Professional Documents

Culture Documents

PA UTR 2021 053 (Final)

Uploaded by

Elias JarjouraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PA UTR 2021 053 (Final)

Uploaded by

Elias JarjouraCopyright:

Available Formats

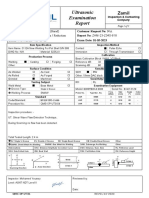

ULTRASONIC TESTING REPORT Report N°: PA-UTR-21-053

PV N°: N/A

Client WPS Contract Constructor Date

Famsco - Lebanon PWPS - J01 - D1.1 N/A N/A 4/20/2021

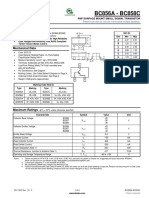

Equipement type Quality level Identification Wave type Connection

Flanged Joints - 20 mm to Shear - Digitalh focused

PA-UT -A1550 Introvisor - ACS Germany 10% Carbon Steel - ST42

25 mm connection array

Line N° Weld N° Welder N° Type of Weld Dia / Thk

J groove - (25 mm -

N/A N/A N/A Na/ 20 mm

grooved 20 mm )

Surface condition Couplant Probe trade

Welded UT - Gel M-9065- Base - ACS - Accoustics Germany

Grinded Type of test: ASME calibration block

Brushed weld V1

Surface prep: Brushed cast V2

Test piece: conform forged Calibration check

Probe type Prob data Amplitude verification

Angular Diameter : N/A Beam exit point

Straight Freq: 4 Mhz Angle : 40 to 80 ° - Evaluation at 70 °

Standard Ref Gain:16 db (4 - 6 db + or - for scaning) Distance Amplitude

Testing: AWS D1.1 -- Part F Acceptance Final cleaning

A B C Water

Interpretation: Table 6.2 Class

-2 db -1 to 0 db + 3 db Degreasing

Testing Data

Acceptance Table 6.2 (Statically loaded non tubular ) D=A-B-C

Joint ID Ref Gain B Gain A -factor D (+db) Length Class Location Verdict

24 FJ- 16.1 16 0 10 16 No defect C Accepted

25 FJ-16.2 16 0 0 16 No defect C Accepted

26 FJ-17.1 16 0 0 16 No defect C Accepted

27 FJ-17.2 16 0 0 16 No defect C Accepted

27 FJ-17.2-B 16 4 2 10 2 mm C @ +32 cm Accepted

28 FJ-18.1 16 0 0 16 No defect C Accepted

29 FJ-18.2 16 0 0 16 No defect C Accepted

30 FJ-18.2 16 0 0 16 No defect C Accepted

31 FJ-19.1 16 0 0 16 No defect C Accepted

32 FJ-19.2 16 0 0 16 No defect C Accepted

33 FJ-20.1 16 0 0 16 No defect C Accepted

34 FJ-20.2 16 0 0 16 No defect C Accepted

35 FJ- 21.1 16 0 0 16 No defect C Accepted

36 FJ- 21.2-B 16 4 2 10 2 mm C @ +34 cm Accepted

36 FJ- 21.2-I 16 5 2 9 1.5 mm C @ +30 cm Accepted

36 FJ- 21.2-O 16 4 2 10 2 mm C @ +15.5 cm Accepted

37 FJ- 22.1 16 0 0 16 No defect C Accepted

38 FJ- 22.2 16 0 2 14 2 mm C Accepted

39 FJ- 4.2 16 0 0 16 No defect C Accepted

40 FJ-20.2 16 0 0 16 No defect C Accepted

41 FJ- 21.1 16 0 0 16 No defect C Accepted

42 FJ- 10.3 16 0 0 16 No defect C Accepted

41 FJ- 10.4 16 0 0 16 No defect C Accepted

NOTE: Scanning was made using a Phased array probe, sectorial wave : 40 to 80 °/ Scanning set at a 4 to 6 db higher than ref gain, once

deffect is located the ref gain will be set back to normal and angle of evaluation will be made 70 °

UT Inspector Data

Name Elias Jarjoura Signature

Qualification SNT-TC-1A-LVl 2- RT,UT,MT,PT,PA

Date 20-May-21

You might also like

- Ultrasonic Testing Report: Famsco - LebanonDocument1 pageUltrasonic Testing Report: Famsco - LebanonElias JarjouraNo ratings yet

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- 1-UT-Pot Shell 588Document2 pages1-UT-Pot Shell 588Azhar GulzarNo ratings yet

- DTC144GKADocument3 pagesDTC144GKAandresoares2007No ratings yet

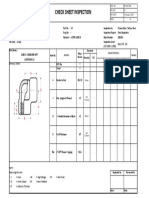

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- PQR - Camsa-02Document1 pagePQR - Camsa-02Jean Carlo Gutarra SocualayaNo ratings yet

- VT Secondary InjectionDocument1 pageVT Secondary InjectionAbhishek RajputNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: VT Secondary Injection TestDocument1 pageCommissioning Service Department Commissioning Standard Test Formats Description: VT Secondary Injection TestssNo ratings yet

- Low Noise Solenoid Controlled Relief ValvesDocument7 pagesLow Noise Solenoid Controlled Relief ValveshectorNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- Feuille Des Donnees Cables F&G: ProjetDocument6 pagesFeuille Des Donnees Cables F&G: ProjetAshraf Ammar100% (1)

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Wolfspeed CMPA601J025F Data SheetDocument12 pagesWolfspeed CMPA601J025F Data SheetNhat Tran XuanNo ratings yet

- HS35 Absolute EncoderDocument3 pagesHS35 Absolute EncoderFernando Nerys da Silva Nerys NerysNo ratings yet

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

- Solenoid Controlled Relief ValvesDocument10 pagesSolenoid Controlled Relief ValvesRenjithSivaNo ratings yet

- WPS Precalificado Aceros Moservin 2022Document2 pagesWPS Precalificado Aceros Moservin 2022Jonathan Espinoza MejiaNo ratings yet

- K Relay-E9 Lowres 26-28 enDocument3 pagesK Relay-E9 Lowres 26-28 enAnonymous CRQ100No ratings yet

- Elbow 2-3000 NPTDocument1 pageElbow 2-3000 NPTJovianto PrisilaNo ratings yet

- 8BFF-C03+R1 - K110Document4 pages8BFF-C03+R1 - K110MahdiNo ratings yet

- MMBD4148TW / BAS16TW: Surface Mount Fast Switching Diode Array FeaturesDocument3 pagesMMBD4148TW / BAS16TW: Surface Mount Fast Switching Diode Array Featuresقناة احترف بنفسكNo ratings yet

- KBP2005G 210GDocument2 pagesKBP2005G 210GВіталій ПузакNo ratings yet

- KBP2005G - KBP210G: 2.0A Glass Passivated Bridge Rectifier FeaturesDocument2 pagesKBP2005G - KBP210G: 2.0A Glass Passivated Bridge Rectifier FeaturesPhong DoNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Pqr-Band Ring PDFDocument3 pagesPqr-Band Ring PDFamitNo ratings yet

- KBP2005G - KBP210G: 2.0A Glass Passivated Bridge RectifierDocument3 pagesKBP2005G - KBP210G: 2.0A Glass Passivated Bridge RectifierCZ ProduccionesNo ratings yet

- Verification Plate PL-21949 UTM SAXI 204Document2 pagesVerification Plate PL-21949 UTM SAXI 204AkhileshNo ratings yet

- RT-VF Catalog (En)Document2 pagesRT-VF Catalog (En)Matt NashrudinNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- KBP2005G - KBP210G: 2.0A Glass Passivated Bridge RectifierDocument3 pagesKBP2005G - KBP210G: 2.0A Glass Passivated Bridge RectifiernmmMJKJNo ratings yet

- Jameco Part Number 1539139: Distributed byDocument4 pagesJameco Part Number 1539139: Distributed bySergio ChicNo ratings yet

- Check Sheet Inspection: Position Actual Dimension Remark Drawing / SketchDocument1 pageCheck Sheet Inspection: Position Actual Dimension Remark Drawing / SketchJovianto PrisilaNo ratings yet

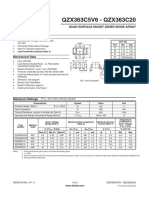

- QZX363C5V6 - QZX363C20: Quad Surface Mount Zener Diode ArrayDocument3 pagesQZX363C5V6 - QZX363C20: Quad Surface Mount Zener Diode ArrayCipto EdiNo ratings yet

- Padle Blank 16-900 RTJDocument1 pagePadle Blank 16-900 RTJJovianto PrisilaNo ratings yet

- Hamza 2 Mill House 6 Top NewDocument1 pageHamza 2 Mill House 6 Top Newmj03127477706No ratings yet

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

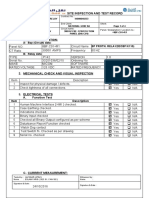

- HT Panel Test ReportDocument4 pagesHT Panel Test ReportItx Adi0% (1)

- 8BFF-C01+R2 - K230Document6 pages8BFF-C01+R2 - K230wazakifyNo ratings yet

- Elbow 0,5-3000 NPT - OKDocument1 pageElbow 0,5-3000 NPT - OKJovianto PrisilaNo ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- Name: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- MMDT2907A: Dual PNP Small Signal Surface Mount TransistorDocument4 pagesMMDT2907A: Dual PNP Small Signal Surface Mount TransistorBruno DutraNo ratings yet

- Bis-Dk-Rt-1051 - Ip2022-NaDocument2 pagesBis-Dk-Rt-1051 - Ip2022-NaTomasPavlovicNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Elbow 2 S40 45D LRDocument1 pageElbow 2 S40 45D LRJovianto PrisilaNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Bis-Dk-Rt-1049 - Ip2022-CeDocument2 pagesBis-Dk-Rt-1049 - Ip2022-CeTomasPavlovicNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Diodes - Inc. BC858C 7 F DatasheetDocument4 pagesDiodes - Inc. BC858C 7 F DatasheetVasile GoraNo ratings yet

- China Civil Engineering Construction Corperation: Repair Welding Procedure Qualification-Manual Metal ArcDocument1 pageChina Civil Engineering Construction Corperation: Repair Welding Procedure Qualification-Manual Metal ArcMakamu Max Las MokgaoganyiNo ratings yet

- HE-MRUT-001Document3 pagesHE-MRUT-001Hao TranNo ratings yet

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Document1 pageUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNo ratings yet

- Panel Under Test: ( D08) - GT-3: Record No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument2 pagesPanel Under Test: ( D08) - GT-3: Record No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoShijumon KpNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Expenses Term 3Document2 pagesExpenses Term 3Elias JarjouraNo ratings yet

- 3 RFP Documents ICLM DB 588Document8 pages3 RFP Documents ICLM DB 588Elias JarjouraNo ratings yet

- Jarjoura's Site VisitDocument15 pagesJarjoura's Site VisitElias JarjouraNo ratings yet

- 00.1 App 1 List of Internal Documents Integrated Preview ENDocument1 page00.1 App 1 List of Internal Documents Integrated Preview ENblitzkrigNo ratings yet

- 17 OilProcess RepoDocument1 page17 OilProcess RepoElias JarjouraNo ratings yet

- 2 - Preventive Maintenance Calendar - M-F-PMC-001-PE - RevDocument3 pages2 - Preventive Maintenance Calendar - M-F-PMC-001-PE - RevElias JarjouraNo ratings yet

- Quality Manual: Free Preview VersionDocument5 pagesQuality Manual: Free Preview VersionAmit Kumar UkeNo ratings yet

- Fuel-Dispensing Stations Checklist BrochureDocument1 pageFuel-Dispensing Stations Checklist BrochureToygar SavkinerNo ratings yet

- Iso 9712 2012 PDFDocument19 pagesIso 9712 2012 PDFBala KrishnanNo ratings yet

- EHQMS Process Audit ReportDocument2 pagesEHQMS Process Audit ReportManuela SavuNo ratings yet

- 5ffcacac1fcf866bc8f2ea63 - Fulcrum Checklist - Gas Station Inspection ChecklistDocument4 pages5ffcacac1fcf866bc8f2ea63 - Fulcrum Checklist - Gas Station Inspection ChecklistElias JarjouraNo ratings yet

- Safety Data Sheet (SDS) Liquefied Petroleum Gas (LPG) : 1. Product and Company DetailsDocument5 pagesSafety Data Sheet (SDS) Liquefied Petroleum Gas (LPG) : 1. Product and Company DetailsFARDANo ratings yet

- Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3Document1 pageWelding Procedure Specification (WPS) : Asme Ix & Asme B31.3Elias JarjouraNo ratings yet

- Ielts Usa Practice Listening TestDocument10 pagesIelts Usa Practice Listening TestsfsfNo ratings yet

- CP-136: API-650 Code Annex-U Requirements For Ultrasonic Examination in Lieu of RadiographyDocument11 pagesCP-136: API-650 Code Annex-U Requirements For Ultrasonic Examination in Lieu of RadiographyElias JarjouraNo ratings yet

- Chania. Greece, 1997Document5 pagesChania. Greece, 1997Elias JarjouraNo ratings yet

- Operation ManualDocument71 pagesOperation ManualElias JarjouraNo ratings yet

- Sigma Ochart 20210608Document1 pageSigma Ochart 20210608Elias JarjouraNo ratings yet

- Iso 22991 2004 en PDFDocument11 pagesIso 22991 2004 en PDFElias JarjouraNo ratings yet

- Method 201aDocument44 pagesMethod 201aamrusyahidNo ratings yet

- CP-136: API-650 Code Annex-U Requirements For Ultrasonic Examination in Lieu of RadiographyDocument11 pagesCP-136: API-650 Code Annex-U Requirements For Ultrasonic Examination in Lieu of RadiographyElias JarjouraNo ratings yet

- Aisc 207-16 Audit Guide All Fabricator, Manufacturer and Erector Programs and EndorsementsDocument31 pagesAisc 207-16 Audit Guide All Fabricator, Manufacturer and Erector Programs and EndorsementsJorge perezNo ratings yet

- Appendix 6 BU Handover ChecklistDocument4 pagesAppendix 6 BU Handover ChecklistK Muhammed AneesNo ratings yet

- GS0303 Stage 1 Audit Report-SigmaDocument7 pagesGS0303 Stage 1 Audit Report-SigmaElias JarjouraNo ratings yet

- Quality Management System Diffusion Matrix - RemarksDocument6 pagesQuality Management System Diffusion Matrix - RemarksElias JarjouraNo ratings yet

- Fuel-Dispensing Stations Checklist BrochureDocument1 pageFuel-Dispensing Stations Checklist BrochureToygar SavkinerNo ratings yet

- Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3Document1 pageWelding Procedure Specification (WPS) : Asme Ix & Asme B31.3Elias JarjouraNo ratings yet

- Fuel-Dispensing Stations Checklist BrochureDocument1 pageFuel-Dispensing Stations Checklist BrochureToygar SavkinerNo ratings yet

- CT VT Basics SonnenbergDocument71 pagesCT VT Basics SonnenbergAnonymous OCDJg17Z67% (3)

- The Company - MicroDocument2 pagesThe Company - MicroMai Hương QuỳnhNo ratings yet

- Silicon Epitaxial Planar Transistor 2SA1179: Galaxy ElectricalDocument5 pagesSilicon Epitaxial Planar Transistor 2SA1179: Galaxy ElectricalsacralNo ratings yet

- Aqa Chm6w W QP Jun02Document18 pagesAqa Chm6w W QP Jun02Diksha KoossoolNo ratings yet

- 10 Effective Ayurvedic Treatment For Hair LossDocument9 pages10 Effective Ayurvedic Treatment For Hair Lossrpav77No ratings yet

- Exercises: (A) Read The Following PassageDocument2 pagesExercises: (A) Read The Following PassageNur Nezanna0% (1)

- Pizza Hut and Dominos - A Comparative AnalysisDocument19 pagesPizza Hut and Dominos - A Comparative AnalysisSarvesh Kumar GautamNo ratings yet

- Pathophysiology of Rheumatic Heart DiseaseDocument3 pagesPathophysiology of Rheumatic Heart DiseaseXtiaR85% (13)

- Pipe Conveyor System: Effective Solutions For Long DistancesDocument8 pagesPipe Conveyor System: Effective Solutions For Long DistancesEugenepaccelli Kolandai SamyNo ratings yet

- Personal Loan For JoiningDocument3 pagesPersonal Loan For JoiningAzim SengalNo ratings yet

- Model CV QLDocument6 pagesModel CV QLMircea GiugleaNo ratings yet

- 2023-24 SR - Super60 (Incoming) STERLING Batch CHEMISTRY Teaching & Test Schedule Code@03!04!2023Document16 pages2023-24 SR - Super60 (Incoming) STERLING Batch CHEMISTRY Teaching & Test Schedule Code@03!04!2023K R I S H100% (1)

- Red Sea Coral Reef InfoDocument7 pagesRed Sea Coral Reef Infoapi-310954411No ratings yet

- PM PillarDocument56 pagesPM PillarNavneet Sharma75% (4)

- 138 Student Living: New Returning Yes NoDocument2 pages138 Student Living: New Returning Yes NojevaireNo ratings yet

- Two-Post Lift Model:210C 210CXDocument36 pagesTwo-Post Lift Model:210C 210CXventitapostNo ratings yet

- Carjackked TrainingDocument7 pagesCarjackked TrainingErios 50No ratings yet

- Magic Coco Tiles: Green Building MaterialDocument17 pagesMagic Coco Tiles: Green Building MaterialnikoNo ratings yet

- SCOPE OF PRACTICE FOR TCAM PRACTITONERS - V - 01Document22 pagesSCOPE OF PRACTICE FOR TCAM PRACTITONERS - V - 01shakkiryousufNo ratings yet

- DeethanizeranalysisDocument7 pagesDeethanizeranalysismindunder36No ratings yet

- Report On Laxmi Niwas PalaceDocument72 pagesReport On Laxmi Niwas PalaceRenu MahayachNo ratings yet

- Presentation On Dysuria 1Document25 pagesPresentation On Dysuria 1ankur acharyaNo ratings yet

- Tle Reviewer 3Document7 pagesTle Reviewer 3Pia louise RamosNo ratings yet

- English The RainDocument2 pagesEnglish The RainsmitaNo ratings yet

- Design of Marina Structures and FacilitiesDocument23 pagesDesign of Marina Structures and FacilitiesAhmed Balah0% (1)

- SECTION 02892 Traffic Signals Rev 0Document65 pagesSECTION 02892 Traffic Signals Rev 0Abdul HannanNo ratings yet

- Steri - Cycle I 160 New GenDocument16 pagesSteri - Cycle I 160 New GenLEO AROKYA DASSNo ratings yet

- HC-33 Maximum Moisture Hair Styling Gel PDFDocument2 pagesHC-33 Maximum Moisture Hair Styling Gel PDFdianaNo ratings yet

- Kuan Yin Prayer Book.Document11 pagesKuan Yin Prayer Book.AddySuBa85% (13)

- Module-1-ISO 13485-DocumentDocument7 pagesModule-1-ISO 13485-Documentsri manthNo ratings yet