-ioanNo ratings yet

- Sop HANDLING ORDER - 2Document1 pageSop HANDLING ORDER - 2alexNo ratings yet

- Sales & Marketing Department Administration Lesson PlanDocument1 pageSales & Marketing Department Administration Lesson PlanSUMAIYAH MAMAT KVGNo ratings yet

- Aasl PPC Procedure Manual 19112016Document85 pagesAasl PPC Procedure Manual 19112016s adakNo ratings yet

- Auxiliary Power Unit Safir 5K/G Mi Manual For The Operation and Technical MaintenanceDocument178 pagesAuxiliary Power Unit Safir 5K/G Mi Manual For The Operation and Technical MaintenanceIvan100% (2)

- WIN-T Increment 2 Second Follow-on Operational Test and Evaluation Report Assesses Network EffectivenessDocument70 pagesWIN-T Increment 2 Second Follow-on Operational Test and Evaluation Report Assesses Network EffectivenessbstockusNo ratings yet

- Procedure For EcnDocument8 pagesProcedure For EcnChintamani GiramkarNo ratings yet

- Emimansys Tech Proc Magneticparticleinspectionrev10Document40 pagesEmimansys Tech Proc Magneticparticleinspectionrev10Devin HardyNo ratings yet

- SHEMPS 8.1 MBU-MIN-PRO-018 Road MaintenanceDocument4 pagesSHEMPS 8.1 MBU-MIN-PRO-018 Road MaintenanceLeocadia ChibamuNo ratings yet

- MODEL NO.: M185B1-P01: TFT LCD Approval SpecificationDocument25 pagesMODEL NO.: M185B1-P01: TFT LCD Approval Specificationcesar calderonNo ratings yet

- ISO 20000-1:2011 Requirement wise Document ListDocument6 pagesISO 20000-1:2011 Requirement wise Document ListHarish NaiduNo ratings yet

- Rotax Operators Manual 912Document84 pagesRotax Operators Manual 912DelNo ratings yet

- QSP-01 FR-01 Masterlist of QMSDocument5 pagesQSP-01 FR-01 Masterlist of QMSWan Mohd FarzrinNo ratings yet

- Corrective Action ReportDocument1 pageCorrective Action Reportmilkiyas ayalewNo ratings yet

- FlowchartDocument142 pagesFlowchartAnup Pathak100% (2)

- P 7.2-01 Prosedür - Müşteri İle İlişkili Prosesler Prosedürü - EngDocument4 pagesP 7.2-01 Prosedür - Müşteri İle İlişkili Prosesler Prosedürü - Engfaruk öztürkNo ratings yet

- F00 Form OverviewDocument3 pagesF00 Form OverviewZhassulan AkhmetovNo ratings yet

- 4M Change RequestDocument5 pages4M Change RequestNJMU LAB67% (3)

- Supplier - Turnover - DocumentationDocument4 pagesSupplier - Turnover - DocumentationBrian MarinNo ratings yet

- P3-Process For Control of Non-ConformanceDocument3 pagesP3-Process For Control of Non-ConformanceBangali SinghNo ratings yet

- Procedure NPD 01apqp HouDocument4 pagesProcedure NPD 01apqp HouHARI OM UDYOG HARI OMNo ratings yet

- SEO Maintenance Management ProceduresDocument16 pagesSEO Maintenance Management ProceduresMajid KhanNo ratings yet

- s Jv Partials TrkDocument4 pagess Jv Partials Trkshift echoNo ratings yet

- Project Quality Plan As Per ISODocument118 pagesProject Quality Plan As Per ISORaju100% (1)

- FLS Checklist (Rev 1 - June 2018)Document34 pagesFLS Checklist (Rev 1 - June 2018)gaongokhoaiNo ratings yet

- PPAP Check List FormDocument5 pagesPPAP Check List FormRaju.PalNo ratings yet

- Preventing Quality IssuesDocument5 pagesPreventing Quality IssuesVivek VNo ratings yet

- P05 - ProductionDocument14 pagesP05 - ProductionEDWARD ACHEAMPONGNo ratings yet

- Ae-qms-p-02 Control of Documented InformationDocument9 pagesAe-qms-p-02 Control of Documented Informationpankaj66668No ratings yet

- CNH Industrial Customer Requirements for ISO/TS 16949Document8 pagesCNH Industrial Customer Requirements for ISO/TS 16949Yo GoldNo ratings yet

- ISO 13485:2012 Certification Documents by Global Manager GroupDocument6 pagesISO 13485:2012 Certification Documents by Global Manager GroupManagement ConsultantNo ratings yet

- Experience Record Proforma Centrifugal Pump (Vertical) : Document No. G225-IEX-SRP-M-ER-0202 Page 1 of 4Document4 pagesExperience Record Proforma Centrifugal Pump (Vertical) : Document No. G225-IEX-SRP-M-ER-0202 Page 1 of 4sumit kumarNo ratings yet

- FT Procedure F1Document10 pagesFT Procedure F1abrayalamNo ratings yet

- AGG-ST-052 Autokiniton Process Approval Sign-Off PPAPDocument19 pagesAGG-ST-052 Autokiniton Process Approval Sign-Off PPAPRamesh DenonNo ratings yet

- MAN002 FDE InventoryManagementCockpit v3.4Document43 pagesMAN002 FDE InventoryManagementCockpit v3.4bearpanzaNo ratings yet

- Ipc Tpe 331-10Document975 pagesIpc Tpe 331-10Cristhian342100% (2)

- MQ SP I 7001 PDFDocument18 pagesMQ SP I 7001 PDFJaseelKanhirathinkalNo ratings yet

- Reliability - A Shared Responsibility for Operators and Maintenance. 3rd and 4th Discipline of World Class Maintenance Management: 1, #3From EverandReliability - A Shared Responsibility for Operators and Maintenance. 3rd and 4th Discipline of World Class Maintenance Management: 1, #3Rating: 5 out of 5 stars5/5 (1)

- 2- Preventive Maintenance Calendar- M-F-PMC-001-PE- Rev(0)Document3 pages2- Preventive Maintenance Calendar- M-F-PMC-001-PE- Rev(0)Elias JarjouraNo ratings yet

- 3 RFP Documents ICLM DB 588Document8 pages3 RFP Documents ICLM DB 588Elias JarjouraNo ratings yet

- Jarjoura's Site VisitDocument15 pagesJarjoura's Site VisitElias JarjouraNo ratings yet

- Expenses term 3 (1)Document2 pagesExpenses term 3 (1)Elias JarjouraNo ratings yet

- 17_OilProcess_RepoDocument1 page17_OilProcess_RepoElias JarjouraNo ratings yet

- 00.1 App 1 List of Internal Documents Integrated Preview ENDocument1 page00.1 App 1 List of Internal Documents Integrated Preview ENblitzkrigNo ratings yet

- Quality Manual: Free Preview VersionDocument5 pagesQuality Manual: Free Preview VersionAmit Kumar UkeNo ratings yet

- Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3Document1 pageWelding Procedure Specification (WPS) : Asme Ix & Asme B31.3Elias JarjouraNo ratings yet

- Chania. Greece, 1997Document5 pagesChania. Greece, 1997Elias JarjouraNo ratings yet

- Safety Data Sheet (SDS) Liquefied Petroleum Gas (LPG) : 1. Product and Company DetailsDocument5 pagesSafety Data Sheet (SDS) Liquefied Petroleum Gas (LPG) : 1. Product and Company DetailsFARDANo ratings yet

- Ielts Usa Practice Listening TestDocument10 pagesIelts Usa Practice Listening TestsfsfNo ratings yet

- EHQMS Process Audit ReportDocument2 pagesEHQMS Process Audit ReportManuela SavuNo ratings yet

- Fuel Dispensing Safety ChecklistDocument1 pageFuel Dispensing Safety ChecklistToygar SavkinerNo ratings yet

- 5ffcacac1fcf866bc8f2ea63 - Fulcrum Checklist - Gas Station Inspection ChecklistDocument4 pages5ffcacac1fcf866bc8f2ea63 - Fulcrum Checklist - Gas Station Inspection ChecklistElias JarjouraNo ratings yet

- Operation ManualDocument71 pagesOperation ManualElias JarjouraNo ratings yet

- Iso 9712 2012 PDFDocument19 pagesIso 9712 2012 PDFBala KrishnanNo ratings yet

- PA UTR 2021 053 (Final)Document1 pagePA UTR 2021 053 (Final)Elias JarjouraNo ratings yet

- Organizational Chart for Jad Jaber CompanyDocument1 pageOrganizational Chart for Jad Jaber CompanyElias JarjouraNo ratings yet

- Aisc 207-16 Audit Guide All Fabricator, Manufacturer and Erector Programs and EndorsementsDocument31 pagesAisc 207-16 Audit Guide All Fabricator, Manufacturer and Erector Programs and EndorsementsJorge perezNo ratings yet

- Ultrasonic Testing Report: Famsco - LebanonDocument1 pageUltrasonic Testing Report: Famsco - LebanonElias JarjouraNo ratings yet

- Method 201aDocument44 pagesMethod 201aamrusyahidNo ratings yet

- API-650 Code Annex-U Requirements for Ultrasonic Examination in lieu of RadiographyDocument11 pagesAPI-650 Code Annex-U Requirements for Ultrasonic Examination in lieu of RadiographyElias JarjouraNo ratings yet

- Appendix 6 BU Handover ChecklistDocument4 pagesAppendix 6 BU Handover ChecklistK Muhammed AneesNo ratings yet

- Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3Document1 pageWelding Procedure Specification (WPS) : Asme Ix & Asme B31.3Elias JarjouraNo ratings yet

- Iso 22991 2004 en PDFDocument11 pagesIso 22991 2004 en PDFElias JarjouraNo ratings yet

- Fuel Dispensing Safety ChecklistDocument1 pageFuel Dispensing Safety ChecklistToygar SavkinerNo ratings yet

- API-650 Code Annex-U Requirements for Ultrasonic Examination in lieu of RadiographyDocument11 pagesAPI-650 Code Annex-U Requirements for Ultrasonic Examination in lieu of RadiographyElias JarjouraNo ratings yet

- GS0303 Stage 1 Audit Report-SigmaDocument7 pagesGS0303 Stage 1 Audit Report-SigmaElias JarjouraNo ratings yet

- Fuel Dispensing Safety ChecklistDocument1 pageFuel Dispensing Safety ChecklistToygar SavkinerNo ratings yet

- The 5 Ws of Intersectoral CollaborationDocument3 pagesThe 5 Ws of Intersectoral CollaborationSanthosh MRNo ratings yet

- Bimbingan Instruksional PBD - Merungkai Standard 3Document37 pagesBimbingan Instruksional PBD - Merungkai Standard 3Feiz Lina100% (1)

- An Senior High Thesis Presented To The Faculty of The AMA Computer Learning Center Antipolo CampusDocument54 pagesAn Senior High Thesis Presented To The Faculty of The AMA Computer Learning Center Antipolo CampusJane SandovalNo ratings yet

- SAT Test 9 Reading and WritingDocument32 pagesSAT Test 9 Reading and WritingOwais MaqboolNo ratings yet

- The Language of Felt Experience - Emotional, Evaluative and Intuitive - William DownesDocument24 pagesThe Language of Felt Experience - Emotional, Evaluative and Intuitive - William DowneshimkeradityaNo ratings yet

- John Rankin Mysticism of Emma Curtis HopkinsDocument27 pagesJohn Rankin Mysticism of Emma Curtis HopkinsMagicien1100% (1)

- Q4 Arts 6 Week3Document4 pagesQ4 Arts 6 Week3MiscaCruzNo ratings yet

- Dual Nature Extraversion: Institute of Psychiatry, Maudsley HospitalDocument10 pagesDual Nature Extraversion: Institute of Psychiatry, Maudsley HospitalAndreea IstrateNo ratings yet

- Final Exam - E-Government As An Innovative Product Theories and Case StudyDocument2 pagesFinal Exam - E-Government As An Innovative Product Theories and Case StudyDarielNo ratings yet

- Writing From The Inside Out: The Practice of Free-Form Writing (SAMPLE)Document20 pagesWriting From The Inside Out: The Practice of Free-Form Writing (SAMPLE)DIVINE ARTS0% (1)

- Personnel Records Management Alignment Performance ScorecardsDocument39 pagesPersonnel Records Management Alignment Performance ScorecardsCarol JacintoNo ratings yet

- 1.the Heterotopic Space of Chirag Delhi, A Study of An Urban VillageDocument3 pages1.the Heterotopic Space of Chirag Delhi, A Study of An Urban VillageSunaina ChauhanNo ratings yet

- Acsai Test Score 0Document5 pagesAcsai Test Score 0Zoiba ShaikhNo ratings yet

- Chapter 4 OrganizingDocument61 pagesChapter 4 OrganizingMOSTAKIN ROYNo ratings yet

- Synopsis Arn Revised2Document8 pagesSynopsis Arn Revised2Tokio87No ratings yet

- Day 11-Lesson PlanDocument4 pagesDay 11-Lesson PlanFT Geeyah TahirNo ratings yet

- To Whomsoever It May ConcernDocument2 pagesTo Whomsoever It May ConcernlalithNo ratings yet

- Burke-Litwin Change Model: Approaches To Managing Organizational ChangeDocument11 pagesBurke-Litwin Change Model: Approaches To Managing Organizational Changeankitgautam89No ratings yet

- 5D Crown and 3rd Eye Combo ActivationDocument27 pages5D Crown and 3rd Eye Combo ActivationEmeraldRay100% (1)

- Lesson Plan in Oral Communication W2 Q2Document4 pagesLesson Plan in Oral Communication W2 Q2Ariane CabasanNo ratings yet

- The 5 Classification Evaluation Metrics Every Data Scientist Must Know PDFDocument22 pagesThe 5 Classification Evaluation Metrics Every Data Scientist Must Know PDFcidsantNo ratings yet

- High-Yield Strategies To Use With HMH RoutinesDocument6 pagesHigh-Yield Strategies To Use With HMH Routinesapi-425909021No ratings yet

- Historical Fiction Project RubricDocument2 pagesHistorical Fiction Project Rubricapi-254133636No ratings yet

- Survey Questionnaire For Effectiveness of C.A.T.Document2 pagesSurvey Questionnaire For Effectiveness of C.A.T.Celesthiana Rielle100% (2)

- Business Across CulturesDocument12 pagesBusiness Across CulturesSol LeNo ratings yet

- INTERNAL CONTROLS STUDYDocument16 pagesINTERNAL CONTROLS STUDYJonathan TanNo ratings yet

- Age On Speaking AnxietyDocument4 pagesAge On Speaking AnxietyKaye PalerNo ratings yet

- Current EventsDocument13 pagesCurrent EventsmrsheatherwestNo ratings yet

- Facilitating Change in Health and Social Care Social Work EssayDocument5 pagesFacilitating Change in Health and Social Care Social Work EssayHND Assignment HelpNo ratings yet

- Presentation TIEDocument13 pagesPresentation TIEtricia0910No ratings yet