Professional Documents

Culture Documents

Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.A

Uploaded by

A. Βρατσιστα0 ratings0% found this document useful (0 votes)

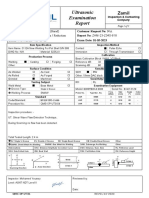

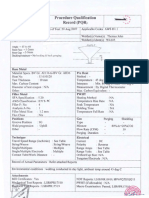

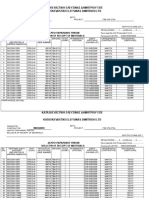

47 views1 pageThis document is an ultrasonic test report for a V-butt weld on a steel component. It summarizes the test methodology, equipment used, and findings. The weld was tested using straight beam and angled beam ultrasonic techniques according to EN1714 test level B. No defects were found above the 33% recording level. The weld was accepted according to the acceptance standards of EN1712.

Original Description:

Original Title

UT-WPQR-V-TEST

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is an ultrasonic test report for a V-butt weld on a steel component. It summarizes the test methodology, equipment used, and findings. The weld was tested using straight beam and angled beam ultrasonic techniques according to EN1714 test level B. No defects were found above the 33% recording level. The weld was accepted according to the acceptance standards of EN1712.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.A

Uploaded by

A. ΒρατσισταThis document is an ultrasonic test report for a V-butt weld on a steel component. It summarizes the test methodology, equipment used, and findings. The weld was tested using straight beam and angled beam ultrasonic techniques according to EN1714 test level B. No defects were found above the 33% recording level. The weld was accepted according to the acceptance standards of EN1712.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

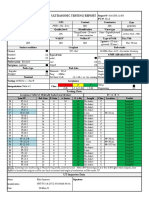

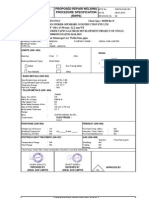

Χάλυβες Καραλή Α.Ε.Β.Ε.

ULTRASONIC TEST Έκδοση (Edition) : 01-08/2006

Karalis Steel S.A.

REPORT

Τμήμα Διαχείρησης Ποιότητας (IN CONFORMITY WITH REQUIREMENTS OF EN1714 TEST

Quality Management Dept. LEVEL B) Σελίδα (Page) : 1 of 1

project : WPQR-V-TEST contract nr. :

component : V-30-12-08 client :

system : Manufacturer : KARALIS STEEL S.A.

drawing Nr. : attached REPORT NR. : UT- V-Test/08 sheet 1 of 2

acceptance standard : EN 1712 class2 date of examination : 20/10/2008

work instruction : According to Table A1 EN1714 Thickness : 30 to 30 mm

: V But-Weld , Sub Merged Welding Machine

test level : B according to EN1714 welding process

+Metal Active Gas (121+135)

base metal : S355J2+N surface condition : machined - ground √

heat treatment : no indication's recording : written description

Ultrasonic Technique reference blocks : V1 ,DAC coupling medium : glutolin

: pos.A, table A1

A. 1 .straight beam √ 2. angled beam √ scanning position coupling difference correction(Vt) : 2dB

EN 1714

Amplification : 0o DAC+ 8dB, 60o DAC+ 14dB,

B. 1 .contact √ 2.imersion - reference level of flaw : Φ3 DAC

70o DAC+ 14dB,

Examination Level: 33% DAC (DAC-10dB)

Recording Level: 50% DAC (DAC-6dB)

instrument type : KARL DEUTSCH -ECHOGRAPH 1090

Test Probes

1. KARL DEUTSCH SE 10/14 PB 4C 2. KARL DEUTSCH WK70 PB 4 3 KARL DEUTSCH WK60 PB 4

refraction angle(φ) : 0 Grad refraction angle(φ) : 70 Grad refraction angle(φ) : 60 Grad

frequency(f) :4MHz frequency(f) : 4MHz frequency(f) :4MHz

DECISION

WELD DATA EXAMINATION FINDINGS

ACCORDING TO EN1712

weld number thickness welder(s) serial defect echo defect defect nature After Repair

(mm) number(s) number of distance from amplitude length depth of

defect reference %FSH (mm) (mm) defect Acc Rej Remarks Acc Rej

point (mm)

W 30 to 30 SMWM+ - - - - - -

MAG √

LF: Lack of Fusion, GP: Gas pores, CR:crack, IN:Inclusions

INSPECTOR THIRD PARTY

A.VRATSISTA INSPECTOR

LEVEL II UT, MT, PT

You might also like

- Welding - Principles and Practices (5th Ed) (Gnv64)Document1,146 pagesWelding - Principles and Practices (5th Ed) (Gnv64)Chandra Sekhar83% (12)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- En1011 7Document44 pagesEn1011 7A. ΒρατσισταNo ratings yet

- TWI ppt-WPE1-Course-Notes PDFDocument72 pagesTWI ppt-WPE1-Course-Notes PDFA. ΒρατσισταNo ratings yet

- Welding Questions PDFDocument42 pagesWelding Questions PDFA. ΒρατσισταNo ratings yet

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- PA UTR 2021 053 (Final)Document1 pagePA UTR 2021 053 (Final)Elias JarjouraNo ratings yet

- Ultrasonic Testing Report: Famsco - LebanonDocument1 pageUltrasonic Testing Report: Famsco - LebanonElias JarjouraNo ratings yet

- Secondary Injection High ImpedanceDocument2 pagesSecondary Injection High ImpedanceEngr Fahimuddin QureshiNo ratings yet

- 1-UT-Pot Shell 588Document2 pages1-UT-Pot Shell 588Azhar GulzarNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: VT Secondary Injection TestDocument1 pageCommissioning Service Department Commissioning Standard Test Formats Description: VT Secondary Injection TestssNo ratings yet

- VT Secondary InjectionDocument1 pageVT Secondary InjectionAbhishek RajputNo ratings yet

- Panel Under Test:: Record No.: Drawing Ref.: Sheet:1 of 7 Contractor: Contract No.: Substation NoDocument7 pagesPanel Under Test:: Record No.: Drawing Ref.: Sheet:1 of 7 Contractor: Contract No.: Substation NoEngr Fahimuddin QureshiNo ratings yet

- Panel Under Test: ( D08) - GT-3: Record No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument2 pagesPanel Under Test: ( D08) - GT-3: Record No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoShijumon KpNo ratings yet

- Ultrasonic Testing Report Steel Beam SpliceDocument1 pageUltrasonic Testing Report Steel Beam SpliceA. ΒρατσισταNo ratings yet

- CT Prim InjectionDocument13 pagesCT Prim InjectionkarimiNo ratings yet

- Pqr-Band Ring PDFDocument3 pagesPqr-Band Ring PDFamitNo ratings yet

- Ultrasonic Test Report SummaryDocument6 pagesUltrasonic Test Report SummaryGibson FisherNo ratings yet

- China Civil Engineering Construction Corperation: Repair Welding Procedure Qualification-Manual Metal ArcDocument1 pageChina Civil Engineering Construction Corperation: Repair Welding Procedure Qualification-Manual Metal ArcMakamu Max Las MokgaoganyiNo ratings yet

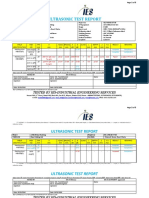

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Lamination Test ReportDocument1 pageLamination Test Reportسعید اینانلوNo ratings yet

- Datasheet RI36-O enDocument7 pagesDatasheet RI36-O enAnthony SaltNo ratings yet

- Procedure Qualification Record (PQR) : 1-2mm 2-5mmDocument26 pagesProcedure Qualification Record (PQR) : 1-2mm 2-5mmDHANEESH VELLILAPULLINo ratings yet

- RTCLNT 142111 Wa 44Document1 pageRTCLNT 142111 Wa 44Mitul KapadiaNo ratings yet

- PQR - Camsa-02Document1 pagePQR - Camsa-02Jean Carlo Gutarra SocualayaNo ratings yet

- 1LE1523-1DB29-0AF5-Z L22+L23+M2F+Q01+Y82 Datasheet enDocument1 page1LE1523-1DB29-0AF5-Z L22+L23+M2F+Q01+Y82 Datasheet enaminullahsharifNo ratings yet

- HRP Ii WPS STR 225Document4 pagesHRP Ii WPS STR 225RohiNo ratings yet

- Ultrasonic Test ReportDocument3 pagesUltrasonic Test ReportMD Shadikul Huq ShezanNo ratings yet

- VT test formDocument2 pagesVT test formEngr Fahimuddin QureshiNo ratings yet

- VT test formDocument2 pagesVT test formTota KamelNo ratings yet

- HT Panel Test ReportDocument4 pagesHT Panel Test ReportItx Adi0% (1)

- R I N C I A N B I A Y A ( ADDENDUM - PENGGANTIAN ATG TYPE SERVO MENJADI TYPE RADARDocument6 pagesR I N C I A N B I A Y A ( ADDENDUM - PENGGANTIAN ATG TYPE SERVO MENJADI TYPE RADARRezky Dian SunartoNo ratings yet

- HE-MRUT-001Document3 pagesHE-MRUT-001Hao TranNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Document1 pageUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- Phased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateDocument1 pagePhased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateshervinyNo ratings yet

- Ultrasonic Testing Report (Structural) (Completed Weld Tubular / Non Tubular)Document3 pagesUltrasonic Testing Report (Structural) (Completed Weld Tubular / Non Tubular)Anna PariniNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Mbci - Pilot Wire Diff RelayDocument2 pagesMbci - Pilot Wire Diff RelayratheeshkumardNo ratings yet

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- Arbab Polypack UT Inspection ReportDocument4 pagesArbab Polypack UT Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- Transfer Torque Wrench: Special FeaturesDocument4 pagesTransfer Torque Wrench: Special FeaturesdabafiNo ratings yet

- Ultrasonic Testing Report (Structural) (Completed Weld Tubular / Non Tubular)Document2 pagesUltrasonic Testing Report (Structural) (Completed Weld Tubular / Non Tubular)Anna PariniNo ratings yet

- Welding Procedure For Plate - WPSDocument1 pageWelding Procedure For Plate - WPSCristian ZidarescuNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Aluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Document1 pageAluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Amin ThabetNo ratings yet

- HRP Ii WPS LGP 332Document4 pagesHRP Ii WPS LGP 332RohiNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- SITE INSPECTION TEST RECORD FOR DISTANCE AND DEF RELAYDocument15 pagesSITE INSPECTION TEST RECORD FOR DISTANCE AND DEF RELAYBalajiNo ratings yet

- Fenac FNC50HDocument4 pagesFenac FNC50HAbo Elbill BosnaliNo ratings yet

- UT PLTU BTG Turbine 1-DikonversiDocument2 pagesUT PLTU BTG Turbine 1-DikonversiWawan KurniawanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Solid Filter - DatasheetDocument1 pageSolid Filter - Datasheetbmanojkumar16No ratings yet

- Tested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureDocument2 pagesTested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureRK KNo ratings yet

- 2mva Tr. For HF-1Document2 pages2mva Tr. For HF-1Vishal Kumar SinghNo ratings yet

- 1 23 090 Stexc1x05f - DatasheetDocument3 pages1 23 090 Stexc1x05f - DatasheetRoberto Martin NavarroNo ratings yet

- DS 4013 Rev-0Document4 pagesDS 4013 Rev-0Dinesh RajNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Approval Record FormDocument2 pagesWelding Procedure Approval Record FormSc TanNo ratings yet

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- MS Data Sheet TanqueDocument2 pagesMS Data Sheet TanqueLION_FIRENo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Penetration Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pagePenetration Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- Amigos Technical Services (S) Pte LTD Operating Procedure Ultrasonic TestingDocument27 pagesAmigos Technical Services (S) Pte LTD Operating Procedure Ultrasonic TestingHoque AnamulNo ratings yet

- hot rolled Φ60 AISI 304L (14.230)Document3 pageshot rolled Φ60 AISI 304L (14.230)A. ΒρατσισταNo ratings yet

- 600 WordsDocument14 pages600 WordsA. ΒρατσισταNo ratings yet

- Welding MetallurgyDocument15 pagesWelding MetallurgySadhasivam VeluNo ratings yet

- ,E/'IAS: Welder Approval Test CertilicateDocument1 page,E/'IAS: Welder Approval Test CertilicateA. ΒρατσισταNo ratings yet

- Words Used With The InfinitiveDocument13 pagesWords Used With The InfinitiveA. ΒρατσισταNo ratings yet

- Penetration Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pagePenetration Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- Welder CertificateDocument6 pagesWelder CertificateA. ΒρατσισταNo ratings yet

- 06 - Weld Ability and Defects in WeldmentsDocument50 pages06 - Weld Ability and Defects in Weldmentsamitjee138463No ratings yet

- 1 4 1Document25 pages1 4 1A. ΒρατσισταNo ratings yet

- Ultrasonic Testing Report Steel Beam SpliceDocument1 pageUltrasonic Testing Report Steel Beam SpliceA. ΒρατσισταNo ratings yet

- ΠΑΡΑΛΑΒΗ ΔDocument4 pagesΠΑΡΑΛΑΒΗ ΔA. ΒρατσισταNo ratings yet

- General - Req - For - Welding - Works PDFDocument88 pagesGeneral - Req - For - Welding - Works PDFvictoraghiNo ratings yet

- 3 Properties of SteelDocument6 pages3 Properties of SteelGopu PushpangadhanNo ratings yet

- Welder CertificateDocument6 pagesWelder CertificateA. ΒρατσισταNo ratings yet

- 121 T BW FPDocument4 pages121 T BW FPA. ΒρατσισταNo ratings yet

- Water Pull 0ff PDFDocument83 pagesWater Pull 0ff PDFA. ΒρατσισταNo ratings yet

- Sample WPS SMAW Stainless SteelDocument7 pagesSample WPS SMAW Stainless Steeldaemsal100% (4)

- Α/Α Cet d HD Q Tp (oC)Document1 pageΑ/Α Cet d HD Q Tp (oC)A. ΒρατσισταNo ratings yet

- WPS SumDocument61 pagesWPS SumA. ΒρατσισταNo ratings yet

- InoxDocument1 pageInoxA. ΒρατσισταNo ratings yet

- Präpositions - Time: English Usage ExampleDocument3 pagesPräpositions - Time: English Usage ExampleA. ΒρατσισταNo ratings yet

- Words Used With The InfinitiveDocument13 pagesWords Used With The InfinitiveA. ΒρατσισταNo ratings yet

- SAS Base Programming Practice Exam V9 QuestionsDocument24 pagesSAS Base Programming Practice Exam V9 QuestionssrinivasaraosomuNo ratings yet

- ECIV 728 Chapter 1-2023Document33 pagesECIV 728 Chapter 1-2023Bren GedsNo ratings yet

- VRRDocument5 pagesVRRGiorno GiovannaNo ratings yet

- CHEM102 FinalExam AnswersDocument19 pagesCHEM102 FinalExam AnswersGlenn Farah Faye RausaNo ratings yet

- Quarterly Assessment Report in Mathematics Grade 1 First Quarter, SY 2019-2020Document5 pagesQuarterly Assessment Report in Mathematics Grade 1 First Quarter, SY 2019-2020William Felisilda100% (1)

- Hybrid Converter: For NEC Microwave Network Management SystemDocument2 pagesHybrid Converter: For NEC Microwave Network Management Systemms_aletheaNo ratings yet

- Micro Teaching Lesson Plan For The Skill of Probing Question (Teach)Document3 pagesMicro Teaching Lesson Plan For The Skill of Probing Question (Teach)Riya Elizabeth J 13No ratings yet

- FMDC HEC PAST PAPERS BY PrepareHOWDocument121 pagesFMDC HEC PAST PAPERS BY PrepareHOWSaad Hassan KheraNo ratings yet

- Woodcock Johnson Achievement ReportDocument4 pagesWoodcock Johnson Achievement Reportapi-254874994100% (2)

- Barthes - S-ZDocument11 pagesBarthes - S-ZJavier Zamudio100% (1)

- DMSO Solvent PropertiesDocument2 pagesDMSO Solvent PropertiesSunny YangNo ratings yet

- Outdoor Site Extend Alarm Detail Design - v1.1Document20 pagesOutdoor Site Extend Alarm Detail Design - v1.1vashishthanuragNo ratings yet

- Machine Design of Hoists, Derricks and Cranes by HessDocument440 pagesMachine Design of Hoists, Derricks and Cranes by HessDickson Leong67% (3)

- Asme Section IX - NewDocument70 pagesAsme Section IX - NewAnaswarps100% (2)

- PK Solutions 2.0 PK Solutions 2.0 PK Solutions 2.0 PK Solutions 2.0Document18 pagesPK Solutions 2.0 PK Solutions 2.0 PK Solutions 2.0 PK Solutions 2.0rigaut74No ratings yet

- Metformin Sustained & Linagliptin Tablets PDFDocument5 pagesMetformin Sustained & Linagliptin Tablets PDFmanoj bhattaraiNo ratings yet

- Week 4 Home Learning PlanDocument11 pagesWeek 4 Home Learning PlanJessel CleofeNo ratings yet

- CRE Notes PDFDocument61 pagesCRE Notes PDFKrunal ThakarNo ratings yet

- Steel - Chapter 4Document18 pagesSteel - Chapter 4Kristoffer NaridoNo ratings yet

- Standard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Document5 pagesStandard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Lupita RamirezNo ratings yet

- XP EnergyDocument9 pagesXP Energylaurent lebourgeoisNo ratings yet

- Datasheet 709Document8 pagesDatasheet 709manojpeehuNo ratings yet

- PVT ModellingDocument6 pagesPVT ModellingFan JackNo ratings yet

- GR 80 CONFIGURATION DIAGRAMDocument20 pagesGR 80 CONFIGURATION DIAGRAMAffan fNo ratings yet

- Paper JLP 2019 224 Original V0Document17 pagesPaper JLP 2019 224 Original V0ЮрийNo ratings yet

- Chapter 1: Introduction: 1.1 What Is COCOMO?Document39 pagesChapter 1: Introduction: 1.1 What Is COCOMO?Blue moon MediaNo ratings yet

- his Life": Λογοτεχνία και διαπολιτισμικές διαδρομές Literature and cross‐cultural routesDocument18 pageshis Life": Λογοτεχνία και διαπολιτισμικές διαδρομές Literature and cross‐cultural routesCharpapathNo ratings yet

- Social Psychology and Group ProcessDocument30 pagesSocial Psychology and Group ProcessTasya aqimarNo ratings yet

- Botsios, S., Georgiou, D., & Safouris, N. (2008) - Contributions ToDocument16 pagesBotsios, S., Georgiou, D., & Safouris, N. (2008) - Contributions TosplakenerNo ratings yet

- Examining Demand and Substitutability Across Terminals in A Gateway Port Network A Discrete Choice Model of Irish Ports PDFDocument11 pagesExamining Demand and Substitutability Across Terminals in A Gateway Port Network A Discrete Choice Model of Irish Ports PDFJCANo ratings yet